ELECTROMOBILITY COMES FROM BELOW - ICONS IN BLACK - Rheinmetall Automotive

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

The magazine of Rheinmetall Automotive ISSUE 02/2017

ICONS IN BLACK

Retro look with state-of-the-art technology

STARTING EARLY PAYS OFF

Trainees become design engineers of electric vehicles

// ELECTROMOBILITY

COMES FROM BELOW

Drive system and energy storage for electric vehicles

in developmentEDITORIAL/CONTENTS

DIVERSITY ON THE RISE

Electrification of the drivetrain is going into high gear.

10E-MOBILITY

COMES FROM

Wherever you look, whether in China, the USA, or in the

streets of Europe, this trend is plain to see and gathering

BELOW

pace. For Rheinmetall Automotive, this is a highly significant

development: In the future-oriented e-mobility segment,

we’ve already booked orders worth over 500 million EUR. And

now, just in time for IAA 2017, we’re expanding our product

range with a new electric motor and an advanced battery

pack. But innovative new developments and improvements in

our legacy product lines are becoming increasingly relevant,

too, particularly in light of heightened requirements for

greater fuel efficiency and lower emissions. At IAA 2017 in

Frankfurt, we’ll be showcasing these as well. This varied issue

of Heartbeat focuses on the diverse range of contemporary

drive technologies as well as the innovative manufacturing

techniques, such as friction welding of steel pistons – but it

also highlights the growing diversity of our company. Offering

an overview, the first Rheinmetall CSR report revealed that

we have a great deal to offer besides products and technol-

ogies. Protecting the environment, personnel development,

and social and community commitment have long formed an

integral part of our corporate ethos. You’ll find a number of

concrete examples of this in the second section of this mag-

azine. Equally up to date is Heartbeat’s new interactive web

magazine format, which is going online in a Chinese language

version, too. Between issues, we’ll also be informing you THE WILD WORLD HIGHLIGHTS

about all the latest news at Rheinmetall Automotive. Whether

OF ENGINES

you’re reading this in the print version or browsing through it

online (www.heart-online.de/en), we wish you an enjoyable

8

and informative experience! 4 Latest from IAA and Personnel

News

Focused on action

Hunting for perfect pictures with

four cameras

4

Peter Hartung FOCUS

Head of Corporate Communications

Rheinmetall Automotive AG 10

E-mobility comes from below

Developing drive system and

// IMPRINT

energy storage for e-vehicles

Published by: Rheinmetall Automotive AG, Karl-Schmidt-Strasse 2–8,

74172 Neckarsulm, Germany, www.rheinmetall-automotive.com

Responsible: Peter Hartung, Folke Heyer

Edited by: Folke Heyer, Annemarie Köhler, Jacquelyn Marsiglio,

Ursula Pohen, Manuela Schall, Bernhard Schenk

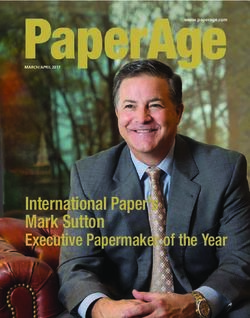

// OUR TITLE PAGE

Implementation: Publik. Agentur für Kommunikation GmbH

Picture credits: Fotolia/karepa; Thomas Frank; Freepik; Getty Images/ The new electric motor and the

Michael H, stockstudiox; Ralf Grothe; iStockphoto: corfoto, Pawel Gaul, underfloor battery of Rheinmetall

jacus, RiverNorthPhotography, smontgom65, Sussenn, Terriana, TommL; Automotive are currently being

Thomas Klink; Jakub Pojmicz; Rheinmetall Automotive AG; Gary Paul Lewis/ integrated into a testbed vehicle

Shutterstock.com based on a Fiat 500.

2 HEARTBEAT 02|2017// CONTENTS

20

PEOPLE

34

A step ahead in every respect

Fifty years ago, NSU launched the Ro 80

36

Joining forces to build a new home

US employees support social housing

project

38

Test drive with Horst Binnig

CEO of Rheinmetall Automotive

41

The hunt for energy savings

Trainees with an eye for the environment

TECHNOLOGY PEOPLE

16 26 ON SITE

E-mobility by law Taking responsibility for the future

The global automobile industry is

looking to China

Report on Corporate Social

Responsibility published

42

The cradle of the American car

18 30 Auburn Hills plant near Detroit

Starting early pays off

Welding in forging quality

Trainees learn to construct e-vehicles

Modern spin welding cell in Neckarsulm

20

Icons in black

Retro look with state-of-the-art

technology

You can find additional

information about these

articles by going to

RHEINMETALL GROUP www.heartbeat-online.de/en

24

Blue-light driving

Rescue units practice extreme

situations

3// FOCUSED

ON ACTION

Hunting for perfect pictures with four cameras

Monte Carlo, Mexico, Wales, Finland, Germany, Portugal, Sardinia …

– there is hardly any spectacular WRC (World Rally Championship)

rally or race event that Jakub Pojmicz has not already chronicled as a

photographer. He even covered the 100th Hill Climb at Pikes Peak.

5The 39-year-old Motor at the international sporting service employee from Kraków, events. “This accreditation as Poland became a rally pho- an official photographer is im- tographer because he had portant because that gets you always been fascinated by into the raceway areas that are action photography at races. off-limits to the normal hobby Of course, it is not easy for an snapshooter, which in turn is amateur to establish himself important for obtaining the re- among the many profession- ally good photo angles,” says als along the racetrack. In a Pojmicz. Moreover, this even certain sense, the publication allows him into the paddock, of a few spectacular photos which affords him a totally in trade magazines was his different insight into how the entry ticket for accreditation rally transpires. 6 HEARTBEAT 02|2017

He has attended 35 rallies in this way and I might have to quickly jump to the side and

shows no signs of slowing down, even though get to safety,” admits Pojmicz. In the mean-

a rally photographer’s day starts very early time, however, he knows the critical spots

and ends late most of the time. Early in the along the racetracks and photographs from

morning, he must scout for access routes to protected positions or uses a tripod and

the critical photo outposts and coordinate remote camera trigger wherever possible.

the general logistics of the day. Evenings are

filled with processing the garnered shots That he still manages to bring home captivat-

and sending them to the home agency as ing racing photos every time is underscored

quickly as possible. Not much time remains not only by having a photo published in the

for sleep. Furthermore, a rally photographer official Mini Auto Calendar but also by his

not only needs to remain permanently “ready many Facebook page visitors (Kuba Pojmicz

to shoot” but must also keep himself wide photo), who have already awarded his images

awake at all times: “I always stand when I’m several thousand “likes”.

taking photos, because I never know when

Above right: If you’re

allergic to dust, rallies

are not for you.

