High-frequency Ignition System Based on Corona Discharge - Knowledge Library

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Knowledge Library

High-frequency Ignition System

Based on Corona Discharge

According to the European emission directive, the CO 2 emissions of passenger

cars are to drop to a fleet average of 95 g/km from 2020 onwards. Promising ap-

proaches to achieving this goal can now be seen in the development of combustion

processes for gasoline engines, and a major role is played by dethrottling, which is

achieved by lean combustion or by using high exhaust gas recirculation rates.

High-frequency ignition is based on the phenomenon of corona discharge and has

the potential to be available on time. Under the name EcoFlash, BorgWarner BERU

Systems is pressing ahead with its development towards series production.

By Steffen Bohne, engine testing and calibration engineer, BorgWarner BERU Systems,

Dr. Georg Rixecker, Senior Manager High Frequency Ignition, BorgWarner BERU Systems,

Dr. Volker Brichzin, Director Global Engineering, BorgWarner BERU Systems, and

Dr. Michael Becker, Director Advanced R&D, BorgWarner

Volume Ignition as an Ideal Solution profit to a considerable degree from an enlar-

The reliable ignition of lea n or diluted fuel-air ged ignition volume, which not only guarantees

mixtures makes extremely high demands on reliable ignition but can also contribute to a

the ignition system. The energy input of con- higher burning rate and thus to more efficient

ventional transistor coil ignition systems is ge- energy release by forming spatially distributed

nerally no longer adequate to limit the increase flame kernels.

of the cyclical fluctuations in operating conditi-

ons such as these. In addition, the lower bur- The technology of choice which meets all tech-

ning rates of the diluted mixtures reduce the nical criteria in the field of passenger cars and

efficiency benefits which can be achieved. This also has the potential to be available on the

is the case for homogeneous as well as strati- market in good time before the CO 2 directive

fied combustion modes. The latter can at least comes into force in 2020 is high-frequency

profit from an extended ignition time, which in- ignition (HFI), which is based on the phenome-

creases the probability that ignitable mixture is non of corona discharge. BorgWarner BERU

ignited during each combustion cycle. Systems is currently pressing ahead with the

development of the system named EcoFlash

Meanwhile, all new high-EGR and lean engine towards series production.

concepts currently in the development stage

BorgWarner Knowledge Library 201 4 1that the high voltage required for the gas

discharge is generated via resonance transfor-

mation using a series resonant circuit [2, 3, 4,

5]. Here it is essential to limit the voltage (de-

pending on the operating point) in such a way

that unintentional flashover cannot occur. This

control task is ideally supported by dimensio-

ning the combustion chamber using electric

Corona formation on an electrode tip in ambient field simulation; this ensures that the field

air strength above the metal combustion chamber

surfaces will never exceed certain threshold

System Layout and State of values [1 ]. If corona control is carried out cor-

Development rectly, virtually all of the energy provided for the

We refer to [1 ] for a brief discussion of the co- gas discharge is transferred to the cylinder

rona discharges. What the current concepts for charge, and in comparison with spark ignition

corona ignition systems have in common is this leads to an advantageous ratio between

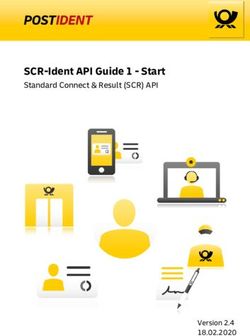

System layout for the high-frequency ignition (top) and the current A and B prototype systems

(bottom)

BorgWarner Knowledge Library 201 4 2largely used in test bench operation and by

customers are successively being replaced by

B level prototype systems. These are currently

undergoing internal validation and include, in

addition to an approximately doubled electrical

efficiency, a newly developed communication

interface.

