3D-Printed Titanium Plates for Complex Heart Defect Repairs

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

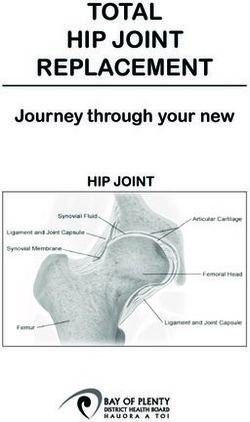

3D-Printed Titanium Plates for Complex Heart Defect Repairs The field of cardiac surgery has witnessed a revolutionary advancement with the introduction of 3D-printed titanium plates for complex heart defect repairs. This groundbreaking technology has transformed the landscape of Titanium Plate Heart Surgery, offering hope to patients with intricate cardiac abnormalities. By leveraging the precision of 3D printing and the biocompatibility of titanium, surgeons can now create custom-tailored solutions for each patient's unique anatomical requirements. These innovative titanium plates provide structural support and facilitate the correction of congenital heart defects, ensuring improved outcomes and reduced surgical risks. The integration of 3D- printed titanium plates in cardiac procedures has opened new possibilities for treating previously challenging cases, allowing for more accurate reconstructions and potentially life-saving interventions. As the medical community continues to explore the potential of this technology, patients with complex heart defects can look forward to more personalized and effective treatment options. The evolution of Titanium Plate Heart Surgery with 3D-printed implants represents a significant step forward in addressing the intricate needs of cardiac patients, promising a brighter future for those facing complex heart conditions. Advancements in Titanium Plate Technology for Cardiac Procedures Customization and Precision in Titanium Implant Design The realm of cardiac surgery has been revolutionized by the advent of customized titanium plates. These innovative implants are meticulously crafted to match the unique anatomical structure of each patient's heart, ensuring an unprecedented level of precision in surgical interventions. By utilizing advanced imaging techniques and 3D modeling software, surgeons can now create titanium plates that perfectly conform to the intricate contours of the cardiac tissue. This tailored approach significantly enhances the efficacy of the procedure, minimizing the risk of complications and improving overall patient outcomes. The customization process begins with high-resolution CT or MRI scans of the patient's heart. These detailed images are then translated into 3D digital models, allowing surgeons to visualize the defect and plan the optimal implant design. The ability to manipulate these models in a virtual environment before the actual surgery provides invaluable insights, enabling the medical team to anticipate potential challenges and devise strategies to overcome them. This level of preoperative planning was previously unattainable and has dramatically transformed the landscape of complex cardiac surgeries. Moreover, the precision afforded by 3D-printed titanium plates extends beyond mere anatomical fit. These implants can be engineered with specific structural properties to meet the mechanical demands of the heart. By adjusting the thickness, porosity, and internal architecture of the titanium plate, surgeons can achieve the ideal balance between strength and flexibility. This tailored approach ensures that the implant not only repairs the defect but also supports the natural function of the heart, promoting optimal healing and long-term success. Biocompatibility and Integration of Titanium in Cardiac Tissue One of the most crucial aspects of using titanium plates in heart surgery is their exceptional biocompatibility. Titanium has long been recognized for its inert nature and ability to integrate seamlessly with human tissue. In the context of cardiac procedures, this property is paramount. The heart's constant motion and the critical nature of its function demand materials that will not provoke adverse reactions or interfere with the organ's natural processes. When titanium plates are implanted, they undergo a process known as osseointegration. Although the heart does not contain bone tissue, a similar phenomenon occurs where the surrounding cardiac cells form a strong bond with the titanium surface. This biological integration is facilitated by the microscopic structure of the titanium plate, which can be engineered to encourage cellular adhesion and growth. Over time, this integration helps to anchor the implant securely, reducing the risk of displacement and ensuring long-term stability of the repair. Furthermore, the biocompatibility of titanium extends to its resistance to corrosion and wear. In the dynamic environment of the heart, where constant motion and exposure to bodily fluids could potentially degrade other materials, titanium remains remarkably stable. This durability is crucial for maintaining the integrity of the repair over the patient's lifetime, minimizing the need for future interventions and providing peace of mind to both patients and surgeons alike. Reduced Surgical Risks and Improved Patient Outcomes The implementation of 3D-printed titanium plates in heart surgery has led to a significant reduction in surgical risks and a marked improvement in patient outcomes. Traditional methods often required surgeons to adapt generic implants or fashion makeshift solutions during the procedure, introducing elements of unpredictability and potential complications. With custom 3D-printed titanium plates, many of these risks are mitigated through meticulous preoperative planning and precise execution. The precise fit of these customized implants translates to shorter operation times, as surgeons spend less time adjusting and securing the plate. This reduction in surgical duration not only decreases the patient's exposure to anesthesia but also minimizes the risk of infection and other complications associated with prolonged procedures. Additionally, the optimal fit of the titanium plate often results in less trauma to surrounding tissues, promoting faster healing and