Below right: A 67 Ford

Falcon approaches

the checkered flag at

legendary Pikes Peak

Hill Climb in Colorado.

Below: Jakub Pojmicz

with his tools.

At rallies, it’s not just

the cars that produce

an adrenaline kick:

take Rally Sardegna

2015, for example.

All pictures © Jakub Pojmicz.

Who says cars For more of his photos, please go to

can’t fly? www.heartbeat-online.de/en/wild-world

7HIGHLIGHTS

VAPOR PUMP

RINSES WITH-

OUT VACUUM

// TAKING ACCOUNT

OF CHANGE

Today it’s not just vehicle

exhaust emissions that

“ChangeDriven” at IAA 2017 are subject to stricter

controls, but fuel fumes,

too. A granular activated

carbon container is used

IAA Cars takes place in Frankfurt, September 14–24, 2017. for catching these fumes,

which has to be regularly

Rheinmetall Automotive will be displaying its products in a rinsed. Pierburg has now

two-story stand with over 500 square meters of floor space developed a compact pump

for this purpose. It rinses

(Hall 8/F26). Adopting the motto “ChangeDriven”, the out the carbon container

company is taking full account of the increasing electrification without the vacuum in the

suction pipe that used to

of the drivetrain. Kolbenschmidt and Pierburg will be be necessary. The first of

its kind, this electric pump

showcasing their latest innovations, including the electric goes into production in

vapor pump that sucks up fuel vapors – a world first. series in 2018.

80 %

INNOVATIVE PLAIN BEARINGS FOR THE INTERIOR

Because electric driving is so quiet, A new Permaglide material,

any noise becomes that much more KS P150 expands the operating

noticeable. This has led to new limits of the company’s tried-and-

requirements for moving parts in tested KS P141. In combination with

the vehicle interior and plain bear- these smooth-running materials,

LE SS WEAR

ing-mounted guides. KS Gleitlager the extremely robust KS P209 is

A N D TEAR

has responded by developing a new particularly well suited to car seat

line of plain bearing materials. applications.

8 HEARTBEAT 02|2017PEOPLE

HEDDEN SUCCEEDS

DR. MERTEN

1.7 % LE SS CO 2

Specially designed for gasoline-powered engines, the Liteks-4

lightweight piston concept is ready to go into series produc-

tion. It is already being offered for high-performance applica- On July 31, 2017, after 17 successful years with

tions in connection with ring carriers and cooling ducts. Mea- the high-tech Rheinmetall Group, Dr. Peter

Merten (63, left) retired after stepping down

surements on the test stand and in a vehicle simulator resulted from his post as Chief Financial Officer of Rhein-

in a CO2 reduction of around 1.7 percent in the NEDC. Over a metall Automotive AG. The Supervisory Board of

100 million Liteks pistons have been installed since 2006. Rheinmetall Automotive AG has appointed Olaf

Hedden (53) to the Executive Board of Rhein-

metall Automotive AG as his successor, effective

August 1, 2017. Facilitating a smooth transition,

Dr. Merten will continue to serve the company in

an advisory capacity.

ACTUATOR ASSURES OPTIMUM Merten was appointed to the post of CFO on the

Executive Board in 2002. During his success-

BOOST PRESSURE CONTROL ful tenure, the company achieved sustained

profitability and emerged as a global auto parts

maker, with units in North and South America,

At IAA, Pierburg is presenting a con- – is so well cooled that it can take a Europe, and Asia, a trend which he fostered and

cept for a wastegate actuator which heavier load, enabling a lower gear guided. Horst Binnig, Chairman of the Executive

(among other things) improves the ratio between the motor and actuator Board, thanked Merten for outstanding services

boost charge control. Because it is sit- shaft and a higher dynamic response. to the company: “During his time at Rheinmetall

uated on the hot turbine, the actuator Furthermore, it is also possible to seal Automotive, company sales more than doubled.

directly propels the wastegate valve. the shaft against the aluminum hous- What’s more, CAGR during this period reached

Thermal decoupling from the housing ing to protect it from gushing water a double-digit 12 percent. This tremendous

in combination with the refrigerant without risking heat damage. achievement, accompanied in recent years by

cooling prevents overheating. This steadily high ROCE figures, was due in very

means that the 12 V DC motor used large measure to Dr. Peter Merten’s unstinting

here – an EC motor is another option efforts.”

Another seasoned industry expert, Olaf Hedden

has been with the Rheinmetall Group for many

years. He joined Rheinmetall AG in 1988, mov-

ing to Pierburg GmbH in 2002 as commercial

managing director. In 2010 he was appointed

chief executive officer of the auto parts supplier

Läpple, returning to Rheinmetall Automotive

in 2014, where, as chairman of the boards of

management of Pierburg GmbH and Pierburg

Pump Technology GmbH, he headed Mechatron-

ics, the company’s largest division, with annual

More information about sales of 1.5 billion EUR.

Pierburg actuators can be

found at www.rheinmetall-

automotive.com/en/products/

actuators

9FOCUS

// ELECTRO-

MOBILITY

COMES FROM

BELOW

Drive system and energy storage for electric vehicles in development

10 HEARTBEAT 02|201711

With its wide range of products, Rheinmetall Automotive is

ready to accommodate the increasing electrification of power

transmission. The company is busy developing a new kind of

modular battery pack as well as a 90 kW electric powertrain.

Both systems are currently being integrated into a testbed

based on a subcompact vehicle. Heartbeat spoke about this

project with Rheinmetall Automotive CTO Heinrich Dismon.

The journey along this path began a long time and series production of electric drives,” says Heinrich

ago, for electric motors are certainly nothing new for Dismon, the company’s Chief Technical Officer, “allow

the design engineers of Rheinmetall Automotive. In us to converge toward the development goal here rela-

the case of ancillary units, the OEM supplier has had tively quickly.” However, he adds that they fell back on

an established development competence for electric additional support from development service providers

powertrains for decades. For example, the company in the initial phase. Dismon’s goal is a completely elec-

conceived the first fully electric coolant pump for the tric traction drive that, in addition to the electric motor,

main cooling system via its subsidiary Pierburg as early also has the control and power electronics as well as a

as 2004 and successfully introduced it onto the market step-down gear made by Rheinmetall Automotive and

in the six-cylinder engines of BMW. designed according to the application.

