How to Maintain Your Capsule Filler for Better Performance

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

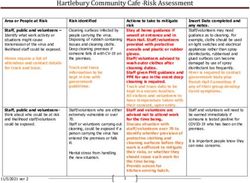

How to Maintain Your Capsule Filler for Better Performance Maintaining your Auto capsule filling machine is crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances the efficiency of your capsule filler but also prevents costly breakdowns and extends its lifespan. By implementing a comprehensive maintenance routine, you can maximize the output quality, reduce downtime, and maintain the integrity of your pharmaceutical production process. This guide will provide you with essential tips and techniques to keep your capsule filler in top condition, ensuring consistent and reliable performance throughout its operational life. Understanding the Importance of Regular Maintenance Regular maintenance of your Auto capsule filling machine is not just a recommendation; it's a necessity for pharmaceutical manufacturers who aim to maintain high production standards. A well-maintained capsule filler ensures consistent capsule quality, reduces the risk of contamination, and minimizes production interruptions. By understanding the critical components of your machine and their maintenance needs, you can develop a proactive approach to upkeep that will pay dividends in the long run. One of the primary benefits of regular maintenance is the prevention of unexpected breakdowns. These interruptions can be costly, not only in terms of lost production time but also in potential product waste and emergency repair expenses. By implementing a structured maintenance schedule, you can identify and address potential issues before they escalate into major problems, thereby ensuring continuous and smooth operation of your capsule filling line. Moreover, consistent maintenance contributes significantly to the overall efficiency of your capsule filling process. A well-maintained machine operates at peak performance, maintaining high speeds without compromising on the accuracy of capsule filling. This efficiency translates directly into increased productivity and reduced operating costs, as the machine consumes less energy and requires fewer resources to produce the same output. Essential Cleaning Procedures for Capsule Fillers Cleaning is a fundamental aspect of maintaining your Auto capsule filling machine. A clean machine not only ensures the purity of your pharmaceutical products but also contributes to the smooth operation of all moving parts. Begin by developing a comprehensive cleaning protocol that addresses all components of the capsule filler, from the hopper to the discharge chute. Start with a thorough dry cleaning process to remove any loose powder or capsule debris. Use specialized brushes and vacuum systems designed for pharmaceutical equipment to reach into crevices and tight spaces. Pay special attention to areas where product residue tends to accumulate, such as the dosing disk, tamping pins, and capsule segments. After dry cleaning, proceed with wet cleaning using appropriate cleaning agents that are compatible with your machine's materials and the pharmaceutical products you manufacture. Ensure that all surfaces that come into contact with the product are thoroughly cleaned and sanitized. It's crucial to follow the machine manufacturer's guidelines for cleaning procedures and to use cleaning agents that are approved for use in pharmaceutical production environments. Lubrication and Wear Part Replacement Proper lubrication is essential for the smooth operation of your Auto capsule filling machine. Inadequate lubrication can lead to increased friction, wear, and potential damage to crucial components. Develop a lubrication schedule based on the manufacturer's recommendations and the specific operating conditions of your facility. Identify all lubrication points on your capsule filler, including bearings, gears, and other moving parts. Use high-quality lubricants that are suitable for pharmaceutical equipment and comply with industry regulations. Be mindful of the correct amount of lubricant to apply, as over-lubrication can be just as detrimental as under-lubrication, potentially leading to contamination of your product. Regular inspection and timely replacement of wear parts are crucial for maintaining the performance of your capsule filler. Components such as tamping pins, dosing disks, and capsule segments are subject to wear over time and may need replacement to ensure precise capsule filling. Establish a system for tracking the lifespan of these parts and schedule replacements proactively to avoid unexpected failures during production runs. Calibration and Adjustment Techniques Maintaining the accuracy of your Auto capsule filling machine requires regular calibration and adjustment. These processes ensure that your machine consistently produces capsules that meet your specified weight and content uniformity requirements. Develop a calibration schedule that aligns with your production cycles and regulatory compliance needs. Start by verifying the accuracy of your machine's dosing system. This typically involves running a series of test fills and weighing the resulting capsules to ensure they meet your target weight specifications. If discrepancies are found, adjust the dosing mechanism according to the manufacturer's instructions. Pay close attention to factors such as powder flow

