EXPERT TECHNICAL GUIDE - PRINTING FOR INTERIORS GUIDE 1: INTRODUCTION - SET 9 - FESPA UK Association

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

FESPA TECHNOLOGY GUIDE BEYOND BEAUTY

TO PRINTING FOR INTERIORS Enhancing surfaces through decoration has created business

opportunities for centuries. Interior decor matters, whether it’s

Printing for interiors covers an enormous range of design and for reasons of warmth and comfort or to convey status, power or

print concepts. A strong emphasis on creativity makes the personality. In the 21st century we have the added dimension of

field extremely difficult to quantify. It covers any interior design digital printing and communications technology, for on demand

application, from offices and factories, through to hotels and photorealistic image quality and fast, convenient production

households. Customers for printed interiors are anyone who wants without the overheads of conventional print methods. According to

to revamp their space often, at reasonable cost and on demand. Global Industry Analysts Inc, a market research company, at a CAGR

Potential clients include individual consumers and businesses of 26.1%, digital printing growth for printed interiors outstrips screen

wanting new printed décor on a regular basis. Interior designers, printing growth.

design companies, architects, government and local authorities,

are all candidates for printed interior services. Advances in wide format digital printing technologies plus substrate

innovations create new applications for the technology, especially

This guide explains the business considerations for printed for printed interiors. Communications advances, including the web,

interiors and presents some ideas for how printing companies can social media and mobile computing fuel creative ideas and demand

tackle the many new applications emerging. Printing can enhance for instant turnarounds.

any surface, so for interiors the array of possibilities is huge. From

large surfaces such as walls, floors, ceilings, doors and windows, There will never be an absolute transition from analogue to

furnishings and upholstery, curtains and blinds, and worktops, to digital production models, and there will always be a market for

small ones such as remote controls, photographs and accessories, handmade wallpapers, textiles, floorings and goods. But wide

the applications are endless. Printed interiors includes any printed format digital printing systems reduce production costs and

surface or decorated object used indoors. This includes glass make processes available to a much wider audience. Turning this

surfaces printed with photovoltaic or insulating materials and new market into a business is about spotting opportunities and

acoustic panels for sound proofing. Digital printing creates new creative business development.

looks for obvious candidates such as walls and floors, to the

Business models that capture significant shares of the printed

less obvious options such as linens and throws, kitchenware and

interiors universe require clear ideas of target markets. They

crockery, placemats and coasters, even clothes.

demand an understanding of how to combine technology that’s

up to the job, with optimised and flexible workflows, automated

online ordering and profitable fulfillment processes. Where to start

is the most important decision, especially the applications you

want to tackle.

2WALL ART

adding LEDs by hand for this type of printed interiors is not cheap,

however it adds a new design option that is relatively simple to

Wallpaper has been around for centuries and its production exploit with wide format digital printers. Wallpaper is also used

has gone through multiple reinventions, evolving in line with for window blinds, drawer linings and shelf coverings, so adding

techniques for other print applications. Today most paper and light to these applications extends the range of the concept.

vinyl wallpapers are produced using rotary screen, flexo or

gravure printing. Wallpapers for specialist markets are often still

printed using block and surface printing, however digital printing

is steadily gaining market share in bespoke wallpaper production.

Expectations for wallpaper performance determine their means

of production, so there are many approaches depending on

budget, quality and durability expectations, especially light

resistance. Wallpapers can for instance be hand painted or

hand-printed using woodblocks or stencils, but compared to

automated manufacturing options the cost of this approach

is substantial. The final application, viewing environment and

quality expectations are primary considerations in any printed

interiors production business model, so if you are adding

capacity for printing wall coverings, make sure you understand

what your customers want and what they are prepared to pay for

your services.

New types of wallpaper come onto the market all the time.

Conductive inks for instance are being designed for use in touch

screens that can be incorporated into wallpaper. Wallpaper

can be printed with special coatings to block WiFi and mobile

phone signals. It’s even possible to create wallpapers that act as

a computer interface with motion sensors and webcams. This

may be too invasive for consumers, but could have considerable

relevance in public interior spaces, such as train stations.

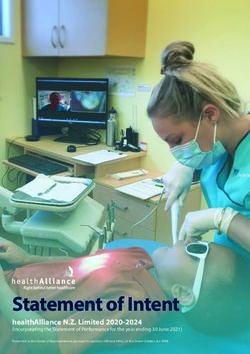

We saw these great examples of just how lovely printed interiors can be

What might have broader appeal is wallpaper that adds lighting at Marco Polo Airport which serves Venice, Italy. The arrival area has been

to a space using crystals and LEDs. Using a digital printer and decorated with an ambitious series of murals.

