Humidity Monitoring Overview U Johannesburg - OPC

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

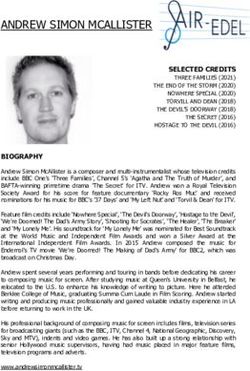

Humidity Monitoring Overview

U Johannesburg

Sensitive region

ATLAS ITK

New radiation hard

fibre optic

humidity sensors

Pair of (LPG for RH, FBR for T)

OPC ATLAS

DAQ PC

UA Server P1

UJ group : 30 June 2021 CFD modelling for the ITk 1Humidity Monitoring – Updates, Issues

1. CFD Studies Ongoing

a) Temp FDR : Inner Pixel Bakeout Sim – interim report

• Meshing now converging

• Sim of N2 flow no thermals OK,

• Add heat transfer, needed to mesh 4 x finer …. Reduce under-relaxation be x 0.1

• Ongoing (maxed out the number of cells over 108, looking at larger meshing resource)

• Adapted the boundary conditions for bakeout … see sketch below

b) Inner Pixels and Outer Pixels CFD

• Outer causing issues to mesh with many narrow gaps – but progress

• Adding simplifications to resolve – Matt to report now

a) Strips CFD study with new N2 flush and in-leak rates

• Completed – Pedro report

b) Manifold Optimisation CFD

• Report available

2. Post PDR

a) Sacrificial Sensors type, connection at PP! being resolved. Need a test

b) https://docs.google.com/document/d/1KWKQOntywhOIrBAmS4C_6m-4UcstzoxT/edit

3. Irradiations

a) Campaign just finished at the Lubiliana TRIGA Reactor

b) Described next slide

UJ group : 30 June 2021 CFD modelling for the ITk 2Humidity Monitoring – Updates, Issues

3. Irradiations

a) Campaign just finished at the Lubiliana TRIGA Reactor

b) 2 days of testing (L Scherino, P Petagnia)

Day 1 4.8 1015 n/cm2 LPGs

Day 2 9.8 1015 n/cm2 FBGs

Many combinations of LPG / FBG

Good results

React linearly or not at all, can use all

Still need detailed analysis

UJ group : 30 June 2021 CFD modelling for the ITk 3Humidity Monitoring – Updates, Issues

3. Bake-out

a) IPT not at 300C !

b) Adapt to more detailed description

Beam-pipe, heaters at 250C, Aerogel, Al foil, air gap, aluminsed layer on IPT, then IPT 1

UJ group : 30 June 2021 CFD modelling for the ITk 4Humidity Monitoring – Updates, Issues

3. Bake-out

a) IPT not at 300C !

b) Adapt to more detailed description

Beam-pipe, heaters at 250C, Aerogel, Al foil, air gap, aluminsed layer on IPT, then IPT 1

1. Vac enveloped enclosed by Be pipe

2. Heaters bonded to the Be outer surface

3. Thermal insulation material: OD = 49.1mm

4. Aerogel material 3.3mm thick, OD = 55.7 mm

• Aerogel thermal conductivity opposite

5. Aluminium foil use 50 micrometers OD = 55.8mm

6. Air gap Remaining Thickness – should be then 1.1 mm thick

7. IPT with inner layer sputtered Al acts again as a thermal mirror

ID = 60.0mm – 2 mm

8. IPT OD = 60.0mm

UJ group : 30 June 2021 CFD modelling for the ITk 5Inner Pixels for Temperature FDR

Good fluid flow, straightforward meshing.

N2 flow model without heat transfer and leaks,

Then add heat transfer

Problem

1. Whether the IPT is at 20 or 300 degrees C, the flow becomes purely buoyancy driven.

2. The velocities before heat transfer are on the scale of 6 mm/s

3. However, once we add heat transfer, they rise to 0.5 - 1.5 m/s.

4. The large body forces make convergence difficult.

5. Numerous approaches attempted.

Convergence for two conditions

1. Finer mesh, adjustments to solver

• Improved performance as mesh is made

smaller

• Initially 10 mm, at 5 mm better, need even

smaller

• Implemented under-relaxation to

successively lower levels

• Finally stabilised at the 20 C condition

• Need somewhat better convergence

2. Mesh on Server class PC, solve on HPC

Cluster

Now at > 100M cells.

