SafeBuild: Risk-Based Analysis of Overhead Electric Distribution Facilities

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

SafeBuild: Risk-Based Analysis of Overhead

Electric Distribution Facilities

Jennifer Lew

Palos Verdes Peninsula High School

Rolling Hills Estates, USA

jennlew2004@gmail.com

Abstract—California has experienced increasingly adverse ef- improves upon existing software: for any wind gust inputted by

fects from the failure of overhead electric infrastructure. In the user, SafeBuild calculates the probability that the pole can

2011, in the San Gabriel Valley, 248 utility poles broke, causing successfully withstand the wind gust. SafeBuild calculates the

an outage to 440,000 customers for up to a week. In 2018, a

component on a transmission tower broke, igniting the Camp stress on poles using large deflection finite element analysis.

Fire, which destroyed 18,804 buildings and killed 85 civilians. SafeBuild then calculates the probability of failure of the

The cause of these incidents can be ascribed, in part, to deficient pole using z-scores based on material median strengths and

methods in accurately capturing the probability that a given pole, coefficients of variation. SafeBuild can also calculate the

conductor, or other component can withstand windy conditions increase in conductor tension due to external forces, which will

without breaking. Existing software and methodology do not

account for material strength variability or even calculate a allow users to calculate the probability of failure of structural

possibility of failure based on known local wind speeds. The members, e.g. wood crossarms. Note that while SI units is the

current research believes that it can correct these shortcomings staple in most fields, SafeBuild uses US Customary Units, as

by introducing a program – SafeBuild – that provides the this is the industry standard.

probability that a structure can withstand any given wind gust.

SafeBuild calculates the stress on poles and conductors using II. M ETHODOLOGY

large deflection finite element analysis. SafeBuild calculates the

A. Pole Deformation due to Wind Loading

probability of failure of any component using z-scores based

on material median strengths and coefficients of variation. The In windy conditions, wood poles will deflect due to wind

research successfully created a program that is user-friendly and loading on the exposed surfaces of the wood pole and the

accurate. SafeBuild fits into the bigger picture of utility safety and facilities it supports. One of the greatest forces on the pole

wildfire prevention by allowing users to design poles to withstand

a wind gust to any desired confidence level. results from wind blowing on overhead conductors [1]:

Index Terms—beam element, cable element, large deformation, Fwind,conductor = QKz Kd GCf V 2 A (1)

utility pole, risk analysis, wind loading

In (1), Q is the air density factor, Kz is the velocity pres-

I. I NTRODUCTION sure exposure coefficient accounting for the increase in wind

In California, the failure of electric utility infrastructure has pressure with height above ground, Kd is the directionality

increasingly led to adverse outcomes. From 2017 to 2019, factor accounting for wind direction, G is the gust effect factor

one utility in California ignited 49 wildfires. Of these fires, accounting for spatial averaging, Cf is the drag coefficient

the 2018 Camp Fire alone destroyed 18,804 buildings and of the conductor, and V is the wind gust in miles per hour.

killed 85 civilians. In these cases and others, the cause of Inputting the necessary variables into (1) will yield a point

the incident can be attributed in some part to the failure of force on the pole in units of lbf. Due to forces such as

the facilities to withstand known local wind speeds. In utility those described in (1), a pole will deflect; when this occurs,

pole design, most commercial software will calculate a pole the weight of the supported facilities - such as conductors,

safety factor by taking the pole’s bending moment resistance cables, and transformers - will cause the pole to deflect

and dividing that by the bending moment due to a reference even more via secondary P-∆ effects. Once the deflection

wind load. However, the drawback of this approach is that of the pole is determined, the bending moment along the

there is no agreed upon method for translating a safety factor pole can be calculated and compared to the bending moment

into a wind speed; indeed, there is not even agreement on resistance along the pole. The current research uses finite

the definition of the term safety factor. Further, the software element analysis [2] to calculate the pole’s deflection, wherein

calculates the bending moment resistance of the pole using the the pole is modeled as a series of elements [3]. Figure 1 shows

median wood fiber strength; as a result, there is a 50% chance an example of a utility pole modeled using three elements,

that the pole safety factor is less than the calculated result. In which is numbered sequentially starting with Element 1 at

sum, a clear result such as “this wood pole can withstand a 112 the base. Using n to denote the index, we note that every

mile per hour wind gust with a 95% probability of success” Element n has, at its tip, a node n (with the remaining node

is not achievable via existing software. The current research 0 representing the base of the pole at ground level). At each

has developed a structural design software – SafeBuild – that node n, a horizontal force Fy,n and a vertical force Fx,n can beAs the pole bends, the base of each element rotates. For an