3ANOTHER BRICK IN THE WALL

and so on. You will need to plan for larger file sizes and perhaps

extend the range of data formats you accept. For the most part this

Prospective customers for printed interiors may already be print will be PDFs but creative and design customers may want to provide

buyers, but may not have considered applications beyond sign and you with TIFFs or native Illustrator files for repeating patterns.

display and commercial print applications. Printed wall coverings They may even want to send you EPS, so be prepared for preflight

for locations and venues are part of the printed interiors universe, so dramas, and especially check that there is a sufficient bleed in

companies who run events, and indoor fairs and conferences, can wallpaper designs to take into account irregularies in walls and

exploit modern wallpaper and related printing technologies. Sports trimming. You may want to consider charging for file preparation

clubs, homes factories and offices, shops, bars and restaurants, and proofing services.

indeed any shared space that benefits from decoration can take Colour matching will be especially demanding if you are producing

advantage of print. work for lots of different surfaces. Make sure you understand the

Capturing such opportunities requires an understanding of viewing situations and the effect of different lighting environments

applications and practical considerations such as shrinkage and on colour appearance. You should also ensure you have profiles for

trimming short run digitally printed wallpaper rolls. Designs may the required ink and substrate combinations.

include repeating patterns which must be matched so that the end

result is a consistent design across the width of walls and where

walls meet. Digitally printed designs must account for pattern

repeats in the run length, as there will unavoidably be wasted

offcuts, adding costs to the job.

The environment in which the coverings are to be used should

also be considered, along with compliance with standards such as

EN13501-1:2007, the fire classification allowing wallpapers to be

used anywhere in a commercial building. Toxicity standards such

as EN 15102:2007, applying to all forms of wallcoverings must also

be considered. Test methods such as the ANSI/BIFMA M7.1 are

available for determining VOC emissions from furnishings, which

must not exceed regulatory levels. The Martindale rub test measures

a fabric’s durability using abrasion to simulate wear and tear.

And then there are the usual considerations a printer must take The theme at Marco Polo in Venice continues on the rubber sections of

into account: file delivery, preflight checking, proofing, colour the baggage delivery belt, to provide a taste of Venice before you’ve even

collected your luggage.

management, ink performance, substrates, finishing expectations

4FLOORED

Digital technologies have made it possible to produce any design

on a flooring substrate. The technology you select should be able to

Production of printed flooring such as carpeting, linoleum, vinyl, produce work that meets customer expectations in terms of quality

laminates and rubber has followed a similar trajectory to that of and lifetime. Your printing system should be flexible so that you can

wallpapers. Synthetic flooring is widely available as printed tiles, produce work with maximum uptime and minimal waste. Hybrid

planks, sheets or rolls, and is generally selected for its durability, printers give you the option to print on flexible roll-to-roll media as

stain resistance, convenience and cost. Compared to wallpaper well as rigid substrates. But if you are set on carpet printing for

the performance criteria for floor coverings and mats are obviously instance, select a machine capable of printing at least three metres

more demanding. Surfaces must be durable, lightfast and able to wide and designed for the application.

resist staining and damage from sharp objects dropped onto them.

Inks for printing floor coverings must be flexible and robust and

work with different surfaces including fibres, acrylics and vinyls.

Every year at Fespa exhibitions there are more and more

manufacturers showing examples of printed flooring using a

variety of substrates, including carpets. This is a fast moving

sector which cannot only replace conventional floor coverings

but which creates a whole new market for bespoke floors. There

are many options for creating a floor, however their functional

requirements are stringent. Floors must be strong enough to be

weight bearing, so they must comply with building regulations as

well as VOC emissions, safety and fire standards. Floor coverings

must be able to withstand the abrasion caused by high volume

footfalls, and exposure to strong sunlight. They must be able to

withstand cleaning without loss of coverage or colour.

Printing ceramic tiles for kitchen and bathroom applications is now

virtually entirely a digital process. High humidity interiors can be

decorated in other ways using digital technology, printing on glass

and mirrors for instance. Prints used in these environments must

be lightfast, and conform to recognised standards such as the

Bluewool test used in Germany, and the ASTM D2247-02 standard Here is a selection of surfaces produced to demonstrate how digital printing

for steam resistance. technologies can transform conventional ideas for printed interiors.

5DRESS UP

Carpet printing is just one small part of printing textiles to enhance

interior spaces. Within the Fespa community and beyond, digital

textile printing is of immediate interest to nearly 65% of wide

format printers. 40% are already printing fabrics and another 20%

are keen to get into this business, specifically to serve fashion and

garment printing customers. Besides linens, upholstery, cushions

and drapery, another option is uniforms and customised clothing,

such as sportsware and related gym equipment. Standards apply

here too and the most important is the globally recognised OEKO-

TEX Standard 100, an independent certification and testing method

for textile products.

Global Industry Analysts Inc, projects global printed textile

production will reach 29.8 billion square metres by 2020. This is

due to the rapid adoption of digital textile printing technologies,

changing fashion trends and fast fashion, and rising purchasing

power in developing countries. Digital technology makes possible

direct to garment printing, mostly with inkjet dye sublimation

printers using specialty inks.

Most digital textile printers, 40.9%, are installed in Europe, the

Middle East and Africa (EMEA), and Asia Pacific (39.5%) which is

also the largest and fastest growing market with a CAGR of 4.4%.

