Food Plant Construction and Site Selection - INSIDE: Food Processing

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

eHANDBOOK

Food Plant

Construction

and Site

Selection

INSIDE:

Pandemic-Inspired Changes in

Food Plant Construction p2

Food Facility Site Selection

Checklist pg6

SPONSORED BYwww.FoodProcessing.com

Pandemic-Inspired Changes

in Food Plant Construction

After being suppressed by the pandemic, capital expenditures are poised to

come back – but with important changes.

By Food Processing

L

ike many aspects of the economy, capi- According to Melius Research, industrial

tal expenditures in the food & beverage firms of all types that reported results

industry tumbled last year. But the in the first half of 2020 predict a 20%

industry is getting ready to resume building. increase in capital expenditures.

Big food processors had to scale back plans Architecture, engineering and construction

to build, renovate, add lines or generally (AEC) firms are starting to see food and bev-

make big improvements, as the pandemic erage processors greenlight capital expansion

forced them to concentrate on making projects that were delayed last year.

adjustments to their current facilities. But

now they are preparing for the economic One effect of the pandemic has been to

boost expected as the pandemic ends. make companies at least temporarily favor

renovation or expansion over new con-

Of the 31 publicly traded major food & bev- struction. Of the 35 sites in our list of plant

erage companies Food Processing has construction projects, only nine were new

researched, 23 spent less on capital projects in plants, compared with 14 last year.

2020 than they had budgeted. But for 2021, all

but four of those plan to spend more. Overall, OPPORTUNITIES

those 31 have budgeted $16.3 billion in capital Although the pandemic suppressed a

expenditures this year, a 13% increase over lot of capital spending, it also created

what they actually spent in 2020. some opportunities for projects, as

companies struggled to adjust to new

That trend mirrors what’s going on with conditions. One of the biggest and best-

American manufacturing as a whole. known effects of the pandemic was a

eHANDBOOK: Food Plant Construction and Site Selection 2www.FoodProcessing.com

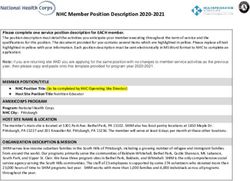

TOP CURRENT PROJECTS

COMPANY LOCATION PRODUCTS PROJECT TYPE SIZE COST COMPLETION

Nestlé Williamsburg Twp., Ohio Pet food New 1,200 $550 2023

Nestlé Hartwell, Ga. Pet food Expansion n/a 550 2025

CJ Foods USA Sioux Falls, S.D. Asian foods New 700 500 2025

Nestlé Eden, N.C. Pet food Acquisition/renovation n/a 450 2022

Keurig Dr Pepper Moore, S.C. Coffee New 708 350 Aug. 2021

Atlantic Sapphire Miami, Fla. Seafood New 1,100 340

McCain Foods Othello, Wash. French fries Expansion 170 300 n/a

AquaCon Federalsburg, Md. Aquaculture New n/a 300 2024

Clemens Food Group Hatfield, Pa. Bacon New n/a 228 2024

Lindt & Spruengli Stratham, N.H. Candy Expansion 200 2022

Frito-Lay Perry, Ga. Snacks Expansion n/a 200 Third quarter 2021

Mars Petcare Fort Smith, Ark. Pet food Expansion 200 145 2022

Hershey Co. Stuarts Draft, Va. Candy Expansion 90 135

Diageo Lebanon, Ky. Liquor New 72 130 June 2021

Ken’s Foods McDonough, Ga. Salad dressings, marinades Expansion n/a 103 Early 2022

Frito-Lay Pulaski, Tenn. Snacks Expansion 100 2022

Maple Leaf Foods Indianapolis Tempeh (soy protein) Acquisition/renovation 118 100 2022

Wells Enterprises Dunkirk, N.Y. Ice cream Expansion n/a 87 n/a

Boston Beer Co. Cincinnati Beer Expansion n/a 85 Late 2021

Conagra Brands Russellville, Ark. Frozen foods Expansion 84 2022

Simmons Pet Food Dubuque, Iowa Pet food Renovation/retrofit 250 80 2023

J.M. Smucker Longmont, Colo. Sandwiches Expansion 240 80 Fall 2022

Pilgrim’s Pride Cold Spring, Minn. Poultry Expansion n/a 75 Late 2021

Ferrero North America Bloomington, Ill. Chocolate Expansion 70 75 n/a

Niagara Bottling Florence, S.C. Bottled water New 502 70 Early 2021

Size is in thousands of square feet; cost is millions of U.S. dollars.