Must either have more powerful server or

simplifications – have chosen simplifications

UJ group : 30 June 2021 CFD modelling for the ITk 6Challenges of the Itk – Outer Pixels (Matt Connell)

1. Primarily geometry: narrow channels restrict flow.

2. Large mesh size, 100 million cells +

3. Ultra low flow – simulation unstable.

4. Large temperature range – largest effect on flow.

Now implementing

simplifications

Matt to report on

progress.

UJ group : 30 June 2021 CFD modelling for the ITk 7Humidity Monitoring – Updates, Issues

2. Post PDR

a) Sacrificial Sensors type, connection at PP! being resolved. Need a test

b) https://docs.google.com/document/d/1KWKQOntywhOIrBAmS4C_6m-4UcstzoxT/edit

Sacrificial Sensors

1. We agree to drop Sensiron SHT85 Digital sensor.

2. Now a two-horse race between the HIH and the SHT31

3. This is now for test in the Environment Chamber

4. Issue of sharing ground and power lines … include in test

5. Saverio d’Auria and Lingxin Meng from Pixel Modules

• have experience of low temp operation of these sensors

• Simon to contact them

UJ group : 30 June 2021 CFD modelling for the ITk 8ITK species

ITK HumiditySR1

andmodelling

Temperature Modelling

Main flow considerations and summary of the simulation

Changes in the flushing rates for SR1 with realism.

New flushing scheme:

N2 flow at 5400l/h for the full Strip, 2700 l/ hr for half Strip, 675 l/ hr (0.1875 l/s) per inlet

Air (humid) at 54 l/h for the full Strip, 27 l/h for half Strip, 4.5 l/hr (0.00125 l/s) per inleak

The new flushing scheme : 25% of N2 and 75% of Air (50% H) led to the DPT Volume Average = - 500C

Proposal to reduce the inleak rate of New flushing scheme by 10,

This led to the DPT Volume Average = - 68.340C

To find a maximum inleak rate, we divided the inleak rate of New flushing scheme by 5

This led to the DPT Volume Average = - 630C

To find a maximum inleak rate, we divided the inleak rate of New flushing scheme by 2.5

This led to the Volume Average = - 57.470C

Other boundary conditions, Model setup and solver unchanged.

For the four simulations,

the inleak rate less then 1/5 with the dew point temperature ( - 630C < - 600C) will meet requirements

Pedro Mafa: 29 June 2021 Status update on the ITK humidity and temperature CFD modelling 9ITK species

ITK HumiditySR1

andmodelling

Temperature Modelling

Main flow considerations and summary of the simulation

Changes in the flushing rates for SR1 with realism.

New flushing scheme:

N2 flow at 5400l/h for the full Strip, 2700 l/ hr for half Strip, 675 l/ hr (0.1875 l/s) per inlet

Air (humid) at 54 l/h for the full Strip, 27 l/h for half Strip, 4.5 l/hr (0.00125 l/s) per inleak

Pedro Mafa: 29 June 2021 Status update on the ITK humidity and temperature CFD modelling 10ITK Humidity and Temperature Modelling

The results

Temperature [oC] and Dew point zoomed contours on YZ- plane on several locations along Z

Temperature, New flushing scheme x 1/5 Dew point, New flushing scheme x 1/5

Scale (Max. Temp= -9oC ) Scale (Max. DPT = -62.9oC )

(Min. Temp = -28 oC) (Min. DPT = -63.5 oC)

Temperature ○C

Dew point

Pedro Mafa: 29 June 2021

Status update on the ITK humidity and temperature CFD modelling 11ITK Humidity and Temperature Modelling

The results

Relative Humidity [%] and Dew Point zoomed contours on YZ-plane on several locations along Z

Relative Humidity, New flushing scheme x 1/5 Dew point, New flushing scheme x 1/5

Scale (Max. DPT = -9oC )

Scale (Max. H= 3% )

(Min. DPT = -28 oC )

(Min. H = 0% )

Relative Humidity %

Dew point

Pedro Mafa: 29 June 2021

Status update on the ITK humidity and temperature CFD modelling 12You can also read