PACKAGING IS BIG & BOLD - at CRP Print & Packaging 24 - Flexo 28 Hunkeler 30 Web to print 40 - Print Business

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

THE MAGAZINE FOR FORWARD THINKING PRINTING

MARCH 2011

Flexo 28

Hunkeler 30

PACKAGING IS

Web to print 40

BIG & BOLD

at CRP Print & Packaging 24Defined by excellence

Driven by innovation

Clockwise from top left:

Buxton Press; CRP Print & Packaging Ltd, Corby;

Plastic Card Services, Macclesfield; Cambrian Printers;

Alderson Print Group; Ashford Colour Press, Gosport.

Across all sectors

across all formats

the leaders in their field

share the same passion for print

KBA

driven by innovation, defined by excellence.

Phone 01923 819922 | www.kba-uk.com People & PrintMARCH

From the editor NEWS 4

Heidelberg sets up

digital demo suite

Eclipse joins forces

T

he iPad is supposed to drive another nail in the coffin of the printed

newspaper, helping it on its inevitable journey to the grave. Just as with 4DM

before it websites and Google have claimed their share of credit in the

death rites of a clunky, inconvenient and outdated mode of

INVESTMENTS &

communication. Only this has not happened. Yes traditional INNOVATIONS 10

newspapers are in decline, a decline that has been going on since the 1950s. Yes Presstek 75DI B2

titles have vanished and publishers are having to manage on acceptable levels of press first installation

profit, not bankers’ levels of margin, but behind the charade of

paywalls, printed papers are delivering something that the COVER STORY 24

electronic media are failing to do. A profit. CRP thinks big in

It’s easy to forget the sheer convenience of a newspaper, its

packaging

portability, its interactive nature, its engaging design and its

pre-eminence as an advertising medium. It is so intuitive to use SPECIAL

that there is no need for instructions, its batteries will not

fail, it’s produced from recycled materials, not rare earth FLEXO 28

metals mined at great environmental cost, its interface can Flexo finds itself on

be read by all and if dropped in a puddle, the only cost is firmer footings

£1 to buy a replacement.

Journalists love to jump on novelty so have a vested OPEN DAY 40

interest in marveling at bright shiny toys, while as a Hunkeler Innovation

nation we love doom and gloom. How else can we

Days sees the best in

account for the popularity of misery soap Eastenders

and the desire to talk down the chances of our sports

digital and finishing

teams if not to avoid bigger disappointments later? PROFILE 40

Thus we tend want to decry the resilience of newspapers

rather than celebrate it.

The Lettershop Group

We at Print Business are not like that. Britain’s stays ahead of the

newspapers are great, everyone one of them. They display game

great printing, great organisation and great writing. There

may be fewer of them in future, because of social shifts,

CAMPAIGN

not technology shifts and because very few people are NEWSPAPERS 16

marketing the extraordinary strengths of newspapers. We The printed word is

believe in the future of print, we believe in the future of

printed newspapers. You should too.

very much alive and

GARETH WARD

kicking

Editor WEB TO PRINT 36

How to get started in

getting your

CONTACT customers online

EDITORIAL

Gareth Ward 01462 416403 • 07866 470124 BOOKS 46

gareth.ward@printbusinessmagazine.co.uk Paul Sherfield chooses

SALES Disrupting the Future

Jacqui Gray 07976 720265 jacqueline@legatomedia.co.uk

Fax 01727 841036

ADMIN 01580 236456 debbie.ward@printbusinessmagazine.co.uk

PRODUCTION 01580 236456 • 07711 696190 • printbusiness@me.com

Published by Print Business Media Ltd

3 Zion Cottages, Ranters Lane, Goudhurst, Kent TN17 1HR

March 2011 3NEWS

Digital sees

Heidelberg sets up digital steady growth

partnership demo suite DIGITAL PRINT is continuing to

grow at double figure rates

despite the pressure of recession.

CHRIS MATTHEWS, that when Heidelberg first sold In its Q1 financial report, HP

Heidelberg UK’s digital press Kodak machines, average says that pages volumes on

specialist, is planning a monthly page rates were well Indigo presses were 26% higher

demonstration facility in below the 1 million pages a than a year previously, while

Heidelberg’s refurbished month capacity of the press. sales of commercial print units

showroom in Brentford. The Ricoh C901 GAE over a had increased 33% in the year.

The announcement that five-year period would have a In the course of last year, HP

Heidelberg is partnering with capacity of 300,000 A4 pages a began selling its T300

Ricoh as it returns to digital month, 500,000 a month over continuous feed inkjet presses

printing named the UK and three years. “This is the sweet which are bound to increase the

Germany as the countries to spot that the Ricoh hits,” he says. revenues HP derives from

Chris Matthews: “This is the sweet

start the roll out of the The fine print on the deal consumables.

spot that the Ricoh hits.”

relationship. Under the deal between the UK end of The Q1 figures attribute

Heidelberg will sell Ricoh’s Heidelberg and Ricoh has to be 66% of the $.6 billion revenue

C901 Graphic Art Edition a great success and Matthews completed before the end of in the three month period to

digital press, linked into with explains that this time around this month ready for the April supplies, 22% to commercial

Heidelberg’s workflow and the existing sales team will be start. Matthews is already print products and 12% to

colour management. expected to sell digital with priming customers, showing consumer products. Revenues

“We are going to have a back up from the small team samples of colour matched jobs in the division were 7% up on

machine in Brentford with all that Matthews heads. that have been produced on the a year previously. Earnings

the software, profiles and post “It’s a slightly different digital press. “We have had were $1.13 billion ($1.05bn).

press, some of which will come route to market and the right some very positive reaction to Meanwhile in the last three

from partners,” says Matthews. choice at this time,” he says. these samples and which stand months of 2010, Xerox reports a

The partnership officially The idea is that output from up extremely well with 19% increase in installations of

comes into force on April 1. the Ricoh press will be samples from the top of the high end digital presses helped

Ahead of then Heidelberg sales matched to output from a market machines because of the by demand for the Color 800

teams are receiving training on sheetfed litho press using colour management.” and Color 1000 products.

the press and the positioning of Heidelberg’s colour Experience in Australia In contrast installations of

a high quality digital press management expertise. For suggests that Heidelberg is high end mono machines fell

alongside litho machines. This around £100,000 printers will acting at the right time. There back 11%. Equipment sales for

is a change from Heidelberg’s be able to move into high the company has been selling Xerox reached $1.05 billion

previous experience of digital quality digital for less than half around two Konica Minolta ($1.02 billion) in the three

when it ran separate litho and the price of a top end machine, presses a month under a deal months to December.

digital operations. That was not Matthews explains. He adds that came into effect last year.

