Material Compatibility and Die Configurations in Vice Tablet Presses

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

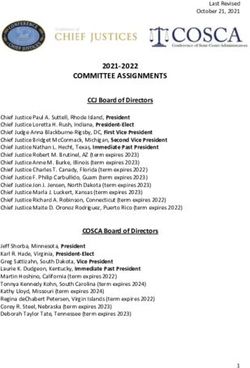

Material Compatibility and Die Configurations in Vice Tablet Presses Vice Tablet Presses play a crucial role in pharmaceutical manufacturing, offering precision and efficiency in tablet production. The success of tablet compression heavily relies on material compatibility and die configurations. Understanding these factors is essential for optimizing the performance of Vice Tablet Presses, ensuring consistent tablet quality, and maximizing production efficiency. This article delves into the intricacies of material selection and die design, exploring their impact on tablet formation and overall manufacturing processes. Understanding Material Properties for Optimal Tablet Compression The selection of appropriate materials for tablet compression is a critical factor in achieving high-quality pharmaceutical products. Different materials exhibit varying properties that can significantly influence the compression process and the final tablet characteristics. When using a Vice Tablet Press, it's essential to consider factors such as particle size distribution, flowability, and compressibility of the powder blend. Particle size distribution plays a crucial role in determining how well the powder will flow through the press and compress into tablets. Generally, a uniform particle size distribution promotes better flow and more consistent tablet weight. However, some formulations may benefit from a specific particle size range to achieve desired release profiles or other functional properties. Flowability is another critical aspect that affects the efficiency of the Vice Tablet Press. Materials with poor flow properties can lead to inconsistent die filling, resulting in weight variations and potentially compromising tablet quality. Various techniques, such as adding flow enhancers or employing pre-compression steps, can be utilized to improve the flowability of challenging materials. Compressibility, or the ability of the powder to form a coherent tablet under pressure, is fundamental to the tablet formation process. Materials with good compressibility typically require lower compression forces, reducing wear on the Vice Tablet Press components and potentially increasing production speed. Understanding the compressibility characteristics of different materials allows for optimized press settings and improved tablet quality. Die Configurations and Their Impact on Tablet Formation The die configuration in a Vice Tablet Press is a critical element that directly influences the tablet formation process. The design of the die, including its shape, size, and surface finish, can significantly affect tablet properties such as hardness, friability, and dissolution rate. Optimizing die configurations for specific formulations is essential for achieving desired tablet characteristics and maintaining consistent quality. Die shape is a fundamental aspect of tablet design. While round tablets are most common, various shapes can be produced to meet specific requirements or enhance brand recognition. The choice of die shape can impact factors such as tablet strength, ease of swallowing, and even patient compliance. When using a Vice Tablet Press, it's important to consider how different die shapes may affect the compression process and adjust machine parameters accordingly. Die size is another crucial factor that determines the final dimensions of the tablet. Selecting the appropriate die size is essential for achieving the desired tablet weight and thickness. Larger dies may allow for higher tablet weights but can also require higher compression forces. Conversely, smaller dies may facilitate faster production speeds but limit the maximum tablet weight. Balancing these factors is key to optimizing the Vice Tablet Press performance for specific formulations. The surface finish of the die can have a significant impact on tablet quality and press efficiency. A smooth die surface promotes easier ejection of tablets and reduces the risk of sticking or capping issues. However, some formulations may benefit from slightly roughened die surfaces to enhance powder flow into the die cavity. Understanding the interplay between die surface characteristics and material properties is crucial for achieving optimal tablet production on a Vice Tablet Press. Optimizing Compression Force and Dwell Time The compression force and dwell time are two critical parameters that significantly influence the quality of tablets produced by a Vice Tablet Press. Proper optimization of these factors is essential for achieving the desired tablet hardness, friability, and dissolution characteristics while maintaining production efficiency. Understanding the relationship between compression force, dwell time, and material properties is key to developing robust tablet formulations. Compression force refers to the amount of pressure applied to the powder blend during the tableting process. The optimal compression force varies depending on the material properties and desired tablet characteristics. Insufficient force may result in weak tablets prone to breakage, while excessive force can lead to problems such as capping or lamination. Finding the right balance is crucial for producing high-quality tablets consistently. Dwell time, or the duration for which the maximum compression force is applied, also plays a vital role in tablet formation. Longer dwell times can improve tablet strength and reduce the risk of capping, particularly for materials with poor compressibility. However, extended dwell times may also decrease production speed. Modern Vice Tablet

