Engineer next-generation eMobility with confidence - eMobility By Yijun Fan, Luca Castignani and Dan Marinac, MSC Software

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

eMobility

Engineer next-generation

eMobility with confidence

By Yijun Fan, Luca Castignani and Dan Marinac, MSC Software

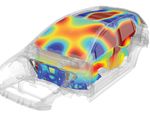

ePowertrain efficiency study

78 | Engineering Reality MagazineComprehensive Hexagon Solutions for EV

Sales of electric vehicle jumped has become modern, fast, beautiful,

30 percent globally in 2020, and is connected, advanced, quiet, and

projected to grow by 70 percent by everything we ever wanted from

2021 according to HIS Markit forecasts. a next-generation automobile. We

Electrification is the single largest crave for something that’s future-

disruptor that has occurred to the proof, and we want to invest in

automotive industry in decades. a vehicle that’s not going to be

outdated in 10 years from now.

The concept of “electric vehicle” has

existed for more than a century, since And that is a major cause for the mass

William Morrison from Iowa created market adoption of electric vehicles

the first successful electric vehicle in in recent years – the products have

the US around 1896. But why hasn’t become much better!

EV become popular until the last

few years? Triggering this largest transformation

in decades, almost all of the major

Of course, environmental concerns automotive manufacturers are

are fuelling vehicle electrification; embarking on the transition to EV

switching from gasoline to electricity manufacturing. They are adopting new

is a vital solution for reducing or replacing their existing processes,

emissions to avoid the worst impacts technologies, and tools for the next-

of climate change. generation vehicle design.

But more importantly, as consumers, Besides the traditional design and

we have experience first-hand of engineering considerations from an

how Tesla and a few other leaders ICE vehicle, developing an electric

have revolutionised the electric vehicle presents its own unique

vehicle. It’s not old, clunky, weird, challenges and requires a new set

ugly, impractical anymore, instead, it of solutions.

Volume XIII - Summer 2021 | mscsoftware.com | 79Cabin Noise Simulation

ePowertrain design the rapidly-growing EV market. certain extent, these other noises are

less tolerable with the ever-increasing

More and more consumers are To develop the optimal ePowertrain standard of electric vehicle buyers.

growing a true passion for EV faster, Hexagon provides not only the

because it’s quiet and powerful, and technologies in terms of software and To provide drivers and passengers a

that distinctive signature results tools, but also the expertise for designing comfortable driving/riding experience,

from a key differentiator between world-class ePowertrain systems. it’s crucial to carefully analyse and

electric vehicles and traditional optimise EV’s interior acoustic

vehicles: Electric Powertrain vs From solving engineering issues like environment, especially early in the

ICE Powertrain. reducing gear whine noise, improving design stage.

drivetrain efficiency, enhancing electric

In order to design a world-class motor cooling, all the way to delivering In order to accurately predict those

ePowertrain, engineers have a turnkey ePowertrain designs to EV noises, engineers typically need to apply

number of issues to tackle, from the start-ups, Hexagon offers the most multi-physics CAE solutions to study the

architecture, performance, durability, comprehensive ePowertrain solutions complex nature of those challenges.

NVH all the way to efficiency. in the industry for you to develop world-

leading electric vehicles. For example, to properly capture

For example: Do I have the optimal the eMotor or transmission noise,

combination of motor and drivetrain? Cabin noise acoustics needs to be coupled with

How long will my ePowertrain operate electro-magnetics, system dynamics

at high RPM without fail? Can I hear With the absence of an internal and/or structural analysis to figure out

the motor noise or gear whine? combustion engine, electric vehicles the vibration sources and how noise

How can I extend vehicle range by are expected to be very quiet by is being generated and propagated

increasing ePowertrain efficiency? consumers. However, other noise inside the cabin.

sources which were previously

All those engineering problems need covered by the engine noise suddenly Likewise, to simulate wind noise, the

to be properly addressed before become a lot more prominent in an aerodynamic excitation applied to the

engineers can come up with a best-in- electric vehicle, such as road/tire side windows need to be simulated

class ePowertrain design that fits the noise, wind noise, gear whine, or even with CFD software before the acoustic

needs from consumers, which provides the high-pitch, high-frequency noise performance of the window/glass

OEMs with competitive advantages in coming from the electric motor. To a vibration can be predicted.

