Corrosion Management - Protecting Pipelines - Institute of Corrosion

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Corrosion

A journal of the Institute of Corrosion

Issue 159 January/February 2021 Management

Protecting

Pipelines

Stay up to date with all Our informative Technical

the latest in Institute Article series continues

News

Page 16

Page 4Corrosion Management

Get qualified today with our

100% ONLINE ICorr courses

including final exams!

Don’t let lockdown stop you gaining

that edge by improving your

knowledge and qualifications!

Wherever you are around the globe get in touch to discuss

your education requirements with the Corrodere Academy.

• ICorr Coating Inspector Level 1

• ICorr Coating Inspector Level 2

• ICorr Coating Inspector Level 2

To see the full prospectus of courses available at the

Corrodere Academy please visit corrodere.com

For more information contact Meena Tipson

on 01252 732234 or email meena@corrodere.com

2 January/February 2021 www.icorr.orgContents

Issue 159 January/February 2021

4 14 26

The President Writes Fellow’s Corner Technical Article

Use of Mesh in Passive Fire Protection coatings

4 16

Institute News Technical Article 28

Reinforced Concrete Structures, Part 2 - Failure Technical Article

10 Investigation of Cooling Tower Reinforced Concrete Application of big data analytics to energy pipeline

Industry News Structures, Results and Discussion corrosion management

12 21 30

Latest Literature Technical Article Sustaining Members

Canadian study of the influence of ultraviolet exposure

13 on stockpiled fusion bond epoxy coated pipe 32

Ask the Expert Diary Dates

Published on behalf of the Institute of Corrosion Editorial copy date for March/April 2021 Tel: 01604 438222

Square One Advertising and Design Limited issue is: Email: admin@icorr.org

Neepsend Triangle Business Centre, Unit 8, 13th March 2021 Website: www.icorr.org

1 Burton Street, Sheffield, S3 8BW. Subscriptions All rights reserved Reproduction without written permission from the

Publisher and Managing Editor UK £70.00 Institute of Corrosion is prohibited. Views expressed in editorial text or

Debbie Hardwick Europe £80.00 advertising copy are the opinions of the contributors/advertisers and

Tel: 0114 273 0132 Outside Europe £90.00 airmail are not those of the Institute or the Publisher.

Email: debbie@squareone.co.uk £80.00 surface mail ISSN: 13 55 52 43

Consulting Editor Enquiries and subscriptions to the Institute of Corrosion at the address

below:

Brian Goldie

The Institute of Corrosion This publication is Recyclable.

Email: brianpce@aol.com

President

Design

Bill Hedges

Square One Advertising & Design

Past President

www.squareone.co.uk

Gareth Hinds

Advertising Manager

Hon. Secretary

Jonathan Phillips

Dr. Jane Lomas

Tel: 0114 273 0132

Fax: 0114 272 1713

Email: jonathan@squareone.co.uk Institute of Corrosion, Corrosion House,

5 St Peters Gardens, Marefair,

Northampton, NN1 1SXInstitute News

The President Writes

Welcome to the first edition up and making sure our members get the support and opportunities they

of Corrosion Management want. Beyond that I have four things I’d like to focus on:

for 2021 and my first column 1. Governance of ICorr

as President. I was honoured

We have a lot of very sensible rules and bye-laws which we follow to ensure

to be given this opportunity

we meet the standards required by the charities commission and the

at our last AGM in November

engineering council. There are many of our members who quietly work

and I have big shoes to fill!

behind the scenes to ensure that this happens, and I’d specifically like to

First and foremost, I want to

thank David Harvey for his dedicated work in this area. I have been thinking

thank Gareth Hinds for his

that it would be good to form a Governance committee to pull all of these

outstanding contributions as

activities together to support David.

President for the last 2-years

– how quickly the time goes 2. The ICorr Training Offer

by. Gareth oversaw many We have world leading training in many areas of corrosion and corrosion

important changes to the control and it’s exciting to see the potential opportunities that are emerging

Institute such as our new brand, for these to be delivered beyond the UK through both ICorr and our

which I love, implementing training partners of Correx, IMechE and Corrodere. David Mobbs has

Institute of Corrosion President, a digital and social media begun to outline how all of our training courses fit together and how they

Bill Hedges. strategy, launching new and help develop corrosion professionals. I want to support this activity so we

updated training courses, can offer a holistic corrosion training programme worldwide that provides a

and the transition to our new agreement with the Society of Operational clear pathway to becoming a fully rounded corrosion specialists.

Engineers. These are the highlights. However, what has impressed me so 3. Balancing ICorr’s mission to promote corrosion understanding

much about Gareth is his willingness to be involved in so many day-to-day and control with our business strategy

activities. He has led by example with his time, energy and enthusiasm –

As I noted earlier, our training courses are very popular – even with the

he epitomises the saying that if you want to get something done give it to

problems brought by Covid-19. I’ve found it quite easy to become

someone who’s busy. Gareth thank you for all you have done for us.

obsessed with how many courses we run and how the income can be used

In his last column Gareth also noted that the strength of our Institute is our to further the goals of our institute. But it’s not only about money - we have

people – I couldn’t agree more. So many of you give generously with your a mission to serve our industry and especially our members. So we need to

“spare” time and support. As the new President I’ve been astonished strike the right balance. Thankfully the Trustees and Council are alert to this

at how dedicated our members are. The list is almost endless and it is balancing act and I want to support this.

impossible to recognise everyone in these columns and so much of your

4. Growth and Support of Our Overseas Membership

work it is unpublicised. But it is recognised and I offer my sincere thanks to

all of you who help make our Institute so special. Should you be that rare Corrosion is a global issue and we are seeing increased requests for

individual who isn’t currently involved with our Institute, but would like to membership from outside of the UK which is fantastic. We need to identify

be, please do reach out to me at my email address below – we always have how we can continue this growth and support our overseas members.

opportunities to help us improve. On the subject of improving if you have These are my thoughts, but I’d love to hear from you if you agree or if you

any ideas of new things we should be doing, or could improve, please also think there are other things we should be focusing on - again please email

let me know via email – but be careful – you may find I ask for your help to me.

bring your idea to reality! I look forward to hearing from you and our journey together.

