Effect of Inflation Pressure loss Rates on Tire Rolling Restistance, Vehicle fuel Economy, and CO2 Emissions - Global Aanalysis

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

ROHSTOFFE UND ANWENDUNGEN

RAW MATERIALS AND APPLICATIONS

Innerliner · Halobutyl Rubber · Tire

Performance · Inflation Pressure Loss

Effect of Inflation Pressure loss

Rates · IPLR · %-Loss/Month · Rolling

Resistance Force · SAE J1269 · Fuel

Economy · CO2 Emissions

Rates on Tire Rolling Restistance,

Using data for the United States, a

method was previously developed to

calculate the additional fuel consumed

Vehicle fuel Economy, and CO2

and corresponding increase in CO2

emissions generated upon switching

from the original equipment to replace-

Emissions - Global Aanalysis

ment tires for small passenger cars and

for SUV/light trucks. Since pneumatic

tires continuously lose pressure due to

permeation of gas through the rubber,

tire inflation pressure loss rates (IPLR)

were used to calculate the additional Based on the low permeability1 to small- · Measure the inflation pressure loss rates

fuel consumed by the vehicle as a molecule diffusants as a result of efficient (IPLR) of tires following the ASTM F1112

function of the increased tire rolling

intermolecular packing2, butyl rubber has protocol9.

resistance resulting from tire under-

contributed significantly to the improve- · Determine tire IPLR values at a typical op-

inflation. Results are estimated for the

fuel consumed as a function of tire IPLR ment in the performance and safety of tires. erating temperature in use on vehicles.

for countries in the Americas, Europe, Halogenated butyl rubbers provide higher · Measure the changes in tire RRF values

and Asia. vulcanization rates and improve the com- as a function of inflation pressure from

patibility with unsaturated rubbers, ena- 221 to 165 kPa when the tire pressure

bling the production of tubeless tires3. Ex- monitoring system must be activated in

Einfluss des Reifendruckverlusts perimental 205/60 HR15 tires made with a the U.S. (25 % underinflation)15.

auf den Rollwiderstand, Kraft- change only in the innerliner Bromobutyl/ · Calculate the increase in tire RRF values

stoffverbrauch und CO2 Emmissi- NR polymer ratio showed direct relation- as a result of tire underinflation assum-

onen - eine globale Analyse ships to tire performance4-8. Quantitative ing an average tire re-inflation time pe-

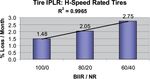

correlations (R2 > 0.99) of Bromobutyl rub- riod of three months.

Innerliner · Halobutylkautschuk · ber (BIIR) level to inflation pressure loss rate · Determine the decrease in vehicle fuel

Reifenleistung · Reifendruckvelustrate · (IPLR)9 values (Fig. 1), and to intracarcass economy as a function of tire IPLR that

% Verlust/Monat · Rollwiderstands- pressure (ICP) were obtained. Durability, result from the increased RRF values.

kraft · SAE J1269 · Kraftstoffökonomie · measured in hours to failure on a 1.7-m lab · Estimate the potential fuel savings if a

CO2 Emissionen roadwheel, tested according to the National tire IPLR specification were to exist by

Aufgrund von Daten aus den Vereinig- Highway Traffic Safety Administration’s using the factor: a 10 % increase in tire

ten Staaten wurde eine früher entwi- Federal Motor Vehicle Safety Standards No. rolling resistance increases light duty ve-

ckelte Methode angewendet um den 13910, but modified by continuing until tire hicle fuel consumption by 1.6 %16.

zusätzlichen Kraftstoffverbrauch und failure, showed a qualitative correlation to · Estimate the potential yearly fuel sav-

den entsprechenden Anstieg der CO2 tire IPLR, Figure 2. Oxidative aging of natural ings as a function of tire IPLR for light

Emissionen beim Übergang auf Ersatz- rubber in the tire belt area is retarded by us- duty vehicles in service in the Americas,

reifen bei PKWs und leichten LKWs zu

ing a liner that gives a low IPLR7,8. in Europe, and in Asia.

berechnen. Da Luftreifen aufgrund der

Gaspermeation kontinuierlich an Druck · Calculate the potential CO2 reductions

verlieren, kann die Reifendruckverlust- Experimental Technique obtained from these examples of esti-

rate zur Berechnung des zusätzlichen A multi-step process was developed11 in or- mated fuel savings17.

