Cold mashing - Analysis and optimization of extraction processes at low temperatures in the brewing process - Analysis and optimization of ...

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

E3S Web of Conferences 247, 01036 (2021) https://doi.org/10.1051/e3sconf/202124701036

ICEPP-2021

Cold mashing - Analysis and optimization of extraction

processes at low temperatures in the brewing process

Niklas Schöttke1,2, and Frank Rögener2,*

1Pfeifer & Langen GmbH & Co. KG, Aachener Straße 1042a, D-50858 Köln, Germany

2Technische Hochschule Köln, Institut für Anlagen und Verfahrenstechnik, Betzdorfer Str. 2, 50679 Köln, Germany

Abstract. According to indications, already 5,000 years ago beer was brewed without heating the mash,

i.e. in the cold mash process. Applying this old method, the question arises to what extent this traditional

knowledge can be integrated into today's brewing processes and to produce new beer styles at reduced

energy consumption. Since cold mashing is hardly explored, this work is dedicated to in-depth analysis

from a process and brewing point of view. Based on theoretical considerations of the mashing process, cold

mashing formulations were estimated and analysed. Parameters for the experimental investigations were

temperature, particle size of grinded grains, mixing ratio between malt and water, mashing time and the

application of various multistage extraction processes. Additionally, at the optimum cold mashing

conditions, a brew of about 10 L was produced, which confirmed the positive effects of the application of

cold mash: Fermentation time is significantly reduced due to the composition of the cold-extracted malt

components.

1 Introduction material transfer (the generated sugar is dissolved in

water). Mashing is the first biochemical process step of

The commercial beer market is currently dominated by brewing and completes the enzymatic degradation,

two production concepts, which to some extend compete which is initiated during malting. In this process,

with each other: large-scale industrial breweries, often enzymes are synthesized. These are essential for the

linked by corporate structures, are juxtaposed with small degradation of large molecules during the subsequent

privately run breweries. These so-called microbreweries mashing [10].

stand for craft beer and produce in small quantities According to Koljonen et al., the applied temperature

individual and - sometimes very unusual - beer styles profile during mashing determines the chemical

[1]. On the other hand, larger breweries often rely on composition of the malt wort [11].

beer styles, which appeal to the widest possible range of The balance between carbohydrates and proteins is

consumers [2]. Due to the highly competitive situation in important for beer brewing using barley malt, as high

the German beer market [3], the demand for new protein content reduces primarily the amount of

products ensures that brewers experiment with still available carbohydrates [10].

unknown or forgotten beer styles [1]. In accordance with Steiner et al. mention that proteins in the form of

current trends, possible health benefits of beer as a enzymes - also in combination with other substances

source of vitamins, minerals or antioxidants were such as polyphenols - affect the whole brewing process.

investigated [4-6]. Furthermore, energy and raw material Enzymes degrade starch, b-glucans, and proteins [10].

savings in the production process are a strong driving Temperature levels, as well as variations of the

force for all brewers to improve processes. However, the retention time, do not only affect the duration of mashing

Reinheitsgebot restricts openness to experiments in and the content of dissolved fermentable sugars, but also

German breweries. the degree of fermentation, flavour and foam of the beer

Against this background, archaeological discoveries [12].

associated with the production of the first beers are The quality of beer depends on several measurable

gaining in importance. There is evidence that 5,000 years parameters, which are based on the raw material and the

ago beers were produced without heating the mash, i.e. brewing conditions. These involve e.g. colour, clarity,

in the cold mash process [7, 8, 9]. However, if this foam appearance, and flavour [13]. But to a large extend,

brewing method has been used, very low alcohol the expression “quality” is defined by the individual

concentrations of not more than 2 vol.-% must be consumers [14, 15].

assumed [7]. This study was performed to evaluate the effect of

Mashing involves material conversion (water-soluble cold mashing and multiple staged mashing procedures

sugar is enzymatically produced out of starch) and on wort composition and the effect cold mashing would

