Subaru Boxer Diesel First Four-Cylinder Horizontally-Opposed Diesel Engine

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

DEVELOPMENT New Engines

Subaru Boxer Diesel

First Four-Cylinder Horizontally-

Opposed Diesel Engine

The integration of the horizontally-opposed engine and the functional principle self-ignition is a

technical challenge. With the series production of the first boxer diesel engine for passenger

cars Subaru has achieved a technological breakthrough. While producing maximum power of

110 kW and maximum torque of 350 Nm, the carbon dioxide (CO2) figure of the 2.0 l four-cylinder

diesel engine is 148 g/km. Low noise, low vibration and compactness are among its features.

38 MTZ 09I2008 Volume 69The Author

1 Introduction The core-technology is not possible with- Kenji Harima

out a boxer engine: Its low height ensures is Staff Manager,

Subaru, the automotive brand owned by a low centre of gravity and a nearly ideal Engine Design Depart-

Fuji Heavy Industries, has delivered hori- weight balance. The horizontally-opposed ment at Fuji Heavy

zontally-opposed petrol engines to the diesel engine is provided to European Industries Ltd. in Tokyo

market since 1966. In 1989, the second- markets since March 2008 on the models (Japan).

generation horizontally-opposed petrol Legacy and Outback.

engines were developed and installed se-

quentially on Legacy, Impreza and Forest-

er. These engines have convinced with 2 Aim of the Development

driving pleasure and comfortable touring

space, as well as driving performance re The aim of the development of boxer die-

presented in the World Rally Champion- sel engine was to create an environmen-

ship. The Subaru boxer diesel engine has tally-friendly engine with specific Subaru-

been newly added to the line-up, Figure 1. performance, driving dynamics and low

It integrates the technologies of fuel injec- CO2 emissions. With the latest common

tion, supercharging and exhaust gas after- rail system, a variable geometry turbo-

treatment, together with the technology charger and a large Exhaust Gas Recircu-

of horizontally-opposed engines. Clear lation (EGR) cooler, it responds to the re-

target was the development of a diesel en- quests in Europe for environmental pro-

gine without sacrificing the benefits of tection and engine performance. In order

the Symmetrical All Wheel Drive (AWD). to make use of the features of horizontal-

Figure 1: Subaru

boxer diesel engine

MTZ 09I2008 Volume 69 39D evelopment New Engines

Table 1: Specifications of the engine

EE20 Boxer Diesel EJ20 (Petrol) EZ30 (Petrol)

Displacement cc 1998 1994 2999

Maximum Power kW (PS)/rpm 110 (150)/3600 110 (150)/6000 180 (245)/6600

Maximum Torque Nm (kgfm)/rpm 350 (35.7)/1800 196 (20.0)/3200 297 (30.3)/4200

CO2 Emission (g/km) 148 (Saloon MT) 202 (Saloon MT) 286 (Saloon MT)

Fuel Economy l/100 km 5.6 (Saloon MT) 8.6 (Saloon MT) 12.1 (Saloon MT)

Compression Ratio 16.3 10.2 10.7

Bore x Stroke mm 86.0 x 86.0 92.0 x 75.0 89.2 x 80.0

Bore Pitch mm 98.4 113 98.4

Bank offset mm 46.8 54.5 46.8

Deck height mm 220 201 202

Diameter of Journal mm ø 67 ø 60 ø 64

Diameter of Pin mm ø 55 ø 52 ø 50

Con-rod Pin Distance mm 134 130.5 131.7

Diameter of Piston Pin mm ø 31 ø 23 ø 22

Compression Height mm 43 33.5 30

Fuel System Common Rail MPI MPI

Turbocharger Variable Turbo – –

EGR Liquid Cooling – –

DPF Open Type – –

Engine Length mm 353.5 414.8 438.4

ly-opposed engines, the development – reduced weight 3 Specifications of the Engine

placed emphasis on the followings: – compactness

– low noise, low vibration and high live- – high rigidity Table 1 shows the boxer diesel engine’s

liness – low centre of gravity major specifications in comparison with

– direct and sporty response – fuel economy. petrol engines. Figure 2 shows a cross-sec-