Kraftstoffverbrauchs als Funktion des der to calculate the fuel consumed by light Available tire rolling resistance force (RRF)

steigenden Rollwiderstands herangezo- duty vehicles (ROHSTOFFE UND ANWENDUNGEN

RAW MATERIALS AND APPLICATIONS

1 2

1 Tire Inflation Pressure Loss Rates as a Function of the Bromobutyl 2 Durability by FMVSS 139 Endurance (to Failure) as a Function of

Rubber / Natural Rubber Ratio Used in the Innerliner Compound7 Tire Inflation Pressure Loss Rate Values7

ed to travel 12,000 miles upon switching

from the original equipment to replace- 3

ment tires for six 2007 model year passen-

ger cars (Fig. 3) and for nine 2007 model

year SUV/light trucks.

Tire Inflation Pressure Loss Rates

Tire inflation pressure is important. “Find-

ings from safety checks conducted on

52,400 cars in 15 E.U. countries in 2009 show

that 81 % of motorists are driving on under-

inflated tyres. This habit is leading to the

annual equivalent of 4.0 billion litres of

wasted fuel, worth € 5.2 billion, and 9.3 mil-

lion tons of additional and unnecessary CO2

emissions - the equivalent of 3.47 g/km of

CO2 a year for every car on Europe’s roads.

3 Gasoline Consumed for 2007 Passenger Cars to Travel 12,000 Miles on the Original

Analysis of these test results show that

Equipment Tires (green), on Replacement Tires that have an Average Rolling Resistance

26.5 % of motorists are driving on seriously

Force Value (green + blue), and on Replacement Tires that have the Highest Rolling

under-inflated tyres (at least 0.5 bar below Resistance Force Value (green + blue + red)11

vehicle constructor recommended pres-

sure) and 7.5 % are putting their safety at

high risk by driving on severely under-inflat- month. In addition, IPLR values of tires Since the average light duty vehicle is not

ed tyres (at least 0.75 bar below recom- measured by the ASTM F1112 test protocol operated on a 24-hour time basis, tire IPLR

mended pressure).” 18,19 are reported in the literature20 with values values for four different tire models were

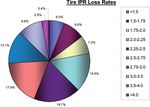

Tire inflation pressure loss rates (IPLR) were ranging from a low of 1.09 %-loss/month to measured in the lab at 21oC according to

measured for tires manufactured during 4.44 %-loss/month. Figure 4 shows the per- the ASTM F1112 test protocol and also

the last 12 years and assembled into a sin- centage distribution of tire IPLR values of were measured at ambient temperatures

gle database if the IPLR value was deter- more than 250 tires. The average IPLR value on different vehicles that were being used

mined according to ASTM F1112 test proto- of tires manufactured worldwide is in service21. Results showed an average in-

col9. No experimental tires were included in 2.36 %-loss/month. crease in the tire IPLR value by approxi-

this database. If the IPLR of one tire model Tires lose inflation pressure more quickly mately 75 % for tires measured on vehicles

was measured repeatedly or if the same tire when loss rates are measured at higher used in-service compared to the ASTM

had been tested in different labs, then the temperatures as during in-service opera- F1112 lab values. The increase in tire IPLR

average value of all measurements was tions15,20,21. In addition, IPLR values for dif- varied widely and depended on the tire

used to represent this tire model as a single ferent tires change differently with tem- model. For example, the IPLR of Tire A in-

IPLR value. However, if the same size and perature changes. For example, two tire creased by 50 %, while the IPLR for Tire C

model tire had been manufactured in dif- models having the same value of IPLR = increased by 225 %, Figure 6.

ferent plants, it would be considered a dif- 2.4 %-loss/month when measured accord- Based on the average of 12,000 miles driven

ferent model and was included in this data- ing to ASTM F1112 at 21oC, had different yearly in the U.S., a vehicle is operated ap-

base. Over 230 different models and/or loss rates when measured at 70oC. Signifi- proximately 6 % of the time, depending

sizes of tires are included in this database cantly higher tire IPLR values of 27.1 %-loss/ upon the average speed that is attained.

with tire IPLR values ranging from a low of month for Tire C and 34.9 %-loss/month for Thus, using 6 % of the tire IPLR value meas-