According to Fibre2fashion a business-to-business marketplace for

the fashion industry, digitally printed fabrics output will reach and

exceed one billion square metres this year and 2.5 billion square

metres by 2020, with a CAGR of 28% from 2015 to 2020. Digital

printing could account for 5% of textile printing by 2020, up from

2% in 2016.

Trade shows are great opportunities to provide unified services for printed

interiors. Floors, signage, textiles as well as marketing collateral are all part

of the printed interiors world.

6OBJECTIFY

But printed interiors are about more than wallpapers, floors and

textiles. Fortunately digital printing supports the production of all of

it. This includes objects such as electronics and furnishings, as well

as conventional prints such as pictures and banners.

Many opportunities for providing print to enhance interior spaces

are specific to different sectors. But consider the possibilities for

supplying objects such as promotional gifts, trophies and plaques,

wayfinding signs, and sports and leisure equipment such as

surfboards and skis. There is also a place for more conventional

forms of print in the printed interior universe, such as menus and

table graphics, health and safety notices, signed original artworks,

customised appliances, decals and stickers, adhesive logos.

Anything that goes along with hospitality décor can be printed, as

can backdrops, scenery and costumes for theatre productions or

school prize days. Bespoke interior designs are much more affordable if the materials are

printed digitally. Convenient production processes make it easy to revamp

An infinity of opportunity for new print applications exists, so spaces more frequently.

choosing the right technology is key. Fortunately there are plenty of

options in the digital inkjet printing universe.

7TECHNOLOGY OPTIONS

bright images. Make sure your ink choice works for preferred

substrates and applications.

Dye sublimation or dye diffusion printing uses transfer paper, Consider also your productivity expectations. Digital printing

heat, time and pressure in the right combination to achieve the for textiles, as well as other flexible and rigid surfaces is moving

desired image quality. This chemical process vaporises dyes to very quickly, with speeds of many hundreds of square metres

transfer images via transfer paper into a substrate where they per hour. If this is a new business direction, consider investing

then bond at the molecular level with surface fibres. Dye-sub in a slower less expensive device before you risk all with a top

printed fabrics are steamed and washed for colour vibrancy and of the line device.

to ensure that they are colourfast. This technology produces

a wide gamut of vibrant colours, but is relatively slow and Throughput capacity rises with the sophistication and cost of

expensive and can be wasteful. There has been a steady move the printer. Your investment decision should consider speed,

towards inkjet dye sublimation technology in recent years. uptime, consumables costs (including printheads), substrate

These machines are available as both desktop and industrial flexibility, service agreements, format and output resolution.

printers, and require no intermediate step, directly printing The number of inks the machine can print is another factor, for

images mostly onto pretreated fabrics which are heated and instance you may want to print an additional white ink to increase

pressed to fix the image. Technology is available that requires colour intensity or merely to create a white background. If the

no pre- or post-treatment for standard fabrics such as polyester choice between flatbed and roll-to-roll technology is not obvious,

and cotton. a lower risk option might be to invest in a hybrid device that can

Digital dye sublimation is increasingly used for clothing and soft print on flexible and rigid substrates. Keep in mind that you may

signage. The technique also works with 3D objects that have need to invest in additions for pre- and post-treatments, such as

a suitable surface coating. It takes the sublimation process a calendaring, washing, cutting and sewing. And don’t forget your

step further, printing images directly onto treated polyester and own interior space and how you will accommodate the new kit in

polymer coated substrates. The substrates can then be heated terms of its size and weight.

to fix the colours. Direct imaging can yield higher quality and

reduce consumables usage, however printheads are vulnerable

to clogging due to the size of the particles in the dyes. Dye

sublimation transfers require technologies based on advanced

printheads capable of achieving consistent and reliable print

density at low cost. Also the dye particles used in many dye

sublimation printers for textile printing are designed to bond

with polymers. This means that the fabrics being printed need

to have a high polyester content or be precoated to achieve

8INKS

Many inks are available and the range constantly changes as

developers come up with new formulations. In addition to dye-

sublimation inks there are aqueous inks suitable for printing on

canvas, board, card and paper. Solvent inks work for these as well

as foamboard which can be used for interior panelling, Aluminium

Composite Material (ACM), acrylic and polycarbonate, meshes,

textiles and static films. The lighter, eco-solvents work for these

applications as solvent inks with the exception of self-adhesive

vinyls. Latex inks and UV cured inks are equally versatile but only

UV works well with materials such as wood, glass and metals.

Alternative to UV cured inks is to print self-adhesive vinyl with latex

ink for instance and use it as a laminate.

Ink performance and colour consistency are also important and

once again the application drives requirements. Adhesion to hard

surfaces, particularly if exposed to cleaning fluids or moisture,

matters as much as lightfastness and rub resistance. If the ink

requires material surfaces to be coated or baked, consider the

impact on workflow flexibility and production times, plus cost

factors. Inks can be cured to different degrees to create textured

matt and gloss effects; this too impacts productivity and cost.

Applications requiring flexible materials, such as for laminating a

curved surface require inks that stretch without cracking or lifting

from the substrate.