Circle Print puts

Herald Chase chooses Tharstern subsidiaries into

administration

Primo for greater business insight

CIRCLE PRINTERS, the pan

HERALD CHASE, Reading, has The installation at the start European web offset and

installed one of the first of the year was accompanied by gravure print group formed

Tharstern Primo MIS in the full training in the new features from the former Quebecor

country. that Tharstern has introduced. business in Europe, has

It replaces an existing Herald Chase managing placed its French subsidiaries

Tharstern SQL system, the director Chris Goslar says: in to protected administration.

printer deciding on replacement “After seeing the new interface Circle Printers France is the

rather than an upgrade because and enhancements featured in second largest print group in

its workload is increasing and Primo, along with the reporting the country and covers the

this was an opportunity to and dashboards, we felt that former Jean Didier business.

change the way the business upgrading to the latest version In all this covers five gravure

worked with management data. offered more flexibility and presses and 11 web offset

As well as the Primo, the would benefit our staff even machines and 1,200 staff.

company has fitted shop floor more. We also find Primo gives The French operations were

data capture units across the us a greater real-time insight always a headache for

Tharstern operator enjoys the

plant and has taken to digital benefits of Primo. into the performance of our Quebecor, with unions resisting

production scheduling. businesses.” almost all cost saving measures.

4 March 2011 www.printbusinessmagazine.co.ukNEWS

Eclipse joins forces with 4DM to

create print and mailing powerhouse

TWO OF THE LARGEST print “Our joint goal is to become

operations in Northamptonshire best in class, providing our

are coming together in a deal to collective clients with a wide

create a print and mailing range of services from the

powerhouse. obvious print and direct mail

Eclipse Colour is taking a through to innovative digital

10% stake in next door multimedia campaigns,” Grant-

neighbour 4DM in a deal which Salmon adds.

will gradually bring the two Combined the companies

businesses together over the will have sales of £34 million

next five years. and become one of the top ten

Simon Moore, managing direct mailing businesses in the

director of Eclipse, and Charles country.

Grant-Salmon have a shared The client base is similar,

heritage dating back 20 years, but not the same. Lance Hill,

splitting when one stayed with sales and marketing director of

Charles Grant-Salmon and Simon Moore have a shared heritage that goes

commercial print and the latter back 20 years. They say they are confident they share a similar culture. 4DM, says that the businesses

concentrated on mailing. Even only share 20% of customers in

though it is 12 years since the common, creating immediate

separate companies were reorganisation necessary last “It’s a fantastic opportunity to scope for expansion. “I was

formed, the two have always year, he returned to take full build a fully integrated very pleasantly surprised at the

shared blue and orange time charge of the business as marketing services provider lack of crossover,” he says. “We

corporate colours, planting the CEO. where two well established have already worked together

seed of a future merger. Since This deal provides him with business with like-minded staff on a number of projects over

Eclipse moved to its current an exit strategy over the next come together to pool strengths, the years and see our strengths

factory in 2001, the companies five years while leaving the technology and innovation,” complementing each other.”

have also been next door to Moore as the main shareholder. says Moore. Eclipse is currently running

each other. In the meantime the visibility “The timing was ideal in white paper trials on a new

In 2007 4DM was sold to a will reassure customers that that as a business we have had Goss M600, which is

management buyout, leaving there will be no disruptive our best year ever, I’m positioned alongside its first

Grant-Salmon as a part time overnight changes. confident that we share a M600 and adjacent to a

chairman. However, with But the merger does more. similar culture.” Scheffer finishing line.

Agfa Graphics buys Litho Supplies out of receivership

LITHO SUPPLIES has become major distribution channel for an official statement from Litho collapse of Woolworths.

a subsidiary of Agfa Graphics a Agfa’s plates in the UK, reaching Supplies. The deal ends any Now Litho Supplies forms

year after corporate recovery smaller customers which were lingering uncertainty as its part of a major consumables

specialist Hilco stepped in to uneconomic for the company to ownership by Hilco was always supplier safeguarding its future

buy the consumables supplier offer a direct sales service. considered to be expedient and as the major UK graphic arts

out of receivership. “Both companies view this a temporary one. Hilco has distribution business.

The deal was signed only acquisition as a natural fit and a specialised in rescuing mostly For Agfa the deal secures

weeks after Dave Spencer took logical progression in their retail chains, paring down costs what has been a major European

over at the head of Agfa’s UK ongoing relationship. This and selling off the stock that channel both for its printing

graphics division following the offers Litho Supplies the comes as part of the package. plates, which are becoming

retirement of Laurence Roberts. opportunity to further grow Its highest profile engagement more of a commodity item, and

Litho Supplies has been a their business in the UK,” says was recovery of cash from the for its growing inkjet business.

The ultimate online global printing directory

Ipex World is the new online resource for the printing industry it’s an easy-to-use global database of suppliers and products,

that is always on hand to give you an edge over your competitors. plus a unique source of industry information and advice.

Sign up to become a Premium member free today!

www.ipex.org

www.printbusinessmagazine.co.uk March 2011 5NEWS

Sign & Digital covers all the bases

for display and large format options

SIGN & DIGITAL UK at the will be the theme of a showcase whose DesignJet range is

NEC next month is shaping up retail environment, displaying increasingly moving to its Latex

to be a key exhibition for window films, floor graphics, inks. On show will be the

printers looking to add large promotional wall coverings, DesignJet L25500 and HP

format and display printing to back lit displays, banners etc. Scitex LX800, both using these

the services offered. Antalis McNaughton will inks as well as the large UV

The line up covers almost also feature a wide range of flatbed Scitex FB500.

all the available roll and flatbed materials including the launch Display print finishing is a

printers up to Fuji and Océ of some special effects products speciality of Zund and

flatbeds and the the 1630mm for high impact display EskoArtwork for its Konsberg

wide HP Scitex FB500 printer. purposes. plotters. Esko plans a full

Media of all types will be on The largest stand is taken by workflow from design to digital

show, as will MIS from GPT, a major distributor for a cutting.