Element n, the rotation matrix is given as follows:

cosφn−1 −sinφn−1 0 0 0 0

sinφn−1 cosφn−1 0 0 0 0

0 0 1 0 0 0

λn =

(4)

0 0 0 cosφn−1 −sinφn−1 0

0 0 0 sinφn−1 cosφn−1 0

0 0 0 0 0 1

The global element stiffness matrix, which accounts for the

aforementioned rotation, can then by calculated as follows:

kn,global = λn · kn · λn T (5)

Fig. 1. Finite element representation of a utility pole.

The global element stiffness matrices for all the elements can

then be combined to form a global stiffness matrix K, as

applied, where the orientation of the x-axis and y-axis has been shown in Fig. 2. Next, the force matrix captures the horizontal

reversed to maintain the convention used in beam bending. force, vertical force, and moment applied at all the nodes.

After forces are applied, the pole will deflect. At each node n, Assuming that the pole is composed of m elements, the force

the horizontal deflection with respect to the base of the pole is matrix is given by:

δy,n , the vertical deflection with respect to its undeformed state

Fx,1

is δx,n (not shown in Figure 1), and the angle of deflection

with respect to vertical is denoted as φn . As shown in Figure

Fy,1

1, the horizontal and vertical deflections can also be broken

down to an element level; that is to say, the deflection of

Mθ,1

an Element n can be found by calculating the deflection at

..

node n with respect to node n − 1. These deflections, which F =

.

(6)

we call element horizontal and vertical deflections, are given

by δy,elem n and δx,elem n , respectively. For Element 1, the Fx,m

element stiffness matrix is given as follows:

Fy,m

AE1

0 0

L1

Mθ,m

12EI1 −6EI1

k1 = 0 L1 3 L1 2

(2)

In (6), Mθ,n represents the moment applied at node n, if any.

−6EI1 4EI1

The displacement matrix, which captures the deflections at all

0 L1 2 L1 the nodes, is given as follows:

In (2), AE1 represents the cross-sectional area of Element 1 δx1

multiplied by the modulus of elasticity of Element 1 and is

in units of lb, EI1 represents the flexural rigidity of Element δy1

1 in lb-f t2 , and L1 represents the length of Element 1 in ft.

The element stiffness matrix for each subsequent element is φ1

given as follows: ..

.

d= (7)

−AEn

AEn

Ln 0 0 Ln 0 0

δx,m

12EIn 6EIn −12EIn 6EIn

0 Ln 3 Ln 2

0 Ln 3 Ln 2

δy,m

6EIn 4EIn −6EIn 2EIn

0 Ln 2 Ln 0 Ln 2 Ln

kn = (3)

−AEn

0 0 AEn

0 0 φm

Ln Ln

The values in the displacement matrix d can be solved using

−12EIn −6EIn 12EIn −6EIn

0 Ln 3 Ln 2

0 Ln 3 Ln 2 the equation:

0 6EIn 2EIn

0 −6EIn 4EIn d = K −1 F (8)

Ln 2 Ln Ln 2 LnIn (8), the calculated horizontal deflection values δy,n is

considered accurate; however, the calculated vertical deflection

values δx,n is considered to have inaccurately captured the

downward deflection of the elements. However, the values

for δx,n can be corrected. Looking at a single element, the

horizontal deflection of the element is given by:

δy,elem n = δy,n − δy,n−1 (9)

The value in (9) can then be substituted into the following

equation to yield the corrected vertical downward deflection

on a per element basis:

s 2

δy,elem n

δx,elem n = Ln − Ln 2 − (10)

0.91879

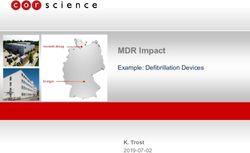

Fig. 3. Model of the conductor using finite elements.