*

Corresponding author: frank.roegener@th-koeln.de

© The Authors, published by EDP Sciences. This is an open access article distributed under the terms of the Creative Commons Attribution

License 4.0 (http://creativecommons.org/licenses/by/4.0/).E3S Web of Conferences 247, 01036 (2021) https://doi.org/10.1051/e3sconf/202124701036

ICEPP-2021

have on barley malt beer. Cold mashing is not common 2.5 Physical and chemical analyses

and is only used by a few experimental microbreweries

for the production of a few beer specialties. Malt and

2.5.1 Weighing

water are mixed without additional heating. Afterwards,

wort (extract) and brewers grain are separated from each For mass estimations, a precision scale type 3000 x 0.1g

other. Resting or warming of partial mashes is digital balance from Tykee was used. The accuracy is +/-

eliminated. After cold mashing and lautering, the 0.1 g.

resulting wort is boiled to kill germs like in the

conventional process [16].

From the results obtained, trends and correlations are 2.5.2 Temperature

derived, which are intended to explain on the one hand

For temperature estimations, a Pt1000 thermometer type

the reactions and on the other hand to design cold-mash GTH 175/PT from Giesinger was used. It has a

processes. Finally, economic conclusions are drawn from measurement range from -199.9 °C to +199.9 °C. The

the technical parameters obtained

accuracy is 0.1 °C.

.

2.5.3 Sugar content

2 Materials and methods

For the estimation of the Brix units, a refraktometer type

RHB-32SG from RZ was used. It has a measurement

2.1 Raw materials

range from 0 to 32. The accuracy is 0,2 %.

The investigations of cold mashing were carried out with

tap water supplied by Rheinenergie Köln, Germany. 2.5.4 pH

The malt employed for cold mashing was basic malt

of the type Viennese malt (manufacturer Weyermann), For the estimation of the pH an electode type SE 102 N

which is made of summer barley. The kiln drying from Knick was used. It has a measurement range from

process leads to a coloration of the malt between EBC pH 0-14 at an accuracy of +/- 0,01. The temperature

5.5 and EBC 6.5. The used malt consists of 66 wt.-% range is -5 – 100 °C.

carbohydrates, which contain 4 grams of sugar per 100

grams of malt.

2.5.5 Light microscopy

Two malt grists from Weyermann were used as

reference samples: Malt type 1 was Viennese malt (EBC: The analysis took place in the lab of WESTO Hydraulik

5,5 – 6,5), type 2 was Pilsen malt (EBC: 2,5 – 3,5). Both GmbH, Pulheim. A light microscope Typ: MM-KKE-M-

reference samples are offered as standard grain for C-U from Hydac was used, which allows enlargements

brewers without further specification. 2,5:1, 4:1, 10:1, and 20:1.

For the detection of complete sacharification of

starch, an iodine test with iodine N 50 solution was

employed. 2.5.6 HPLC

High pressure liquid chromatography (HPLC) is a

2.2 Milling chromatographic technique employed for the

identification and quantification of the individual organic

For milling, a cast iron malt mill with a capacity up to 30 components of a solution [10]. The estimation of the

kg/hour from Victoria was used. The grinding gap can be extract composition by HPLC took place at Pfeifer &

adjusted infinitely with the help of different washers. Langen Innovations Center in Elsdorf, Germany.

Accordingly, the denotations refer to employed washer

heigt, e.g. M 1,75 means a washer height of 1.75 mm.

2.5.7 Particle size

2.3 Mashing For the estimation of the particle size of the milled

grains, a sieving machine type Vibro from Retsch was

Mashing was done with a French press type Caffettiera used. The sieve tower was equipped in accordance with

French Press with a volume of 1 L from Bodum. The the current standard DIN 4188 (MEBAK).

height was 175 mm, the inner diameter was 90 mm.