Figure 2: Cross-section of the Subaru boxer diesel engine

40 MTZ 09I2008 Volume 69tion of the engine. In order to fulfil the Table 2: Comparison of inertia force and moment

aim of the development the following

technologies have been adopted: H4 engine

– compact design 1st-order 0

Unbalanced inertia force

– low friction and low inertia moment 2 -order

nd

0

– lightweight and highly-rigid cylinder

1st-order 0

block and crankshaft Unbalanced moment

2 -order

nd

– 2mrec ω rs1 / λ cos2θ

2

– common rail system with 1800 bar

fuel injection pressure L4 engine

– lightweight, compact and dedicated 1 -order

st

0

Unbalanced inertia force

solenoid injectors 2nd-order 4mrec ω2r1 / λ cos2θ

– variable geometry turbocharger

1st-order 0

mounted underneath the engine Unbalanced moment

2nd-order 0

– exhaust gas aftertreatment system

installed downstream of the turbo- mrec: reciprocating weight; ω: crank angle speed; θ : crank angle;

charger. r: crank radiator; λ: connecting-rod lenght / crank radiator; s: bank offset

Owing to its mechanical system proper-

ties, a horizontally-opposed engine does

not produce any unbalanced inertia forc-

es from the reciprocating piston system gine, the turbocharger is placed under- conditions, the oxidation catalytic con-

weight. Table 2 shows the unbalanced in- neath the front right side of the engine. verter generates nitrogen dioxide (NO2)

ertia forces and unbalanced moments – In addition, the variable geometry turbo- which oxidise the collected diesel par-

first- and second-order – compared be- charger enables efficient supercharging ticulate inside the DPF. In addition, an

tween a four-cylinder horizontally-op- in all operating ranges, controlling the EGR cooler is adopted for Nitrogen oxide

posed (H4) engine and a four-cylinder in- exhaust turbine’s vane opening angles (NOx) reduction to comply with Euro 4

line (L4) engine [1]. Note that engine’s according to the operating conditions. emissions standard.

rolling moments are not included in Placed closely downstream of the tur- The fuel system adopts a common rail

Table 2, both for H4 and L4. bocharger is the exhaust gas aftertreat- system with maximum fuel pressure of

The second-order unbalanced inertia ment converter with an oxidation cata- 1800 bar [2]. It consists of a high-pressure

force of an L4 diesel engine is large, more lyst and an open Diesel Particulate Filter fuel pump and eight-hole solenoid injec-

than 10 kN at 4000 rpm. On the other (DPF) inside. This layout has shortened tors placed at each cylinder, capable of

hand, the second-order unbalanced mo- the warm-up time of the catalyst to acti- multiple injection events. Compact-size

ment of the boxer diesel engine (H4) is vate in a cold condition, enhancing the solenoid injectors were developed exclu-

around 250 Nm at 4000 rpm, having emissions conversion performance in sively for the boxer diesel engine, in or-

little impact on engine vibration. Thanks wide ranges. The oxidation catalytic con- der to make the engine width equivalent

to such good engine vibration character- verter has been positioned below the en- to that of petrol engines.

istics, the boxer diesel engine does not gine together with the turbocharger. It The combustion chamber is of a re-

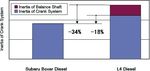

need a balance shaft, and realises low in- separates unburnt fuel into water and entrant type. Together with atomisation

ertia moment, low friction and reduced CO2. The unit has been made compact characteristics and swirls in the combus-

weight, Figure 3. enough to be activated soon after the en- tion chamber, it has allowed the fuel

For achieving good diesel combus- gine has been started. If the temperature economy, engine performance and emis-

tion, the piston stroke of the boxer diesel rises to 250° C under certain driving sions performance to be satisfied at the

engine has been extended compared to

that of an H4 petrol engine. The engine

overall width is kept equivalent to the H4

petrol counterpart, ensuring the mount-

ing capability to existing vehicles. With a

shortened bore pitch, the engine overall

length is 61.3 mm shorter than that of

an H4 petrol engine. This has made the

boxer diesel engine more compact than

its H4 petrol counterpart.

For better performance of exhaust gas

purification and a lower centre of gravity,

the turbocharger layout has been revised.