Several people have asked me what do I want to achieve as the President Bill Hedges, Institute of Corrosion President

of ICorr? This is something I’ve been thinking about during my time as vice- Email: president@icorr.org

president and I should start by saying my primary goal is not to mess anything

From the Editor

I would also like to welcome you to this first issue maybe the coated pipes will have to be stored

of 2021. Although the year hasn’t started well, even longer. The second themed article from

both for staff and businesses, there is hope on Australia gives an introduction to the use of

the horizon. “Big Data” to determine the condition of active

Due to the lockdown at the end of last year, pipelines and their fitness for service. It is hoped

there has been a less news of our industry, and to bring you an article covering the actual use

fewer local branch meetings, so to counteract of this technique on a pipeline later in the year.

this, I have included four technical articles The reinforced concrete corrosion article is the

for you. Two deal with pipeline coatings and second part dealing with cooling towers, and

inspection, the theme of this issue, together with covers the use of the techniques described in the

an article on passive fire protection (PFP), and a first part, in an actual case. Finally, the PFP article

case study about reinforced concrete corrosion. looks at the use of reinforced mesh.

The first pipeline article describes the effect of Remember it is your magazine, so let me know

stockpiling FBF coated pipe in Canada for the if there are topics you would like covered, and

Keystone pipeline project, and its suitability for remember to submit any technical questions you

use after 10 years. However, it has just been have for answer by our panel of experts I can be

announced that the new administration in the contacted at, brianpce@aol.com.

USA has cancelled the pipeline permit, so Brian Goldie, Consulting Editor

4 January/February 2021 www.icorr.orgInstitute News

An Apology to Tony Gerrard

New Members Tony Gerrard is a long-standing

member and Fellow of ICorr who

has provided high quality Cathodic

Welcome to our 249 new members and 9 Sustaining Company

members who joined the Institute in 2020. Protection training to hundreds of

students for many years on behalf

TOGETHER WITH THE CONGRATULATIONS of the Institute to all the of the Institute. In 2020, ICorr

following members who have attained Professional Status in 2020. suggested that he had marked

three CP exam papers incorrectly

TECHNICIAN l Vijaygavel Thangavel and over-ruled his assessment of the

l Dean R J Stonehouse l Rajkumar Betala candidates. Following an investigation, we realised we were

wrong to do this as Tony had followed the ICorr marking scheme

l Jessica B Rothwell l Stephanie Amarachi Okoye correctly. We apologise unreservedly to Tony for this mistake

l Abdul Kayum Shaikh l Muhammad Naveed Alam and desire to state that he has our full confidence as a CP tutor

and that he remains one of our approved tutors.

l Thomas Baxter l Wayne J Dodds

l Quang Hoai Vu

ICorr Cathodic Protection Courses Leading to

PROFESSIONAL l Mubashir Zawar

Competence Certification to BS EN ISO 15257

l Simon Dunn l Dilip Kumar Singh

These courses are now being held in conjunction with the Corrosion

l Michael George l Zeeshan Rajool Prevention Association at the new ICorr training site at Telford, and

details can be found in the new ICorr Cathodic Protection Course

l Muhammedsaleh Shokat Giteli l Jeffrey Didas Brochure which can be downloaded from, https://www.icorr.org/

l Anil N Kookkiri l William A Ritchie cathodic-protection-training, and see also, https://www.icorr.org/

cathodic-protection-training

l Andrew W Brown l Matthew Walters

Dates of the courses being held in the next two months can be found

l Muhammad Ashfaq l Chukwudi Obinna Nwanko on the Diary page of this issue. All dates are subject to bookings to a

maximum of 10 Candidates, and may be postponed. Book early, secure

l Nijanthan Kumar Rajaselvam l Bayu Aji

your place (s) for when the C-19 restrictions ease. Your booking will be

l John Ketley secured into suitable later courses if postponed.

l Craig McCann FELLOW Bookings for Courses and Exams can be made at Corrosion Prevention

Association: admin@corrosionprevention.org.uk

l Arivazhagan Vellaichamy l Shubhadeep Sarkar

l Ibrahim Elomari l Ethem Tug

l Joshua Owen l Marcos Anthony Garcia INTERNATIONAL CORROSION CONTROL INC.

INTERPROVINCIAL CORROSION CONTROL COMPANY LTD.

l Mohammedikram Geeteli l H Seshadhri Srinivasan

Industry Leaders … since 1957

l Abdul Jabbar l Patrick I Vashiharan Rabindran

l Prantosh Naha l Richard Barker

l Alex Pasmore l Imran Ashraf

Rustrol Cathodic Isolator

® ®

l Rakesh Ramasamy l Malcolm J Morris effectively blocks the DC current

needed for cathodic protection,

l Simon Cox l Adil Saeed while providing grounding path for:

l Sardar Ahmad Khan l Ardjan Kopliku • AC Fault Currents

l Padippurakkakath l Mohammad Abbas • Lightning Protection

Ibrahmimkutty Aliakbar • Mitigation of Induced AC Voltages

l Odagboyi Philip Enegela

l Faisal Jamal • Power Switching Surge Currents

l Mathivanan Lakshmanan

l Sudarshan Srinivasan Cathodic Isolator features

®

electronic/electrical construction

l Khaled Assad Abdelmageed that responds instantly, protecting

HON FELLOW

Mohamed personnel and equipment against

l Trevor C Osborne electrical shock hazards.

l Dean Covell

ATEX

Visit the E-mail: Contact@Rustrol.com

ICATS website Central Fax: 905-333-4313

www.icats-training.org www.Rustrol.com

www.icorr.org January/February 2021 5Institute News

ICorr awards – call for nominations

Each year the Institute of Corrosion bestows a range of internationally- The paper elegantly describes a novel approach using a helium

renowned awards in recognition of excellence in corrosion science bubble marker layer to study 316L oxide growth and dissolution under

and engineering, and to reward outstanding service to the Institute simultaneous proton radiation and corrosion in 320°C hydrogenated

and the wider corrosion community. Many of these awards are open water. Helium implantation was chosen since it is chemically inert and

to nomination by both members and non-members of the Institute. compared to heavier noble gases it generates fewer radiation defects

Below is a brief description of each award together with details of how and has a greater implantation range.

to nominate potential candidates.