Solid and liquid phase were separated by the filter

element of the French Press with a mesh size of 0.5 mm. 3 Results

Based on the theoretical background [16, 17], cold

2.4 Test brew based on cold mashing mashes were prepared and analyzed. For this purpose,

malt was used in various dry milled grain fractions.

A mashing kettle type DRE 3000 P W00 from Saier with Amongst others, milling conditions are supposed to have

a volume of 30 L was used for the production of cold a strong impact on wort quality [18]. Varied parameters

mashed beer. For the subsequent lautering a bottom plate in cold mashing were temperature, grain size of the malt,

type Läuterboden 357 mm from Mattmill was used. mixing ratio of malt and water, mash time and various

2E3S Web of Conferences 247, 01036 (2021) https://doi.org/10.1051/e3sconf/202124701036

ICEPP-2021

multi-stage process variations. Investigated parameters 3.2 Influence of the malt load on the extract

were the concentration of dissolved extracts after concentration in cold mashing

mashing, the compositions of the extractives, the pH of

the mash and the qualitative detection of starch. The blue lines in Figure 2 mark all measurements in

Malt load was varied between 0.15 and 0.025 g Malt / which 9 grams of self-milled malt were used as an

gWater, as these values are typical of conventional extraction material. The green lines represent the use of

brewing processes [19]. 6 grams of malt, the red lines are based on a mixture of 3

Table 1 shows the performed investigations. grams of malt and 40 grams of water. 1.096

measurements were performed to estimate the curve of

Table 1. Investigations. the extract concentation as a function of malt type and

malt load (gmalt/gwater).

Investigated Analysis

Parameter Aim

material methods

Condition Optical

Malt grind Milling gap

of husks evaluation

Particle

size Sieving

distribu- machine

tion

Optical

Form

evaluation

factor

(partially light

estimation

microscopy)

Extract

Wort Refractometer /

mixing ratio concentra-

(extract) stop watch

tion

Fig. 2. Extract concentation as a function of malt type and malt

Extract

Tempera- Refractometer / load (gmalt/gwater) at room temperature.

concentra-

ture thermometer

tion At about 1.5-2 hours of mashing time, an optimum

Extract concerning the extract concentration can be seen. In

Residence composi- HPLC and pH

time tion and electrode

figure 3 a comparison between 2 and 6 hours of mashing

pH time is depicted.

Control of

Phases of Proof of starch

saccharif-

wort

ication

Influence

of cold Selected

Self brewed

mashing brewing

beer

on beer parameters

quality

3.1 Particle size analysis

The particle size of several self-milled grains as well as

two commercial grains was estimated. Type 1 stands for Fig. 3. Extract concentration after 2 and 6 hours mashing time

Viennese malt, type 2 stands for Pilsen malt, s. figure 1. at room temperature.

It can be seen, that when the mash time increases, the

influence of grain size on extract concentration

decreases.

M-1,75 was selected for further tests because M-1,5

and M-1,25 did not exhibit a sufficient lautering

behavior.

3.3 Influence of the temperature on the extract

concentration in cold mashing

During the test series described above, the temperature

Fig. 1. Particle size distribution of the self –milled malt grist was in a range between 17.5 and 19.5 °C. In the next

and the two commercial reference malt grists. stage of the study, it was examined to what extent

The analysis shows that the self-milled malt grists M- temperature fluctuations in the range between 11 and 26

1.5, M-1.75 and M-2 show particle size ranges °C show a result-relevant influence on the achieved

comparable to the commercial grist types 1 und 2. extract concentrations. Even if the temperature of the

mash was never below 17 °C or above 20 °C during the

3E3S Web of Conferences 247, 01036 (2021) https://doi.org/10.1051/e3sconf/202124701036

ICEPP-2021

performance, the temperature range for the examination

was increased in order to evaluate to what extent the

temperatures in these areas influence the mashing

process. For the following trials, malt type M-1,75 was

used. A malt load of 0.15 gMalt/gWater - the mean value of

the investigated malt load - was kept constant and the

mashing temperature was varied. Figure 4 shows the

results.