In an H4 petrol engine, the turbocharger

is placed above the back right side of the

engine. In the Subaru boxer diesel en- Figure 3: Comparison of the inertia moment on the crankshaft system

MTZ 09I2008 Volume 69 41D evelopment New Engines

4.1.2 High Balance

Performance by Boxer Layout

A boxer engine balances out the inertia

force of reciprocating parts. Therefore, a

secondary balancer system is unneces-

sary. Compared to an L4 engine with sec-

ondary balancer system, the second or-

der engine vibration is low, from low- to

high-speed ranges, Figure 5.

4.1.3 Low Vibration by

Highly Rigid Crankshaft

Figure 4: Study of combustion chamber shape by CFD The crankshaft of a boxer engine is short-

er in overall length, and thus more rigid,

compared to that of an L4 engine. When

the rigidity is low, the crankshaft causes

same time. The compression ratio is mass f lywheel clutch system is em- resonant torsional vibration in high-speed

16.3:1, and the maximum combustion ployed to reduce noise and vibration in range of actual driving, which results in

pressure is 18 MPa. For the study of the drivetrain. In many of the front-en- engine vibration. On the contrary, with a

combustion chamber shape, Compu gine rear-drive vehicles, the rubber cou- boxer engine, the crankshaft’s resonant

tational Fluid Dynamics (CFD), Figure 4, pling mechanism of propeller shafts torsional vibration does not occur in high-

has been utilised. absorbs noise and vibration in the driv- speed driving, Figure 6. Therefore, the inte-

etrain. This mechanism, however, re- rior noise is clear even at high speed.

duces the rigidity of the drivetrain. Even

4 Characteristics of the Engine if a dual mass flywheel clutch system is 4.1.4 Reduced Combustion Noise

employed, many resonance points are For reducing combustion noises that are

4.1 Low Noise, Low Vibration generated, which would cause the specific to diesel engines, dedicated

and High Liveliness booming noise of 100 Hz or less. On the acoustic shields are employed for the cyl-

The combination of the Symmetrical contrary, the Symmetrical AWD system inder block, intake manifold and trans-

AWD and the boxer principle has maxim- can absorb the diesel engine’s large mission housing case, all of which are

ised the potential of the engine that works torque fluctuations with its four wheels. main sources of radiation. This has de-

favourable to noise and vibration perform- Therefore, the vibration at each part creased the combustion noise of the

ance, and has successfully decreased the that suspends the drivetrain is small. In power unit as a whole, Figure 7, and real-

noise specific to diesel engines. This real- addition, since it is a highly rigid drive- ised a quiet diesel engine at idling and in

ises small noise and vibration in all ranges train system that does not use rubber all speed ranges.

from idling to high speed. coupling, there are only a few resonance

points that cause the booming noise of 4.2. Direct and Sporty Response

4.1.1 Highly Rigid Drivetrain 100 Hz or less. Thus, a pleasant interior

by Symmetrical AWD noise is realised from the very start of 4.2.1 Engine Output Performance

To deal with the large torque fluctua- the driving, with low vibration and no The engine develops a maximum output

tions of diesel engines, a dedicated dual booming noise. of 110 kW at 3600 rpm and a maximum

Figure 5: Engine vibration (second order) Figure 6: Engine vibration (sixth order)

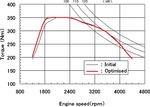

42 MTZ 09I2008 Volume 69Figure 7: Engine noise (octave sound pressure level 2 kHz) Figure 8: Engine output performance

torque of 350 Nm at 1800 rpm. While the 4.2.3 Acceleration Performance and is superior to those of other passen-

torque curve gradually starts to descend The developers of the boxer diesel en- ger car diesel engines of the same dis-

in the latter half of 2000 rpm, the output gine focused on intensive tuning for placement.

keeps increasing, even after the peak of controllability, aiming at an accelera-

3600 rpm, the engine will revolve briskly tion feel linear to the acceleration pedal 4.3 Compactness and High Rigidity

up to the rev limit of 4750 rpm, Figure 8. stroke. The acceleration time in second

This is characteristic for the Subaru box- and top gear is the evaluation index for 4.3.1 Basic Configuration of the Engine

er diesel engine. the engine muscularity in low- and mid- The basic configuration of an H4 engine

Compared to an L4 engine, the crank- speed ranges frequently used in Euro- enables a compact, lightweight and

shaft is 50 % lighter in weight and the pean roundabouts and Autobahns. The highly rigid design compared to an L4

rotational inertia is reduced by 18 %. Con- acceleration performance of the boxer engine. It offers a good noise and vibra-

sidering the elimination of the balance diesel engine outweighs that of a natu- tion behaviour, engine performance and

shaft, the inertia moment is reduced by rally-aspirated petrol engine of Subaru, fuel economy. In order to make the

34 %. With such low inertia, the boxer

diesel engine has achieved good response

to the accelerator pedal position.