Orders for electric motor casings

Since its market launch in 1995, the electrically com-

mutated water recirculation pump, likewise developed

by Pierburg and produced at the Hartha plant site in

Saxony has meanwhile already exceeded an output of

50 million units and is utilized worldwide by leading PRODUCTION OF

manufacturers and suppliers in automotive engi- BATTERY-POWERED VEHICLES

neering and beyond. In addition orders come from Forecast of IHS Automotive for worldwide production

international OEMs for electric motor and aluminum of battery-powered vehicles in million units

battery casings soon to go into series production at

Rheinmetall Automotive. The product range of the 2025

company in electromobility is supplemented through 4 3.84

electric oil and vacuum pumps, electric coolant valves

and actuating elements, a heat pump and special light

aluminum constructional components. 3

Complete traction drive as the goal

Now, with its new electric drive and parallelly de- 2 2017

veloped battery pack, the international automotive

supplier is starting a new chapter in its development 0.77

history. For its newly conceived products in electromo- 1

bility, Rheinmetall Automotive decided not to focus on

energy storage and electric drive (with its peripheral

equipment) solely due to market-related reasons. 0

“Our basic competences in the development chain 2010 2017 2025

12 HEARTBEAT 02|2017Inquired!

their car three times per week

and even then merely for short

trips most of the time.

Moreover, due to the technical

Compact class targeted parameters, e-mobility will bring

The newly introduced electric powertrain with 90 kW us into a situation in which

power, however, aims not at the absolute upper levels we must compensate for our

of performance à la Tesla but rather is located in the previous “carefree attitude”

upper segment of compact electric engines. In its cur- through a more well-planned

rent design, it aims at smaller vehicle classes, whereby way of acting. In the future, we

the scalability of the system also enables utilization will certainly have to give more

in larger vehicles. The reason for this was the insight thought to which distance we

that “electromobility will develop from the bottom Heinrich Dismon can master in which timeframes

up,” says Dismon. He estimates that the future will Chief Technical Officer and calculate accordingly.

Rheinmetall Automotive AG

bring various forms of drive systems ranging from the

central drive unit to drives close to the wheels. At the In the medium term, I believe

same time, electric vehicles for, say, urban zones will // Will electrical mobility alter electromobility will happen

be more likely to come in smaller power performance our driving habits? within a range of up to 400

ranges of 30 to 50 kW. We currently have the situation km radius. That’s absolutely

that vehicles are offering ever adequate for the predominant

more comfort, but also bearing share of our normal driving

ONE ALSO NEEDS TO CONSIDER more weight. In e-mobility we destinations.

will increasingly see vehicles

SMALL VEHICLES BEYOND that are decidedly conceived In 2030, we won’t yet be ready

THE PASSENGER CAR for electric driving. Inevitably, to fully replace the combustion

they will have to be smaller and engine with new technologies.

lighter and have less power. I even believe we won’t be able

New players on the market to completely replace it.

Furthermore, new manufacturers (OEMs), for whom In this respect, e-mobility will

a proprietary development of an electric drive is not influence us. But there are also

necessarily a priority, will be active in this area in the people today who only drive

future. In addition there will be new market segments,

such as multipurpose applications extending beyond

pedelecs. The drive that will therefore be proprietarily

manufactured by Rheinmetall Automotive in the future

is tunable and scalable for the intended use in terms

of performance and torque. The engine technology

is also basically insertable into a mild hybrid and

applicable there for functions such as electric parking,

autonomous driving into the garage, or for shifting the

operation range of the combustion engine to save fuel.

Underfloor batteries preferred tion space requirements, enables a very flexible and

In the layout design of the developed battery pack, broad application basis in electrified vehicle concepts.

Rheinmetall Automotive assumed that a significant

portion of future electric vehicles and even hybrids An important question at the outset was whether one

will possess underfloor batteries. They do not sig- should commit to using a certain cell type. Howev-

nificantly limit the load volume of the vehicle and, in er, the company pursues an open strategy here that

addition, also offer advantages regarding both weight enables integration of various different battery cell

distribution and possible incorporation into the vehicle types and can therefore be interesting for many OEMs.

structure. Dismon: “Today almost all vehicles on the Dismon: “We don’t want to get into cell technology, but

market are derivatives of existing concepts on the rather to configure a system for our customers with the

basis of combustion engine drives. In the future, that cells of their choice.”

will no longer be seen.”

High energy density

The battery pack features a very high energy density in Due to their high specific energy density and good

proportion to its weight and, due to its small installa- thermal conditionability, Rheinmetall Automotive

13utilizes pouch cells for the rechargeable batteries of its

testbed. Beyond this, however, concepts with cylindri-

cal or prismatic cells also exist, enabling one to cater

135

to customer-specific requirements. KM/H

is the top speed attained by

Temperature control also in the battery pack the Rheinmetall Automotive

To ensure that the battery packs can also withstand testbed vehicle, which is

high power drains and prove suitable for heat-intensive based on a Fiat 500 with an

rapid charging, they were outfitted with a coolant-per- electric motor.

fused floor cooling, which drew from the manufactur-

ing expertise of the supplier in aluminum die casting.

An electric coolant pump conducts the coolant into

a heat exchanger. In connection with the similarly

developed heat pump, recuperation can occur or the COMPACT

energy can be used for heating or cooling the interior. DESIGN

Moreover, at low temperatures it is also possible to

The space-saving design of the

regulate the temperature in order to avoid damage to

drive used here is intended for

the battery.

smaller vehicles.