Fig. 6. Influence of multistage processes on extract

concentrations.

As can be seen, the increase in the number of process

steps has a greater influence in the counterflow than in

the crossflow mode. A four-staged counterflow mashing

process is the preferred solution to achieve high extract

concentrations.

3.6 Test brew based on cold mashing

Fig. 4. Extract concentration as a function of cold mashing

temperature. The generated cold-mashed beer meets the criteria of a

light lager beer, s. table 2.

No clear relation between cold mash temperature and The taste turns out to be very light and the hops

extract concentration was detected. dominate the end of the sip.

Table 2. Characteristics of the generated cold-mashed beer.

3.4 Extract composition in single-stage cold

mashing Parameter Value

Extract concentration before rest 4.5 Brix

Selected mash samples with a malt load of 0.15 Extract concentration after rest 6.0 Brix

gMalt/gWater were examined chromatographically and the Extract concentration calculated 4.2 Brix

composition of the extract phase was determined. The Energy savings compared to

32.8%

composition of the worts studied is shown in Figure 5. conventional mashing

Relation of malt employed for cold

mashing compared to conventional 2.48

mashing

Original gravity 6.8 °Plato

Brewhouse effciency 28.8%

Final gravity 56.6%

Alcohol 2.4 wt.-%

4 Discussion

In the course of these studies, it was shown that small

temperature fluctuations have no direct influence on the

result of the cold mashing.

Fig. 5. Extract composition in single-stage cold mashing.

However, the selected particle size of the malt can be

The composition of the respective worts shows seen in the discord between mashing and lautering

increasing concentrations of maltose, glucose, and conditions. Accordingly, M-1,75 is chosen as the

dextrins with increasing mash time. preferred grain.

Due to the measured time histories, an ideal mash

time per mashing stage of 2 hours is determined. This

3.5 Extract composition in multistage cold mashing also in line with the lautering time on industrial scale.

For batchwise beer production, a matching of the two

In addition to the single-stage procedures, investigations

process step times is favourable.

of the extraction behavior were carried out also in multi-

The optimum mixing ratio of water and malt needs to

stage crossflow and counterflow. Based on the single-

be defined according to the specifications chosen

stage studies described before, malt M-1,75 was used.

individually. Considering the relatively smaller amount

As can be seen in figure 2, mash times larger than 2

of fermentable sugars in the generated wort and the

hours do not contribute to a significant increase of the

composition of the extract with a high proportion of

extract concentration. Accordingly, a mash time of two

short-chained carbohydrates, a reduced fermentation

hours per stage was chosen. Figure 6 shows the results of

the multistage investigations.

4E3S Web of Conferences 247, 01036 (2021) https://doi.org/10.1051/e3sconf/202124701036

ICEPP-2021

time compared to conventional brewing processes is the required hop mass, which increases the cost-

expected. effectiveness of cold mashing. Furthermore, beers

Multi-stage processes involving four reaction stages produced by cold mash are in the trend of alcohol-

provide optimal results for a malt load of 0.175 g malt/g reduced beers and thus calorie-reduced foods. This fact

water in both cross current and the countercurrent mode. can be used as the basis for a successful marketing of the

By applying iodine tests, it was shown that the product.

extract dissolved in the wort does not contain any starch. The approaches shown in this work can be carried

However, the wort is clouded due to finely distributed out without costly technical conversion of existing

solid components. These are highly starchy, but they brewery equipment. Thus, cold mashing is an

could be saccharified by heating the wort. With regard to opportunity for each brewery to expand the product

the relationship between material conversion and transfer portfolio, create a new type of beer and enrich the beer

of substances during mashing, it could be shown that the market.

conversion of the substance is the decisive factor for

increasing the extract concentration.