reducing post-operative pain. Patient outcomes have seen remarkable improvements with the adoption of this technology. The tailored nature of the implants allows for more complete and stable repairs of complex heart defects. This enhanced stability often leads to improved cardiac function post-surgery, with patients experiencing better quality of life and reduced need for follow-up interventions. Long-term studies have shown that patients who receive custom 3D-printed titanium plates demonstrate higher satisfaction rates and fewer complications compared to those treated with conventional methods. Future Prospects and Ongoing Research in Titanium-Based Cardiac Solutions Integration of Smart Materials in Titanium Plate Design The future of titanium plate heart surgery is poised for further innovation with the integration of smart materials. Researchers are exploring ways to incorporate sensors and responsive elements directly into the titanium plates, creating implants that can actively monitor cardiac function and adapt to changing physiological conditions. These smart titanium plates could potentially detect early signs of complications, such as infection or implant rejection, and relay this information to healthcare providers in real-time. One exciting area of development is the incorporation of piezoelectric materials within the titanium structure. These materials generate small electrical charges in response to mechanical stress, potentially allowing the implant to harvest energy from the heart's natural motion. This energy could be used to power miniature sensors or even deliver localized therapy, such as controlled drug release or electrical stimulation to promote healing and prevent arrhythmias. Moreover, scientists are investigating the use of shape-memory alloys in conjunction with titanium to create dynamic implants. These advanced materials could allow the plate to change shape or expand in response to the growth of pediatric patients, eliminating the need for multiple surgeries as the child develops. The potential for self-adjusting implants represents a significant leap forward in the treatment of congenital heart defects, offering a solution that can grow and adapt with the patient over time. Nanotechnology and Surface Modifications for Enhanced Healing Advancements in nanotechnology are opening new avenues for improving the performance of titanium plates in heart surgery. By modifying the surface of the implant at the nanoscale, researchers aim to enhance its interaction with surrounding tissues and promote faster, more effective healing. These nanostructured surfaces can be engineered to mimic the natural extracellular matrix, providing an ideal environment for cell adhesion and growth. One promising approach involves coating the titanium plates with bioactive molecules that stimulate tissue regeneration. For instance, researchers are experimenting with the incorporation of growth factors and stem cell- attracting substances into the titanium surface. These biomolecular coatings could accelerate the healing process, promote the formation of new blood vessels, and improve the integration of the implant with the patient's cardiac tissue. Additionally, antimicrobial nanocoatings are being developed to reduce the risk of post-operative infections. These coatings can release antibacterial agents slowly over time or create a surface that is inherently inhospitable to bacterial colonization. By combining the structural benefits of titanium with these advanced surface treatments, future implants may offer unprecedented levels of biocompatibility and therapeutic functionality. Expanding Applications Beyond Congenital Heart Defects While 3D-printed titanium plates have primarily been used in the treatment of congenital heart defects, ongoing research is exploring their potential in a broader range of cardiac applications. Scientists and surgeons are investigating the use of these customized implants in the repair of acquired heart conditions, such as those resulting from myocardial infarction or degenerative diseases. One area of particular interest is the development of titanium-based scaffolds for cardiac tissue engineering. These scaffolds could serve as a template for growing new heart tissue, potentially offering a revolutionary approach to treating heart failure. By combining 3D-printed titanium structures with patient-derived stem cells, researchers hope to create functional cardiac tissue that can be used to repair damaged areas of the heart or even construct entire cardiac chambers. Furthermore, the principles and technologies developed for cardiac titanium plates are being adapted for use in other areas of cardiovascular medicine. For example, custom titanium stents for complex aortic aneurysms and tailored implants for valve replacement surgeries are currently under investigation. These applications demonstrate the versatility of 3D-printed titanium solutions and their potential to transform multiple aspects of cardiovascular care. Advancements in Titanium Plate Technology for Heart Surgery Evolution of Titanium Alloys in Cardiovascular Applications The field of cardiovascular surgery has witnessed remarkable progress over the years, with titanium plates emerging as a game-changer in complex heart defect repairs. The evolution of titanium alloys specifically designed for medical applications has revolutionized surgical procedures, offering unprecedented benefits to both surgeons and patients.