Tharstern, Shuttleworth and host of companies, including Private label inks are

Optimus highlighting their Mimaki, Agfa, Canon and represented by Colorific which

capabilities in this sector. Epson. It will include 63in is introducing UV cured inks

But the draw will be the wide roll and sheet printers for the wide format market. It

inkjet machines themselves, from the Agfa Anapurna family, produces inks for Roland DG,

ranging from entry level Mimaki’s UV range, alongside Mimaki and Mutoh solvent

devices from Roland DG and solvent and waterless machines machines and eco-solvent inks

covering Mutoh, Agfa, Durst, from Epson and Canon. for use in non ventilated areas.

Efi, Mimaki, Screen as well as Granthams is another of the Now it is bringing to market

Fuji and Océ. The latter pair major distributor/integrators inks for the superwide sector,

sell the same device: the Acuity with space in the NEC with where the manufacturers have

under a Fuji badge, the Arizona many of the same machines. It ceased development for their

in Océ colours. There will be On show at Sign & Digital UK, at plans to introduce Elements as older machines and the growing

the NEC 12-14 April, will be (from

Arizona 550XT and 350GT at an eco-friendly alternative to base of flatbed UV printers.

top): Output from HP Scitex range;

the event and linked to a Zund the Acuity from Fuji, also sold by solvent inkjet. It adds up to a collection of

plotting table. Océ under the Arizona name; CWE Solutions will have products and companies worth

Fuji will also have an Acuity Agfa’s Apurna range will be on the HP DesignJet Z6200, the seeing for those contemplating

on show, producing work on distributor GPT’s stand; Roland DG Latex models and the launch of an investment in the still

will have a range of entry level

materials from its Euromedia the Seiko Colourpainter W64S. growing large format digital

devices.

division. The versatility of these Leader in this field is HP and display print sector.

Konica Minolta Canon on acquisition trail as it European print

signs distribution aims for Top 100 listing worth €150bn

deal with Kodak says Infotrends

CANON IS ON the look out for 2015,” the company says. In

KONICA MINOLTA, which acquisition opportunities as the 2010 net sales were ¥3.7 trillion THE EUROPEAN printing

some had expected to be named Japanese company sets its sights with an operating profit of industry is worth €150 billion

Heidelberg’s digital press on becoming a worldwide Top ¥387.6 billion. “Targeting this according to research by

partner, has extended a 100 corporation. change and transformation, we Infotrends.

distribution deal with Kodak. It aims to “achieve the will make active use of M&As.” The project follows work it

The agreement is now a overwhelming No 1 position in An operation dedicated to published in 2004 and is

global partnership and brings all core businesses and looking for acquisition intended to bring its

Konica Minolta a high end expanding related and opportunities was set up at the understanding of the industry

digital press in the Nexpress peripheral businesses” the start of this year. up to date. The biggest segment

series of machines and the company states in its full year Printing products fall within of businesses across Europe are

Digimaster mono cutsheet figures. This will require setting its Office Documents division classified as commercial

presses in some countries. up manufacturing and R&D where sales were boosted by printers, accounting for almost

Kodak gains a light production centres in three parts of the the launch of new ImageRunner one third of the total. Inplants

machine with Konica Minolta’s globe – North America and models and by the acquisition account for 12%, while

C8000 press in the US, UK, Europe as well as Japan. “We of Océ. Joint development packaging accounts for less

Germany and France. It will aim to achieve net sales of more projects are to be accelerated than 3% of the number of

also sell the C6000 and C7000 than ¥5 trillion, an operating under the new corporate five establishments, but around

in these territories. ratio of more than 20% by year plan. 10% by value.

6 March 2011 www.printbusinessmagazine.co.ukChemistry use

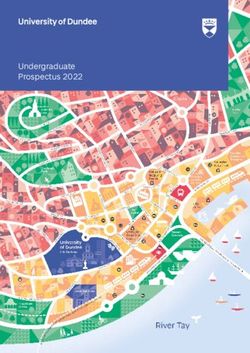

1,200

1,200 L

1,100

1,000

Are you

900

Typical thermal CTP

throwing

money down

800

the drain?

700

Our LH-PJE plate and multi-

award winning ‘ZAC’ processor

use less chemistry and require

less maintenance than any other

600

similar system on the market.*

For the best performance and

profit, choose lo-chem plate

*This graph shows chemistry use assuming 10,000 B1 plates are produced over a 1-3 month period.

solutions from Fujifilm. 520 L

500

The smart way to make plates.

Typical thermal

400

‘Chemistry-Free’

300

216 L

200

SETTING NEW STANDARDS

100

LH-PJE

litres

EJP-HL

www.powertosucceed.eu/plates

POWER TO SUCCEEDFUJIFILM INKJET

Diversification paves the

way for Fujifilm fortunes

Fujifilm has analysed the markets and is aiming

its entry into presses at the top end. This is not

a toe in the water but the start of a long term

commitment with the backing of considerable

finance and expertise.

L

ater this year Keith Dalton will Sericol among others. It also explains

begin working for the third why, with economies around the globe

printing press supplier of his still faltering in the climb out of recession,

career. He had a spell with the Fuji is not panicking. “We have been able

late-lamented UK web press to benefit from being a strong company,”

manufacturer Baker Perkins, then moved says Dalton. “The UK has been badly hit

to Harris. Now, the UK managing director and is a bit behind Germany and France

of Fujifilm Graphic Systems expects to be on the way back. I believe that 2011 will

marketing and selling sheeted B2 presses be flat. The UK has not returned to the

before the year ends. But he will not be point it will as yet.”

moving jobs to do so: Fujifilm is moving

into the press business with the THIS IS MANIFEST in the difficulties the

JetPress 720. industry finds itself in, struggling for

This time also, the press manufacturer profits and fighting to convince its

is not going to be absorbed into a bigger customers that print has value despite the

business or sold. Baker Perkins became appeal of new electronic media. “There

part of Goss and its Peterborough factory are new toys in the toy box,” he adds, “but

closed, Harris became part of Heidelberg children will always return to old

during the Harmut Mehdorn’s tenure at favourites like Lego. It’s the same with

the business and at the time when new media. Today there are so many ways

Heidelberg was on a mission to sell every of reaching customers, yet the most

type of printing device. That strategy Keith Dalton: “This is a Test Match, not a 20:20. effective way is still print. Advertisers will

collapsed in on itself and the web offset In the short term someone can come in and revert to print because it is the most

division was sold to Goss. Now Goss has make an impression, but nobody remembers effective way to reach a customer.