switch from foodservice to retail. That led chart, three of the top four projects are new

some processors with some dependence or renovated pet plants for Nestlé Purina,

on foodservice to reconfigure lines for totaling $1.5 billion. Mars Petcare and Sim-

the retail channel. In some cases, that mons Pet Food are also expanding plants.

also meant different types of packaging

formats … and packaging machinery. FLEXIBILITY NEEDED

The priorities of companies building or

But foodservice is likely to come roaring renovating plants haven’t exactly been

back once restaurants reopen to full capacity. changed by the pandemic, but some of

One of the biggest projects, a $300 million them have been intensified, with more

potato-processing plant for McCain Foods in of an emphasis on flexibility. This isn’t

Othello, Wash., was paused from April to Sep- surprising, since one of the biggest

tember of last year due to the pandemic. problems for the industry during the

pandemic was having to shift abruptly

The pandemic caused a big increase in between products and packaging formats.

pet adoptions by bored or lonely families

or individuals, and that’s resulted in more AEC firms we talked to see customer priorities

new pet food plants. Again referring to our as speed to market; automation, especially

eHANDBOOK: Food Plant Construction and Site Selection 3www.FoodProcessing.com

through artificial intelligence and robotics; discourage mingling among employees.

availability of cold storage space; manufactur- Common spaces, break areas and worksta-

ing redundancy; and consolidation. tions are all spaces that are being evaluated

and reconfigured to promote more distance

Flexibility has become more important in between workers as well as to control the

the face of the pandemic, with many pro- flow of personnel.

cessors having to switch quickly between

products, ramping up some SKUs while In addition, the pandemic has brought a

scaling back or eliminating others. It will new emphasis on ventilation, with HVAC

continue to be important as they cope with equipment makers researching how best to

the pandemic’s end, if consumer prefer- filter airborne droplets – COVID’s primary

ences shift back to previous patterns. source of transmission – out of the air.

WHAT’S TO COME? Probably the most important large-scale

Of course, the pandemic hasn’t disappeared initiative to deal with any future pandemic

yet. Many experts wonder if there will is something of an industry imperative

be a future pandemic, and if so, what anyway: automation. It’s the only viable

should be done to prepare for it? long-term strategy for establishing greater

distance between workers, in the same

When food companies have reconfigured or space, while maintaining the same output.

altered production lines in response to the

pandemic, it has mostly been in a reactive Many companies are taking a different view

way, working within the space at hand to of automation and robotics projects now,

install barriers or take other measures. That after dealing with the past year’s labor

may continue in a proactive way. Compa- shortages and worker health concerns.

nies planning to build a new space have to Automated lines will not only improve effi-

decide whether to accommodate require- ciency and flexibility but may address the

ments like social distancing in case it’s need for continued spacing of employees.

required by another pandemic.

With the end of the pandemic at least the-

Many plants already feature restrictions on oretically approaching, America is eager to

personnel flow, for example between sani- shake off its shackles – and the food indus-

tary and less-sanitary areas. The pandemic try will be there to accommodate it.

has led many companies to reconfigure

flow to allow temperature scanning or ther- Read the complete story on

FoodProcessing.com.

mal imaging. Future designs should also

eHANDBOOK: Food Plant Construction and Site Selection 4Got a Taste for

Design Done Right?

ESI always designs food facilities from the inside out.

Need to minimize worker touchpoints? Maximize work floor space? ESI will find

the fresh efficiencies in your process and then design the walls around it.

Let us offer you a recipe for success!

Automation / Cold Storage / Food Distribution & Processing / Logistics

Designing and Building Visit: esigroupusa.com

Follow Us:

Quality Food Facilities

Nationwidewww.FoodProcessing.com

Food Facility Site

Selection Checklist

By Timothy Gibbons, VP of Design, ESI Group USA

C

ongratulations, you are considering

buying land for your future process

or distribution facility. Site selec-

tion is the first major decision you will make

about your project, and the most critical.