WE DON’T WANT TO GET

INTO CELL TECHNOLOGY

Underfloor battery pack with special protection

The skeletal structure of the battery casings developed

by Rheinmetall Automotive for these applications

consists of aluminum, which is additionally protected

from damage through a superimposed fiber compos-

ite structure. The corresponding fiber is supplied by SCALEABLE

a Rheinmetall affiliate that specializes in protective

applications. SYSTEM

In terms of output and torque,

Testbed with systems approach the drive is scalable. This

The battery pack of Rheinmetall Automotive’s Fiat means that it can also be used

500-based testbed (see cover image) is equipped with for powering larger vehicles.

a nominal storage capacity of 29 kWh. In connection

with the new electric drive, the vehicle achieves a top

speed of 135 km/h and a range of up to 275 kilome-

ters. These parameters are accomplished without

limiting the usable space for the trunk or passenger

compartment known from the series production

vehicle. Rheinmetall Automotive sees this configura-

tion oriented toward future electric vehicle concepts

as an example for a possible series concept, whereby

of course other constellations can also be realized in

accordance with customer wishes. POUCH CELLS

Pouch cells are built into the

testbed vehicle’s batteries;

but it is also possible to

integrate other cell types.

14 HEARTBEAT 02|2017AT A GL ANCE

A multitude of innovative features characterize

the electric motor and underfloor battery.

Rheinmetall Automotive is currently integrating both

new systems into a testbed vehicle. 90KW

output produced by the

Rheinmetall Automotive

motor.

275

KM

is the operating range of the

QUICK CHARGING testbed vehicle equipped

Thanks to the coolant- with the battery pack.

circulating floor cooling system,

the battery pack is suitable for

heat-intensive quick charging.

29 COMPOSITE FIBER

STRUCTURE

KWH

is the nominal storage capacity

MODULAR A composite fiber structure encloses

the battery case, providing it with

of the battery pack built into the DESIGN added protection from damage.

testbed vehicle. The modular design enables

a high degree of flexibility

with regard to application.

15TECHNOLOGY

// E-MOBILITY

BY LAW

The global automotive industry is looking to China

China is emerging as the world’s leading market for electrically powered

vehicles. Eager to help e-mobility make the ultimate breakthrough, the

government in Beijing has adopted a policy of ambitious legal quotas,

massive subsidies, and systematic expansion of infrastructure.

Measured in absolute numbers, China e-vehicles and 98,000 plug-in hybrids were action in the country’s urban centers: many

is already the world’s most important sold last year in China, including 336,000 of China’s megacities suffer from severe

market for new energy vehicles, or NEVs. passenger cars and 171,000 commercial air pollution; switching to e-buses is an

The government in Beijing defines these as vehicles. By way of comparison, during the efficient means of improving air quality.

electrically powered cars, plug-in hybrids, same period in Germany, a mere 11,400

and fuel-cell vehicles, although the latter pure electric vehicles were sold, plus Incentives and infrastructure

still play no role. 13,744 plug-in hybrids. When it comes to passenger cars, the

government is also taking the lead. For one

NEVs in the fast lane Of those 171,000 commercial vehicles, thing, the purchase of e-cars and plug-in

In 2016, some 417,000 electric cars were 115,000 are electrically powered buses – hybrids is being promoted financially in a

produced in China. With annual production an excellent example of China’s top-down multitude of different ways; for another,

of around 200,000 e-vehicles, Germany “e-volution”: more and more public trans- vehicles with alternative drive technologies

comes in second place, followed by the port companies are converting their fleets in metropolitan areas receive coveted reg-

USA with 148,000. When it comes to new to nonpolluting vehicles. In doing so, they istration much more quickly than conven-

registrations, however, China’s lead is even are toeing the party line. The government in tional vehicles. Last but not least, China is

more impressive: no less than 409,000 pure Beijing has recognized the need for urgent swiftly expanding its network of charging

16 HEARTBEAT 02|2017poles. In the future, all new buildings will cles. The production licenses are valid only

be required to have charging stations for for NEVs and are awarded in an accelerated

electric vehicles. Ten percent of existing process. In May 2017, for example, a license

parking places are being retrofitted with of this type was awarded for a joint venture

charging units. By 2020, no fewer than 4.8 between Volkswagen and Anhui Jianghuai

AMOUNT OF NEW

million charging stations are to be installed Automobile Company.

in the People’s Republic of China.

ENERGY VEHICLES FOR

NEW CARS IN CHINA Rheinmetall Automotive is upbeat

(OBJECTIVE OF THE CENTRAL

In the future, the share of e-cars will con- “The Chinese government’s extensive pack-

GOVERNMENT)

tinue to increase significantly. The central age of measures in conjunction with new

government has set ambitious targets: in forms of supply will continue to spur the

the year 2020, two million NEVs are to be market for electric vehicles on, solidifying

built in China, and by 2025, somewhere China’s pioneering role as the world’s most

between 15 and 20 percent of all new 2025 important automobile market,” declares

vehicles sold in the country are supposed

to be e-vehicles or plug-in hybrids. By 2030,

15–20% Horst Binnig, Rheinmetall Automotive’s

chief executive. In the meantime, the

the share should rise to forty or even fifty 2030 Neckarsulm, Germany-based Group sees

percent. There is no room for doubt that

Beijing is serious about this plan. The first

40–50% itself as well equipped to deal with the

altered underlying conditions. The company

big step – at least as things stand at the has been present in China for over twenty

moment – is due to take place very soon: in years. In the meantime, its 5,000 employ-

June 2017, the central government passed ees generate annual sales of just under

a law stipulating that, starting next year, 1 billion EUR. Rheinmetall Automotive’s

PRODUCTION OF

carmakers will have to make sure that eight presence in China now runs to ten com-

percent of all vehicles sold are either purely E-CARS IN 2016 panies: three fifty-fifty joint ventures, two

electric or plug-in hybrids. This rule applies majority joint ventures, and one minority

to all carmakers with a production volume joint venture for piston rings.

CHINA

of over 50,000 units per year. Despite

political resistance from Germany, Beijing is

409,000 Rheinmetall Automotive’s array of products

sticking to its guns. extends from electrified components for

hybrid drives (e.g. controllable ancillary

These government measures are also shap- GERMANY generators and pumps) to lightweight

ing the structure of the industry. Following 200,000 designs and products for pure e-mobility.

a decision by the Central Committee in Oc- These include battery mounts for electric

tober 2016, new vehicle manufacturers will vehicles and special casings for complete

receive a permit without difficulty only if USA electric motors, which in the future Rhein-

they are capable of producing electric vehi- 148,000 metall Automotive plans to manufacture on

location for the Chinese market. Moreover,

both the company’s Range Extender REx

and new heating and cooling module offer

numerous potential uses in electric vehicles

Chinese police departments also (see Focus story page 10 onwards ).

increasingly opt for electric vehicles.