itself been taken over by Shanghai Electric However, print has to change to become

Company, but even this behemoth has more dynamic.”

little chance of buying Fujifilm, assuming drug development is a costly affair. But so It is doing so already. QR codes and

that it wanted to. too is the development of a new type of other forms of 2D barcode allow print to

printing press. It requires both funds and a become interactive and for advertisers to

FUJIFILM IS ONE OF the largest and most commitment to the long term. Fuji has both. track the effectiveness of their message

successful companies operating in the As Dalton puts it: “This is a Test Match, through responses. A printed

graphic arts, even if its business with the not a 20:20. In the short term someone can advertisement becomes measurable.

printing industry has suffered a little in come in and make a momentary

recent years. Year on year sales for the first impression, but nobody remembers INKJET ALLOWS PRINT TO work on

nine months of the year were flat, but at them.” Fuji is playing the long game and almost any substrate, opening a whole

£1.3 billion, this is a big business. But has the financial muscle to do so. host of new applications, let alone

even then printing is only part of Fuji’s It is a message that Dalton is keen to get reviving some older tools, such as

information systems division and that across. There is something like £14 billion lenticular displays.

joins Imaging (its consumer film, cameras of cash in the bank and the company is One of the key attractions of print,

and growing lenses business), Office able to set aside that portion of revenue for Dalton explains, is that the user controls

Documentation (covering Fuji Xerox) and R&D. It helps explain why it can develop the pace at which information is received.

a rapidly growing healthcare and the JetPress inkjet machine and why in An electronic display will move at a pace

pharmaceuticals business. recent years Fuji has built up a portfolio set by the advertiser or by the technology

Undoubtedly this swallows most of the of businesses in inkjet printing, buying which may be too fast for a potential

7.5% of sales that is committed to R&D, as head creator Dimatix and ink specialist customer to take in. On the other hand,

8 March 2011 www.printbusinessmagazine.co.ukANALYSIS

the digital display has movement while sections in order to survive you will need “We have aimed at the top end of the

print is static. But consider the lenticular to become a thoroughbred, but there is market, rather than chase transactional

advertisement, says Dalton, with the only room for a few companies like this. work, as a deliberate policy which looks

message changing as a customer walks There are probably more web offset pages to have been a good move.”

past, showing the motion in sequence printed today than a decade or so ago, but The availability of a press like this is

according his ambulatory pace. the are far fewer web offset printers.” likely to spur development of new

“Furthermore, online is very much product types, just as the confluence of

search-led, where print is very much push THOSE PRINTERS THAT do not compete digital cameras, digital printing and

and that's always going to be the case. in volume terms need to distinguish broadband file delivery resulted in the

Why otherwise does a company like Dell themselves in some way. Dalton argues photobook. Printing single copies or

with huge online sales spend so much that it is not the litho print element that highly limited editions of high quality

money on print? Even books which work will bring the profits, but the services brochures, art and exhibition books and

very well on readers like the Kindle, work around that. And this increasingly will pitch documents becomes possible.

better in print because print gives them an include different print technologies. Early But Dalton is not limiting the JetPress

emotional value and these fundamental adopters of digital printing in many cases to this sort of emerging market. He has

values will not change.” have struggled to make money, partly highly practical applications in mind,

This is important as the world becomes down to the shortcomings of the topping up short numbers of sections in

more complex, as the sources of information technology at the moment and partly due the bindery for example. Currently

become more diverse and audience to trying to compete with offset litho printers will print enough overs to cover

fragments away from a handful of television rather than to complement it. “People make ready at the finishing stage, often to

channels towards time spent in front of a tend to look for absolutes, but it’s no throw these away with cost of time and

Fujifilm is moving into the press business with the JetPress 720.

computer screen or listening to a radio. longer either/or – it’s about one materials that this entails. Dalton reckons

Even on television, time delayed viewing technology complementing the other. that printers will be able to slash the level

means skipping the commercials. As the Printers need to have different types of of overs knowing that should there be a

internet continues to expand, it becomes output device and to be able to take on all problem, the JetPress will be eliminate the

more difficult for marketers to predict how different types of work. shortage almost instantly.

to reach consumers, and for publishers to “For example in the future a company “Making a mistake at the finishing

make money. Google dominates, taking can have a Xerox machine for variable stage is much more costly than in prepress

68% of all online ad revenue, and this will data work, even a web offset press for long because plates will have to go back on

continue until new context-aware semantic runs and the JetPress for fast turnaround press with all the cost that this causes.

search engines are developed. work.”

The JetPress was seen at Ipex in “PEOPLE WHO SEE THIS as similar to a

FOR DALTON, THIS IS GOOD news for prototype form. It is now in Fuji’s traditional digital press are completely

print with its ability to deliver high facilities in Japan where customers are wrong. This is a different tool altogether.”

quality imagery, its emotional impact and being invited to come in and put the It is not, however, going to be the

for its value of discovery. machine through its paces with real jobs. saviour of the printing industry. That is in

Print though is changing. It is no longer The first beta site comes this month to be the hands of the industry itself and is

about clear divisions between processes. followed by the first machines to Europe probably as difficult a nut to crack as any

In large format screen has given way to and North America. At this point the new technology being dreamt up in Fuji’s

litho and digital. In commercial, digital is press is limited to printing on uncoated research labs. “We have to get value from

growing in importance. In packaging, papers and a predecided range of paper all the new technology and new ways of

flexo can match the quality of gravure on formats, but as this is the first generation doing things,” says Dalton. “As suppliers

films while litho is being used to add of the technology, this is scarcely a we have to get value to cover the R&D

marketing messages to the box for shelf surprise. “It’s doing what it’s meant to costs and printers have to get value from

appeal. do,” says Dalton, “Producing work of high the industry’s customers. How we get

“As a supplier you have to be much quality and consistency and with a colour value from the advertisers, how we

wider in terms of what you offer, while as gamut that is bigger than offset. This encourage them to spend money on print.

a printer you have to become much more means that you can achieve almost any That’s the challenge we have to face as an

specialised. If you are just printing A4 spot colour from the four-colour process. industry.” n

www.printbusinessmagazine.co.uk March 2011 9INNOVATIONS & INVESTMENTS

Murray moves to CIP3 with TG Print adds

Technotrans

Heidelberg Speedmaster for consistent

environment

MURRAY THE PRINTERS has the data sent to the platesetter. return on investment should not

saved itself a vast amount after It is still early days and the be too long, we reckon two to TG PRINT, in Woolwich,

buying a secondhand company has yet to do the three years at the most and we London, last year installed a

