Full control by volume simulation for sheet metal forming - Stampack

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

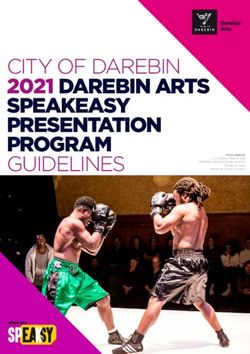

USER REPORT

For difficult forming operations,

Fütterer Werkzeugbau relies

on Stampack. The simulation

software convinces the special-

ist for transfer, deep-drawing

and progressive dies especially

in terms of flexibility, efficiency

and optimisation potential.

1/ The interview partners: Christian Fütterer

(l.) and Frank Hornung from Men at Work

Full control by volume simulation

for sheet metal forming

Founded in 1986, Fütterer While turning, milling, grinding, The toolmaker clearly sees his

Werkzeugbau with its 35 em- wire and sink erosion are carried core competence in method plan-

ployees today is an expert in the out in-house, hardening is done ning and tool design: "Custom-

design and manufacturing of externally. The Baden-based ers often contact us with the first

high-quality sheet metal forming company delivers the tools it pro- idea of a component. We then

tools as well as prototypes and duces - processing sheet metal offer the entire portfolio - product

prototype tools. The family-owned from 0.4 to 5 mm - to customers development, feasibility analysis,

company, located in Elchesheim- in the automotive, construction, forming simulation, optimisa-

Illingen near Karlsruhe, Germany, household appliance and electri- tion," Managing director Christian

manufactures about 30 tools cal industries. In addition, Fütterer Fütterer explains. "Very important

per year. Depending on size and is also active as a contract service for the customers are the toler-

complexity, the lead time of a tool provider; the range of services ances and reliable data on mate-

can be up to 24 weeks. The tools extends from CNC-turned parts to rial consumption and stroke rates.

weighing up to 10 tons are tested single-part production and form- We consider how the part can be

on the company's own test press. ing simulation. produced, how many steps are

2a + b/ In the simulation of an exhaust system component, Stampack calculates multi-stage forming processes completely in volume (A).

The component of a car exhaust system will later be installed in a Porsche (B)

12 The mold & die journal 1/2021 www.fachverlag-moeller.deUSER REPORT

necessary, which operations are

carried out in which sequence,

how large the required blanks

must be or what strip width is re-

quired". A great deal of know-how

and design engineering hours are

already involved in the phase be-

fore the offer is made. This is the

reason why Fütterer often makes

an invoice for complex tools as

early as the quotation stage,

which is charged when the order

is placed.

VISI, a product family for tool and

mould making currently compris-

ing 22 modules from Hexagon

(formerly Vero Software), was

recently installed at Fütterer. In

a first step the CAM and Pro-

gress modules of the 3D industry

solution will be used at Fütterer.

For around four years now, the

toolmaker has been relying on

Stampack, an advanced and pro-

ductive simulation software for all

areas of metal forming.

"Stampack's highlights include

stretch forming, forming of thick

sheets, fast springback and com-

pensation determination, stretch

forming of sheets and profiles,

and other special forming pro-

3a + b/ Original part and simulation in Stampack - the simulation software allows Fütterer

cesses. Due to its own 3D volume

to analyse and predict material flow, formability, wrinkles and surface defects

solver, Stampack is particularly

suitable for the calculation and

simulation of progressive die pro- Bietigheim, which is which is tool design and development

cesses," Frank Hornung explains, located near by , has been sell- When commissioning Stampack,

He is Managing Director of Men at ing the simulation software since the Baden-based company took

Work GmbH, the most success- 2009. Fütterer was so impressed a special approach, similar to

ful Stampack dealer worldwide. by the first Stampack applica- on-the-job training. A software

"The practice-oriented software tion that the desire to bring the developer from Men at Work, who

is intended for product develop- system in-house quickly arose. had never held a piece of sheet

ers and method planners alike. "The main reason for purchasing metal in his hands before, came

Previous knowledge and practical the software was that I no longer to Fütterer for a fortnight. Through

experience in FEM is not required, want to outsource the know-how two concrete projects he learned

after three days of training expe- contained in our designs. After all, how a tool works and the tool-

rienced designers can work with I no longer wanted to pay others maker learned how the software

Stampack without any problems". money for supplying them with works. So it's a classic win-win

Since both companies have my knowledge," Christian Fütterer situation for both sides. Fütterer

been working together more than looks back. Finding employees supplies 95% of the tools ready

twenty years in tool design and who are familiar with the design for series production, only the

method planning Fütterer pur- and simulation of tools is becom- training and finishing are carried

chased forming simulation as a ing increasl difficult. Modern out at the customer's premises

service from Men at Work in the simulation tools increase the on the series press. This is why

beginning. Men at Work from attractiveness of the workplace in Stampack is first used during an

www.fachverlag-moeller.de The mold & die journal 1/2021 13USER REPORT

4/ One of the essential new features of

Stampack is the automated cross-linking of

tools from external data, without the user

having to introduce parameters

order for method planning, which am absolutely sure". Since analyse and predict material flow,

is the basis for calculation. The Stampack impressed the tool- formability, wrinkles and sur-

elaboration of the method plan- maker so much after the first or- face defects," Christian Fütterer

ning can take up to two weeks, ders, he is now offering simulation draws a positive conclusion. "The

usually in teamwork of the three as a service to his customers. optimisation potential thanks to

designers in house. Various ques- Stampack has proven to be the determination of springback

tions have to be answered, such absolutely reliable at Fütterer with compensation calculation for

as the number of steps in the tool, Werkzeugbau.. One software li- tool adjustment should also be

whether the tool can be formed cence is used by the boss himself emphasised. Another significant

in one operation, how big the tool in Elchesheim-Illingen, another advantage for us is the efficiency

will be, whether the method works one for the design engineers of Stampack, because the use of

and which press is required. increases the capacities. In practi- the software saves us at least two

Stampack is used for testing with cal use, the simulation software change loops per tool".

a pre-simulation, initially only in offers the Baden-based company

the shell simulation. "It's a kind numerous advantages: For ex-

of quick and dirty variant that ample, its flexibility, as it makes

doesn't require so much comput- calculations for sheet thick-

ing time and gives me a rough nesses from 0.4 to 6 mm. "We are Stampack GmbH

indication of whether the motion also impressed by the element Stampack GmbH was founded in

sequence will work," Christian technology, because Stampack 2018 and acquired the Stampack

Fütterer describes. "For critical supplies both shell and 3D vol- product line for metal forming

areas I simulate in volume, then I ume simulations. And allows us to simulation software from Quantech

ATZ in Barcelona, Spain. The com-

pany took over the development

5/ Previous knowledge team and the entire operational

as well as practical business from the previous owner.

experience in FEM is

Since its market launch in 2010,

not required. After three

days of training, expe- Stampack has become the leading

rienced designers can simulation in the field of progres-

work with Stampack sive dies. Thanks to enormous

without any problems improvements in the comput-

(Pictures: Stampack) ing speed of its own shell solver,

Stampack is now also suitable for

large-area automotive parts. Since

2018, the computing time for a

benchmark simulation has been

reduced from over 6 hours to 24

minutes. The practice-oriented

software is equally interesting for

product developers and method

planners. Previous knowledge and

practical experience in FEM is not

required.

14 The mold & die journal 1/2021 www.fachverlag-moeller.deYou can also read