For more information about

Rheinmetall Automotive in China visit

cn.rheinmetall-automotive.com

17TECHNOLOGY

// WELDING IN

FORGING QUALITY

Modern spin welding cell in Neckarsulm

The Kolbenschmidt factory site Neckarsulm is the main

plant for steel pistons within the Group. In its state-of-

the-art premachining line for steel pistons, Rheinmetall

Automotive exploits an innovative technology: spin welding.

The premachining line consolidates

all of the working steps downstream from

forging under one roof. This has not only

increased the in-house production depth

in the Neckarsulm plant but has also

cemented its status as a worldwide leading

production facility for steel pistons. One

particular highlight of the line is its spin

welding cell.

Frictional heat instead of electric arcs

Now to explain how the process works

or, more precisely, the flywheel friction

welding variant used here: firstly, the top

and bottom sections of the steel piston are

machined. The bottom section is tightly

mounted in a tailstock; the upper section is

held from the chuck of a spindle possess-

ing a flywheel. The flywheel is accelerated

until it reaches a predetermined rotational

speed. The power is then switched off and

both parts are pressed together through a

hydraulic cylinder exerting up to 100 metric

tons of pressure. The resulting friction de-

celerates the flywheel and simultaneously

The heat caused by converts the kinetic energy into frictional

friction makes metal heat, which is sufficient to melt both the

so soft that the

work-pieces fuse to

adjacent surfaces of the two parts. In this

each other. state, the two component parts can be

bonded. Besides the automotive industry,

18 HEARTBEAT 02|201780–200

MILLIMETERS

IS THE DIAMETER

RANGE OF THE

PROCESSED STEEL

PISTONS

60

SECONDS

REQUIRED FOR A

WELDING PROCESS

270,000

COMMERCIAL VEHICLE

STEEL PISTONS C AN

BE PRODUCED AN-

NUALLY ON THE NEW

PRODUCTION LINE IN

Processes in the welding NECKARSULM

cell are extensively

automated.

the flywheel friction welding process also process, thermal stress on the material is

for example finds application in aerospace minimal, which bears out in the outstand-

technology. ing quality of the resulting bond. Schaller

can also list further advantages: “The base

Flexible cells material isn’t melted, so that prevents any

The facility in Neckarsulm is now exclusive- danger of pore formation, solidification

ly used for manufacturing steel pistons, defects (like gas porosities) or slag inclu-

having also been especially designed for sions. Even liquations – meaning undesired

this purpose. The friction welding cell is separations – can’t occur. The quality is on

flexible in terms of the size and design the same level as forging.”

of pistons it can accommodate: welding

is possible for pistons with diameters No emissions

ranging from 80 to 200 mm. Currently Employees also appreciate flywheel friction

manufactured steel pistons are composed welding when they are working near the

of the heat-treatable steel 42CrMo4 or the largely automated welding cell: the process

micro-alloyed steel 38MnVS6. However, normally requires neither additional weld-

one can also use alternative steel material ing material or gas nor emits harmful radi-

grades, such as Inconel steel. ation, splatters, or fumes. “No suction is

necessary because workers face absolutely

The procedure offers many advantages over zero danger from hazardous substances,”

Christian Schaller with friction-welded conventional welding with regard to both explains Schaller. “Friction welding does

steel piston components. production flow and quality. For example, without electric arcs or laser beams, which

welding times are exceedingly short. “In thereby eliminates any risk from optical

the new friction welding cell, a commercial radiation. This not only makes it easier to

vehicle piston can be welded every 60 view the process but also removes any pos-

seconds,” explains Project Leader Christian sible qualms or uneasiness about getting

Schaller. Furthermore, because the material hands-on.”

is only heated and not melted during the

19TECHNOLOGY

// ICONS IN

BLACK

Retro look with state-of-the-art technology

Back in black: The majority of the

next generation of London taxis

will also be painted in black.

20 HEARTBEAT 02|2017Just like Tower Bridge, Big Ben, or the red double-

decker buses, they are the emblem of the British

capital: the characteristic black cabs. Locals

and tourists use this means of transportation

300,000 times per day to reach their destination

through the maze of streets in the vibrant city. The

manufacturer is LEVC – a company that produces

only taxis, and soon a model with electric drive.

Around 20,000 of the rolling classic Despite the retro look, the London Electric

cabs are currently driving through the Vehicle Company (LEVC), that operated as

London streets. Not only the current mod- the London Taxi Company until July 2017,

el, the TX4, but also many older versions builds modern technology. It’s no surprise

– an indication of the robust design that – after all, the latest generation of black

characterizes the London taxis. With their cabs was a new product in 2007, and is

striking radiator grille, round headlamps, undergoing constant development.

and tapering snout the black cabs give

the impression they are behind the times. Nimbler than a Polo

The strength of the concept lies in the

details. From the very beginning the

TURNING CIRCLE ONLY vehicle was designed as a taxi, which has

AROUND EIGHT METERS – manifested itself in many unique design

features. One example would be the small

LESS THAN THE CURRENT turning circle: the black cab needs only

POLO about eight meters to turn on the road;

which is two meters less than the current

VW Polo.

This can clearly be seen in the heredity

of their famous predecessor – we are High comfort

speaking about the Austin FX4 which was There is room for five people in the

constructed with the nearly the same look separated passenger compartment as

from 1958 to 1997. But this itself is one of standard. Where the front passenger seat

the reasons why the traditionally-minded would be – of course on the left in the

English still love their taxis so much today. United Kingdom – there is no seat. Passen-

21Whether in narrow

alleys or in front of

luxury hotels – the

new electric black

cabs look good

everywhere.

ger baggage is stowed here. The cab is ex-

emplary when it comes to comfort for the

elderly and disabled: a seat can be folded

out towards the sidewalk when the door is

open, and a wheelchair ramp is standard

equipment. But LEVC has not only thought

about the passengers, but also about

the driver. The taxi has a special safety

feature: the rear doors cannot be opened

when the driver keeps the brake pedal

pressed down. So passengers cannot

disappear before they have paid.

HOW DO I GET THE GREEN BADGE?

Not everyone in London can Mental and physical health: The FROM 2018, TAXIS WITH

get one of the sought-after taxi applicant may not suffer from, for

licenses, called the Green Badge. example, heart conditions, mental DIESEL ENGINES WILL NO

Applicant requirements are among disorders or nervous disorders.

the strictest in the world.