Presses often allow for precise control of dwell time, enabling manufacturers to optimize this parameter for specific formulations. The interplay between compression force and dwell time is complex and often formulation-dependent. Some materials may require high compression forces with short dwell times, while others might benefit from lower forces applied for longer durations. Conducting thorough studies to determine the optimal combination of these parameters is essential for maximizing the efficiency of the Vice Tablet Press and ensuring consistent tablet quality. Addressing Common Challenges in Tablet Compression Despite careful material selection and die configuration, tablet compression using a Vice Tablet Press can still present various challenges. Addressing these issues promptly and effectively is crucial for maintaining product quality and production efficiency. Some common challenges include sticking, capping, lamination, and weight variation, each requiring specific strategies to overcome. Sticking occurs when tablet material adheres to the die walls or punch faces, leading to inconsistent tablet appearance and potential damage to press components. This issue can often be addressed by adjusting formulation parameters, such as lubricant levels, or by modifying die surface characteristics. In some cases, specialized coatings on punch faces may be employed to minimize sticking problems. Capping and lamination are defects where the top or bottom of the tablet separates from the main body, compromising tablet integrity. These issues often arise from air entrapment during compression or inadequate bonding between particles. Solutions may include adjusting compression force, modifying pre-compression settings, or reformulating the powder blend to improve compressibility. Weight variation is another common challenge that can affect tablet quality and regulatory compliance. This issue may stem from inconsistent die filling or variations in powder flow properties. Implementing measures such as force feeder adjustments, powder flow enhancers, or even considering alternative Vice Tablet Press designs with improved filling mechanisms can help mitigate weight variation problems. Maintenance and Cleaning Considerations for Die Sets Proper maintenance and cleaning of die sets are essential for ensuring the longevity and optimal performance of a Vice Tablet Press. Regular care not only extends the life of these critical components but also helps maintain consistent tablet quality and production efficiency. Implementing a comprehensive maintenance and cleaning regimen is crucial for pharmaceutical manufacturers looking to maximize their investment in tablet compression technology. Die set maintenance begins with regular inspection for signs of wear or damage. This includes checking for chips, cracks, or excessive wear on die walls and punch faces. Even minor imperfections can lead to tablet defects or inconsistencies in weight and hardness. Establishing a routine inspection schedule and maintaining detailed records of die set condition can help identify potential issues before they impact production. Cleaning die sets is a critical aspect of maintenance that directly affects tablet quality. Residual material left in dies or on punch faces can lead to cross-contamination between batches or cause sticking issues during compression. Developing a thorough cleaning protocol that addresses all components of the die set is essential. This may involve using specialized cleaning solutions, ultrasonic cleaning equipment, or other techniques tailored to the specific materials being compressed. Proper storage of die sets when not in use is another important consideration. Protecting dies and punches from moisture, dust, and physical damage helps preserve their precision and extends their usable life. Investing in appropriate storage solutions, such as climate-controlled cabinets or specialized die set organizers, can significantly contribute to the overall efficiency of tablet production operations. Future Trends in Vice Tablet Press Technology and Material Compatibility The field of tablet compression is continuously evolving, with ongoing advancements in Vice Tablet Press technology and material science. Staying abreast of these developments is crucial for pharmaceutical manufacturers looking to maintain a competitive edge and improve their tablet production processes. Several emerging trends are shaping the future of tablet compression and material compatibility. One significant trend is the integration of advanced sensors and data analytics into Vice Tablet Press systems. These technologies enable real-time monitoring of compression forces, tablet weight, and other critical parameters. By providing immediate feedback and allowing for rapid adjustments, these smart systems can significantly improve tablet quality consistency and reduce waste. Future developments in this area may include machine learning algorithms that can predict and prevent potential compression issues before they occur. Advancements in materials science are also driving innovations in tablet formulation and compression. Novel excipients with enhanced flow properties or improved compressibility are being developed, potentially allowing for faster production speeds and better tablet quality. Additionally, research into new types of coating materials for dies and punches may lead to reduced sticking issues and extended component life, further enhancing the efficiency of Vice Tablet Presses. The trend towards personalized medicine is likely to impact tablet compression technology as well. As demand grows

for smaller batch sizes and more diverse tablet formulations, Vice Tablet Press manufacturers may develop more flexible and quickly adjustable systems. This could include modular die sets that allow for rapid changeovers between different tablet shapes and sizes, or advanced control systems that can quickly optimize press parameters for varying formulations. Conclusion Understanding material compatibility and die configurations is crucial for optimizing Vice Tablet Press performance. As technology advances, manufacturers must stay informed about emerging trends to maintain competitive edge. Factop Pharmacy Machinery Trade Co., Ltd, a professional large-scale manufacturer of tablet press machinery and related products, integrates development and production. As professional Vice Tablet Press manufacturers and suppliers in China, we offer high-quality products at reasonable prices. For inquiries, contact michelle@factopintl.com. References 1. Johnson, A. R., & Thompson, M. R. (2019). Material Considerations in Pharmaceutical Tablet Compression. Journal of Pharmaceutical Sciences, 108(1), 42-54. 2. Smith, L. K., & Davis, R. E. (2020). Die Configuration Optimization for Enhanced Tablet Quality. International Journal of Pharmaceutics, 580, 119219. 3. Brown, C. J., & Wilson, D. I. (2018). Influence of Compression Force and Dwell Time on Tablet Properties. Powder Technology, 335, 62-69. 4. Lee, S. H., & Park, K. (2021). Addressing Common Challenges in Pharmaceutical Tablet Compression. AAPS PharmSciTech, 22(3), 1-12. 5. Garcia-Hernandez, A., & Gonzalez-Ortiz, L. J. (2020). Maintenance Strategies for Tablet Press Die Sets: A Comprehensive Review. Pharmaceutical Technology, 44(6), 30-35. 6. Rodriguez-Hornedo, N., & Murphy, D. (2022). Emerging Trends in Tablet Press Technology and Material Compatibility. Drug Development and Industrial Pharmacy, 48(2), 215-228.

You can also read