Increasing the EGR Tolerance under

Running smoothness comparison between a Partial Load

conventional 90 mJ transistor coil ignition (TCI) A current turbocharged four-cylinder engin e

and the high-frequency ignition system (HFIS) with a displacement of 1 .4 l and direct injection

EcoFlash in the case of progressive charge which was additionally equipped with a cooled

dilution by exhaust gas recirculation (operating low-pressure exhaust gas recirculation system

point 2000 rpm and IMEP = 6 bar) was used for a detailed comparison between

the EcoFlash A level prototype ignition system

and a conventional transistor coil ignition sys-

energy input and energy transferred to the pro- tem with an ignition energy of 90 mJ. The igni-

cess gas. ter was positioned in the centre of the

combustion chamber and the injector was side-

The configuration of the EcoFlash version for mounted. The flat piston bowl designed for

use in passenger cars comprises a controller combined flow and wall guidance of the mix-

and three to six igniters depending on the ture did not have to be modified for operation

number of cylinders. The high-frequency ca- with the high-frequency ignition. However, it is

bles between controller and igniters are of the to be assumed that an additional modification

coax type. As the last stage of voltage trans- of the combustion chamber geometry would

formation is carried out by a resonant circuit in- have allowed even clearer advantages than

tegrated into the igniters (see above), the those described in the following to be achie-

voltage to be transferred here is limited to less ved.

than 1 kV. The maximum effective power input

of the EcoFlash A level prototype system is The test program included the EGR tolerances

350 W in the six-cylinder version. When the A under partial load, for load points between

level prototype system was used on a turbo- 2000 and 4000 rpm and at mean pressure of

charged 2.0-l four-cylinder engine with intake 2 to 1 4 bars. Other results concerning the lean

manifold fuel injection, ignition energies of limit, the knocking behaviour and the EGR to-

50 mJ were adequate in order to comply with a lerance under full load have already been pre-

COVIMEP < 2.6 % over a large part of the engi- sented elsewhere [1 ]. For the example of the

ne map. Also, an ignition energy of less than load point 2000 rpm/6 bar, EcoFlash shows a

25 mJ was adequate in order to operate, in a considerable increase in the EGR rate in com-

further test series, a small two-stroke gasoline parison with a transistor ignition. If a running

engine with a displacement of 92 cm 3 in a [6]. smoothness criterion of COV ≤ 5 % is used, an

external EGR rate of 29.7 % is achieved, i.e.

The A level prototype systems which are still 1 3 % more than with the conventional ignition.

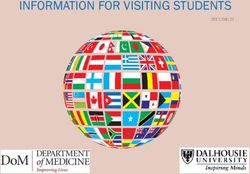

BorgWarner Knowledge Library 201 4 3Time behaviour of the primary current during an

endurance test under full load with cyclical va-

riation of speed between 2000 and 5500 rpm

(top) and electrode wear of an igniter after 0,

1 50, 320 and 480 h (bottom, all igniters were ful-

ly functional at the end of the endurance test)

advantage compared with the conventional

ignition is approximately 5 to 1 0 % (2 to

3.5 °CA), even if the mixture is highly diluted,

and this leads to immediate advantages in

terms of efficiency.

Corona formation at high pressures in nitrogen; Behaviour at High Ignition Pressures

each individual image shows image sequences and under Full Load

integrated over an ignition process with a It is known from the literature that the spatial

duration of 500 µs: 20 bars chamber pressure extension of the corona discharges scales in-

and 80 % DC power setpoint (top), 30 bar and versely with the gas pressure - but less stron-

95 % (middle) and 40 bar and 1 00 % (bottom)

gly than it would in the case of inverse

proportionality [1 , 3]. Therefore, a sufficient co-

rona size at high ignition pressures is crucial as

The improvement of the EGR tolerance in the this would allow the volume ignition character

other operating points is similarly positive. Be- of the high-frequency ignition to be used in

sides an in general considerably shorter igniti- high load points too. This requirement can be

on delay, the burning duration is on average easily met in the present state of development

shorter in the case of a high-frequency ignition, of the EcoFlash ignition system. The specific

as a precise analysis of the mass conversion advantages of volume ignition during ignition.

points shows. The ignition delay is generally It has already been said elsewhere [1 ] that, in

5 to 20 °CA shorter, with a rising trend as char- the case of the 1 .4-l-turbocharged engine

ge dilution progresses. In terms of the com- equipped with an EcoFlash ignition system, it is

bustion time (5 to 90 % conversion), the possible under full load to shift the 50 % mass

