FLEXIBLE DRILLING & MACHINING SOLUTIONS - ASP Events

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

CMA WAS FOUNDED IN 1951

IN ALZIRA, SPAIN

36 km to the south of Valencia where we are working in a

factory with more than 3.000 square meters and have now

become one of the world’s leading manufacturers of CNC

Drilling Machines and Tapping Machines.

Custom made in house, these machine tools are built to order

and are geared towards increasing efficiency and lowering

production costs for our customers.

With bed sizes ranging from 3-25m' on the x-axis, and

0.8-3m on the y-axis, this machine is capable of handling

any and all parts that would enter a manufacturing

Lorem ipsum

facility. With Torque of 500Nm and spindle speed up

to 6000RPM makes flexibility a key component.

What ensures CMA products stand out from

other machine centres the most is the ability to

work in 'Pendulum Mode' which allows for

100% spindle uptime.

This process lets the operator safely

load/unload one side of the machine

while the spindle is working on the

other side, and vice versa.

We are pleased to invite you to

consider our products which

you may find personalised

value added solutions to

your projects.3RD SERIES CNC MACHINE

DESCRIPTION

The CMA 3RD-CNC drilling center is the third generation of our flagship model used daily on all

continents of the world. The machine is equipped with the latest generation industrial PC-control,

servodrivers and servomotors produced by OMRON (Japan).

What capabilities should a drilling-center offer?

· Fast and easy drilling on the exact position (an incorrect positioned hole leads to problems during assembly

and high additional costs).

· Suitable for single-parts (1 or 2 holes drilled in manual-mode) and for small and large series.

· Possibility to use conventional HSS-drills as well as modern Carbide-drills for fast production.

· Production of (several) small as well as large workpieces.

· Suitable for drilling, tapping, countersinking and flowdrilling.

· Perform light milling-jobs to avoid products being clamped / set-up on different machines.

Unique features of the 3RD-CNC drilling-center:

· Easy intuitive graphical programming, including GoTo-function in manual mode.

· Free programming in ISO-language (G-codes), f.e. complex milling-shapes, threadmilling, use of special tooling like

deburring-tools.

· 2-axis interpolation on X/Y-axis, 3 axis interpolation for helical milling (X/Y/Z-axis).

· Positioning-speed X-axis = 30 m/min., Y-axis = 30 m/min.

Model 3RD-3006 3RD-4506 3RD-6006 3RD-7506 3RD-9006 3RD-105-06

Spindle motor 13,1 kW

Spindle type BT40 or CAT40

Length of table 3000mm 4500mm 6000mm 7500mm 9000mm 10500

Width of table 580mm

T-slots 3 T-slots 20mm, distance 250mm

Stroke X-axis 3000mm 4500mm 6000mm 7500mm 9000mm 10500

Stroke Y-axis 600mm

Stroke Z-axis 450mm

Spindle-table 150-600mm

Speed X-axis 30m/min

Speed Y-axis 30m/min

Speed Z-axis 9,6m/min

Weight 6000kg 7000kg 8000kg 9200kg 10200kg 11500kg

Max Drill and Tap 42mm Drill/M30

Order Example 3RD6006/BT40/4000GRD SERIES CNC MACHINE

DESCRIPTION

The CMA GRD Series CNC controlled gantry machine comes in a range of standard sizes but can be manufactured to

your requirements. The GRD is fitted with a 13.1 KW machining spindle which is perfect for many operations such as

rapid drilling, thermal drilling, tapping up to M45 holes, thread milling, milling and slot drilling. The Machine features a

mono-block, welded steel frame with high rigidity and a t-slot machine bed. Moving along precision ground liner rails on

all 3 axes, CMA ensure consistent high tolerance machining over the length of the machine bed. All moving parts are

self-lubricating to reduce machine downtime and the machine spindle is driven by a programmable servo-motor.

Features Control

· Mono-block, welded steel frame with high rigidity. · Conversational & ISO (G-code) Programming.

· 12” color touch screen control. · OMRON color touch screen control.

· Machine moves along linear guideways on all axes. · Memory up to 999 programs.

· Self-lubricating moving parts along all axes. · 50 programmable zero-points.

· Spindle driven by a programmable servo-motor. · 3 axes controlled (X,Y,Z ).

· Automatic tool changer for up to 12 tools. · Z axis can be programmed at different speeds along column.

· Electric panel with cooling system. · Helical Milling.

· External coolant systems, pump and tank. · Load programs with USB or data connection.

· Chip conveyor.

· Water protection screen.

· Automatic tool calibrator.

· RJ45 fast connection mounted on the frame.

Model GRD-30 – – GRD-45 – – GRD-60 – – GRD-75 – – GRD-90 – – GRD-105 – –

Spindle motor 13.1 kW

Spindle type BT/CAT40 or BT/CAT50

Length of table 000 / 4500 / 6000 / 7500 / 9000 / 10500mm or customized

Width of table 1200 / 1700 / 2000 / 2500 / 3000mm (applies to all Models)

T-slots 6 / 8 / 9 / 11 / 13 / 20mm – distance 250mm

Stroke X-axis 3000 / 4500 / 6000 / 7500 / 9000 / 10500mm or customized

Stroke Y-axis 1200 / 1700 / 2000 / 2500 / 3000mm (applies to all Models)

Stroke Z-axis 500mm or customized

Distance Spindle-table 120-620mm

Table Height 880mm

Speed X-axis 30m/min

Speed Y-axis 30m/min

Speed Z-axis 4,8m/min

Max Drill and Tap 60mm Drill / M45 (using 13.1 Kw spindle motor)

Order Example GRD4517/13.1/BT40/4000BRD SERIES CNC MACHINE

DESCRIPTION

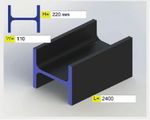

Introducing our lastest model the CMA BRD-CNC profile drilling center. The machine has been developed for fast,

accurate and economic production of steel profiles and is equipped with the latest generation industrial PC-control,

servodrivers and servomotors. But most importantly it has been fitted with a CNC controlled Hydraulic clamping system

to minimise product set up times and increase the ease of product removal. Fitted with a 13.1 kW motor and an

automatic toolchanger for up to 6 tools, this machine is the must have for fast and accurate metal profile machining.