Galloway Award

U.R. Evans Award The Galloway Award is presented to a student author for the best

The U.R. Evans Award is the premier scientific award of the Institute publication describing original research in corrosion science and

of Corrosion and is presented annually for outstanding international engineering as judged by a sub-committee of the Corrosion Science

achievements in pure or applied corrosion science. The recipient is Division. The student should be the primary author of the work and

selected by a Corrosion Science Division panel and presented with a preferably first author. A summary of the winning paper is published

sword at the annual Corrosion Science Symposium. The symposium is in Corrosion Management and the prize consists of a certificate and

one which seeks to encourage the participation of the junior members a cash sum of £300. The Institute does not retain copyright of the

of the corrosion community who would appreciate the visit of, and material, so this does not prevent separate publication of the work in a

address by, a corrosion scientist of international repute. The form scientific journal. Submissions (in the form of a paper published within

of the award symbolises the fight in which we are all engaged. The the past 12 months, or a draft publication) may be sent via email at any

recipient is also granted Honorary Life Fellowship of the Institute. time to the CSD Chair, Julian Wharton (J.A.Wharton@soton.ac.uk).

Nominations may be submitted at any time via email to the CSD Chair, Supervisors may also nominate students.

Julian Wharton (J.A.Wharton@soton.ac.uk). In 2020, the Galloway Prize recipient was Arpit Goyal (Coventry

Paul McIntyre Award University) for his paper published in Construction and Building

Materials journal entitled ‘Predicting the corrosion rate of steel in

The Paul McIntyre Award is presented to a senior corrosion engineer, cathodically protected concrete using potential shift’ (https://doi.

who, as well as being a leading practitioner in his field, has advanced org/10.1016/j.conbuildmat.2018.10.153). The paper examined the

European collaboration and international standards development. The possibility of predicting the corrosion rates using polarisation data and

award consists of an engraved trophy, which is presented at the annual the Butler-Volmer equation to develop cathodic protection criterion

CED Working Day meeting. The recipient is requested to present a for reinforced concrete exposed to the atmosphere.

brief overview of their activities and encouraged to prepare an article

for publication in Corrosion Management. Nominations should be Lionel Shreir Award

submitted to the CED Chair, Nick Smart (nick.smart@jacobs.com), by The Lionel Shreir Award is given to the best student presenter at the

12th March 2021. annual Corrosion Science Symposium. Selection of the recipient is

T.P. Hoar Award carried out by a sub-committee of the Corrosion Science Division. The

award consists of a certificate and a cash prize of £125.

The T.P. Hoar Award is presented to the author(s) of the best paper

published in the scientific journal Corrosion Science during the The Shreir award in 2020 was presented to Christos Kousis (University

previous calendar year. The winning paper is selected by a sub- of Manchester) for his presentation entitled ‘An investigation of the

committee of the Corrosion Science Division and the author(s) receive effect of chloride ion concentration on the localised corrosion of the

a certificate and a cash sum of £400. E717 magnesium alloy’. Christos gave an insightful talk on using the in

situ scanning vibrating electrode technique, coupled with time-lapse

The winning paper in 2020, from papers published in 2019, was imaging, to study magnesium corrosion behaviour.

authored by Rigel Hanbury and Gary Was (University of Michigan), for

their paper entitled ‘Oxide growth and dissolution on 316L stainless For further details on the Institute awards, including lists of past

steel during irradiation in high temperature water’ (Corros. Sci. 157 recipients, please visit https://www.icorr.org/icorr-awards/

(2019) 305-311 - https://doi.org/10.1016/j.corsci.2019.06.006).

Social Media - Digital strategy review for 2020

The Institute of Corrosion began its digital strategy implementation in social media channels include Instagram, Facebook and Twitter, and all

February 2020. The primary objectives of this were to raise awareness of continue to have a steady growth in followers.

the ICorr Brand, both nationally and internationally, increase the social This increased presence on social media is having a positive impact on

media presence, increase membership numbers, and increase the number visitor numbers to the website. In 2020 we had 2343 referrals from social

of applicants booking onto training courses. media, this is a 768% increase on 2019, which highlights the importance of

There is still lots of work to do, but the initial figures for the first 10 months of a strong social media presence.

the campaign have been very encouraging. Overall visitor numbers to the website are also on the increase, 2020 saw

On the social media front Linkedin was the main platform targeted due to 41,490 people visit the site which is a 10% increase on the previous year.

its professional nature. The new Institute of Corrosion Linkedin page now This is a result of a number of factors including the increased social media

has 4,446 followers and is gaining around 300 new followers every month presence and the Search Engine Optimisation (SEO) work that has been

which is very encouraging. Due to the quality of the content that we post ongoing during 2020.

on social media, and its regularity, we have a superb engagement rate (ER) The digital strategy working group have agreed that whilst these figures

of 4.78%. If you compare this to well established pages in the industry this are very encouraging and have surpassed the initial expectations, they are

is an excellent rate of engagement, NACE for example have an ER of 3.58% only a very good starting point. We now want to focus on establishing how

and The Society for Protective Coatings have an ER of 2.63%. Our other these increased visitor numbers convert into new members and attendees

at training courses, and what we can do to improve this conversion.

6 January/February 2021 www.icorr.orgInstitute News

We are also looking to increase the amount of video content available on The NII process is essentially a 4-step process.

the ICorr website and social media. With so many conferences, seminars 1. Firstly, in the assessment phase the vessels’ history, process, and risks, are

and branch meetings being held online there has never been a better time reviewed to determine the suitability of techniques.

to collate this content and share it with our members.

2. A work scope is then developed with respect to instructions, locations

As members you can help by liking, sharing and engaging with the content and reporting requirements.

that we put onto social media. We are always interested in potential new

content so If there is anything that you would like to see more of please let 3. The inspection phase is then carried out to fully meet all requirements.

us know via the usual channels, or a direct message on social media. 4. Finally, the process of evaluation is carried out and any repair

recommendations made.

Branch News

A thorough screening process is first undertaken to assess whether a vessel

is suitable for NII. Once agreed, it is assessed as to whether degradation

of vessel wall is expected to occur on an A, B or C type level of severity

(see later for explanation of these levels), and if it can be safely predicted.