In a final calculation of the energy and malt demand References

required for cold mashing, a comparison was drawn with 1. Deutscher Brauer-Bund e.V.: Zahl deutscher

conventional mashing. It turned out that cold mashing Brauereien wächst weiter. URL:

can save up to 18.9% of the required energy, while the https://www.brauer-

required malt mass increases by a minimum factor of 2.2 bund.de/index.php?id=930&ageverify=16&PHPSE

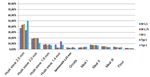

and a maximum factor of 5.2, see figure 7. SSID=021b103a29d753301d0da78b6e145d3a

(accessed: 26.03.2020)

2. H. Dornbusch: Brauwelt 37-38 (2019)

3. P. Henrich: Bierabsatz in Deutschland bis 2019.

URL:

https://de.statista.com/statistik/daten/studie/3406/um

frage/bierabsatz-in-deutschland-seit-dem-jahr-1999/

(accessed: 26.03.2020)

4. L.C. Salanta et al., Processes 8 (2020)

5. S. Sohrabvandi, A.M. Mortazavian, K. Rezaei, Int.

J. Food Prop. 15 (2012)

Fig. 7. Influence of multistage processes on extract 6. O.J.R. Neto et al., J. Funct. Foods 34 (2017)

concentrations. 7. P. Damerow, Cuneiform Digital Library Journal 2

(2012)

5 Conclusion 8. M. Zarnkow, A. Otto, B. Einwag, Interdisciplinary

investigations into the brewing technology of the

From an economic point of view, the cold mashing ancient Near East and the potential of the cold

process cannot be regarded as a substitute for mashing process (Berghahn Books, New York,

conventional mashing, due to the greatly increased malt 2011)

requirement with only small energy savings. However, 9. M. Zarnkow et al., Cold mashing process - a

cold-mashed beer can play a role in the trend of new, technology possibly used in ancient times in the

alternative beers. Thus, the material conversion and Orient. Brauwelt Int 5 (2006)

material transfer processes at temperatures in the range 10. E. Steiner, M. Gastl, T. Becker, Eur Food Res

of 20 °C ensure that taste-slim and very light beers are Technol 232 (2011)

produced. As a result, cold-mashed beer can be

developed as a new type of beer that stands out from 11. T. Koljonen, J. Hämäläinen, and K. Sjöholm, J.

conventional beers in terms of taste and production. Food Eng. 26 (1995)

In order to work as efficiently as possible in the 12. A. Juric et al., Inst. Brew. 121 (2015)

production of cold-mashed beers, a multi-stage process 13. M. Moir, Brewers’ Guardian 118 (1989)

management is recommanded. Thus, for the 4-stage 14. M.A. Igyor et al., Process Biochemistry 36 (2001)

countercurrent operation, with a loading of 0.175 g malt

per g of water, an increase in the extract concentration of 15. L. Salant et al., Bull. Univ. Agric. Sci. Vet. Med. 74

more than 75% compared to the analogously performed (2017)

single-stage method was determined. Also in cross 16. L. Narziß: Abriss der Bierbrauerei. 7th, updated and

current operation, the yield can be increased compared to extended edition (Wiley-VCH, Weinheim, 2005)

the single-stage process. 17. R. Schneid: Verfahrenstechnische Beeinflussungen

The properties of the wort based on cold mashing des Maischens sowie dessen Auswirkungen auf den

provide a number of possibilities to change conventional Brauprozess und die Bierqualität. Dissertation (TU

brewing processes even after mashing. Cold-mashed Berlin, Berlin, 2019)

worts reduce boiling and fermentation times and reduce

5E3S Web of Conferences 247, 01036 (2021) https://doi.org/10.1051/e3sconf/202124701036

ICEPP-2021

18. F. Pereira de Moura, T.A. Rocha dos Santos

Beverages 4 (2018)

19. W. Kunze: Technologie Brauer und Mälzer. 8th,

updated edition (VLB, Berlin, 1998).

6You can also read