If you are focusing on textile printing consider the inks required to

print natural fabrics such as linen, silk, cotton, wool and blends, and

synthetics such as lycra. How these materials will be used matters:

you cannot use UV-cured inks for garments in case uncured ink

comes into contact with skin, but they are fine for soft furnishings. More of the amazing work at Marco Polo Airport in Venice. This floor

Consider the ink’s performance when printing textiles on both sides continues the view of them presented on the walls and selected panels of

as well as only one. the luggage belts.

9MATERIALS

which can be printed direct or used with a preprinted self-adhesive

vinyl. Besides composites, metal and plastics, rigid materials

Printer versatility, its printhead, substrate and ink options include ceramics and glass plus natural materials such as wood.

determine what you can print. If you want to sell refurbishment Prior to investment test candidate ink and material combinations,

and remodelling services for printed interiors, consider which ensuring that inks and substrates perform in the printing system

materials your printed interiors customers are likely to want to use. as required.

Alternatively consider printing to laminates that can be applied to

surfaces, such as flooring, windows and furniture. Furniture and

objects such as electrical appliances can be customised with total

or partial wrapping with printed materials, if inks and substrates are

up to the task.

Wallpapers for instance should have a smooth finish, be of

sufficient weight and readily accept ink without wicking. Ideally they

should be mould and mildew resistant, especially if they are for use

in kitchens and bathrooms. Some wallpapers for digital printing

are prepasted and have an approved fire certificate so they meet

commercial wallcovering standards. Indoor permanence should be

rated for at least two years, and preferably up to twenty years.

Self-adhesive fabric wallpapers that can be removed and

repositioned, are suitable for temporary installations such as events

and parties. Various fabrics can be printed for wall coverings,

including synthetics and natural ones such as satin, suede and

canvas.

The range of materials is clearly vast: flexible coated and

uncoated substrates including backlit materials, meshes, banners,

vinyls, metallised films, photographic and fine art papers, canvas,

wallpapers, polypropylene, eco leather, fabrics and films. Films are

available to provide one way viewing either into or out of a space,

and window tinting and blackout films can be printed for privacy

or to reduce sunlight glare. The range of rigid options suitable for This series of printed spaces includes object printing as well as surfaces

and shows how light can affect colour appearance.

interiors includes acrylic plastic and polycarbonate, plus ACM

10FINISHING DON’T FORGET ABOUT THE WORKFLOW

As with all forms of print, without finishing processes there is no end For years the graphics industry has focused on the performance

product. For printed interiors finishing ranges from the trimming of of output devices. However in the internet age, workflow and

wallpapers, to the installation of floor coverings, and the cutting data management are at least as important, especially for on

and sewing of textiles. Technology provides some answers, but demand customised work. Set up of printed interiors workflows

practical considerations determine cost effectiveness. to support production models that assume every output type is

unique. This provides two big benefits the first of which is that

having such a set up requires you to understand the capabilities

of your workflow. The second benefit is that you will have a

foundation from which to expand capacity and output type

as your business grows, and can immediately respond to new

output requests.

Business opportunities in this sector are as wide and tempting

as the range of applications, but this is an exploding and

therefore competitive market so use your imagination. Services

for printed interiors can be limited to the print or could take

the form of subcontracting for organisations such as event

managers, marketing and advertising agencies, and even

wedding planners and caterers. This extends to other entities

such as local authorities and municipalities, flooring and interior

design companies, sporting venues such as racecourses, tourist

destinations and themeparks. You might even find local schools

and universities asking you about marketing services for use in

waiting rooms and elsewhere in their premises. There are even

opportunities to provide print services for airport lounges, on

escalators and in baggage halls.

Printed surfaces can be turned into tables and chairs for temporary

applications, such as for exhibition stands. Depending on the strength of

the substrate they even work for longer lasting applications.

11NEXT STEPS The world of printed interiors is clearly enormous, so setting up a new business to exploit the opportunities requires thought and solid business planning. Start with defining goals and considering your existing constraints and budget. Most devices for production of printed interiors are large, so consider where you will locate your new capacity. It might be more cost effective to set up dedicated print facilities dealing exclusively with the target clientele or as an added service to extend an existing sign and display or commercial printing business. If you want to take a more careful step into this sector, organise your factory so that the new business doesn’t compromise existing production flows. Most important is the technology investment choices you make which must be suitable for the part of the printed interiors puzzle you want to tackle. The golden rules apply: price, quality, speed. It’s often said that you can only have two of these three, but digital printing technologies let you break that convention. This benefits your business and creates amazing opportunities for your customers. WWW.FESPA.COM

SET 9

MAY 2017

EXPERT TECHNICAL GUIDE

PRINTING FOR INTERIORS

GUIDE 2: WALLPAPERPRINTING INTERIORS – GETTING STARTED SUBSTRATES AND TEXTURES

WITH PRINTING WALLPAPER DIGITALLY Anyone who has been shopping around for wallpaper knows what a

fantastic variety there is to choose from. Some wallpapers are quite

Wallpaper has been popular for hundreds of years and is a simple: a pattern printed on a flat surface, and typically on a quite

well established industry with a proud tradition and history. thick paper stock. But many wallpapers have a surface texture that is