Aberdeen Branch

Calculations can then be made of the required NII coverage for A, B or

C graded vessels, and the probability of detection of any metallurgical

flaws of given depth/aspect ratio. There is also consideration given to the

homogeneity of any expected flaw distribution.

In October the branch hosted a 2-part Non-Intrusive inspection (NII)

webinar. The two speakers skilfully interweaved their presentations to For the scope and inspection, the HOIS practice has recommended

explain the background to recent NII adoption, and the practical aspects techniques in the form of simplified tables which relate to the vessel shape,

of the new HOIS, for the benefit of a large corrosion engineer audience. cladding, weld types, and nozzles and flanges. The evaluation phase later

looks at whether the inspection has met the requirements that were set

Dr Susan Osbeck, Principal Consultant of ESR Technology started the out, i.e. was the right coverage and targeted locations achieved, were the

proceedings off with a talk entitled ‘The Updated HOIS Recommended correct scanning techniques utilised and the overall probability of detection

Practice for Non-Intrusive inspection”. assessed.

The inspection of pressure vessels is traditionally done by internal visual The latest revision was published as HOIS-RP-103 in 2020, and updates,

inspection (IVI) with human entry that is both risky, and disruptive to and the new features mentioned here, can be found at: https://www.

production. IVI is required to be carried out during shutdown after esrtechnology.com/index.php/32-news/news-articles/423-updates-to-

isolation and cleaning of equipment, and is both a costly and hazardous recommended-practice-for-non-intrusive-inspection-hois-rp-103

activity with considerable production losses incurred during this period.

By contrast for NII, the assessment and inspection are carried out externally This excellent introduction to the NII Process was followed by further insights

using advanced automated NDT techniques with the vessel remaining in from Neil Wilson, Principal Corrosion Engineer ENGTEQ, who discussed ‘A

operation. Corrosion Engineer’s Perspective’.

HOIS (Harwell Offshore Inspection Service) is a very well established (>30 The presentation focused on detailing the physical aspects of NII which

years) joint industry project covering all aspects of good practice for Non- are most relevant to corrosion engineers, for example, in predicting where

Destructive Testing (NDT) in the oil and gas industry. NII is a process not damage may occur and the evaluation of results. It was stressed that all

a technique, and HOIS have developed a framework to improve industry NII requires buy-in at senior management level in terms of acceptance of

confidence in it. These inspection design concepts started in high value alternative NII procedures (not every item of equipment being suitable).

projects in the nuclear industry and were then taken up by Oil Industry On the plus side there may be considerable cost savings due to increased

operators, particularly in the North Sea. HOIS Guidelines were originally production time (less inspection down time). Corrosion engineers are

published as DNV-RP-G103 and over the years the practice has spread very central to the NII process in the preparation of the assessment, the

worldwide throughout the Oil & Gas industry. work-scope, the evaluation of documented results, and in using the data

obtained to drive future inspection programmes.

The NII Process - Dr Susan Osbeck.

www.icorr.org January/February 2021 7Institute News

Neil emphasised that NII is certainly not a substitute for RBI (Risk Based Professor Debra Carr (CEng FIMMM FCSFS CF), Defence and Security

Inspection) approaches and it is only one component of the overall RBI Accelerator, gave a fascinating presentation on body armour called “Saving

assessment process. their Skin (and other organs): Military and Police Personal Armour”. The

The performance of an NII assessment Inspection was fully explained: talk focused on personal armour such as is worn by police and military

personnel, the design of the garments, the specialist materials employed,

1. Strategy Type A, where no degradation is expected; this usually applies and how they work to afford protection.

to Corrosion Resistant Alloy (CRA) vessels, commonly of stainless steels

and Carbon steels (CS) with low degradation rates, such as vessels in dry Protective armour can be in the form of simple tabard style waistcoats with

gas service, with good service history and high confidence of no upsets helmets, eye protection or visors. Other types of armour such as body

that would cause internal corrosion. It also applies to CS vessels which suits, ballistic blankets and shields are used for control of public order

are internally clad with a layer of CRA. Typically, one would inspect 5-10% or ordinance disposal. The main purpose is to save lives and prevent or

of the vessel looking to confirm absence of degradation at all locations minimise life changing injuries.

throughout the vessel. There is usually high focus on nozzles and ports, Body map injury pattern summaries from conflicts during the last century

with a larger percentage selected and all types covered. A study of a CS have shown that there is a greater threat of injury to military personnel from

vessel with hot rolled CRA bonded cladding was described, for which scattering fragments than there is from direct ballistic hits such as bullets.

the data showed the results for wall thickness only, and confirmed that the So secondary fragments are more likely to kill or incapacitate personnel

cladding interface was is intact with no wall loss breach or disbondment. than direct impact from bullets, making general body armour covering

2. The study then moved on to a Type A+ vessel with an internal weld overlay more important than say just head or torso protection. This is borne out

cladding around the nozzle which had multiple overlay welds (MOW) with by surface wound mapping which demonstrates that injuries are spread

a much coarser grain structure and an uneven surface determined by the generally across torso, limbs and head, rather than target the central torso

weld beads. This type of structure normally causes scatter of NDT beam or head.

detection methods and it is thought impossible to detect stress corrosion Wound ballistic studies have been extensively studied using high speed

cracking (SCC), or fine pitting in MOW, so how can this be assessed? The video to capture images of ball bearings fired through blocks of translucent

focus in this NII situation would be at the interface of cladding, and CS gelatine, which is a good model for human and swine tissue, and visual

corrosion would be evident at the CS interface, (if present) following failure patterns show creation and subsequent collapse of cavities, replicating the

of the CRA cladding. wider damage during the passage of a bullet. The damage patterns were

3. For Type B Vessel inspection, the likelihood of defects being present reproduced using prepared swine and deer carcasses to show realistic

is often much higher, so inspection coverage is closer to 25%. The entire tissue damage expected in humans.

vessel floor would be included along with most nozzles. Some of the greatest threats these days to police appear to come from

4. For inspection of Type C, such as polymer coated CS, significant sharp weapons such as knives and concealed blades, low velocity pistols

degradation would be expected with medium to high progression and and shotguns. Common kitchen knives are often ‘weapons of choice’ of

the locations not easily predicted. Coating breakdown is often random in urban conflict. Studies of knife use and attacker behaviour are used to

distribution and even with 50% of areas inspected and no flaws detected, identify critical areas required for protection of officers. However, essential

there is still little confidence that there are no flaws, so often 100% NDT areas of coverage have to be balanced with the ability of personnel to

inspection is necessary. For NII it is necessary here to inspect fully for wall do their job and avoid restriction of movement. PPE (Personal Protective

thickness loss, as coating condition cannot be seen or verified accurately. Equipment) such as jacket and helmet design have to be arrived at through

Such an inspection is significantly more costly of course. balance of these criteria.