Standard features of the BRD-CNC profile-drilling-center:

· Perform Drilling (max Ø42mm), Milling, Tapping (max M30), Chamfering, Thermal Drilling and Engraving operations.

· Hydraulic clamp system, which works in conjunction with machine head to drastically reduce machining set up times.

· Automatic tool-changer with 6 positions, fitted into machine column.

· X-axis 200 mm movable while product is clamped (for milling operations).

· 2-axis interpolation on X/Y-axis, 3 axis interpolation for helical milling (X/Y/Z-axis).

· Positioning-speed X-axis 25 m/min, Y-axis 25 m/min.

· Oil coolant spay system.

Model BRD 12000 BRD 16000

Min/Max profile-demensions 50x50 – 610x610 mm (optional 610x1050 mm)

Spindlemotor 13,1 kW

Spindle RPM 2000, 2400, 3000, 4000, 5000

Spindletype BT 40 or CAT 40

Length of table 12000 mm 16000 mm

Stroke X-axis 12000 mm 16000 mm

Stroke X/Y for milling 250x600 mm (optional 250x1000 mm)

Stroke Y-axis 610 mm (optional 1050 mm)

Maximum toollength 300mm

Minimum distance spindle-workpiece 50mm

Speed X-axis 25m/min

Speed Y-axis 5m/min

Speed Z-axis 5m/min

Max Drill and tap 42 mm Drill/M30 Tap

Order example BRD1600/13.1/CAT40/4000OPTIONAL EQUIPMENT · Coolant through spindle/tool. · Pressure 4 bars. · Pressure 7 bars. · Spraying system (minimum lubrication system with air+oil) for drilling/milling in profiles upto approximately 6 mm wall thickness. · Spraying time and interval programmable in the CNC control. · Automatic system for measuring height of the workpiece (Z reader). · 100% accurate flowdrilling and counter sinking. Tolerances in height of material and/or clamping systems are automatically compensated. · Avoids crash of tool in case of eventual programming mistakes. Max. allowed tolerance can be set in the parameters. In case the height of the product is out of tolerance the program will be interupted and an error message appears. · Maximum tool length 315 mm. · 4th axis (tube rotation), including selfcentering 3-jaw chuck. The rotary table is mounted on table with linearguides for fast set-up. · diameter 250 mm. · diameter 400 mm. · Lightcurtain in Y-direction 500 mm above the table on both sides of the gantry. · Safety measure to protect operators climbing on the table for clamping parts on wider machines. · GRD Only. · Spindle BT 50, including automatic rotary toolchanger for 10 tools. · Distance spindle-table 80-580 mm. · DrillCam; Complete CAD-CAM software for converting 2D DXF, DWG, DSTV or 3D STEP, IGES files into ISO machine-programs. Loading of programs into the control of the machine through Ethernet connection. · RPM and feed of tools are automatically set based on programmable library for different types of tools and materials. · Bigger Y-travel to work with profiles with maximum dimension till 1.050 mm. · Graphical programming; Generate a 3D drawing by selecting the shape of the material/profile and add the operations + positions through macros. The cutting data are set automatically based on the selected type material and tool (these data are entered in the toollibrary in the software). Including easy setup of nestings for 1 or multiple (identical or different) pro-ducts, graphical simulation and collision-warning .

JIG & FIXTURE DESIGN Using high-level personnel skills and years of experience, our design team of engineers offer a variety of services to our clients. With savings on both costs and production times we are able to offer our customers a complete design solution from fixture concept through to manufacturable detail drawings, using our vast knowledge of Jig and Tool design and stress capabilities. If required CMA UK can arrange for the manufacture of any Jig and Fixture using our manufacturing partners. Our designers have been involved with the design of numerous lifting tools, holding fixtures and assembly jigs. We believe in efficiency, accuracy, cost control and most importantly successful communication with our customers to achieve the perfect design for our customers. Contact us for more details about our Jig & Fixture Design +44 (0)161 292 3206 INFO@CMAMACHINETOOLS.CO.UK

CMA MACHINE TOOLS UK

84 Northcliffe Road, Stockport

Cheshire SK2 5AQ

+44 (0)161 292 3206

INFO@CMAMACHINETOOLS.CO.UK

SPAIN HEADQUATERS GERMANY HEADQUATERS

Pol. Ind. El Pla Parcela M18 CMA Mashinen GmbH

46600 ALZIRA (Valencia – Spain) Jakobistrasse 17

46354 Oeding

ITALY HEADQUATERS USA HEADQUATERS

Via Donatori di Sangue 8/10 851 Industrial Drive

22060 Arosio (CO) – Italia Wapakoneta

P.IVA: 03071500130 Ohio 45895You can also read