But as with so many other industries, things changed with the an integral part of the design. Complex textured effects such as are

digital revolution. Over the last ten years or so digital printing of found with flocked wallpapers are not normally possible to produce

wallpaper has taken off and is on the rise. But there are some using standard digital printing methods.

challenges and limitations for digitally printed wallpapers, and

we’ll go through some of them in this article. This is the first limitation for digitally printed wallpapers, because you

may find that not all of those textured paper types will work well in

Traditionally wallpaper production was a craft, requiring a your digital printer. Instead you are likely to find that you’ll have to limit

lot of manual work. But like most other print applications your offering to some few paper grades and types, to be sure they

profitable volume production demanded industrial methods and will behave well and as predicted in the printer. But there are some

technologies. Today large volume wallpaper production is mainly structured vinyl substrates suitable for digital printing, depending on

produced in dedicated screen and flexo printing machines, and what printer and type of ink you will use.

also gravure print technology. To print a 30 m roll with screen

printing technology demands either a very large flatbed screen, or As usual the choice of substrate will also affect how to colour

using a rotary screen printing press. It goes without saying that the manage the artwork, so you might be better off limiting the number

volume needs to be quite big to justify the start-up costs in these of papers to those you have tested and know can provide predictable

types of printing presses. colour results.

Enter the digital printer and wallpaper printed on-demand. As with Other considerations when choosing what type of paper stock to

other types of digital printing there is no time consuming or costly print wallpaper on is whether it should be self-adhesive or needs

printing forme to prepare for a digital press, although the prepress conventional wallpaper paste when hung. There are low tack

side of things can be quite demanding and time consuming. But self-adhesive paper stocks on offer, which can be removed and

for quite simple patterns, or when printing a particular motif on a repositioned. Yet another consideration is the paper’s fire resistance.

smaller wall, like for example a map or a photo, the time needed Even here there is quite a wide range of papers and substrates to

to prepare the artwork shouldn’t be that long. The challenges choose among for digital printing, but it is a thing to be aware of.

when printing wallpaper digitally are instead in three main areas:

limitations in substrates and textures, limitations regarding

special inks and finally the economic and efficient finishing of

digitally printed wallpapers.

2WHAT INK TO USE?

As with all printing presses, both analogue and digital, a particular

press or printer is designed for and optimised to use a certain type

of ink. A big wallpaper printing factory may have a whole range

of printing presses to switch between, depending on what type

of final texture the wallpaper should have. If you plan to invest

in a digital printer for wallpaper production you must choose

carefully the technology that best suits your needs, because

the digital printer can probably only use one type of ink. Within

digital printing there are several main categories of inks used:

aqueous inks, dye based, solvent based, UV-curable ink and latex

inks, just to mention some of the most common. Whatever ink Wallpaper on-demand, digitally printed, is definitely on the rise. Here an

you use, you typically want colour accuracy, but also lightfastness example from the collection at Hevensent, a start-up company founded by

and durability in general. Durability will mean different things for Janet Hodcroft, England.

different people, and you might want to test out if your digitally

printed wallpaper qualifies as being scrubbable, meaning that

they it’s more durable than wallpaper that is washable. A washable

wallpaper can be lightly cleaned using a sponge or damp cloth.

Most paper wallpapers are probably only wipeable, and even that

should be done with great care.

If you are tempted to offer metallic inks for the artwork you will

probably be disappointed with what is on offer when printing

digitally. While there is some progress in this area, using real

metallic inks remains a big challenge. You may however be able

to print on some type of metallic substrate and possibly achieve a

similar artistic effect to what you are looking for. It all depends on

if the printer, and so the ink, can print on that substrate. The good There is a wide range of printers to choose between suitable to print

news is that inkjet digital printing technologies can print on more wallpapers digitally, here as an example the Mimaki JV300-160 using

or less any type of substrate. solvent based ink.

.

3PREPARING THE ARTWORK FINISHING THE WALLPAPER

Printing on wallpaper makes some special demands on artwork While there are some challenges and limitations in the substrates

preparation. Often these demands are very similar to those and inks that can be used in digital printing, perhaps the biggest

associated with printing on rolls of fabric. An obvious difficulty challenge is how to properly finish the printed wallpaper. By

is to calculate the pattern repeat and its possible overlap. There finishing we mean trimming or cutting the printed substrate to

are various special software tools which can help with this, and size ready for hanging. This must be done to tight tolerances,

also specialised Raster Image Processing (RIP) systems, like since by its nature wallpaper has to match exactly from roll to

for example Caldera Textile Pro, with such features. Another roll, especially with a repeated pattern. Precise registration is of

common task is to try and limit the spot colours used in the course also crucial when printing a large image in several parts,

design since these are costly to use in the printing press. When or a big map. Both applications are very popular for on demand

using analogue printing techniques you could technically use as digital wallpaper production. While there are many digital printer

many spot colours as you like, although this would be expensive. types to choose among from vendors like HP and Mimaki,