0.86 %-loss/month to a high of 3.53 %-loss/ Tire L20 are reported, Figure 5. ured at 70oC and adding it to 94 % of the

46 KGK · Januar/Februar 2012 www.kgk-rubberpoint.demeasured ASTM F1112 tire IPLR lab value sistance using three test protocols: SAE Results show that the average of the meas-

measured at 21oC, affords an adjusted tire J1269 single-point, SAE J1269 multipoint, ured rolling resistance force (RRF) values of

IPLR value that is increased by approximate- and SAE J2452. Data was measured for the three tires in each of the four sets in-

ly 72 %. This increase is approximately the three tires each of the four sets at seven creased with decreasing tire inflation pres-

same as the 75 % average increase in IPLR specified tire inflation pressures: 260, 221, sure, regardless of advertised as a low roll-

measured for tires at ambient temperatures 214, 207, 193, 179, and 165.5 kPa. In particu- ing resistance tire. Tire RRF value range

on vehicles being used in service21. lar, tire inflation pressures of 221 to 165.5 from 3.94 kg to 5.13 kg at 221 kPa inflation.

kPa were selected to cover that inflation Figure 7 plots the RRF values as a function of

Effect of IPLR on Tire Rolling pressure range representing a properly in- tire inflation pressure. The increase in RRF

Resistance flated tire (selected to be 221 kPa) and a with decreasing tire inflation pressure oc-

Four sets of tires were tested: an advertised 25 % underinflation situation (165.5 kPa) curs regardless of the value measured at

low rolling resistance tire manufactured in when the vehicle’s tire pressure monitoring 221 kPa. The average increase in tire rolling

Europe, and an advertised low rolling resist- system (TPMS) should be activated to alert resistance force is 16.5 %. Hence, the ability

ance tire manufactured in Japan. Smithers the driver of low tire inflation pressure in of the tire to maintain the proper inflation

Scientific Services measured tire rolling re- accordance with FMVSS No. 13822. pressure is most important.

The increase in tire RRF will also vary with

the tire IPLR value. Even though the TPMS

4 4 Distribution of light may not be activated within a three-

Inflation Pressure

month time period, the approximate tire

Loss Rates Values

for 250 Tires Man- re-inflation time period in the U.S.23, the tire

ufactured Glo- is still underinflated, the rolling resistance

bally11 force value is increased (see Figure 8), and

thus the vehicle fuel economy is reduced.

For a light-duty vehicle tire with an IPLR =

1.5 %-loss/month, the RRF value calculated

at the end of the three-month period has

increased 2 % from the initial RRF value

measured at 221 kPa. This corresponds an

average increase of 1 % over the three

month time period based on the area under

the curve of the right triangle, Area =

½*(H*L). For a tire with an IPLR = 3.5 %-loss/

month, the increase in the RRF value at the

5 5 Tire IPLR Monthly

end of the three month time period is calcu-

Loss Rates Deter-

mined According to lated to increase 4.67 %, and the average

ASTM F1112 at increase in RRF over the entire three months

21oC (blue) and at is 2.33 %, Figure 8.

70oC (purple)

Potential Fuel Savings for the United

States

The potential yearly fuel savings for the

United States can be estimated if the under-

inflated tire issue can be resolved. Based on

2006 data there were 234.5 million light

duty vehicles registered with 57.7 % being

6 7

6 Tire IPLR Monthly Loss Values Measured According to ASTM F1112 7 Tire Rolling Resistance Force Values Shown as a Function of Tire

in the Laboratory (blue), and on Vehicles Used In-service (purple) Inflation Pressure

www.kgk-rubberpoint.de KGK · Januar/Februar 2012 47ROHSTOFFE UND ANWENDUNGEN

RAW MATERIALS AND APPLICATIONS

passenger cars and 42.3 % SUV/light trucks.

8

For the estimated average 12,000 miles

(19,300 km) driven per vehicle per year vehi-

cles consume about 600 gallons (2271 lit-

ers) of gasoline per vehicle per year, or ~20

mpg24.