LONGER BE LICENSED

“The Knowledge”: the biggest

Minimum age: An applicant must hurdle is to pass this test. The

be at least 21 years old, although applicant must prove knowledge Zero-emission future

there is no maximum age. of 320 routes in a six-mile radius For all of its tradition, LEVC knows the im-

around Charing Cross. These portance of keeping up with the times. The

Character: Each applicant must include around 25,000 streets and next taxi generation, the TX5, will there-

declare any previous convictions. 20,000 landmarks. Most drivers fore be electrically powered. On the one

Suitability as a taxi driver may be need a preparation time of between hand, LEVC is following the general trend

ruled out for serious offences. A two and five years before they can towards sustainability. Additionally, there

person who withholds information pass this test. is also a very special reason for this in

is barred from the application

London itself: since 2008, nearly the entire

procedure.

city area has been a low emission zone in

which very strict conditions for operation

22 HEARTBEAT 02|2017The hard tests for the

new model were held

in the widest range of

climatic conditions.

of motor vehicles apply today. In 2020, the grounds, please see the next issue of

inner city area, which extends from Victo- Heartbeat.

ria Station in the west up to Tower Bridge

in the east, will also be designated as an First pure electric car plant in Europe

ultra low emission zone with even greater The electric car comes from a brand-new

demands on emissions. This will have mas- factory in Ansty near Coventry that opened

sive effects on the taxi industry as early as in March 2017. The plant is not only the

next year: from January 1, 2018 taxis with first new car factory in the United Kingdom

diesel engines will no longer be licensed. from some ten years, it is also the first in

The vehicles must be able to drive for up Europe that builds only electric vehicles.

to 48 kilometers with zero emissions. They The LEVC parent company, the Chinese

may discharge a maximum of 50 grams Geely Group, has invested over 300 million

CO2 per kilometer. pounds here in the Midlands. The plant ca-

pacity lies at over 20,000 vehicles per year

Revolution under the hood and over 1,000 new jobs were created. The THE LONDON ELECTRIC

The TX5 fulfils exactly these requirements. TX5 market launch is planned for late 2017

VEHICLE COMPANY

The electric motor made by the LEVC sister in the United Kingdom, and 2018 for the

company Volvo is derived from the T8 Twin rest of the world. But whilst new ground In 1899, LEVC was originally

Engine that is currently in service in the has been broken with the inner workings, founded as London Taxi Company

Volvo XC90. Exact performance details the optical changes are moderate. A black Ltd. From the very beginning its

have not yet been announced, but they cab will remain a black cab, even in the operations covered solely the

are good enough to accelerate the TX5 to future! development and production of

130 kph. The lithium-ion battery enables taxis. The company has been a

pure electric driving for over 160 kilome- wholly owned subsidiary of the

ters. When the battery reaches its limits a Chinese Zhejiang Geely Holding

since 2013. The manufacturer is

three-cylinder range extender takes over.

on the road to success, as is illus-

The range extends to over 640 kilometers trated by the new plant in Ansty.

with the Volvo 91 hp gasoline engine. Since July 2017, the company has

Rheinmetall Automotive supplies several been operating as the London

components for these vehicles. To learn Further information at w

ww.theelectrictaxi.co.uk Electric Vehicle Company – a clear

more about details and technical back- and www.tiny.cc/taxis-minicabs statement on electric mobility.

23RHEINMETALL GROUP

// BLUE-LIGHT

DRIVING

Rescue units practice extreme situations

As realistic as

possible: Software

engineer Peter

Hürzeler experiences

emergency driving

in a simulator from

Rheinmetall Swiss

SIMTEC.

24 HEARTBEAT 02|2017The rhythmically flashing blue lights reflect

on the walls of the buildings in the deepening

twilight. Meanwhile, rain droplets beat

down upon the ambulance windshield in since early this year. Among other product lines, his

company specializes in this type of training simulators

loud exploding spheres, accompanied only within the Rheinmetall Technology Group.

by the penetrating blare of the siren. At the forefront of technology

In the meantime, the special blue light driving simula-

tors account for about 20 percent of its annual sales

revenue. Walther knows that maintaining as much

realism as possible is crucial for the success of the

exercise: “The realism depicted in the simulators never

ceases to delight our customers.” By contrast with

The dispatcher reconfirms the emergency location competing systems, his almost 180,000-EUR-machines

over the radio. Through the vibrations in his seat and feature ultrahigh 4K resolution monitors. In a certain

steering wheel, the driver senses the cobblestone pave- sense, they function as the windshields of the emergen-

ment beneath his racing ambulance. He instinctively cy vehicle – and can even fog up when desired to make

moves in parallel with the rolling motion of his vehicle the exercise more challenging. Furthermore, the entire

as he speeds across downtown Zurich to the reported driver’s cab rests on servomotors that are maneuver-

scene of the accident. He glances in the rearview mirror able in six directions. Jolts and vibrations are directly

to see whether he can switch back into his lane after relayed to the driver via the seat. The simulators are

just passing a motor scooter. He has just spotted the equipped with very complex software jointly developed

“School Crossing” sign in the corner of his eye when with the parent company in Bremen that – whether it be

a child suddenly jumps out from behind a parked car in a police car, ambulance, or fire truck – simulates vir-

onto the rain-slicked street. tually any conceivable crisis situation, thereby enabling

it to be drilled and practiced.

Deer on the right

IT’S NOT ONLY IN SWITZER- It doesn’t matter what the road condition, weather,

crisis scene or dangerous situation might be. From the

LAND THAT PRACTICING aforementioned urban street scenario to an unexpected

EMERGENCY AMBULANCE deer crossing on an icy country road to a multi-vehicle

pursuit of a lunatic driver on the highway, almost every

DRIVING PROCEDURES IS possible contingency can be trained and prepared for.

Other realistic situations increasingly encountered

GENERALLY PROHIBITED. include a missing emergency lane or a traffic partic-

ipant overwhelmed by the flashing blue lights of an

Johann Walther, Managing Director of approaching vehicle.