The accuracy of the process in (9) and (10) was validated

against known beam bending experiments [4]. Once the deflec-

tion curve of the pole is fully known, the bending moment BM B. Conductor Deformation due to External Forces

in lb-ft at any point along the pole can be found. If we assume As shown in Fig. 3, a conductor can be modeled using m

that BM is calculated at the pole’s groundline (commonly elements, where each element can be numbered sequentially

the weakest point of a typical distribution pole), then BM starting with Element 1 at the left attachment point. The con-

will need to be compared to the bending moment resistance ductor’s left and right attachment points will be Node 0 with

BMres at groundline. The bending moment resistance of the coordinate (x0 , y0 ) and Node m with coordinate (xm , ym ),

pole, in lb-ft, at its groundline is given as follows: respectively. Using n to denote the index, an Element n has an

axial force of Nn and a length of Ln . As an initial condition,

BMres = 0.000264Cg 3 (1 − z · CV ) Fb,med (11) the coordinates of the nodes should represent the curvature

of the conductor at the time of installation. The length Ln of

In (11), Cg represents the pole’s groundline circumference in element n is given as follows:

inches, z is the z-score, CV is the coefficient of variation of q

2 2

the wood species, typically given as 0.2 [5], and Fb,med is Ln = (xn − xn−1 ) + (yn − yn−1 ) (12)

the wood’s median fiber strength in psi. The value of z in

The axial force of Element 1 can be found as follows:

(11) shall be adjusted until BMres just equals the bending

moment BM at the same point. Then, a table of z-scores can R0 L1

N1 = (13)

then be referenced to determine the probability that the pole y1 − y0

can withstand the bending moment imposed by the wind gust. In (13), R0 is the reaction force at Node 0 in the conductor’s

initial condition, which is equivalent to the vertical component

of tension at the left attachment point. The axial force of every

element except the first element is given by:

xn−1 −xn−2

Nn−1 · Ln−1

Nn = xn −xn−1 (14)

Ln

The direction cosine for Element n is given by:

xn − xn−1

cn = q (15)

2 2

(xn − xn−1 ) + (yn − yn−1 )

The direction sine for Element n is given by:

yn − yn−1

sn = q (16)

2 2

(xn − xn−1 ) + (yn − yn−1 )

The stiffness matrix for Element n is given by:

ka,n −ka,n

Fig. 2. Global stiffness matrix.

kn = (17)

−ka,n ka,nwhere: TABLE I

" # " # CONDUCTORS AND EQUIPMENT SUPPORTED ON THE

EA cn 2 cn sn Nn (1 − cn 2 ) −cn sn EXAMPLE POLE

ka,n = + (18)

Ln cn sn sn 2 Ln −cn sn (1 − sn 2 ) Conductor Attachments

Left Right Diameter Heightb Weight No. Type

The element stiffness matrices can be combined together to Span Span or

Lengtha Length Density

create a global stiffness matrix K via the same method shown 400 ft 300 ft 0.25 in 44 ft 0.2 lb/ft 3 Wire

in Fig. 2. At each Node n, forces can be applied that represent 400 ft 300 ft 0.50 in 33 ft 0.5 lb/ft 1 Wire

external forces such as a falling tree branch. If we use Fx,n 400 ft 300 ft 0.75 in 24.5 ft 1 lb/ft 1 TV

cable

and Fy,n to denote the forces on Node n, then the force matrix 400 ft 300 ft 0.50 in 20.3 ft 0.5 lb/ft 1 Phone

will be as follows: cable

Equipment Attachments

Fx,1 0 0 0 37.5 ft 600 lb 1

a Length of the conductor span to the left or right of the pole.

XFMR

b Attachment height of the conductor or equipment on the pole.

Fy,1

..

F =

.

(19)

If the out-of-balance forces are significant, then a further nodal

Fx,m−1 displacement can be found as follows:

Fy,m−1 q = K −1 ∆F (24)

It is expected that values in (19) are sufficiently large to ensure Using (24), the nodal coordinates can be updated as many

that K does not reach singularity. With this understanding, the times as necessary to achieve accuracy. The final axial forces

forces in (19) will cause the conductor to deform such that the in all the elements will be given by (13) and (14).

coordinates of a Node n will change. This is captured in the III. R ESULTS

nodal displacement matrix, q:

A. Wind Loading of a Utility Pole

∆x1 A utility pole is wind loaded in three trials. The Class 4 pole

has a length of 50 feet, with 6 feet underground. The facilities

∆y1

supported on the pole (e.g. conductors, cables, transformers),

..

shown in Table I, is identical for all trials. For Trial 1, the pole

q=

.