A potential savings of 322 million gallons

(1.22 billion liters) of gasoline each year is

calculated if inflation pressure loss rates did

not exceed 2.5 %-loss/month for any pas-

senger car or SUV/LT tires11. Figure 9 is a

summary of potential savings as a function

of tire IPLR. A maximum IPLR=2.5 %-loss/

month is expected to affect about 42 % of

tires (see Figure 4). Potential CO2 savings

8 Average Increase in the Rolling Resistance Force Over the Three-month Time Period

would be 2.84 million metric tonnes per

Prior to Tire Re-inflation; the Increase in the RRF Value is Two Times that of the Average

year17. Use of lower tire IPLR values could Value Shown

generate additional savings.

The potential savings of 322 million gallons 9

(1.22 billion liters) of gasoline per year is

equivalent to not shipping three Ultra Large

Crude Carriers (tankers) which carry about

one million tonnes of crude oil, not refining

16.5 million barrels of crude, and not send-

ing 53,700 tanker trucks to deliver gasoline

to local service stations (5,000–7,000 gallon

tanks per truck). The corresponding savings

in CO2 emissions would be equivalent to

taking 537,000 light duty vehicles off of the

roads in the United States. Since the aver-

age tire lifetime is 3.6 years25, 1.16 billion

gallons (4.38 billion liters) of gasoline could

potentially be saved and over 10 metric mil-

9 Potential Annual Gasoline (blue) and CO2 Emissions (green) Savings as a Function of Tire

lion tonnes of CO2 emissions would not be-

Inflation Pressure Loss Rate11

ing generated, Figure 10. The use of lower

tire IPLR values could generate additional 10

potential savings.

RESULTS AND DISCUSSION

The effects that tire inflation pressure loss

rates have on vehicle fuel economy and CO2

emissions based on the number of light

duty vehicles in service in countries in the

Americas (excluding the United States), in

Europe and in Asia Pacific is calculated.

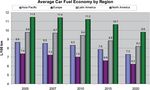

It is important to know that the fuel econo-

my of cars varies significantly in different

regions and different countries within a re-

gion in the world26, Figure 11. Differences

may arise from a number of factors and can

include the size and types of light duty ve- 10 Potential Savings over 3.6-Year Tire Lifetime of Gasoline (blue) and CO2 Emissions

(green) as a Function of Tire Inflation Pressure Loss Rate11

hicles driven, the road conditions and infra-

structure, climate conditions, and individu-

al driving habits. were in use, which included 92.6 million 1237 liters of fuel/year. The total number of

passenger vehicles and 15.9 million light medium and heavy commercial vehicles,

Americas commercial vehicles28, see Table 1. An aver- such as long-haul trucks and buses, are also

In 2008, countries in the Americas including age of 9.7 liters/100 km of fuel was con- listed in Table 1, but are not a part of this

Canada, but excluding the United States, sumed by each vehicle in 2007, and assum- analysis.

had an estimated total population of 722.5 ing that each light duty vehicle was driven Statistics for the individual countries within

million people27, see Table 1. An estimated an average of 12,000 km/year the average the Americas varies significantly. For exam-

total of 108.6 million light duty vehicles vehicle would have consumed a total of ple, the percentage of light commercial ve-

48 KGK · Januar/Februar 2012 www.kgk-rubberpoint.de1 Selected Data for Canada, Mexico, Argentina, Brazil, and Other Countries in the Americas A yearly savings of 347 million liters of fuel

Country Canada Mexico Argentina Brazil Other is calculated if tire inflation pressure loss

Latin rates did not exceed 2.5 %-loss/month for

America

any tires based on using the savings for

Passenger Vehicles, Millions 21.76 24.02 7.11 24.68 15.09 passenger car values previously calculated

Light Commercial Vehicles, Millions 3.83 4.66 1.07 2.85 3.50 (Figure 3) for the number of passenger ve-

Commercial Vehicles, Millions 0.82 1.06 0.45 2.08 1.73 hicles listed in Table 1, and using the saving

Total Vehicles, Millions 26.41 29.73 8.63 29.61 20.32 for SUV/LT results previously generated11

2008 Estimated Population, Millions 33.2 110.0 40.5 196.3 342.5 for the number of light commercial vehi-

Passenger Vehicles/1000 People 655.1 218.4 175.5 125.7 44.1 cles listed in Table 1. In addition, the gen-

eration of 0.79 million metric tonnes of

2 Potential Yearly Fuel and CO2 Emission Savings for the Americas, Excluding the United States CO2 emissions may be prevented. These

Tire IPLR, Estimate of Average Rolling Potential Annual Potential Annual amounts are equivalent to taking approxi-