Consider every factor as you look at differ-

ent sites so you can compare your options

critically. These key requirements should

be outlined and made available to the real

estate broker so they can help narrow down as obtaining a Phase One Environmen-

the site search and provide you only quali- tal Assessment, determining if there are

fying site options. any Environmental Operating Permits,

1. Due Diligence. Due Diligence is a broad Wetlands or regulations pertaining to

term that business and real estate attor- Flood Zones. As well, an investigation

neys and professionals use but is often must be conducted to determine if

misunderstood by clients. Typically any endangered species reside on the

the term is used to refer to the inspec- site that may limit its use or, if there is

tion and investigation of real property, an airport nearby, the FAA may have

personal property or a business entity height and use restrictions.

conducted before a buyer makes the 2. Location. Is there ready access to major

final decision to purchase. There are highways leading to the site? How do

many factors that must be considered these interact with other major high-

prior to the purchase of property such ways? Like two sites but can’t decide?

eHANDBOOK: Food Plant Construction and Site Selection 6www.FoodProcessing.com

Perform an analysis on freight/delivery the site and its ability to grow in a bal-

costs on both and you will be surprised anced nature will have longstanding

at how quickly savings are realized. operational and financial ramifications

Also, if delivery from the site is done on for the facility and the company. Also,

a daily basis, knowing the range of com- consider municipal restrictions that

pany drivers is critical to avoid having limit site development. This percentage

to double up on operators. Work force or ratio of the size of the building to

availability should also be considered. the land on which it resides is called the

3. Site size. When evaluating a site for “land to building ratio.” The building

size suitability, examine the ability of can get no bigger than the allowable

the site to fit the facility at full build land to building ratio. Know this restric-

out. Have your architect design a com- tion prior to purchase.

plete master plan for the site so any 4. Access. Easy entry and exit from the

future expansion is thought out and interstate highways will make life easier

done with reason. This involves more on you and provide added incentive to

than just drawing boxes that represent choose your facility. Check right- and

future expansions. It should include left-turn access, curb-cut locations

production/storage space, mechan- (existing and potential), traffic islands,

ical room expansion, office growth turn lanes, medians and other traffic

and truck yard, including maneuvering impediments leading to the develop-

room. The location of the building on ment. Also visit the site during busy

eHANDBOOK: Food Plant Construction and Site Selection 7www.FoodProcessing.com

traffic times to see if nearby traffic con-

trol devices cause backups that would

inconvenience clients. Also consider

if crossing a rail line, the potential for

blockages caused either by shunting

railroad cars or worse, derailment. Both

issues can severely affect the desired

access to the site.

5. Topography and Subsurface Condi-

tions. Look at the overall lay of the land;

check for extreme slopes or depressions

that could make development difficult and other amenities such as sidewalks,

or more expensive. Remember, moving hydrants, regional stormwater detention,

a lot of dirt around is costly. And even a et al. It is important however to verify the

flat site can be difficult if it has no nat- capacity of each so the building oper-

ural drainage for storm water. As your ation can be supported now and in the

interest in the property increases, be future. This is particularly true of water

sure to perform a geotechnical analysis and sewer. Water tanks and waste water

of the site to determine any subsurface treatments plants are expensive add-ons

conditions that may make building more to make the building work. Otherwise,

expensive to construct. This should be the building owner will need to supple-

performed by a geotechnical engineer- ment. In the case of food processing and

ing company contracted by you. Do not distribution, refrigeration systems con-

rely on any report supplied by the cur- sume large quantities of water and some

rent owner of the property. municipalities, especially in the west,

6. Know the Municipality. Meet with cannot guarantee water requirements

Zoning and Development regulators needed for operation.

to determine the long-term plans for 8. None of the items listed above comes

the future of the surrounding areas. without a cost or time investment. Be

Building in an area near residential prepared to spend some money up front

developments will have long-term to safeguard your decision and help you

ramifications on the operation and select the best piece of property for the

expansion capabilities. company’s future.

7. Amenities. Verify that the site has

CLICK HERE to check out some of ESI

required improvements, such as elec- Group’s trade education pieces discussing

site selection, among other topics.

trical, sewer, water, telephone, gas,

eHANDBOOK: Food Plant Construction and Site Selection 8You can also read