NII is really for internal condition assessment only, external corrosion and Typical types of materials used in jackets:

issues such as corrosion under insulation (CUI) remain difficult and are 1. High strength woven fabrics which are either para-aramids such as

assessed by other accepted procedures/technologies. Kevlar® or UHMWPE (Ultra High Molecular Weight Polyethylene) such as

For the final stage of the process, the results must be checked against Dyneema® or Spectra®, like those used in high stiffness ropes. Multiple

the requested work scope, e.g. are the NII findings as predicted for the layers of these fabrics are used to provide increasing amounts of protection,

category of vessel inspection? Are there new previously unidentified but a typical Police vest only weighs about 2 kg.

damage mechanisms additional to previously identified and are there 2. Sharp object protection armour which still uses old fashioned chainmail

others that don’t seem to be currently active? or resin coated fabrics, (the key to prevention of knife penetration is to

The vast majority of NII inspection results are quantitative and these allow change the kinetic energy density during an impact event by blunting the

accurate prediction of remaining vessel life. The results also increase tip or capturing tip within the mail).

confidence in the prediction of degradation types and locations for 3. To stop penetration of fragments and pistol bullets, the specialist fabric

future inspections, and provide useful information about density and also works by dissipating impact energy along yarns during fibre failure.

homogeneity of corrosion. These items are typically not well covered by Pyramidal patterns occur in the fabric due to vertical and horizontal lattice

traditional intrusive type inspection and manual NDT, therefore this is a alignment of fabric. The high effectiveness of the police body armour was

major advantage of using NII. demonstrated by the mushrooming of 9mm pistol bullets on impact.

The branch held its annual joint 4. For threats such as high velocity rifle bullets, ceramic based composite

event with IOM3/MIS (The backed plates are used on top of the general armour. The ceramic plates are

Mining Institute of Scotland) typically alumina or silicon carbide which are up to five times the hardness

on Tuesday 24th November of steel and bonded with composite fabric on the rear. The ceramic is

2020. impacted but being much harder, the bullet deforms and may fracture itself

This webinar presentation was and its trajectory hindered. It leads to a conical deformation of the ceramic

specifically designed to make and a buckling of the adhesive and fabric backing without failure.

members of the audience Professor Debra Carr went on to describe ‘Behind Armour Blunt Trauma’

think outside the box in terms (BABT), which is a non-penetrating injury resulting from armour covering

of approaches to materials the body. The bullet does not penetrate the armour but there may be minor

selection, and how the breathlessness, bruising or occasional rib fracture.

research work of the defence The main challenges for the future maybe in the types and thicknesses

and emergency services can of materials used in armour, as the key objectives are to reduce bulk and

be utilised in protection of mass, whilst preserving the protection level. It is also essential to prevent

personnel employed in the restriction of movement of the wearer while increasing coverage and

NII Inspection Strategies for Offshore Vessels Energy Industries. improving breathability, cooling and ventilation.

- Neil Wilson ENGTEQ.

8 January/February 2021 www.icorr.orgInstitute News

For Oil and Gas drilling and other Energy / Mining The latest information about Aberdeen events

applications, there are many potential applications can be found on the diary page of this magazine,

of these corrosion free and advanced materials. and at; https://www.linkedin.com/in/aberdeen-

Blast test curtains supplied from US companies, icorr/, and all Aberdeen events are recorded and

are commonly used Offshore, but Professor Carr may be found at; https://sites.google.com/site/

and her team are now assisting UK companies with icorrabz/

specific Oil and Gas protection problems, and

would welcome any enquiries at: djcarr@dasa.

service.mod.uk

The branch sponsorship level continues to grow

despite challenging times. Branch sponsors have

remained extremely loyal and appreciative of the

large number of technical events being provided.

There are presently 17 confirmed sponsors for Visit the ICorr website

2020-2021 session. Joining us this year are:

Axcess Corrosion (US), IMRANDD Consultants,

for all the latest news

NCIMB (Laboratories) Ltd, Oil and Gas Corrosion

Ltd.

www.icorr.org

Protective Helmet Design - Professor Debra Carr.

London Branch

with an advanced abrasion resistant coating, ARO (abrasion resistant

overcoat) with enhanced barrier properties coupled with flexibility

characteristics typically associated with a single layer FBE system. Jeff

The first technical presentation of 2021 was held on 7th January, and fully described the properties of the new technology, application

featured an on-line talk by Dr Jeff Rogozinski of Sherwin-Williams, characteristics, and performance with emphasis on resistance to

who discussed an advanced FBE (fusion bonded epoxy) technology damage and more. Demonstrations of field testing these properties

called Moisture Resistant Overcoat (MRO). Jeffrey has over 29 years were also shown.

of coatings experience and is a Global Product Director in Sherwin As there was a high presence of pipeline protection experts within the

Williams Protective & Marine Coatings division. He has been with audience, there was a very interactive Q&A session. The chair thanked

Sherwin Williams for 10 years and held previous positions in protective Jeff for his interesting presentation and for standing in at short notice.

coatings and powder coatings, resin and additive development for

coatings science with an emphasis on polymer synthesis and structure- It is intended to publish a detailed article on this technology in a future

property characterisation, as well as multiple academic positions. issue of Corrosion Management.

More than 50 members, from around the UK and further afield The presentation has been uploaded to the Institute website and can

(including one from South Africa) heard a very interesting talk from be accessed at https://www.icorr.org/moisture-resistant-overcoats-

an expert in pipeline coatings. Jeff explained that this new concept is advances-in-damage-tolerance-and-barrier-properties-7-jan/

quickly gaining traction with end users all over the world. It combines The March meeting will be the branch AGM and the “Presidents” talk.

the protective properties of a traditional, approximately 40-year old Full details of future branch events can be found on the diary page of the

technology designed for pipelines operating at high temperatures, magazine, and on the Institute website.