%-Loss/Month Number of Resistance Increase at Fuel Savings Reduction in CO2 mately 280,000 light duty vehicles off the

Tires Affected Three Months Emissions road in countries in the America, excluding

1.5 % 98.2 % 2.10 % 599 MLiters 1.37 MMtonnes the United States. Table 2 is a summary of

2.0 % 77.8 % 3.60 % 543 MLiters 1.24 MMtonnes potential savings of fuel and CO2 emissions

2.5 % 40.8 % 4.40 % 347 MLiters 0.79 MMtonnes as a function of tire IPLR. Use of lower tire

3.0 % 16.7 % 5.10 % 190 MLiters 0.43 MMtonnes IPLR values could generate additional po-

3.5 % 7.4 % 5.90 % 64.5 MLiters 0.15 MMtonnes tential savings.

3 Potential Yearly Fuel and CO2 Emission Savings for the 27 Countries in Europe

Europe

In 2008, the 27 countries in Europe had an

Tire IPLR, Estimate of Average Rolling Potential Annual Potential Annual

%-Loss/Month Number of Resistance Increase at Fuel Savings Reduction in CO2 estimated population of 731.7 million peo-

Tires Affected Three Months Emissions ple27 and had an estimated total of 268.8

1.5 % 98.2 % 2.10 % 3199 MLiters 7.29 MMtonnes million light duty vehicles in use, which in-

2.0 % 77.8 % 3.60 % 2531 MLiters 5.77 MMtonnes cluded about 244.9 million passenger vehi-

2.5 % 40.8 % 4.40 % 1153 MLiters 2.63 MMtonnes cles and 23.9 million light commercial vehi-

3.0 % 16.7 % 5.10 % 395 MLiters 0.90 MMtonnes cles28. The total number of passenger vehi-

>3.5 % 7.4 % 5.90 % 84.6 MLiters 0.19 MMtonnes cles per 1000 people in Europe is 335; how-

ever, greater than 78 % of these passenger

vehicles were located in the western Euro-

4 Selected Data for China, India, Japan, South Korea and Taiwan, and Other Countries in the Asia-

Pacific Region pean counties. An average of 7.2 liters of

fuel is consumed in order to drive 100 km

Country China India Japan South Taiwan Other

Korea Asia each for light duty vehicle in 2007 (see Fig-

Pacific ure 11)26, and using an average of 15,000 km/

Personal Vehicles, Millions 39.89 14.51 65.64 13.17 6.56 40.56 year driven for each light duty vehicle the

Light Commercial Vehicles, Millions 13.78 1.44 9.99 3.82 0.49 11.44 average vehicle consumed a total of 1080

Commercial Vehicles, Millions 7.51 3.74 0.83 0.31 0.21 3.64 liters of fuel/year. Medium and heavy com-

Total 61.18 19.69 76.45 17.30 7.26 55.64 mercial vehicles are not a part of this analy-

2008 Estimated Population, Millions 1330.0 1148.0 127.3 48.4 22.9 1375.4 sis.

Passenger Vehicles/1000 People 30.0 12.6 515.6 272.2 286.2 29.5 A potential annual savings of 1.15 billion lit-

ers of fuel is calculated if tire inflation pres-

sure loss rates did not exceed 2.5 %-loss/

5 Potential Yearly Fuel and CO2 Emission Savings for the Asia-Pacific Region

month for any light duty vehicle tire. The

Tire IPLR, Estimate of Average Rolling Potential Annual Potential Annual generation of 2.63 million metric tonnes of

%-Loss/Month Number of Resistance Increase at Fuel Savings Reduction in CO2

Tires Affected Three Months Emissions CO2 emissions could also be saved. These

values are equivalent to taking approxi-

1.5 % 100.0 % 2.10 % 1274 MLiters 2.90 MMtonnes

mately one million light duty vehicles off

2.0 % 93.4 % 3.60 % 1269 MLiters 2.89 MMtonnes

the road in countries in Europe. Table 3 is a

2.5 % 60.1 % 4.40 % 1053 MLiters 2.40 MMtonnes

summary of potential fuel and CO2 emission

2.75 % 37.9 % 4.75 % 559 MLiters 1.94 MMtonnes

savings as a function of tire IPLR. Use of

3.0 % 12.9 % 5.10 % 201 MLiters 0.46 MMtonnes

lower tire IPLR values could generate addi-

3.5 % 0.9 % 5.90 % 16.4 MLiters 0.04 MMtonnes

tional potential savings.