4.2.2 Turbocharger

A variable geometry turbocharger is em-

ployed, which is capable of an optimum

control of the exhaust gas flow at the

turbine inlet according to the operating Figure 9: Variable

range, Figure 9. geometry turbocharger

While the engine extensibility at

high speed was already sufficient with

the engine specification in the mid-de-

velopment stage, emphasis was put fur-

ther on the turbine size and the specifi-

cation of variable vanes in order to real-

ise the engine flexibility, responsiveness

and driving feel for controllability at

low speed. Thus, the torque at 1800 rpm

and below by a maximum of 20 Nm

could be improved, as well as the tran-

sient characteristics.

An intended low-speed performance

has been realised, while maintaining the

maximum output and other high-speed

performance.

MTZ 09I2008 Volume 69 43D evelopment New Engines

Figure 10: Motoring bility with a narrower width of the bear-

friction ing compared to an in-line engine.

4.3.4. Cylinder Head and Valve System

High strength cylinder heads have been

used to withstand the high combustion

pressures. Compact and low friction end

pivot type roller rocker arms have been

used in combination with a Double Over-

head Cam system. The diameter of the

intake valves has been optimised for en-

hanced breathing performance and swirl

ratios, resulting in improved combustion

efficiency. The combination of an intake

swirl port system and optimised intake

valve diameter results in ample swirl per-

stroke longer than that of an H4 petrol H4 petrol engines. The block design uses formance. A highly durable chain system

engine while keeping the engine overall the semi-closed deck type that has proven has been used to drive the camshaft to

width equivalent to a petrol engine, the its durability in the turbocharged petrol handle the variations in torque produced

service hole in the cylinder block, which models. This increases rigidity around by the diesel engine.

served as a guide in assembling the pis- the head gasket mating areas.

ton pin and the connecting rod, was 4.4 Fuel Economy and Engine Friction

eliminated and instead a diagonally frac- 4.3.3 Crankshaft For less CO2 emissions, the friction loss is

ture-split connecting rod employed, The deflection of the crankshaft under a kept at a low level. Since a horizontally-

whose cap is assembled from the oil pan high combustion pressure is smaller in a opposed engine counteracts the second-

side. This minimised the increase of the horizontally-opposed engine than in an order acceleration of reciprocating iner-

cylinder deck height. in-line engine, since the span of the main tia weights such as pistons, and thus al-

The large ends of the connecting rods journal receiving the load is shorter. lows the absence of the balance shaft

feature an asymmetrical profile, which Therefore, the load at the bearing end is and the system that drives it, the friction

increases precision during assembly and reduced, where the oil film thickness is loss is reduced. The roller rocker arm is

in roundness of the surface connecting at smallest. This has led to higher relia- adopted in the valve system and also low-

the crankpin for reduced friction. It has viscosity lubricating oil is employed. All

also contributed to minimise the rota- together, a friction of the boxer diesel en-

tional path thus enabled to employ an gine could be achieved, which is among

extended piston stroke inside the compact

Krupp ahead of Subaru? the lowest level among the 2.0 l class

The world’s first boxer diesel engine for a pas-

cylinder block. Moreover, the compres- cars, Figure 10.

senger car, which was described as a “revolu-

sion height has been reduced by adopting The specific fuel consumption has

tion” by Subaru, does in fact have a predeces-

the pistons made of high-strength alu- been lowered in all speed ranges, by re-

sor, although not in a car. Exactly 75 years ago in

minium alloy and by lowering the piston ducing friction in the engine hardware,

1933, Krupp launched a boxer diesel for light

temperature with forced oil cooling using and by calibrating the engine to satisfy

trucks. Like the Japanese engine, Krupp’s ver-

cooling channel. In addition, the cylinder both fuel economy and performances in

sion also had a cast aluminium crankcase and,

head height has also been reduced. All to- to save weight, the designer Adolf Roth (1892-

a most balanced way. As a result, the CO2

gether the new boxer diesel engine is 1966) used air to cool the engine. The result was figure of the Legacy is 148 g/km, which is

compact with an overall width equivalent the industry’s lightest engine (325 kg, compared among the lowest in 2.0 l class cars, de-

to that of an H4 petrol engine. to Subaru’s 160 kg, wet) and a power-to-weight spite the fact that it is an AWD saloon.

ratio of 6.5 kg/PS (Subaru 1.07 kg/PS).