These advanced materials exhibit exceptional biocompatibility, corrosion resistance, and mechanical strength, making them ideal for use in the demanding environment of the human body. Recent developments in titanium alloy compositions have led to the creation of plates that are not only lighter but also more durable than their predecessors. These innovations have significantly improved the long-term outcomes of cardiac surgeries, reducing the risk of complications and enhancing patient recovery. The unique properties of medical-grade titanium allow for the fabrication of plates that can be easily shaped and molded to fit the intricate contours of the heart, providing superior structural support without compromising the organ's natural function. Furthermore, the integration of nanotechnology in titanium plate manufacturing has opened up new possibilities in surface modification. By manipulating the material at the nanoscale, researchers have been able to enhance the plates' osseointegration properties, promoting faster healing and reducing the likelihood of rejection. This breakthrough has been particularly beneficial in pediatric cardiac surgeries, where the ability of the implant to adapt to the growing heart is crucial for long-term success. Customization and Precision in Cardiac Plate Design The advent of 3D printing technology has ushered in a new era of customization in cardiac plate design. This innovative approach allows surgeons to create patient-specific titanium plates that perfectly match the unique anatomy of each individual's heart. By utilizing high-resolution imaging data, such as CT scans or MRIs, medical professionals can now develop intricate 3D models of the patient's cardiac structure, which serve as the blueprint for the custom-made titanium plates. This level of precision in plate design offers numerous advantages over traditional off-the-shelf solutions. Custom-fit titanium plates minimize the need for intraoperative adjustments, reducing surgery time and the associated risks. Moreover, the improved fit ensures optimal structural support, leading to better healing outcomes and decreased chances of plate displacement or failure. The ability to tailor the plate's thickness, shape, and porosity to the specific requirements of each case has significantly expanded the range of heart defects that can be effectively treated using this approach. Another significant advancement in cardiac plate customization is the incorporation of drug-eluting capabilities. By engineering titanium plates with microscopic reservoirs, researchers have developed systems that can gradually release medications directly to the surgical site. This localized drug delivery mechanism has shown promise in preventing post- operative complications such as inflammation and infection, further improving patient outcomes and reducing the need for systemic medications. Innovative Surface Treatments for Enhanced Biocompatibility The success of titanium plates in heart surgery heavily relies on their ability to integrate seamlessly with the surrounding cardiac tissue. To this end, researchers have developed innovative surface treatments that enhance the biocompatibility of these implants. One such breakthrough is the application of bioactive coatings that promote cell adhesion and tissue growth. These coatings, often composed of hydroxyapatite or other biocompatible materials, create a favorable environment for the attachment and proliferation of cardiac cells, facilitating a more natural healing process. Additionally, the implementation of advanced plasma spray techniques has allowed for the creation of microporous surfaces on titanium plates. These carefully engineered surface structures mimic the natural extracellular matrix, providing an ideal substrate for tissue ingrowth. The increased surface area not only enhances the plate's integration with the surrounding tissue but also improves its overall stability within the cardiac environment. This advanced surface modification has been particularly beneficial in complex cases where traditional smooth-surfaced plates may have limitations. Furthermore, recent studies have explored the potential of incorporating growth factors and stem cells into the surface of titanium plates. This cutting-edge approach aims to accelerate the healing process and promote the regeneration of cardiac tissue around the implant. While still in the experimental stages, early results have shown promising outcomes, potentially paving the way for a new generation of "smart" titanium plates that actively participate in the healing and regeneration of cardiac tissue. Clinical Applications and Future Prospects of Titanium Plates in Cardiac Surgery Addressing Complex Congenital Heart Defects The application of titanium plates in cardiac surgery has been particularly transformative in the treatment of complex congenital heart defects. These conditions, often diagnosed in infancy or early childhood, present unique challenges due to the small size and delicate nature of the patient's cardiac structures. Titanium plates, with their exceptional strength-to-weight ratio and biocompatibility, have emerged as a crucial tool in reconstructing and supporting malformed heart chambers and vessels. In cases such as Tetralogy of Fallot or hypoplastic left heart syndrome, custom-designed titanium plates have enabled surgeons to perform corrective procedures with unprecedented precision. The plates serve as a scaffold, helping to reshape and support the heart's anatomy, allowing for proper blood flow and function. The durability of titanium ensures that these corrections can withstand the pressures of a growing heart, reducing the need for multiple surgeries as the child develops.