But when printing digitally you will have to translate the special there are fewer vendors of dedicated postpress (or finishing)

spot colour to the closest match using the CMYK process equipment for digital print production. If you only aim at custom

colours. Some colours simply can’t be reproduced with CMYK made digital wallpaper production in small volumes and believe

only, and then you will need a printer with additional inks to that you can charge a premium, then you might be able to handle

achieve a larger colour gamut. Today it’s increasingly common the finishing process more or less manually. This will take quite

to add Orange, Green and Violet to extend the gamut and reach considerable time and may require reprints if you exceed the

up to 99% of Pantone colours. Make sure that the proofs clearly tolerances, or make mistakes. For higher volumes and for digital

show how well a special colour can be matched on your system. wallpaper production in fiercely competitive markets, you will

need to invest in fast and precise finishing equipment that works

To print a large map or photo on a whole wall as a mural, the image

within tight tolerances. Customers won’t come back to you if they

resolution needs to be very high to be of satisfactory quality.

are not happy with the end result, which is when the wallpaper is

But the viewing distance comes into play, so the general rule of

hung successfully where it was supposed to go.

thumb that images should be at 300 ppi (pixels per inch, often

mistakenly written as dpi, dots per inch, which really is about So saying there are fantastic opportunities with digitally printed

output resolution) could be stretched a bit. So if you consider wallpapers, especially when combining creative design with the

a typical viewing distance for looking at the wallpaper is about use of new materials, be it substrates or inks, or a combination of

one meter, you could accept as low a resolution as about 100 both. So go explore, and let your imagination go wild!

ppi. But even so for example a 5x2.5 meter size image will create

a 500 MB image at 100 ppi. Such large sizes have an impact on

WWW.FESPA.COM

workflow which you need to take into account in production.SET 9

MAY 2017

EXPERT TECHNICAL GUIDE

PRINTING FOR INTERIORS

GUIDE 3: FILE SUBMISSION GUIDELINESFILE SUBMISSION GUIDELINES FOR

file format, but can save or export file formats such as PDF and SVG

(Scalable Vector Graphics).

PRINTED INTERIORS Most prepress departments will accept incoming artwork as native

Properly prepared artwork is key to every successful print Illustrator files. Illustrator can place pixel based images into the

production project, and this is no less crucial when printing interior artwork, but only works with single page documents. This is important

designs especially digitally. information to give your printed interiors customers. Also if they want

to create multi-page documents they should use Adobe InDesign or

While many printers provide guidelines for how to supply artwork, Quark Xpress. Customers should be aware that InDesign can place

and in detail these may vary somewhat from printer to printer, both pixel and vector graphics, and although like Illustrator it has its

there are many aspects that are quite generic and commonly own file format, InDesign can export artwork in a range of file formats.

accepted. Among them are the image resolution required for high Most of the time files should come in as PDFs or possibly Postscript

quality print production, and commonly accepted file formats. (EPS). Customers should also have the professional version of Adobe

But when it comes to applied colour management, things often Acrobat, since the free Reader version lacks the nifty features of

start to get quite complicated, and instructions start to vary quite preflight and softproofing which might come in handy.

a lot. There are different expectations for whether images can be

supplied as RGB-images or not, and if so, which RGB colour gamut While the fonts may be embedded when customers supply artwork

is preferred. There are several areas of concern to think about plus as a PDF, it’s better to ask them to always supply fonts with their

general good practices for artwork. files. Some fonts contain a flag telling InDesign and/or Acrobat NOT

to embed them. To avoid problems with fonts in an Illustrator file you

might convert all text to vector graphics, an old trick that still comes

COMMONLY USED SOFTWARE in handy now and then. If artwork is supplied as a native InDesign file

make sure you also get the original image files, in case they have not

While there are many image retouching softwares available, it’s safe been embedded with the InDesign file.

to say that most imaging professionals use Adobe Photoshop. It has

been around for many years and has reasonably good support for

colour management. The only weakness is perhaps how to properly

handle spot colours, but more about that later. Photoshop is pixel

editing software, so it’s only suitable for scanned or digitally captured

images. For line art, or vector based artwork, Adobe Illustrator (or

When you produce a hardcopy or contract proof, make sure that it can be

similar) is commonly used. Illustrator was the first software to be validated to conform to ISO 12647-7, the international standard for proofs.

able to edit artwork saved as Postscript, and has since been extended A commonly used control strip is the Ugra/Fogra media wedge shown

to also be able to open and edit PDF files. A strong link still exists here, with a series of colour patches which all need to be reproduced within

between Postscript and PDF. Illustrator however uses its own internal certain tolerances to be acceptable.