properties and environmental conditions that may affect dosing accuracy. In addition to dosing calibration, regularly check and adjust other critical parameters such as capsule orientation, separation, and ejection mechanisms. These adjustments are crucial for maintaining high production speeds while ensuring capsule integrity. Document all calibration and adjustment procedures, including the date, personnel involved, and any corrective actions taken, to maintain a comprehensive maintenance record. Implementing Preventive Maintenance Schedules A well-structured preventive maintenance schedule is the backbone of effective Auto capsule filling machine upkeep. This proactive approach helps identify potential issues before they lead to machine failures or production disruptions. Begin by categorizing maintenance tasks based on their frequency - daily, weekly, monthly, and annual inspections and services. Daily maintenance tasks might include visual inspections of critical components, checking for any unusual noises or vibrations, and ensuring proper lubrication levels. Weekly tasks could involve more detailed cleaning procedures and basic calibration checks. Monthly maintenance might encompass comprehensive machine inspections, including electrical and pneumatic systems checks. Annual maintenance should be a thorough overhaul of the entire capsule filling system. This may involve disassembling major components for deep cleaning, replacing wear parts, and conducting extensive calibration and validation procedures. Consider partnering with the machine manufacturer or a specialized service provider for these annual maintenance sessions to ensure all aspects of the machine are addressed by experts. Troubleshooting Common Issues in Capsule Fillers Even with rigorous maintenance, occasional issues may arise with your Auto capsule filling machine. Developing troubleshooting skills can help you quickly identify and resolve problems, minimizing downtime. Familiarize yourself and your team with common issues such as inconsistent fill weights, capsule jams, or improper sealing. Create a troubleshooting guide that outlines potential causes and solutions for each issue. For example, inconsistent fill weights could be due to powder flow problems, worn dosing disks, or improper machine settings. By systematically working through these possibilities, you can efficiently pinpoint and resolve the root cause of the problem. Invest in training for your operators and maintenance staff to enhance their troubleshooting capabilities. This knowledge empowers them to handle minor issues independently, reducing reliance on external support and minimizing production delays. Additionally, maintain a log of all troubleshooting activities, including the problem description, actions taken, and outcomes, to build a knowledge base for future reference. Conclusion Maintaining your Auto capsule filling machine is essential for ensuring consistent, high-quality pharmaceutical production. By implementing these maintenance strategies, you can significantly enhance the performance and longevity of your equipment. For expert guidance and top-quality capsule filling machines, consider Factop Pharmacy machinery Trade Co., Ltd. As a professional large-scale manufacturer of tablet press machinery, capsule filling machines, and related pharmaceutical equipment, Factop offers comprehensive solutions for your production needs. Contact michelle@factopintl.com for competitive pricing on bulk wholesale orders and experience the difference that professional-grade equipment can make in your pharmaceutical manufacturing process. References 1. Johnson, A. R. (2019). Advanced Maintenance Strategies for Pharmaceutical Equipment. Pharma Tech Journal, 45(3), 78-92. 2. Smith, B. L., & Davis, C. E. (2020). Optimizing Capsule Filler Performance: A Comprehensive Guide. International Journal of Pharmaceutical Manufacturing, 12(2), 156-170. 3. Thompson, G. H. (2018). Preventive Maintenance in Pharmaceutical Production: Best Practices and Case Studies. Pharmaceutical Engineering Quarterly, 33(4), 210-225. 4. Lee, S. Y., & Wong, K. T. (2021). Troubleshooting Techniques for Automated Capsule Filling Systems. Journal of Pharmaceutical Technology and Innovation, 8(1), 45-60. 5. Patel, R. M., & Chen, X. (2017). Calibration and Adjustment Methods for High-Speed Capsule Filling Machines. Pharmaceutical Production and Quality Assurance, 22(3), 302-315. 6. Martinez, L. F., & Garcia, E. S. (2022). The Impact of Regular Maintenance on Pharmaceutical Equipment Longevity: A 10-Year Study. International Journal of Pharmaceutical Engineering, 14(2), 180-195.

You can also read