Heidelberg Speedmaster 74 as analysis on how much waste intend to keep the press for five five-colour Speedmaster XL75

part of a move and major and time is being saved though years, so the investment makes with coater. It has since added a

expansion last year. Chard is already certain that sense. We are saving time and Technotrans reverse osmosis

The press was CIP3 ready make ready times have been having more accurate settings and filtration system to this

but had not had the necessary cut. “We do a lot of very quick for the press operators as ink investment, choosing the

prepress interfaces fitted. To turnaround work – customers ducts are already 90% there and Basic.fc filtration system and

buy this technology from today expect the same delivery for reprinted jobs, it’s fantastic.” the Alpha.r reverse osmosis

Heidelberg would have been times from litho as from digital. The company is imaging unit.

impractical, says managing We’ve already noticed that we Fuji’s Pro-T plates through a

director Pat Chard. Instead the can turn jobs around quicker.” Screen platesetter. The next

Milton Keynes company turned The 11-strong business had step is to look at adopting the

to Compose Systems, which invested in an HP Indigo 5500 Hamillroad Auraia screening

had earlier provided an inkjet and large format inkjet printer software, also through

proofing system, and has last year as well as changing Compose. This is a means of

installed Inkscript and a press premises. “It’s all about delivering FM quality at

console connection kit to pushing forwards and so we relatively low imaging

handle the CIP3 functionality wanted that bit more from the resolutions, using new

linking by its Screen platesetter presses as well,” he adds. algorithms to overcome some of

and workflow to the new press. Inkscript reads CIP3 data the limitations of existing FM

“This was our first from the prepress area. Prior to screening. It is a step towards

experience of working with making the decision Chard says differentiating Murrays from

CIP3 data and it is working he visited Fox Print in Leicester, rival B2 printers. “We produce

fine,” he says. A hot folder which was using the work for Aston Martin and David Duhig: “It would be stupid to

run a top of the range car with cheap

system links the press and application, and ran other tests Mercedes. We see this as a way

petrol and the same applies to a top

platesetter, enabling the ink duct to ensure that it would improve to give them better quality,” he performance press.”

settings on the press to match Murray’s productivity. “The adds.

The aim is to delivery a

consistent and stable chemical

environment for the press,

Hickling & Squires upgrades its spending £10,000 with

Technotrans to achieve this.

cutting area with CCM guillotine The 15,000 cph press is

delivering 50% increase in

productivity over the machine

NOTTINGHAM PRINTER it replaced and the decision to

Hickling & Squires has stabilise the conditions the

upgraded its cutting area with a press works in to achieve its top

new CCM guillotine to keep speed.

pace with the flow of jobs Says managing director

coming through. David Duhig: “It would be

Managing director Richard stupid to run a top of the range

Wells says: “As we expereinced car with cheap petrol and the

an increase in the volume of same applies with a top

orders, our decision to buy was performance press.

based on a product that would “The filtration system

keep up with the digital and means that we don’t have to

litho print production process. flush out the dampening

The CCM Premier Plus is also solution as frequently as we did

Hickling & Squires managing director Richard Wells says: “The CCM Premier

versatile and very accurate and Plus is versatile and extremely accurate and meets the challenges.”

on the SM74. On that press we

meets the challenges some of would have to clean the

our jobs create. The investment Services in Nottingham. It has machinery or the production dampening once a week, now

also means that we can meet 15in touch screen guiding the network. it’s only about every 12 weeks.

client commitments with even operator through set up via Hickling & Squires added That leaves our operators to

more confidence.” easy to follow prompts. A USB the guillotine two years after focus on other areas of

The CCM guillotine is connection allows the the installation of a ten-colour maintenance safeguarding the

supplied by Terry Cooper guillotine to talk with other Speedmaster CD74. resale value of the machine.”

10 March 2011 www.printbusinessmagazine.co.ukeffective, reliable, Powerful W2P

Client: Able Labels

TM

Labels

I was turned on to RedTie in 2008

Before investing in RedTie Able Labels operated as a traditional

business with a high cost of order and we needed a web

solution that the public with almost no printing knowledge

could use to quickly and efficiently order a wide range of

products online.

Before RedTie we had 60% personnel in the front office and

40% in the back now we have 60% in production and 40%

in admin which has allowed us to reduce costs and improve

productivity. Through RedTie we stack the orders when they

come in from the web, review them and then flow them into

Jason SStather-Lodge

tatherr-Lodge

a template where 174 orders go onto one print run rather than

Group CE

Group O, Able Labels

CEO, L Ltd

Ltd handling them individually. A huge benefit for us.

www.able-labels.co.uk

www .able-labelss.co.uk

Simply the most

effective W2P solution

on the market

RedTie software provides printers, marketing

agencies and companies with real tools to

capture orders at a lower cost providing a

visible ROI.

RedTie – Exactly what you need.

Partnered with:

...create

...create it printt it! www

it,, prin www.red-tie.com

w .red-tie

e.comINNOVATIONS & INVESTMENTS

Presstek 75DI B2 press with 6-min

makeready has its first installation

THE FIRST INSTALLATION of sheets where electrophoto-

Presstek’s 75DI B2 press has graphic presses hold sway to

been made in the US, less than a 20,000 sheets or more. This is an

year after the machine was area where demand is on the

shown in prototype form at Ipex. increase and where conventional

The delivery marks the full litho presses find it hard to

commercial availability of the remain competitive. Waterless

press, which offers a six-minute printing with UV curing enables

makeready allied to a 16,000sph the press to print on plastics

running speed. At the initial where the relatively high cost

customer for the new press, per sheet makes means that

Advanced Digital Printing in waste needs to be controlled.

Brooklyn, New York, a full An aqueous coater at the end

makeready to 1,000 good sheets of the press will ensure that fully

on the floor took just 12 minutes, dry sheets are received in the

providing a significant boost over delivery for instant processing in

previous production capacity. the bindery.

The Presstek 75DI is a unit The US customer saw the

construction machine which press at the Graph Expo show in

continues to be a waterless litho Chicago late last year and

machine like the smaller format ordered the press on the spot.