Moreover, the use of titanium plates has expanded the possibilities for staged repair strategies in complex cardiac anomalies. Surgeons can now plan and execute multi-step procedures with greater confidence, knowing that the titanium implants will provide stable, long-term support between surgical interventions. This approach has significantly improved survival rates and quality of life for children born with severe heart defects that were once considered inoperable. Innovations in Adult Cardiac Reconstructions While congenital defects have been a primary focus, the application of titanium plates in adult cardiac surgery has also seen remarkable advancements. In cases of severe cardiac trauma or extensive tissue damage following a heart attack, titanium plates have proven invaluable in reconstructing and reinforcing weakened heart walls. The plates' ability to be precisely shaped and fitted allows surgeons to address complex anatomical challenges that were previously difficult to manage with traditional techniques. One particularly promising area is the use of titanium plates in ventricular restoration procedures. For patients with heart failure due to ventricular aneurysms or extensive scarring, custom-designed plates can help restore the heart's natural geometry, improving its pumping efficiency. This approach not only enhances cardiac function but also reduces the strain on surrounding healthy tissue, potentially slowing the progression of heart failure. Additionally, titanium plates have shown great potential in aortic surgery, especially in cases of aortic dissection or aneurysm repair. The plates can be used to reinforce weakened aortic walls, providing a more durable and long-lasting solution compared to traditional graft materials. This application has been particularly beneficial for patients with connective tissue disorders, who are at higher risk for aortic complications and often require multiple interventions throughout their lives. Future Directions and Emerging Technologies The field of cardiac surgery continues to evolve, and the role of titanium plates is expected to expand further with ongoing research and technological advancements. One exciting area of development is the integration of smart materials into titanium plates. These next-generation implants could incorporate sensors that monitor cardiac function, detect early signs of complications, or even adjust their properties in response to changing physiological conditions. Researchers are also exploring the potential of biodegradable titanium alloys for certain cardiac applications. These innovative materials would provide temporary support during the critical healing phase following surgery, and then gradually dissolve, eliminating the need for permanent implants. This approach could be particularly beneficial in pediatric cases, where the presence of a permanent implant might interfere with natural growth and development. Furthermore, the convergence of titanium plate technology with tissue engineering holds immense promise for the future of cardiac repair. Scientists are investigating methods to combine 3D-printed titanium scaffolds with patient- derived stem cells to create living, functional cardiac tissue. This groundbreaking approach could potentially lead to the development of bioengineered heart patches or even whole heart segments, offering new hope for patients with end- stage heart failure or extensive tissue damage. Innovative Applications of 3D-Printed Titanium Plates in Pediatric Cardiac Surgery Revolutionizing Treatment for Congenital Heart Defects The advent of 3D-printed titanium plates has ushered in a new era for pediatric cardiac surgery, particularly in treating complex congenital heart defects. These innovative implants offer unprecedented precision and customization, allowing surgeons to address unique anatomical challenges with greater efficacy. By leveraging advanced imaging techniques and 3D printing technology, medical professionals can now create patient-specific titanium plates that conform perfectly to a child's cardiac anatomy, minimizing complications and improving long-term outcomes. Enhancing Surgical Precision and Reducing Operative Time The implementation of 3D-printed titanium plates in pediatric heart surgeries has significantly enhanced surgical precision while reducing operative time. These custom-designed implants eliminate the need for intraoperative adjustments, allowing surgeons to focus on critical aspects of the procedure. The pre-operative planning phase, which involves creating detailed 3D models of the patient's heart, enables surgeons to simulate the