Rheinmetall Swiss SIMTEC AG

Eye tracker sees everything

Test persons in the driver’s seat are thoroughly pushed

A situation absolutely no one wants to encounter – the to their limits. For example, even when using blue

kind that tests the nerves of even the most highly expe- lights and the siren while in hot pursuit of a potential

rienced ambulance drivers. A situation everyone is hap- criminal, police must constantly weigh the appropriate-

py to have faced as an exercise in a simulator without ness of their actions and decide accordingly. No wonder

anyone actually getting hurt. “Since Switzerland isn’t sweat appears on the foreheads of practicing drivers

the only country where running rescue training mis- as a modern, completely helmetless and goggleless

sions with blue lights and sirens is generally forbidden, eye-tracking system registers the fixed points in the

police, ambulance, and fire rescue units have no other rearview mirror or direction of travel and relays them to

option than to practice their crisis skills in a simulator,” the monitor of the exercise instructor. After all, practice

explains Johann Walther, who has been CEO of Rhein- makes perfect – especially when driving under blue-

metall Swiss SIMTEC AG based in Thun, Switzerland light conditions.

25PEOPLE

// TAKING RESPON-

SIBILITY FOR THE

FUTURE

Corporate Social Responsibility report published

We live in an age of far-reaching changes and worldwide challenges. The rise

in geopolitical and economic insecurities, demographic imbalances, altered

societal values, resource scarcity, climate change and new mobility concepts

and production precepts like Industry 4.0 are only a few of the underlying

trends. Public interest in sustainability and environmental and ecological

protection is increasing. At the same time, companies are also increasingly

called upon to contribute toward sustainable societal development.

26 HEARTBEAT 02|2017their activities upon society. This includes

economic, ecological, and social aspects.

In concrete terms, for example, it involves

fair business practices, an employee-orient-

ed personnel policy, frugal use of natural

resources, protection of our climate, ecol-

ogy, and environment, sincere social and

societal dedication in our local areas, and

assumption of responsibility, especially in

the supply chain.

// Was that uncharted territory for the

company?

Ursula Pohen: No, sustainability is nothing

new and no “buzzword” within the Rhein-

metall Group. Rather, it has already been

an established component of the company

culture for many years. The Management

Board is committed to holistic, transparent

management oriented toward long-term

business success which, in addition to eco-

logical factors, also integrates social and

Corporate Governance factors into business

operations. At the same time, assuming

The companies within the Rheinmetall responsibility has always been a matter of

Group are doing a great deal for the envi- course.

ronment and society in numerous ways and

the first report on Corporate Social Respon- // The first sustainability report has now

sibility (CSR) was also recently published. been published. What was the deciding

Why this area is so highly important within factor for this?

the Group is explained in the following Ursula Pohen: Rheinmetall has already

interview with Ursula Pohen, responsi- been reporting about CSR on its web-

ble for CSR both at Group level and the site and in the annual report since 2011.

corporate Defence Division, and Annemarie However, the requirements for content

Köhler, responsible for CSR at Rheinmetall and structure placed on reporting about

Automotive. sustainability topics have significantly in-

creased in the past several years. This trend

// First, a basic question: how do you de- has been strengthened not only through

fine Corporate Social Responsibility? national initiatives, international standards,

Ursula Pohen: Corporate Social Responsi- and CSR indices but also through legisla-

bility, CSR, encompasses the responsibility tion. Starting in the 2017 fiscal year, the

of companies for the repercussions of CSR Guideline Implementation Act will ob-

CORPORATE RESPONSIBILITY

CORPORATE CORPORATE

CORPORATE GOVERNANCE

SOCIAL RESPONSIBILITY CITIZENSHIP

ECONOMIC ECOLOGICAL SOCIAL

RESPONSIBILITY RESPONSIBILITY RESPONSIBILITY

27ligate certain large capital market-oriented we are naturally in the public eye. But

companies, as well as large credit institu- customers and business partners also need

tions and insurance companies in Germany, detailed information from us regarding

to report about essential nonfinancial organization, structures, and procedures in

matters. As a minimum, the reporting here the area of CSR. Above all, comprehensively

280,000 * encompasses details about environmental, evaluating the supply chain in terms of sus-

employee, and social concerns, observance tainability is becoming increasingly import-

LITERS OF FUEL

OIL SAVED of human rights, and combating corruption ant. We need to ensure that environmental

AT UNTERLÜSS and bribery. and social standards are maintained along

the entire value chain. For example, the

Annemarie Köhler: Our stakeholders, guiding principles of the industry standards

which include shareholders, customers, AIAG and the European Automotive Working

employees, applicants, investors, suppli- Group on Supply Chain Sustainability are

ers, analysts, creditors, media, the local very important for Rheinmetall Automotive

communities at our sites, and of course the within this context. All prominent manufac-

50,000 general public, expect transparent, infor-

mative, and understandable information

turers are working to fulfill these standards

and pass them along the supply chain.

KWH SAVED about how our corporate Group handles its

BY LED LIGHTING societal responsibility. What we do, how we Ursula Pohen: One should also add that in-

AT TRITTAU

do it, and why. With the CSR report, which vestors are increasingly taking environmen-

is oriented based on the internationally tal, sustainability, and human rights factors

leading Version 4.0 standard of the Global into consideration in their decision-making

Reporting Initiative, we present many processes. In this respect, rating agencies

examples of responsible conduct in a broad also evaluate Rheinmetall regarding Com-

survey across the entire Group. pliance, Corporate Governance, HR, and en-

vironmental aspects. With the data material

// Leaving legislation aside for the mo- prepared in a structured way for the CSR

300,000 ment, were there additional reasons for

publication?

report, we can now answer enquiries more

completely and thoroughly. We have here

KWH SAVED Annemarie Köhler: As a company listed in the chance to score better in the ratings. In

AT BREMEN

the German MDax stock exchange index, addition, this allows us to further develop

* All numbers refer to the

2016 fiscal year.

Rheinmetall Automotive

backs Formula Student,

helping to pave the way

to sustainable mobility.

28 HEARTBEAT 02|2017SUSTAINABILITY REPORT

2017

The Sustainability Report documents

Rheinmetall Group’s commitment

to economic, ecological, and social

responsibility.