34 and 52DI presses. Unlike Advanced Digital Printing

The first Presstek 75DI B2 press has gone into Advanced Digital Printing in

them, the new press has an already had two Presstek DI

New York, less than a year after the prototype was shown at Ipex.

imaging unit which travels machines, one a standard 52DI

across the plate cylinder as it which is to be replaced, the

rotates rather than a fixed laser The plates are Presstek’s register through a colour other a 52DI-AC to designate it

diode array. polyester ablative plates which managed Rip, with no unexpected has a coater attached. The

The laser is split into 64 fibre are held for mounting in a dot gain during plate making, company specialises in rapid

channel beams each imaging a cassette system that has been good quality sheets can be turnaround of CD and DVD

16 micron spot. Cylinder adapted from that used in the pulled after 20-30 sheets, though inlays along with marketing

rotation is increased to 600rpm smaller machines. Each roll can in some cases, commercially collateral, direct mail and books.

which helps account for an end hold 23 plates. Loading and acceptable work is achieved in The impact of the DI75 will be to

to end imaging time of two and a unloading is fully automatic. fewer than ten sheets. triple capacity with outline

half minutes. This helps the While the company has no The press in a standard plans to install a second before

press deliver the six-minute recycling facilities for the plate configuration will cope with the end of the year. “We looked

makeready, compared to a ten- mechanism in the UK, stock thickness from 0.04mm to at conventional offset with CTP

minute makeready on previous negotiations to put a service in 0.6mm, though this can rise to as part of our analysis. It was a

Presstek machines which have a place are underway. 0.8mm to cope with carton no brainer to add additional DI

smaller sheet format. The waterless printing boards. Print format is to a capability. The 75DI allows us to

The plate is washed during technology helps to keep make maximum of 788 x 600mm giving go from digital file to printed

imaging thanks to a declutching ready waste down as there is no a 760 x 580mm image area. sheet five times faster and much

mechanism freeing the plate ink-water balance to achieve. As Presstek is aiming the press more cost effectively than using

cylinder from the ink rollers. the plate is imaged in perfect at a niche from about the 500 a conventional offset press.”

Holographic ‘proofing’ from API Foils Dalim releases ES2

upgraded version

API FOILS and Holographics holographic effect foils and the interest from a range of sectors

has launched Holonique as a bespoke holographics which and from companies of all sizes DALIM HAS released an

holographic design tool to are expensive and slow to as the benefits of holographics upgrade of ES2, the customer

show those putting together produce mock ups. are made available to a wider facing version of its workflow,

projects using holographic foils Standard patterns, images audience,” says API sales and V6.3 of Twist, its workflow

what the final product will look and logos can be combined director Dave Stansfield. automation engine. As well as

like and to make it easier to use with a range of effects and Holonique has been used on colour accurate remote proofing,

the special effects foils in colours to produce impressive the cover of Nuts magazine and ES2 allows publishers a greater

marketing products. results in a matter of days for as well as decorative appeal, is level of collaboration, flatplanning

Holonique is positioned pack mock ups. expected to be used as a first for western and Asian editions

between the off the shelf “We expect to see huge level anti counterfeiting tools. and built in FTP server.

12 March 2011 www.printbusinessmagazine.co.ukINNOVATIONS & INVESTMENTS

New additions

to Mondi’s PaperCo fills gap with Club

portfolio of

digital papers

woodfree coated brand

PAPERCO HAS ACTED quickly its classy looks and its to hold standard sizes at good

MONDI HAS launched Color to fill a gap in its range with a printability,” he says. The stock levels for instant call off.

Copy Indigo and DNS Indigo as top quality woodfree coated product branding harks back to The grade’s environmental

uncoated papers adding to a brand, complete with the the Art Deco age through credentials are strong. It

growing portfolio of papers for highest environmental artwork commissioned from qualifies under FSC and is

digital printing. credentials. Danish illustrator Mads Berg. being supplied as a Carbon

Both are optimised for As a merchant brand Club “This was a period of Balanced grade. This is

printing on the HP Indigo covers gloss, silk and matt innovation, quality and becoming more important since

presses and have received a 3 finishes from 90 to 400gsm. It elegance. These traits are its introduction by the Paperlinx

star rating from the press will be stocked at each of matched in Club,” he merchanting group last year.

manufacturer, indicating the PaperCo’s locations to ensure continues. “This is the first woodfree

highest performance levels in that printers receive speedy PaperCo is offering the Silk coated paper that is Carbon

terms of runnability, fixing and delivery and that availability and Gloss grades with its Any Balanced,” says Eaton. Under

blanket compatibility. remains good. Size service, which allows this scheme, any carbon used

The papers all show good printers to specify the exact in manufacturing the paper can

printability with bright white format size they need for the be offset through acquisition of

hue, intense detail, good ink job, thus minimising trim waste equatorial rain forest in South

gloss and wide colour and keeping costs down. America under a project

reproduction, according to Minimum order size for this organised by the World Land

PaperCo head of marketing service is low and lead times Trust. Products that have had

Charles Eaton. kept short to underline the their paper Carbon Balanced in

“Designers and printers will value to the printer. At the this way are permitted to carry

love this new product for both same time PaperCo has pledged the World land Trust logo.

The papers are produced at the

Neusiedler Mill in Austria using the

Sappi first for high speed inkjet

unique triple layer production system.

SAPPI has produced its first ways to develop new papers.

The papers have the coated paper designed for high Anne-Sophie Gombart,

necessary primer for adhesion speed inkjet web printing. business development manager

of the Electroink added during Jaz was developed in digital papers at Sappi says:

the production process, so there collaboration with HP to suit its “This is a great example of the

is no need to precoat the papers T series inkjet presses. The first power of collaboration to

before printing. This guarantees grade to reach the market is Jaz design innovative products that

that provided other conditions Silk, designed for direct mail actually lead the digital market.

are right, that the papers will printing in 115 and 130gsm Full colour personalised

store for years before use. weights. Further weights from printed communication with

Color Copy is being 90 to 150gsm will be available offset look and feel and that can

recommended for photobook next month. It is being be produced quickly, is now

production as well as produced at the Lanaken Mill available to many more

applications demanding a high in Belgium and is FSC and businesses than ever before. It

quality finish. DNS Indigo is PEFC certified. is a revolution that is

suited to high contrast text, The shortage of suitable happening today.”

graphics and colour printing, papers has been a hurdle for Sappi is not alone in this

making it ideal for point of sale, inkjet web printing, particularly work. UPM has launched DIGI