Young ICorr Look to the Future

In December, Young ICorr looked to the future

with a festive spirit. Dr Bijan Kermani presented

“Challenges and Future of the Discipline” expressing

a positive outlook for the energy sector and how our

niche sector of materials and corrosion will be vital

in supporting a sustainable future. A key theme of

Dr Kermani’s address was how we will inevitably

rely on both innovation of materials and integrity

management technologies, but also how we must

maximise the economy and use of more common

materials, such as carbon steel. It is a combination

of the things that we have learned, and have yet to

learn, that will shape the future of energy.

Taking advantage of the online forum, the talk was

widely attended with participants from across the

world. As it was Christmas, what better way to

celebrate than with a Corrosion festive quiz with

questions including the RAL number for Christmas

Red? How small is the world’s smallest Christmas

card? And what metal was tinsel first made from? Young ICorr committee and some of the quiz participants.

Congratulation to the winners: team Dr Magnetite!

www.icorr.org January/February 2021 9Industry News

Industry News

New Association for Materials New Board appointment at

Protection and Performance (AMPP)

Winn & Coales (Denso) Ltd

The Board of Directors of Winn &

Coales (Denso) Ltd have recently

announced that Mr James Winn, the

great grandson of the founder of the

The new organisation, the Association for Materials Protection and company has been appointed to the

Performance (AMPP), was formed by the merger between NACE Board.

International and SSPC: The Society for Protective Coatings, and aims to James Winn has worked for the

provide a unified voice for the corrosion control and protective coatings company for over 25 years and he

industries. brings a wealth of knowledge and

AMPP consists of two governance structure; AMPP, which will provide experience to the management team.

services to members in the areas of certification, accreditation, membership,

advocacy and public affairs, and AMPP Global Center, which will focus

on standards, technical and research activities, conferences, events,

education, training, publications and pre-professional programming. The

CEO of the new organisation is Bob Chalker, previously CEO of NACE.

PRA Training Courses

The schedule for 2021 training courses is now available at www.pra-world.

com, and bookings are now being taken. All courses are held virtually with

NACE Corrosion Expo 2021 a strict limit of 15 participants.

The next course of possible interest to readers is:

Due to the State of Utah’s COVID-19 limitations on group gatherings, Paint Technology, 19 - 22 April 2021

CORROSION 2021 can no longer take place at the Salt Palace

Convention Center in Salt Lake City, and will now be held virtually on This course has been designed for newcomers to the industry who

April 19-30, 2021. This two-week event will provide a collaborative need a firm foundation in the technology of organic surface coatings.

and convenient platform for corrosion and coatings industry To gain maximum benefit from the course it is helpful if delegates have a

professionals to network, learn, and develop new business. knowledge of chemistry to university entrance standard.

To ensure attendees get the most out of the conference content, It is a comprehensive and intensive four day course that contains

and exhibitors and buyers easily connect, CORROSION 2021 Virtual an overview of the raw materials used in surface coatings and their

Conference & Expo will utilise Artificial Intelligence matchmaking contribution to the final properties of the coatings. The study of coating

tools. Registration is now open. systems emphasises the changes taking place in modern technology.

Attendees previously registered for CORROSION 2020 that deferred The cost is £1,850.

to CORROSION 2021, and any deferred registration fees will be To register or for further details, contact the PRA at, on +44 1664 501365,

applied to the CORROSION 2021 Virtual Conference & Expo. For or email, coatings@pra-world.com

attendees who would prefer to defer to transfer their registration to

a different event or product, to Coatings+ 2021, to the 2022 Annual

Conference, or request a refund, should contact NACE International’s For all the latest news, events

First Service team. Similarly, exhibitors and sponsors, can transfer

their bookings or obtain a refund. and debates join us on

NACE International’s First Service team can be reached at

firstservice@nace.org or by phone at +1-281-228-6223 worldwide.

Leading Coating Contractor opens new division

The leading coating applicator, Pipeline Induction PIH Industrial Coating Services is the result of a commercial venture

Heat, has launched a specialist coating division – with local company HJC Protective Coatings. which has over 25

PIH Industrial Coating Services – with the opening of years of experience and success within the sector and will continue to

its first blast and coating facility in Watton, Norfolk. employ the highly skilled team of staff who hold both NACE 2 and 3

PIH has gained a reputation in providing coating qualifications.

services to the international oil and gas pipeline The company will offer customers a range of services including, blast

sector. The new division will specialise in the application of protective cleaning, the application of wet applied paint systems, thermal metal

coating systems to a wider customer base, and across a broad range of spray coating, passive fire protection and insulation. It will also offer

sectors, including engineering, marine, utilities and renewables as well a variety of additional services, including a packaging and logistics

as the oil and gas industries. service on a national and international scale, consultation and support,

coating specification review and in-house inspection.

10 January/February 2021 www.icorr.orgIndustry News

Gritco’s unique testing centre in the Netherlands

As they saying goes, practice is the best teacher. This is especially true when contractors are considering purchasing blasting equipment.

However, everyday practice usually shows that too little thought results in blasting solutions not meeting the expectation. To avoid making costly

mistakes, you should take a close and thorough look at all the possible blasting solutions (of which there are many) before deciding what method

and equipment will really fit your blasting needs. Finally, if possible before you should try before you buy.

That’s why Gritco recently set up a unique, professional Experience Centre where blasting specialists and companies can get advice on the wide

range of high quality, innovative blasting equipment, and personally experience the different blasting possibilities, and media, in practice.

There is a choice of, pressure blasting, wet/vapour blasting, soda blasting, fine blasting and vacuum blasting methods, including blasting

cabinets, blast pots, vacuum blasting machines, after coolers, dust extractors and personal protection.