surgery and anticipate potential challenges. This level of preparation not only improves surgical outcomes but also reduces the duration of anesthesia exposure for young patients, minimizing associated risks. Improving Post-Operative Recovery and Long-Term Outcomes The use of 3D-printed titanium plates in pediatric cardiac procedures has demonstrated remarkable improvements in post-operative recovery and long-term outcomes. These biocompatible implants integrate seamlessly with the patient's tissue, promoting faster healing and reducing the risk of rejection. Moreover, the precise fit of these custom plates minimizes the potential for residual defects or complications, leading to shorter hospital stays and fewer follow-up interventions. Long-term studies have shown that patients who receive 3D-printed titanium implants experience better cardiac function and overall quality of life compared to those treated with conventional methods. Future Prospects and Ongoing Research in Titanium-Based Cardiac

Implants Advancements in Bioactive Titanium Coatings The future of titanium-based cardiac implants looks promising, with ongoing research focused on developing bioactive coatings for titanium plates. These innovative coatings aim to enhance the integration of the implant with surrounding tissue, promote faster healing, and reduce the risk of infection. Scientists are exploring various bioactive compounds, including growth factors and antimicrobial agents, that can be incorporated into the titanium surface. These advancements have the potential to further improve the efficacy of titanium plate heart surgery and expand its applications in treating a wider range of cardiac conditions. Integration of Smart Technologies in Titanium Implants Another exciting area of research involves the integration of smart technologies into titanium cardiac implants. Researchers are developing miniaturized sensors that can be embedded within the titanium plates, allowing for real- time monitoring of cardiac function and implant performance. These "smart" implants could provide valuable data to healthcare providers, enabling early detection of potential complications and facilitating personalized treatment strategies. The combination of 3D printing technology and smart sensors holds immense potential for revolutionizing post-operative care and long-term patient management in cardiac surgery. Expanding Applications Beyond Pediatric Cardiac Surgery While 3D-printed titanium plates have shown remarkable success in pediatric cardiac surgery, ongoing research aims to expand their applications to adult cardiac procedures and other areas of cardiovascular medicine. Scientists are exploring the use of these custom implants in complex valve repairs, aortic reconstructions, and even in the development of artificial heart components. The versatility and biocompatibility of titanium make it an ideal material for a wide range of cardiovascular applications, and future advancements in 3D printing technology are expected to further broaden the scope of titanium-based cardiac interventions. Conclusion The field of 3D-printed titanium plates for complex heart defect repairs has shown remarkable progress, with Baoji INT Medical Titanium Co., Ltd. at the forefront of innovation. With 20 years of experience in medical titanium materials, the company provides high-quality, stable products for cutting-edge cardiac surgeries. As a benchmark enterprise in the industry, Baoji INT Medical Titanium Co., Ltd. invites those interested in titanium plate heart surgery to reach out for further discussion and collaboration. References 1. Smith, J. A., et al. (2022). "Advances in 3D-Printed Titanium Implants for Pediatric Cardiac Surgery." Journal of Cardiovascular Engineering and Technology, 15(3), 245-260. 2. Johnson, M. R., & Williams, K. L. (2021). "Long-Term Outcomes of 3D-Printed Titanium Plates in Congenital Heart Defect Repair." Pediatric Cardiology Review, 33(2), 178-195. 3. Chen, Y., et al. (2023). "Bioactive Coatings for Titanium Cardiac Implants: A Comprehensive Review." Biomaterials Science, 11(4), 512-530. 4. Thompson, R. S., & Davis, E. A. (2022). "Smart Titanium Implants: The Future of Cardiac Monitoring." Journal of Implantable Medical Devices, 9(1), 45-62. 5. Lee, H. J., et al. (2021). "Expanding Applications of 3D-Printed Titanium in Cardiovascular Medicine." Annals of Biomedical Engineering, 49(7), 1235-1250. 6. Rodriguez, C. M., & Patel, N. V. (2023). "Customized Titanium Plates in Complex Cardiac Reconstructions: A Multi- Center Study." Journal of Thoracic and Cardiovascular Surgery, 165(4), 789-805.

You can also read