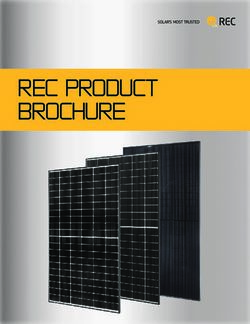

BorgWarner Knowledge Library 201 4 4Potentials for the development of combustion processes using corona ignition

fraction burnt point up to 4° CA earlier in com- Engine Endurance Test

parison with a transistor ignition at the same In a high-load engine endurance test of the

engine knocking intensity. This allows the 1 .4-l turbocharged engine lasting for more than

mean pressure to be increased by 0.5 bar wi- 500 h, the constancy of significant operating

thout the necessity of further design measures. parameters of the high-frequency ignition such

Alternatively, it was possible to add up to 4% as the power input and the mean frequency of

external EGR under full load while maintaining the igniters over time was examined. The en-

the maximum torque achievable with a 90 mJ durance test was interrupted at regular inter-

transistor ignition system and thus to reduce vals and the wear on the ignition electrodes

the exhaust gas temperature by 1 0 K and the was documented. The parameters of the igniti-

specific consumption by 2 %. on system did not show any significant syste-

matic changes over the operating time; the low

On the basis of these results, it is possible to wear on the tips of the electrodes also allows

reduce the enrichment under full load and – as us to expect a lifetime in the vehicle of consi-

a result of the more rapid ignition and the hig- derably more than 1 00,000 km.

her knock resistance – to increase the torque

at low engine speeds. This has already been Conclusions and Outlook

demonstrated in tests conducted with develop- This article explains system layout and basic

ment partners and customers [7, 8]. principles of the high-frequency or corona igni-

tion and documents the advantages of the

BorgWarner Knowledge Library 201 4 5technology via test bench results. These tests sion, Behaviour of Small Two-Stroke SI Engi-

showed an increased EGR compatibility, an nes, SAE 201 3 Small Engine Technology Con-

improved knocking behaviour and thus also an ference, Taipei, paper no. 201 3-32-xxxx,

improved specific consumption – even in the accepted for publication

absence of any special geometrical modificati- [7] Berndt, F. et al.: Lean burn combustion for

ons of the combustion chamber. gasoline engines: potential of high frequency

ignition and high pressure injection, Procee-

In conjunction with the many tests conducted dings of the 1 3. Stuttgart International Sympo-

on the EcoFlash ignition system with custo- sium on Automotive and Engine Technology,

mers and development partners, we now have Stuttgart, 201 3, paper no. 253

a clear picture of the possibilities and degrees [8] Rixecker, G. et al.: Corona ignition as an

of freedom which corona ignition has newly in- enabler for lean combustion concepts leading

troduced into the development of combustion to significantly reduced fuel consumption of

techniques: The volume ignition characteristics turbocharged gasoline engines Proceedings of

of corona discharges not only pave the way for the 22. Aachen Colloquium on Automobile and

high-EGR and lean combustion techniques – Engine Technology, Aachen, 201 3

they also allow special concepts such as the

minimisation of gas exchange losses via redu-

ced charge motion or efficiency improvement

via Miller valve timing.

References

[1 ] Rixecker, G. et al.: The High Frequency

Ignition System EcoFlash. Proceedings of the

1 . International Conference on Advanced Igni-

tion Systems for Gasoline Engines, Berlin,

201 2, 65-81

[2] Freen, P. D.: Radio Frequency Electrostatic

Ignition System, Final Report, Energy Innovati-

ons SmalI Grant Program, Titusville, 2005

[3] Auzas, F. : Décharge radiofréquence pro-

duite dans les gaz à pression élevée pour le

déclenchement de combustion, Ph. D. Thesis,

Université Paris Sud–XI, 2008

[4] Heise, V.; Farah, P.; Husted, H. : High Fre-

quency Ignition System for Gasoline Direct In-

jection Engines, SAE 2011 World Congress,

Detroit, 2011 -01 -1 223

[5] Burrows, J.; Lykowski, J.; Mixell, K.: Coro-

na-Zündsystem für hocheffiziente Ottomotoren, Contact

Motortechnische Zeitschrift 74, 201 3, 482-485 Email: technology@borgwarner.com

[6] Hampe, C. et al.: Influence of High Fre- For more information, please visit

quency Ignition on the Combustion and Emis- borgwarner.comYou can also read