Jaz from Sappi has been developed

corporate literature and as it climbs from transactional in collaboration with HP to suit its Color Jet as a paper for full

brochures. use, printing on uncoated T series inkjet presses. colour inkjet printing as part of

Mondi has also launched papers with light ink coverage, an expanding portfolio of DIGI

Nautilus ReFresh, a 30% to more commercial printing have helped deliver a papers tailored for different

recycled content produced at applications with heavy consistent result while post applications including books,

the Neusiedler Mill in Austria weights of ink. As the inks are print varnishing has pushed the newspapers and transactional

using the unique triple layer water based, press finished quality up. and for electrophotographic

production system. The inner manufacturers and the paper The future, however, lies in and inkjet printing. Currently

layer is made up of the recycled industry are seeking ways to developing papers which meet these are woodfree uncoated

content while the outer layers increase the stability of papers the requirements of high speed papers designed for fast ink

are produced from TCF virgin while delivering high quality inkjet. Press and paper absorption, low bleed and

fibre. results. Bonding coats before manufacturers are working on tolerance of water.

www.printbusinessmagazine.co.uk March 2011 13INNOVATIONS & INVESTMENTS

Manor Printing adds to Colorscan

changes

bindery with Horizon AFC tack with

MANOR PRINTING Services at

Wooton-under-Edge has added

massive impact on our speed of

throughput,” says managing

kept in house, increasing the

retained margin and saving on

Morgana

the Horizon AFC-566F director Chris Holloway. “Not fuel used to shunt pallets of

combination folder to its only can be complete a lot more work around. COLORSCAN IMAGING,

bindery line up. work faster, but with the variety The folder has JDF Burton on Trent, bought a

The folder, supplied by of pre-set folds, we can execute connections and Holloway says Xerox iGen to continue the

Intelligent Finishing Systems, our standard work to a very this can link the folder to the company’s transition from a

has replaced a 30-year-old Stahl high degree, quickly and MIS and will download job photo lab to digital printer, and

and brought an immediate simply. We can also add a instructions. Set up is via a has now added £90,000 of

boost to production. The variety of more complex touch screen panel. finishing equipment from

Horizon can put 10,000 to options to customers looking to Before making the decision, Morgana to work alongside the

15,000 folded sections on the achieve something a bit Holloway considered all press.

floor each hour, while the old different.” options. “We wanted to be sure The investment has brought

Stahl could only manage 3,000- Previously this type of work the folder would see us through the company an AutoCreaser

4,000. “This has made a was sent out, now it can be the next 15 years,” he says. Pro 50, CardXtra, DFC die

cutting system and EBA

guillotine. And now Colorscan

is looking to add web to print to

Challenge for Bookbinders of London round off the services it can

offer the brewing trade in

particular.

BOOKBINDERS of London has because of the automated Managing director Keith

gone from strength to strength features, partly because of the Forster says the company has

since installing a Duplo DPB- robust build and partly on the become “a leading supplier of

500 PUR perfect binder almost back of the ongoing marketing and point of sale

two years ago and has now relationship with Duplo, which material to the brewing

added a Challenge CMT-300 supplied the new machine. industry”, covering the largest

book trimmer to help keep up Now says Bailey: “It has businesses that operate from

the flow of book blocks to the made us far more automated. the UK’s home of brewing to

binder. Our guillotine operator has specialist independent brewers.

The century-old business been freed up and it has “We’d reached the stage

added photobook work to its allowed us to be more flexible where the vast majority of

established market in thesis Ian Bailey: “It has made us far and responsive to our output is printed digitally, so

binding in 2009. Thanks to the more automated and flexible.” customers. Costs are also down we’ve felt the need to upgrade

perfect binding capability it has as we have less labour involved the productivity and quality of

taken on more trade work and and quality of product, we are in each job and no need for our finishing.”

now is introducing a school now looking at our costly overtime, which was The Digifold was top of the

yearbook service via a web efficiencies.” common when time pressures list, the Pro version being

portal. The decision to buy an became too much.” launched at Ipex last year. “As

Managing director Ian autotrimmer was made after The CMT-130 (introduced at well as creasing and folding in

Bailey says: “The PUR binder examining the options of Ipex) is a single knife book one pass, the Digifold gives us

has become the heartbeat of our increasing staff or buying a new trimmer capable of processing high speeds and the ability to

operation. When we purchased guillotine. The specialist 500 books an hour, each up to handle stocks up to the 350gsm

it it was all about peace of mind machine won out, partly 60mm thick. produced on the iGen3.”

LCP Printing stays faithful to Heidelberg with XL75

LPC PRINTING, Southampton, old machine. Autoplate and Nick Lee:

digital printing. Both operations

has bought a ten-colour Inpress Control have sliced “There are are Heidelberg houses and this is

Speedmaster XL75 having makeready time to ten minutes. reasons why crucial says managing director

bought Midas Press from the To cope with the greater we return Nick Lee. “We return to

repeatedly

administrator last year. volume of work, LPC has also Heidelberg because they are

to

The new B2 machine replaced its ST100 saddle Heidelberg.” substantially larger than other

replaces a ten-colour SM74, but stitcher with an ST 450 and a suppliers and so R&D keeps

thanks to much faster KH 66 combination folder. pace. The source of minders

makeready times, it is proving a Southampton remains the you can attract is broader and

cost effective purchase with far B2 centre while the Midas site the service and repair base is

greater productivity than the brings B1 capacity as well as critical for 24/7 working.”

14 March 2011 www.printbusinessmagazine.co.uk8-up production

4-up price

920 series

With a sheet size of 640 x 920mm,

the Ryobi 920 series handles 8-up A4 with trims

LED UV is just one of many

£ SAVE on PRICE

SRA1 for the price of B2

innovations which make Ryobi

presses both cost effective and

Ryobi’s revolutionary environmentally responsible.

SAVE on POWER

Up to 40% less than typical B1 press LED UV system is an Let Ryobi take you forward

option on the Ryobi 925 into the 21st century!

SAVE on PAPER

Use SRA1 not B1 for 8-up A4

SAVE on SPACE

Only 65% of typical B1 press size

LED UV •

•

•

70% less power than conventional UV

Up to 12 times more lamp life

Completely eliminates ozone emissions

• Uses ink with no VOC solvents

SAVE on PLATES

30% less than B1 per plate

Saving can mean over £20,000 p.a.

The solutions provider Green shootsNEWSPAPERS

MAKING

headlines

Newspapers are dead, they say. Would those be the 12 million copies that

are sold every single day in the UK? The same newspapers that financially-

aware media companies are investing millions in plants to print?