2IMAGE RESOLUTION COLOUR MANAGEMENT

There is an old rule of thumb stating that images should be This is perhaps the trickiest issue for artwork submission guidelines,

at 300 pixels per inch (ppi), based on the assumption that the and there are often strong feelings among prepress operators of

screen used is at 150 lines per inch (lpi). Since the screens for what is the right or wrong way to handle it. It’s very common that

CMYK separations are rotated up to 90 degrees, twice the image printers require incoming artwork to be pre-separated CMYK files,

resolution is required to avoid blurriness in print, hence 300ppi. while not always being very clear on what type of CMYK gamut

(Image resolution is often mistakenly written as, dots per inch this means. Other printers prefer images as RGB, but may not be

(dpi), but dpi relates to output resolution, not image resolution). specific on what type of RGB gamut they want. With proper colour

Most digital printers print at quite high resolution, perhaps 1200 management in place you should actually be able to accept artwork

dpi or more so for pixel based lineart (bitmap images) you should either in RGB or CMYK, as long as it’s absolutely clear what colour

use a resolution close to that of the final output, or at least 600 ppi. gamut (what ICC profile) is used. And you can even accept files with

special colours, which are neither in RGB or CMYK.

Advise customers that the image resolution required for photos

must take into account the viewing distance and that it’s only if

artwork will be viewed close up that 300 ppi image resolution is

necessary. If the viewing distance instead is about one meter,

When working with spot colours,

resolution can be as low as about 150 ppi, less if the viewing there are other tools than Photoshop

distance is further. Be aware that this refers to images which to use. For example GMG’s plugin

haven’t been scaled up, so work with a factor of 1:1. Images ColorConversion shown here.

scaled in for example InDesign for placing at 200%, a scaling

factor of 1:2, the image’s actual resolution is halved and may not

be sufficient in print.

One advantage of using RGB is that it’s close to how the original

While it’s common to let InDesign resample images when

images were captured, either by scanning original artwork like a

exporting the artwork to PDF, it’s safer to ensure the images

painting or hand made illustrations, or images captured using a

are used in the artwork without scaling and to switch off the

digital camera. But it’s important that when images are edited and

conversion to JPEG in the export. This makes sure that there is

adjusted for colour, it’s done on a high end monitor calibrated to for

no risk that images become jagged in the PDF. Better to suggest

example Adobe RGB. In this way everyone is sure that the colours are

customers scale (resample) the images in Photoshop, and place

what’s required and what is seen on the screen. When the images are

them at 100% in the artwork. In this way the risk of jaggedness

saved in the Adobe RGB colour gamut, your prepress department will

is avoided, since Photoshop has much better algorithms in the

know how best to convert them to CMYK, adjusted and optimised for

downsampling than InDesign does.

the printer, ink and substrate to be used in production.

3If you want to insist that artwork is supplied in CMYK, you need to

tell customers which CMYK ICC profile you intend to use, since it’s If you use Adobe Creative Suite

(or Creative Cloud) for image

the ICC profile which describes and determines the colour space retouching, you should create

you work in. The advantage of using CMYK as the colour space for a colour management setting.

artwork is that it can be softproofed for how it will look in print by We generally recommend

telling Photoshop, Illustrator, InDesign and Acrobat Pro to activate Adobe RGB as the colour space

for RGB images, and an ISO

this particular ICC profile. Customers should be able to do this even 12647-2 compliant profile for

with the artwork as Adobe RGB: the difference is that it will only be the CMYK images.

shown temporarily as CMYK, in the softproofing stage. But be aware

that if you change to another CMYK ICC profile the appearance will

most likely change. You should notify the customer if you do this and

There are other considerations for the artwork, especially when

explain why the original profile wasn’t suitable.

printing on fabrics or wallpaper, if you have repeated patterns. But

For artwork where spot colours are used, the Adobe Creative suite those requirements are often so specialised that they need to be

software does a reasonable job of colour managing those spot agreed with the client before they finish their artwork. They must take

colours, but some special solutions have additional benefits. A into account the size of pattern repeats, overlaps, shrinkage and trim

plugin to Photoshop from GMG called ColorConversion offers a requirements. Once these are clarified, file submission conforming

better preview of the spot colours in artwork, and also has good tools to these guidelines should be a breeze.

when editing the use of spot colours. Caldera and Esko also provide

sophisticated solutions for advanced handling of spot colours.

To be sure that incoming artwork is handled correctly in the prepress

department you should ask for an ISO 12647-7 compliant hard copy

proof or offer this as a service. ISO 12647-7 is the most commonly

used standard for contract proofs. However it may not show the

spot colours correctly, so in that case a proof or sample, produced

in the actual printer which will be used for final production should be

approved. This proof should be made with the same ink setup and

substrate, to check the colour accuracy.

WWW.FESPA.COMSET 9

MAY 2017

EXPERT TECHNICAL GUIDE

PRINTING FOR INTERIORS

GUIDE 4: FREQUENTLY ASKED QUESTIONSFREQUENTLY ASKED QUESTIONS

PRINTING FOR INTERIORS

1. HOW ARE PRINTED FABRICS MADE TO BE COLOURFAST? 5. HOW DO I ENSURE THAT COLOURS PRINTED ON 8. DOES IT MATTER WHAT RESOLUTION I PRINT AT?

Depending on the print method, the colours are bonded FABRIC AND OTHER MATERIALS MATCH? Resolution is a tricky subject and it definitely matters. The

with the fabric using different techniques to ensure that Robust colour management at all stages of the project is viewing distance is a useful guide to the ideal resolution:

they resist friction and washing. the only way. From design through to final printing, you the closer the work is viewed the higher the resolution. We

need to manage colour data. Profile the combination of work with 300 ppi for prints that are to be looked at close

2. WHEN IS THE BEST TIME TO INVEST IN NEW inks, substrates and devices, and make sure everyone up. For larger formats viewed at a distance, the image

resolution can be lower down to about 100 ppi.