4.3.2 Cylinder Block A further highlight was the fact that the diesel 4.5 Overview of the Control System

The cylinder block in a horizontally-op- engine could be easily converted back into its

posed engine is lightweight and highly original form as a petrol engine (1932) by replac- 4.5.1 System and Hardware

rigid. For higher strength and rigidity all ing a few parts. Turbocharging, which gives the The Engine Control Unit (ECU) employs

five main journals in the cylinder block Subaru engine an extremely agile response, the supplier’s standard ECU hardware,

incorporate metal matrix composite was not introduced by Roth until 1934 – for the allowing a significant cost reduction.

journals which are inserted during the two-stroke version, which had a specific output Systems other than the fuel injection

casting process, resulting in higher lev- of 20 PS/l (Subaru 75 PS/l). Although the figures system, such as the communication sys-

els of quietness due to its high rigidity prove that a good deal of evolution has taken tem, the air conditioner, the radiator

and similarity in the thermal expansion place, Subaru can count itself lucky that Krupp fan and the cooperative control with the

ratio to that of crankshaft. This is a tech- never built cars. Erik Eckermann Antilock Brake System and the Vehicle

nique that has already been validated in Dynamics Control systems, are shared

44 MTZ 09I2008 Volume 69injection pattern change, the correc-

tion control of cylinder-to-cylinder dis-

persions and the learning control for

micro injection quantity as described

above was adopted.

5 Summary

Figure 11: Multiple injection events Subaru has launched the series produc-

tion of the first boxer diesel engine for

passenger vehicles and has begun to pro-

vide it to European customers in 2008 on

with the current petrol engine vehicles written into the ECU during vehicle the models Legacy and Outback. In addi-

so that revisions are minimised and the assembly to conduct the correction of tion to the high engine performance and

original ECU potential suited to the Leg- injection quantity. responsiveness, the low noise and vibra-

acy is maintained. – Learning control of micro-injection tion and the fuel economy have been bal-

quantity: It is important to enhance ac- anced at a high level. Although Subaru

4.5.2 Controls curacy of pre-injections and after-injec- was a latecomer in diesel engines, the de-

The injector is capable of multiple injec- tions. To fulfil this, injectors undergo velopers focused on the proprietary tech-

tion events, up to five injections in one learning controls. During stable idling, nology, which led to the creation of an

stroke, Figure 11. It is important for the the dispersion of injection is measured unprecedented horizontally-opposed die-

injector to inject the fuel in high accura- for each injector of all four cylinders, sel engine that possesses sufficient com-

cy so that low noise and vibration of the and then used for correcting the injec- petitiveness and product performance

boxer diesel engine is realised. There are tion amount. Since this learning con- for success in the international markets.

two measures taken for this purpose: trol is an essential factor for the prod-

– Injector Qick Response (QR) Code writ- uct performance of the vehicle, it is

ten into ECU: The dispersion data of conducted at the time of shipment References

each injector’s properties are printed from the plant, and also on regular ba- [1] Society of Automotive Engineers of Japan, Inc.:

in the form of a QR Code (a two-di- sis when the customer is driving the Jidosha Gijutsu Handbook (Handbook of

mensional bar code) at the top of the vehicle. Based on the precise setting Automotive Engineering Handbook). Tokyo:

Society of Automotive Engineers of Japan, Inc.,

injector. In the engine plant, the code and calibration of fuel injection pat-

2004

reader reads the QR Codes for all cyl- tern, the tailing process, the gradually [2] Tanaka, Y.; Nagata, K.: 1800 bar Common Rail

inders of the assembled engines. Later changing of the injection quantity at System for Diesel Engines. In: DENSO Technical

in the vehicle plant, these data are each injection event at the time of fuel Review (2006), Vol. 11, No. 1

MTZ 09I2008 Volume 69 45You can also read