I

n the science fiction film Minority Report Tom Cruise’s spend has been beyond £1 billion, headed by the £650 million

character jumps on a subway train to escape his pursuers, that News International has invested in three modern day

but is rumbled when a passenger’s copy of USA Today cathedrals for print.

automatically updates with news that a renegade Since the start of this year, Northern & Shell has announced

policeman is on the loose. that it will build a new site in Luton to be filled with KBA

It is interesting that although the film was made nine years presses, equipped with dryers for semi commercial products.

ago now, the passenger is reading something that is recognisably Shortly after A&N Media, parent of Harmsworth Quays Printing,

a newspaper, albeit a broadsheet of something like ePaper, and announced that it is planning to move from Rotherhithe to a

the design, while image heavy, is still a newspaper. Even in greenfield site near the Dartford Crossing in Essex. While it plans

science fiction newspapers continue to exist. to move and modernise the KBA Courier flexo presses it has at

Surrey Quays, it will still be spending close to £50 million. It

IN CONTRAST PUNDIT AFTER PUNDIT is predicting the would not be doing this if the move did not make financial sense.

demise of a product that has been around for more than 300

years, ever since printing became cheap enough to become THIS CAN BE JUSTIFIED BY FREEING up land in an area where

ephemeral. The future either lies with paywall protected web development sites are sought after, but also by reducing costs of

sites, subscriptions to versions for iPads or similar tablet production through greater efficiencies. According to A&N

computers. Their case is strengthened by the seemingly endless Media the move to Thurrock is expected “to deliver significant

decline in newspaper sales and now a steady flow of closures. savings once implemented”.

However, digital initiatives are not generating the cash to fund This also justified News International’s move from Wapping to

themselves and remain dependent on the revenue that the Broxbourne. While the initial move to the East End caused a furore

printed product brings in. And this product is going to continue. because fewer staff would be needed, the reduction to one third of

In the UK all the national newspaper groups have made or have previous manning levels went almost unremarked. But it has

announced plans for new generation production plants. The boosted the cost efficiency of producing newspapers. And it hasCAMPAIGN

enticed the Telegraph Group to become the first national newspaper Italy have very vibrant newspaper markets says Bell, with the

group to close its own facilities and contract print its titles. latter taking on dryers and new formats to increase sales. Italian

The rise of superplants is squeezing out many regional publishers have in the past offered hard cased cookery books or

operations, a trend that will continue according to Eric Bell, Goss art history books to entice subscribers.

director of marketing services. “Newspapers have a future, what UK publishers have been slower to offer such inducements.

will change is the way that they are produced because there is They have also been slower to develop the level of inserting that

too much over capacity and publishers cannot justify a plant is commonplace in the US where publishers can segment their

each. Consumers will not see a change, but papers will be printed readership down to Zip code zones, or to take on added value

further away from their town.” gimmicks like stick on vouchers such as Ferag has offered, nor

Eventually this may create demand for smaller simpler local indeed to push design and quality up the agenda.

production sites to complement the vast super-sites. Already Ovens and UV dryers are being used in the Middle East,

KBA produces presses that are suited to this type of operation Africa and Russia he adds. These are markets where newspaper

and Bell foresees an increasing demand for single width style sales are on the increase. In the developed world, the decline is

presses to fill the gaps in more remote locations. This style of steady as charted by ABC falls in the UK. However, there are still

machines is also in demand in the developing countries where more than 12 million newspapers bought in the UK each day and

newspaper readership is on the rise as educational standards and several million more if free newspapers like Metros and the

economies grow. Evening Standard are included. No other country has as many

national newspapers shifting as many copies as the UK.

THERE WILL ALSO BE GROWTH in plants able to take on But sales declines will worsen the overcapacity issues and

different types of work, presses with dryers and the ability to the next round of newspaper press investment in around 15

print semi commercial work in order to justify the investment in years’ time, will be markedly different to today. “Will we still be

a press. The Goss FPS fits this mould, able to switch between making newspaper presses in 15 years?” says Revill. “I hope so.

heatset and coldset inks and between formats in minutes. Thus But they might be using hybrid technology.” The partnership

a print site can become a revenue generator by taking on more with Océ certainly points to developments in this direction.

work, rather than simply a cost centre. What is almost certain to happen is that newspaper publishers

Norman Revill, managing director of Manroland GB, agrees: will switch more and more to contract printing, either closing

“Very few print sites only work for four hours each night. Very down production sites altogether or else hiving off these

few sites are not working during the day on contract jobs to sweat businesses into independent print operations as magazine

their assets. It’s poor management not to.” publishers have done over the last generation. In short more will

The company’s Colorman presses through bearer to bearer follow the Telegraph’s move.

design are coming close to commercial heatset quality and there

are sites around the world where these machines are linked to WHAT WILL NOT CHANGE HOWEVER IS PRINT’S UNIQUE

heatset ovens running glossy products which may be wrapped role in delivering memorable newspapers. Nobody is going to

around the normal newspaper to enhance its appeal. remember the web page with its headline carefully tailored to

Few publishers seem inclined to take on this level of suit search engines. “History is defined by newspaper front

innovation, which is standard in mainland Europe. Germany and pages,” says Bell. “Not by web pages.”

Cambridge First: first past the post with design

Cambridge First is a newspaper title launched last year by Archant, the east of England

based newspaper group. It was billed as a newspaper for the 21st century. Here Paul

Richardson, editorial director at Archant Herts and Cambs, explains why this is a

different type of newspaper.

THERE WERE A NUMBER OF SIGNIFICANT differences that

we wanted to highlight at the time of this launch.

In the 20th century, newspapers were the prime source of

news and information, despite competition from (in particular)

radio and television.

In addition, newspapers were generally either broadsheet or

tabloid and, from the 1970s onwards, embraced colour rather

than black and white rather tentatively or poorly.

The newspaper content was produced on print, usually with

little regard to pleasing design or ease of use for the reader. This

was because the words (text and headlines) were of prime

importance. Plus the route to market was restricted to paid-for

(for the majority of the century) via a newsagent, who may also

have a home delivery service, which he charged extra for. During

the latter two decades, many weekly titles became free, usually

delivered directly to targeted (for the advertisers) households.

A newspaper for the 21st century has to provide so much

www.printbusinessmagzine.co.uk March 2011 17You can also read