Ursula Pohen, CSR Officer, Annemarie Köhler, CSR

Rheinmetall Group and Officer, Rheinmetall

Rheinmetall Defence. Automotive. CO R P O R AT E R E S P O N S I B I L I TY R E P O RT 2 01 7

our CSR activities in an even more targeted system. Prudent handling of materials,

manner, to start Group-wide campaigns energy, water, and waste – as well as the

regarding individual topic clusters, and plan avoidance of hazardous consequences to

our goals more easily. the environment in business and produc-

tion processes – are among the central

// Which subjects do you believe come bases for the business operations of the

as a surprise to the readers of the CSR companies. This not only preserves the

report? environment but at the same time can also

Ursula Pohen: Many ecological and societal reduce costs. Moreover, 40 companies and

aspects of our sustainability activities plant sites are currently certified pursuant

are little known to the public or are not to ISO 14001, according to ISO 50001, as The complete Sustainability Report

necessarily associated with us. In addition well as eight according to OHSAS 18001 – is available to download:

www.rheinmetall.com/en/rheinmetall_ag/

to our involvement in ecological and animal with more to follow. corporate_social_responsibility/csr_report

protection on plant premises in Germany,

Switzerland, and South Africa, these in- // In your view, which sustainability activi-

clude for example the creation of 100 train- ties are important for the employees of the

ee and apprenticeship positions to support Rheinmetall Group?

integration of foreign refugees in Germany. Annemarie Köhler: I think that the diverse

And they also include entire urban district advanced training programs, numerous

building developments in Düsseldorf and offers regarding work-life balance, and

Hamburg. frequent events within the framework of

health management are very well received

// How is sustainability anchored in the by our colleagues. In addition, the dedica- 5,000

company organization? tion of the Rheinmetall Group is positively M 3 WATER

Annemarie Köhler: First of all, sustain- evaluated in the areas of science, educa- SAVED AT

NECKARSULM

ability falls directly within the responsibil- tion, athletics, and regional aid projects.

ity of the CEO of Rheinmetall AG. Due to

advancing developments in this sector, we

restructured this area in 2014. The Corpo-

rate Responsibility Panel, which represents

executives from all Divisions as well as the

Management Holding, promotes the ex-

pansion of sustainable activities. The topic

areas comprise Corporate Governance,

Corporate Citizenship, and Corporate Social

Responsibility with a focus on economic, 8,700

ecological, and social responsibility. TREES DONATED BY

KS KOLBENSCHMIDT

// Does that also apply in Production? WITH PARTNERS AT

NOVA ODESSA,

Annemarie Köhler: Absolutely. We define BRAZIL

conservative use of natural resources as

an integral component of the management

29PEOPLE

// STARTING EARLY

PAYS OFF

Trainees become design engineers of electric vehicles

Starting calls for

full concentration.

So don’t get dis-

tracted, even when

SWR television is

present.

30 HEARTBEAT 02|2017Neckarsulm’s training officer

Nobert Roth gave the starting

signal for “The Race“.

Racing fever has hit Rheinmetall Automotive.

The staff parking lot at the Neckarsulm plant

has been transformed into a mini autodrome

overnight. Pup tents and a workshop truck line

the track. Alongside are the pit box positions

of five small but quick-to-accelerate electric Clear rules

vehicles, to which the various young design The young design engineers were able to

let their creativity run free in the project,

engineers are busily putting their finishing but had to observe precise guidelines

regarding necessary safety requirements.

touches in preparation for the race. At the same time, the shape of the vehicle

bodywork and the applied material could

be freely chosen. However, the vehicle

A start and finish line with a velocity dimensions were subject to a size lim-

indicator complete the image of a drag itation. Guidelines also governed the

relay demanding to be mastered. 280 train- chassis frame: in addition to a floorboard

ees of the automotive supplier encircle the and pneumatic tires of variable size,

course, roaring cheers for their individual front-wheel steering had to be installed.

teams at the drop of the starter’s flag. The mandatory braking system was also

supposed to withstand repeated brake

Everything began a good half a year ago applications.

when the company announced the race

competition to its trainees, thereby also As in real racing sport, drivers of course

bringing the subject of new drive technol- had to wear helmets. Moreover, the vehi-

ogies into focus for its young employees. cles were only allowed to drive at a maxi-

With a budget of 2,500 EUR each, their mum of 25 km/h, which was controlled by

task was to develop and build a fully func- a speedometer panel. High standards were

tional race car with an alternative drive in also set for the energy storage system,

only a few months. At the German national which had to be designed to last for the

trainee day, now hosted for the fifth time, entire race because switching batteries

they were then supposed to test their was not allowed.

mettle in a drag race. This challenge drew

plenty of takers: in total, five teams from High demands

Berlin, Neckarsulm, Neuss, Papenburg, and “We’re of course aware of the challenges in

St. Leon-Rot entered the race. the planning,” says Werner Böckle, Senior

31The winning team:

Pierburg from Neuss.

Vice President of Human Resources at challenge. “Our advantage also lay in

Rheinmetall Automotive, “but this is how constructing the auto in a way that allowed

our trainees learn to take responsibility the driver to get in and out quickly,” Simon

for handling the project in a team and Rambow summarized. The mechatronics

completing it on time – in addition to the engineer in his second year of apprentice-

purely technical contest involving electric ship was responsible for the drive devel-

vehicles.” opment for the Niederrhein team. Further-

more, intensive preparatory training also

The self-built electric vehicles presented proved to be an advantage and saved the

subsequently came about through metic- winning team precious seconds.

ulous preparation, though things did not

always run smoothly. As Robert Hüsken,

student apprentice responsible for the NOT ONLY THE PER-

chassis frame on the Niederrhein team,

summed it up: “You only realize all the FORMANCE OF THE

things that can go wrong and learn how to CONSTRUCTION WAS

collaborate with people effectively and well

during the actual work.” The project was CREATIVE, BUT ALSO

thus a meaningful experience for him. THE PRESENTATION

In the end, everyone came out as winners

In the final race, the five teams needed However, winning the drag race was not

to complete a short 100-meter-long track. the sole factor in determining the over-

The vehicle was turned around at the all result. Teams were also evaluated on

end points and then it was time to switch the presentation of the project, technical

Also this young colleague drivers. That allowed each team member implementation, and design quality of

from Papenburg jumped to drive along the raceway themselves the vehicle, as well as general teamwork

straight into action.

and navigate the team vehicle under race and internal organization. The teams also

conditions. At the end of the time trial, demonstrated a high degree of creativity

the trainees and student-apprentices in their presentations. Introductions of

from Pierburg in Neuss came out on top, participants and vehicles were peppered

whereby however everyone unanimously with special effects and video messag-

agreed that every team profited from the es, while the poetry slam composed by

32 HEARTBEAT 02|2017You can also read