(20)

is Red Cedar (median fiber strength of 5800 psi) and the wind

gust is 112 mph. The results in Fig. 4 show that the pole has

∆xm−1

an 8.69% chance of withstanding the wind. For Trial 2, the

∆ym−1 pole is Douglas Fir (median fiber strength of 8000 psi) and the

wind gust remains 112 mph. The results in Fig. 5 show that

Notice that (19) and (20) do not include forces and displace- the pole has a 67.36% chance of withstanding the wind. For

ment values, respectively, for the attachment points at Node Trial 3, the pole is Douglas Fir and the wind gust is lowered to

0 and Node m as these points are fixed. The displacement 92 mph. The results in Fig. 6 show that the pole has a 97.13%

matrix q can then be calculated as follows: chance of withstanding the wind.

q = K −1 F (21)

Solving for (21) is just the first step in solving for the

deformation of the conductor due to external forces. Once q

is known, all the nodal coordinates (xn , yn ) need be updated.

Once this is done, any out-of-balance force can be found by

applying force equilibrium at the nodes. For example, the out-

of-balance force in the x-direction at Node 2 can be found as

follows:

−N2 (x2 − x1 ) N3 (x3 − x2 )

∆Fx,2 = + + Fx,2 (22)

L2 L3

The out-of-balance force in the y-direction at Node 2 can be

found as follows:

−N2 (y2 − y1 ) N3 (y3 − y2 ) Fig. 4. Trial 1: The pole has an 8.69% chance of not breaking.

∆Fy,2 = + + Fy,2 (23)

L2 L3Fig. 5. Trial 2: The pole has a 67.36% chance of not breaking.

Fig. 7. Conductor in installation stage.

Fig. 6. Trial 3: The pole has a 97.13% chance of not breaking.

B. Tree Branch Falling on an Overhead Conductor

Assume an American Wire Gauge (AWG) No. 6 copper

conductor is supported by poles installed 660 feet apart. The Fig. 8. Tree branch falling on conductor.

conductor height on the left and right pole is 34 feet and 39

feet, respectively. The installation tension is 610 lbf. This is

SafeBuild can also prevent utility poles in low wind areas from

shown in Fig. 7. Assume a 25 lb tree branch falls 30 ft onto

being overbuilt, thereby saving money.

the conductor at a distance d = 330 ft, as shown in Fig. 8.

Per SafeBuild, this produces an average impact force of 100.5 ACKNOWLEDGMENT

lbf, which will cause the tension in the conductor to increase The author thanks her advisor, Derek Fong, PE, Senior

to 1004.5 lbf. As the tensile strength of AWG No. 6 medium Utilities Engineer Supervisor at the California Public Utilities

hard drawn copper is 1000 lbf, the conductor will break. Commission, for his technical guidance, editing, and direction.

IV. C ONCLUSION R EFERENCES

Current design tools calculate a pole safety factor based [1] M. M. Alam, B. E. Tokgoz, and S. Hwang, “Framework for measuring

the resilience of utility poles of an electric power distribution network,”

on a reference wind load. However, safety factors cannot be Int. J. Disaster Risk Sci., vol. 10, pp. 270–281, 2019.

easily translated to a wind speed. Instead of generating a safety [2] N. Kim and B. V. Sankar, Introduction to Finite Element Analysis and

factor, SafeBuild calculates the probability that a pole can Design. New York, NY: John Wiley & Sons, 2009.

[3] B. L. Barton, M. S. Shetty, V. Birman, and L. R. Dharani, “Tapered

withstand a given wind gust. Thus, SafeBuild can be used to cylindrical cantilever beam retrofitted with steel reinforced polymer or

design an electric system using a risk-based methodology. For grout,” Composites: Part B, vol. 42, pp. 207–216, 2011.

example, an engineer can use SafeBuild to design all poles [4] C. Neipp and A. Belendez, “Large and small deflections of a cantilever

beam,” Eur. J. Phys., vol. 23, pp. 371–379, May 2002.

to have a 99% probability of withstanding the greatest 50- [5] R. W. Wolfe and R. O. Kluge, “Designated fiber stress for wood

year wind gust in a given area. SafeBuild can prevent utility poles,” U.S. Department of Agriculture, Forest Service, Forest Products

poles from being underbuilt, thereby enhancing public safety; Laboratory, Madison, WI, USA, Gen. Tech. Rep. FPL-GTR-158, 2005.You can also read