TECHNOLOGY FOR PRINTED INTERIORS? in the supply chain understands how to ensure colour

appearance consistency.

Investment depends on the growth needs of the business

and on taking advantage of new market and technology

9. HOW CAN I BE SURE WORK WILL BE PRINTED AS

options. But investment decisions should be based on clear 6. HOW SHOULD I ADVISE CUSTOMERS TO CALCULATE EXPECTED?

business objectives and realistic evaluations of the market. DIGITALLY PRINTED WALLPAPER REQUIREMENTS? Get customers to supply a proof of what they want with

Make sure they measure the walls accurately and that you the job or provide proofs compliant to ISO 12647-7 which

3. IF WE WANT TO GET INTO PRINTED INTERIORS, take into account any pattern repeats in their design when defines digital data proofing processes. This is especially

important if you want to ensure that colour appearance

WHERE DO WE START? printing the job. Make sure they include sufficient bleed or

overlap in their production files. matches expectations.

Start with a full audit of your existing business: capacity,

technology, range of services, customer and job profiles

and staff capabilities. An audit will help you to identify 7. DO I NEED SPECIAL SOFTWARE FOR INTERIORS? 10. WHAT RESOLUTION SHOULD SCANNED IMAGES HAVE?

where you have scope for expansion and how you can grow Adobe Illustrator is the most commonly used application We generally recommend 300 pixels per inch (ppi), but

the business on the basis of services for printed interiors. for two dimensional design work. Adobe Photoshop if you are planning to use a digital image, say an A4

works too and there are various plugins are available to photograph, for a huge poster the higher the better. Keep

in mind that every time you enlarge the scanned image

4. WHAT IS THE BEST TECHNOLOGY FOR add specialisation. Other options are Edrawsoft Edraw for

wallpapers, and The Fabric Stuido’s Fabric Studio for textiles. you are spreading the captured data across a wider area.

PRINTING WALLPAPERS? This means less data or pixels and printed dots per square

This depends on the volume you want to print and if you are inch (ppi and dpi), so the image has to have sufficient

printing murals or conventional wallpaper. Most wallpapers resolution to look good when blown up.

are printed using screen, flexo or gravure, depending on run

lengths. Digital printing is a cost-effective option for short

run bespoke work on certain substrates.SET 9

MAY 2017

EXPERT TECHNICAL GUIDE

PRINTING FOR INTERIORS

GUIDE 5: WALLPAPER PRINTING FAQsFREQUENTLY ASKED QUESTIONS

WALLPAPER PRINTING

1. CAN I PRINT ON ANY SUBSTRATE FOR 5. HOW DO I ADD TEXTURE TO THE WALLPAPER? 9. DOES IMAGE RESOLUTION MATTER FOR WALLPAPERS?

WALLPAPER APPLICATIONS? Textured substrates are available for conventional Wallpapers can be viewed close-up so any design,

In theory yes, but practically not really. The material must wallpaper printing. Adding texture is not really an option especially those with fine details will definitely need to

be suitable for sticking onto the wall as well as printing, so if you are printing digitally, unless adding coating layers. take into account image resolution.

choose substrates designed for the application. This is generally not economically viable for wallpapers.

10. CAN WALLPAPERS BE PRINTED WITH

2. WHAT IS THE MINIMUM RUN LENGTH FOR 6. WHAT IS THE PATTERN REPEAT? PANTONE COLOURS?

WALLPAPER PRINTING? Strips of wallpapers with complex regular patterns must Adding spot colours is not problem for wallpaper printing,

be aligned so that the patterns match when the strips are however if you can print the Pantone colour in CMYK

There is no minimum if you are printing digitally. For other

on the wall. The repeat and its frequency will influence costs will be lower.

methods customer requirements, budget and process will

how much wallpaper has to be printed for a given space.

determine the minimum run which can be as little as 30

metres.

7. DO I NEED TO COLOUR MANAGE WALLPAPER

3. DO PRINTED WALLPAPERS NEED SPECIAL FINISHING? DATA FILES?

The print needs to be rolled and shrink-wrapped or boxed. Colour management is fundamental to all print production.

The rolls need to be trimmed so that the edges are In applications where large areas of colour are viewed

perfectly straight and fit together on the wall with no gaps. close up, it is expecially important. It is also crucial if you

are using multiple presses to produce a single job.

4. CAN I USE THE SAME TECHNOLOGY TO PRINT

WALLPAPERS AND OTHER FORMS OF PRINT? 8. CAN I PRINT WALLPAPERS WITH METALLIC INKS?

Yes if you are screen printing or using flexography. There

Up to a point, but a better approach is to invest in

are some solutions for digital printing but they generally

equipment that produces the optimum results on the

fall short of the quality available with other methods.

materials your customers want to print on.You can also read