hicles based on the total number of light Latin American countries (18.8 %). However, Asia-Pacific

duty vehicles (the total of passenger vehi- the total number of passenger vehicles per In 2008 there were an estimated four bil-

cles and light commercial vehicles) is similar 1000 people varies significantly: United lion people living in countries within the

for countries in the Americas: United States Sates (770), Canada (655), Mexico (218), Ar- Asia-Pacific region27. An estimated 221.3

(21.2 %), Canada (15 %), Mexico (16.2 %), Ar- gentina (176), Brazil (126) and other Latin million light duty vehicles were in use in

gentina (13.1 %), Brazil (18.8 %), and other American countries (44), Table 1. these countries, which included about

www.kgk-rubberpoint.de KGK · Januar/Februar 2012 49ROHSTOFFE UND ANWENDUNGEN

RAW MATERIALS AND APPLICATIONS

180.3 million passenger vehicles28. The to-

11

tal population and the total number of ve-

hicles used in-service varies widely by

country. For example, the total number of

passenger vehicles per 1000 people varies

significantly: Australia (561), Japan (516),

Taiwan (286), and South Korea (272) have

the highest ratios of passenger vehicles in

the Asia-Pacific region. However, the aver-

age for all countries in this region is only

0.045 passenger vehicles for every 1000

people. China (30 passenger vehicles/1000

people) and India (13) had a significantly

lower passenger car ratio, see Table 4;

however, in 2007 there were about 87.1

million motorized two-wheel vehicles in

China29, excluding electric bicycles and mo-

torcycles, and 64.7 million motorized two-

wheel vehicles in India30. 11 Average Car Fuel Economy in Liters Consumed per 100 km Driven by Region Estimated

The average fuel economy for cars in the Through 2020

Asia-Pacific region is 8.5 liters/100 km in

12

2007, but also varies widely26, see Figure 11.

Using an estimated 10,000 km/year driven

for each car, the average light duty vehicle

consumed 850 liters of fuel each year. Me-

dium/heavy commercial vehicles used in

the region are not a part of this analysis.

The average tire IPLR value worldwide is

2.36 %-loss/month; however, for over 100

tires that were manufactured in the Asia-

Pacific region a value of 2.61 %-loss/month

is obtained. Thus, for approximately 150

tires that were manufactured in plants in

the Americas and Europe the average IPLR

value is 2.2 %-loss/month. Figure 13 shows

the distribution of tire IPLR values. 12 Average Car Fuel Economy in Liters Consumed per 100 km Driven by Region Estimated

Using these values, a yearly savings of 1.05 Through 2020

billion liters of fuel is calculated if tire infla-

tion pressure loss rates did not exceed Area Billion liters of fuel Million metric tonnes of CO2

2.5 %-loss/month for any light duty vehicle United States 1.22 2.84

tire. In addition, 2.4 million metric tonnes of Americas 0.35 0.79

CO2 emissions could also be prevented. This Europe 1.15 2.63

is equivalent to taking approximately 1.24 Asia-Pacific 1.05 2.40

million light duty vehicles off the road in 3.77 8.66

Asia-Pacific countries. Table 5 is a summary

of potential fuel and CO2 emission savings

References

as a function of tire IPLR. Use of lower tire [1] G. J. van Amerongen, Rubber Chemistry Technol- [8] W.H.Waddell, R.C.Napier, D.F.Rouckhout, D.S.Tracey

IPLR values should generate additional po- ogy, Rubber Reviews 37 (1964) 1065. and U.Karmarkar, Rubber World 238 (6), (2008) 21.

[2] D. J. Plazek and K. L. Ngai, Macromolecules, 24 [9] Standard Test Method for Static Testing of Tube-

tential savings.