Nippon Paint receives Efficient inspection of

NORSOK approval complex piping systems

The interior of pipelines that carry

Nippon Paint Marine has recently announced that its tank coating,

hazardous material are commonly

NOA60HS, has been certified by the Norwegian Technology

inspected for corrosion and other defects

Standards Institution.

using videoscopes. Long, complex

According to the company, the self-indicating technology used piping is especially difficult to navigate

in the coating meets the requirements of the NORSOK M-501 and inspect because of complex bends

standard, and is specifically designed for use in ballast water tanks, and potential obstructions. TheIPLEX™

oil and petrochemical tanks, and void spaces. GAir long scope from Olympus,

NORSOK M-501 provides the guidelines for the selection of coating combines maneuverability with high-

systems, minimum dry film thickness and surface preparation quality, wide-view images to make

requirements to ensure quality of products in the offshore and other complex pipe inspections fast and

industries. efficient, at distances up to 30 metres

with outstanding image quality.

According to the company, the

Seal For Life videoscope’s unique guide head enables

it to slide easily through pipe joints while pneumatic articulation provides

announces acquisition fine control, even when the 30 m insertion tube is fully extended. To enable

easy inspection, a gravity sensor automatically rotates the onscreen image

Private equity firm Arsenal Capital Partners has recently announced regardless of the scope’s orientation, while the insertion length indicator

that its coatings platform, Seal For Life Industries has acquired the tracks how far the videoscope has been extended.

Canusa-CPA and Dhatec businesses from Shawcor. For dangerous or hazardous inspections, such as inside nuclear power

Canusa has operations in Canada, the Netherlands, the United plants, users can set up the videoscope and control it from a safer location

States and the United Arab Emirates and employees more than up to 100 m away. The videoscope’s touch screen can be detached from

250 employees, and its products include, visco-elastic adhesives, the main unit and positioned up to 5 m, while wireless capabilities make

mechanical protection systems and liquid epoxy coatings. it easy to share screen images with colleagues, concluded the company.

On the acquisition, Jeff Oravitz, CEO of Seal For Life said, “We are

delighted to welcome the Canusa team to the Seal For Life family, Visit the ICorr

and look forward to working with them to accomplish our vision of

being the leading global provider of protective coating and sealing

website for all

solutions for infrastructure markets.” the latest news

www.icorr.org January/February 2021 11Innovative Products

Latest Literature

Intumescent coatings for ISO 14571 Metallic coatings on non-metallic basis materials —

Measurement of coating thickness — Micro-resistivity method

steel fire protection ISO 15156-1, 2, 3 Petroleum and natural gas industries — Materials for

use in H2S-containing environments in oil and gas production — Part 1:

General principles for selection of cracking-resistant materials, Part 2:

Intumescent coatings are a great alternative for passive protection of metal Cracking-resistant carbon and low-alloy steels, and the use of cast irons,

substrates against fire, with the binder polymer being one of the main Part 3: Cracking-resistant CRAs (corrosion-resistant alloys) and other alloys

components of the system. The objective of a recent work was to compare

five different resin types (epoxy, acrylic, alkyd, silicone, and silicone–epoxy ISO 19902 Petroleum and natural gas industries — Fixed steel offshore

hybrid) in an intumescent formulation and to study the influence of resin structures

concentration on the fire protection performance of the coating. ISO 21716-1, 2, 3 Ships and marine technology — Bioassay methods

Results from TGA and MCC analysis of resins and coatings indicated for screening anti-fouling paints — Part 1: General requirements, Part 2:

that coatings containing silicone are thermally stable and release smaller Barnacles, Part 3: Mussels

amounts of heat. In the fire resistance test, samples containing epoxy ISO 23221 Pipeline corrosion control engineering life cycle — General

and silicone resins had lower temperatures (130–160°C) compared to requirements

the other samples. It was also found that it is possible to decrease resin

ISO 23226 Corrosion of metals and alloys — Guidelines for the corrosion

concentration in formulations containing epoxy and silicone resins by up

testing of metals and alloys exposed in deep-sea water

to 25.6% and to maintain or even improve their fire protection capability.

The study was published in Journal of Coatings Technology and Research,

Volume 17, 2020.

CEN

Previous ISO standards now issued by CEN.

Studying the water EN ISO 15156-1, 2, 3:2020 Petroleum and natural gas industries - Materials

for use in H2S-containing environments in oil and gas production - Part

permeation in coatings 1: General principles for selection of cracking-resistant materials, Part 2:

Cracking-resistant carbon and low-alloy steels, and the use of cast irons,

The objective of this new work was to develop and evaluate Part 3: Cracking-resistant CRAs (corrosion-resistant alloys) and other alloys.

experimental approaches using different analytical techniques EN ISO 18086:2020 Corrosion of metals and alloys - Determination of AC

to measure the permeability, diffusivity, and solubility of water in corrosion - Protection criteria (ISO 18086:2019)

model coatings.

This document specifies protection criteria for determining the AC

These properties are of primary relevance in studies of coatings for corrosion risk of cathodically protected pipelines. It is applicable to

corrosion protection. For water permeation measurements, test buried cathodically protected pipelines that are influenced by AC traction

rigs were designed and prepared to facilitate measurements by systems and/or AC power lines. The document does not cover the safety

microcalorimetry, gravimetry, and thermogravimetric analysis. For issues associated with AC voltages on pipelines. These are covered in

sorption measurements, films were prepared in various thicknesses

www.icorr.org

to allow a proper analysis with Fourier-transform infrared

national standards and regulations (see, e.g., EN 50443).

spectroscopy in transmission mode and gravimetry. All methods

were successful in determining water uptake kinetics.

The work was published in Journal of Coatings Technology and

Research, Volume 17, 2020.

STANDARDS UP-DATE TO ADVERTISE

ISO IN CORROSION

The following documents have obtained substantial support during the past two

months and have been submitted to the ISO member bodies for voting, or formal

MANAGEMENT

approval.

ISO/DIS 2080 Metallic and other inorganic coatings — Surface treatment, please contact

metallic and other inorganic coatings — Vocabulary (Revision of 2008

standard)

Jonathan Phillips

ISO/FDIS 22848 Corrosion of metals and alloys — Test method for or Debbie Hardwick at:

measuring the stress corrosion crack growth rate of steels and alloys under

static-load conditions in high-temperature water Square One Advertising & Design

ISO/DIS 23721 Corrosion of metals and alloys — Rating method by +44 (0)114 273 0132

appearance of rust and stains of atmospheric corrosion for stainless steels

enquiries@squareone.co.uk

New international standards published during the past two months.