80 | Engineering Reality MagazineTorque vectoring controls evaluation

Hexagon provides not only best- development requires interactions achieved simply through electronically

in-class point CAE solutions in the between additional integrated controlling the power distribution

industry, but also the best-in-class sub-systems (battery pack, power between the two motors, which can be

multi-physics and co-simulation electronics, electric drive, etc.) to be done on a millisecond scale. And the

technologies that engineers can rely understood and optimised. new torque vectoring controllers need

on to tackle the complicated acoustics to be studied and evaluated with the

challenges and drastically reduce the With the ePowertrain, many control EV mechanism.

overall EV cabin noise. strategies also need to be re-created

or re-designed. For example, torque In order to improve the overall vehicle

Vehicle dynamics vectoring has been used on traditional dynamics of electric vehicles, engineers

ICE vehicles to distribute torque would run co-simulation between

While the shift to electric is primarily among four wheels to improve the the full vehicle MBD models and the

motivated by environmental and vehicle traction during acceleration 1D controller models, to study and

sustainability concerns, it opens up or steering on a wet surface. With optimise various control algorithms

new challenges for vehicle dynamics electric motors, torque vectoring early on in the design cycle, and avoid

optimisation. Electric vehicle between front and rear axles can be expensive, late design changes.Lightweighting engineers can capture the correct the optimal temperature range of

local anisotropic stiffness and the battery pack? How do I predict

For electric vehicles, lightweighting damping behaviours depending structural integrity for new materials

is not optional - it’s mission-critical. on the frequency and the local under severe loads? How do I ensure

Reducing vehicle mass increases the fibre orientations. Incorporating battery safety when it hits obstacles

EV range and improves the vehicle those materials’ behaviours into on the ground?

performance, which greatly contribute the NVH and durability models

to faster EV adoption. greatly enhances the accuracy and To effectively predict and resolve all

reliability of the simulation results, those challenges, engineers again

The most common way of removing and ensures that reducing vehicle need to not only rely on the point

mass without compromising design weight doesn’t come at a cost of physics solutions, like CFD, Structural

is by introducing new materials. performance degradation. FEA, Fatigue, MBD, Materials, but also

Application of composites material integrate multiple physics together to

is essential for weight reduction, but Battery design address the fundamental issues in a

such material’s behaviours are highly more accurate way.

nonlinear and anisotropic, and the As the most expensive and heaviest

different manufacturing processes component of an electric vehicle, the For example, to study the battery

influence the final part’s performance battery makes up for about 30% of the frame impact from hitting an obstacle

(e.g. NVH, Durability) in different ways. total vehicle cost, and can weigh up (like a stone) underneath, engineers

to 600 kilograms. It is recognised as need to consider not only the non-

For example, one of the options to the most important component of an linear contact and permanent

lightweight the battery pack is to use EV because it determines the crucial deformation on the frame itself, but

fibre-reinforced polymers to replace factors such as the range, cost, safety, also how the vehicle suspension

metals for the battery tray. While this recharging and so on. system is going to react to the impact,

certainly reduces the overall weight of which may affect the results of the

the battery, we also understand that Automotive engineers face a number battery damage. Without the holistic

using new materials may often come of design challenges when it comes to understanding for the full system

with some level of degradation in NVH battery on different aspects such as behaviour or the detailed contact

or Durability performance. thermal, material, safety and durability. model, the simulation doesn’t provide

a reliable way to predict the actual

With Hexagon’s industry-leading For example: How do I design the event, which could lead to either

materials simulation software, cooling or heating system to assure failure or overdesign.

Battery thermal management

82 | Engineering Reality MagazineBattery frame welding simulation

Battery manufacturing To help OEMs take total control of We are proud to say that Hexagon’s

the entire product quality lifecycle, solutions have been trusted by not

Quality needs to be integrated into Hexagon has been investing heavily only the current global top 25 auto

every aspect of the battery system, into both software and hardware OEMs, but also every recognisable

from battery cell, battery module, technologies to connect the dots electric vehicle company and some

battery tray to battery assembly, with between engineering, manufacturing of the major battery suppliers in

the highest standards. and quality control. the world. Over 70% of the electric

vehicles on the market have been

On a high-volume production line, With the industry-leading CAD-CAM- enhanced with the help of Hexagon

battery welding is a process with a CAE software and the most advanced tools and services over the past

narrow time window for assembly metrology technologies for both 15 years.

and inspection. There are over 3,500 stationary and portable applications,

cylindrical battery cells in a typical Hexagon not only provides the point We aim to offer a new set of smart

design, which means there are solutions, but also understands how to manufacturing technologies for

over 10,000 welds in the assembly. integrate each stage of the workflow engineers, designers and OEMs,

Even with a 99% weld success rate, together to help OEMs shorten design-to- blending our experience in automotive

there will be 100 weld failures that production times and improve the overall design and engineering, production

compromise range and safety. It is of product quality while lowing the cost. and metrology to help you make the

paramount importance that each weld journey toward 100%EV faster and

is carefully studied and tested. 100% of vehicles in the world more cost-effective.

need to be electric

To achieve the highest level of quality,

relying only on inspection itself is not EVs are predicted to represent a third

enough. One of the biggest challenges of the automotive market by 2025

that OEMs face is how to engineer and 51% by 2030. But we believe the Download our eMobility eBook to learn

quality into the battery design and automotive industry can make this more: www.mscsoftware.com/eMobility/

the manufacturing processes in the shift even faster, and we want to eBook

first place. support your efforts to do so.

Volume XIII - Summer 2021 | mscsoftware.com | 83You can also read