(1991) 1222. less Pneumatic Tires for Rate of Loss of Inflation

[3] E. N. Kresge and H.-C. Wang, “Butyl Rubber” in Pressure” ASTM F1112 - 06

SUMMARY “Kirk-Othmer Encyclopedia of Chemical Technol- [10] U.S. Department of Transportation, TP-139-01,

By requiring that all tires for light duty vehi- ogy”, Fourth Edition, M. Howe-Grant, Editor, May 26, (2005); TP-139-03, March (2007) 6.

cles worldwide, both original equipment John Wiley & Sons, New York 8, (1993) 934. [11] W. W. Waddell and R. C. Napier, “Rubber & Plas-

and replacement market, have a maximum [4] D. S. Tracey and W. H. Waddell, Rubber & Plastics tics News, 14. and July 12. (2010) 20.

tire inflation pressure loss rate of 2.5 %-loss/ News 34, 14, May (2005) 30. [12] B. Lambillotte, “Task 4 Rolling Resistance Testing:

[5] W. H. Waddell, S. W. Botfeld, R. C. Napier, California Energy Commission’s Fuel Efficient

month, it is calculated that significant po-

D. F. Rouckhout and D. S. Tracey, Rubber World Tire Program, presented at the Workshop on The

tential savings in fuel consumed can be ob- 233 (4), (2006) 33. Fuel Efficient Tire Program, December (2007).

tained thus preventing CO2 emissions. Every [6] W. H. Waddell, D. S. Tracey and D. F. Rouckhout, [13] www.fueleconomy.gov

year 3.75 billion liters of fuel can be saved Kautschuk Gummi Kunststoffe 59 (12) (2006) 659. [14] “OEM Tire Size Guide 1998-2007”, J. Garfield,

and 8.66 million metric tonnes of CO2 emis- [7] W. H. Waddell, R. C. Napier, D. F. Rouckhout and Chief Editor, A Bennett Garfield Publication,

sions prevented. D. S. Tracey, Rubber World 236 (2), 36, 40, (2007) 43. Copyright (2007), Tire Guides Inc.

50 KGK · Januar/Februar 2012 www.kgk-rubberpoint.deguy/2010/10/news-release-driving-on-under-

13 inflated-tires.html, October (2010) 13.

[20] J. D. MacIsaac Jr., L. R. Evans, J. Harris, and E. Ter-

rill, “The Effects of Inflation Gas on Tire Labora-

tory Test Performance”, International Tire Expo-

sition & Conference, Akron, OH, September

(2008).

[21] R. C. Napier and W. H. Waddell, Rubber & Plastics

News, 16. November (2009) 30.

[22] Preliminary Regulatory Impact Analysis, NPRM

on Tire Pressure Monitoring System, FMVSS No.

138 (Docket No. 2004-19054-3) (9/16/04) (69FR

55895); Final Regulatory Impact Analysis, Tire

Pressure Monitoring System, FMVSS No. 138

(Docket No. 2005-20586-2) (4/8/05) (70FR 18136).

[23] “Tire Pressure Special Study: Interview Data”,

DOT HS 809 316, August (2001).

[24] “Tires and Passenger Vehicle Fuel Economy. In-

forming Consumers, Improving Performance”,

Transportation Research Board Special Report

(2006) 286.

[25] www.idavette.net/tire_wheel/tire_myths.htm

[26] Exxon Mobil Corporation Information, Fleet Av-

erage PC-Light Trucks LPKM (2007).

13 Distribution of Inflation Pressure Monthly Loss Rates Values for Tires Manufactured in [27] The World Factbook (2008) and (2009) CIA,

the Asia-Pacific Region (purple), and Tires Manufactured in the Americas and Europe www.cia.gov/library/publications/the-world-

(blue) factbook/geos/xx.html

[28] ExxonMobil Chemical Information, Global Tire

[15] W. H. Waddell, R. C. Napier and D. S. Tracey, Rub- [17] w w w. e p a . go v/OM S/clima te/420 f 050 0 4 . Trends (2010).

ber Chemistry and Technology 82 (2009) 229. htm#step1 [29] Beijing Traffic Management Bureau, www.bjjtgl.

[16] C. Lerner, presented at the IQCP - 4th Intelligent [18] Bridgestone Europe NV/SA, www.bridgestone. gov.cn/publish/portal1,tab165/info16307.htm

Tire Technology Conference, Wiesbaden, Ger- eu, March (2009) 10. [30] w w w.transpor t.rajasthan.gov.in/PDF%20

many, October (2008). [19] w w w. c h i c a g o n o w. c o m / b l o g s / t h e - t i r e - Files/.../Table%209.1.pdf

www.kgk-rubberpoint.de KGK · Januar/Februar 2012 51You can also read