12 January/February 2021 www.icorr.orgAsk the Expert

Ask the Expert

In this issue the questions relate to monitoring of CP on pipelines and what

causes amine blush on epoxy coatings. Readers are reminded to send in

have had good performance from our reference electrodes!). Sylvain

Fontaine, Cathodic Protection Expert, GRTgaz, Compiègne,

their technical questions for possible inclusion in the column in future. France

Question: Question:

I maintain a buried pipeline in an environmentally sensitive area and I wish What causes amine blush on epoxy coatings? PS

to follow best practice in monitoring the CP system on it. I am thinking of Answer:

fitting remote monitoring but I am concerned how accurate and reliable

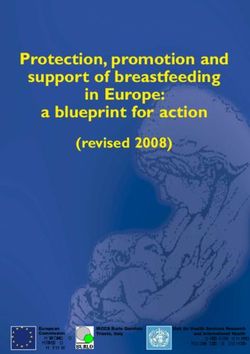

any reference electrodes that I use with a data logging system will be. Amine blush is a combination of three unwanted reactions between

Related to this I do not want to excavate to install the reference electrode to amines and moisture/carbon dioxide which lead to the formation of amine

pipe depth, can I bury the reference electrode just below the surface near hydrates (with water), ammonium carbamates (with carbon dioxide) or

the existing Test Point? BK carbonates (with carbonic acid). It is the latter of these which presents the

biggest problem as the reaction is irreversible and leads to surface defects

Answer: which are difficult to remove (carbonation). In epoxy coating systems this

The practice you describe is one that is widely followed, for example in will normally be at the surface/air interface as a result of the amines in the

GRTgaz France on their high- pressure gas transmission system they use curing agent. Since carbonation is essentially an acid/base reaction it is

remote monitoring equipment from Italy and fixed reference electrodes kinetically favoured over the amine/epoxy reaction which we would prefer.

often buried close to the surface under open bottomed surface boxes to This is particularly problematic in application conditions of low temperature

aid their location and replacement. National Grid in the UK use remote and high humidity where the amine/epoxy reaction is retarded even

monitoring extensively. However, there are a number of issues for you to further, and we have high levels of carbonic acid.

consider: It has often been

1. Fixed reference electrodes can be significantly unreliable and suggested that

their electrode potential can drift significantly from what you and the the way to resolve

manufacturer may expect. This may be particularly so with electrodes in this would be to

soils with significant groundwater movement. It is recommended that all make the amine-

fixed reference electrodes are supported with a method such as a UPVC epoxy reaction

tube from ground level to electrode level to permit a calibrated, portable faster, but using

reference electrode, likely a Cu/CuSO4 to be deployed close to the fixed more basic

electrode and the drift assessed. Depending upon how important the amines simply

accuracy is, this should be done frequently. leads to more

2. Placing electrodes remote from the pipe will introduce errors in carbonation as

Figure 1. Reactions of isophorone diamine with H2O and CO2. they will more

measurement, more in high electrical resistivity soils than in low, this is due

to IR errors due to CP current flowing in the soil. The errors may be low with readily produce blushing via the acid/base interaction. It is interesting to

the electrode directly over the pipe and if your pipe coating quality Is high. note that in the past when the use of aromatic amine curing agents was

more common there was no issue with blushing when using these products

3. You might also consider deploying a steel ‘coupon’ that most remote because aromatic amines are not basic. Of course, these products are now

logging systems will permit to be switched ‘OFF’ for Instant OFF considered as toxic and as a result are no longer allowed in many parts of

measurements that should be more accurate in respect of IR errors in the the world.

soil. But if your reference electrode is in error these data will also be in error.

We can see from this that using less basic amines should therefore lead to

4. Large, simple, old fashioned porous pot Cu/CuSO4 reference improved blushing resistance, but they will also produce slow hardeners

electrodes are pretty reliable if properly constructed but there may be with long drying times. The question then becomes, how do we

concerns regarding soil contamination with CuSO4. If you use these with produce hardeners which will give the best combination of drying times

coupons, the coupon should be remote (upstream of downstream along and resistance to blushing? This is particularly relevant for solvent free

the pipe, not laterally spaced from the pipe) from the Cu/CuSO4 electrode systems where we have no drying advantage from the use of solid binders.

to prevent CuSO4 leaching into the soil and plating out on the coupon. If Curing agent manufacturers have over time developed curing agents with

this happens all the measured data will be wrong. improved resistance to blushing using various formulating methods. For

5. In France they consider that the values they measure in the way above example, forming amine adducts will improve the performance against

to be accurate only to 50-70mV. So be cautious with data close to under bushing because the adduction process will remove some of the more

or over-protection values if the data come from this sort of installation. basic amine functionality in the curing agent which is often responsible

B.Wyatt, Corrosion Control Ltd for blushing. It will also improve the compatibility of the amine with the

resin thus reducing migration of free amine to the surface of the coating.

In GRTgaz France, we have installed and used Remote Monitoring Systems

Advances in curing agent development mean that today the best

(RMS) with fixed reference electrodes for about 8 years. They are installed

performing hardeners for blushing resistance in topcoats are based on

in open bottomed surface boxes to be regularly compared to a portable

formulated adducts of one or more amines.

reference electrode (during detailed and comprehensive assessment of CP

by a CP operator in the field). As they are used for general assessment of CP, Of course, epoxy resin and curing agent manufacturers can develop and

the requirement for their accuracy is lower than that for portable reference test their resins and hardeners in combination as clear coatings, but the final

electrodes used in the field for detailed and comprehensive assessment of paint will be formulated by coatings manufacturers where the fillers and

CP ±100 mV for a fixed reference electrode to be compared to ±20 mV for additives used will also have an effect on the carbonation resistance of the

a portable reference electrode. To facilitate the evaluation of the accuracy end product. Even with the recent advances in curing agent performance,

of fixed reference electrode, GRTgaz France decided to install them in the end result will still depend on correct mixing and application of epoxy

the open bottomed surface boxes as it is then easy to minimise the gap systems on site ensuring that the conditions in which the coating is applied

between both electrodes (fixed buried and portable) and to change the meet with the manufacturers recommendations.

fixed reference electrode when required (which is very seldom, as we Stuart Darwen, CTP Advanced Materials GmbH, Germany

www.icorr.org January/February 2021 13You can also read