VAPO HYBRID ECO - SPOT LTD

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

MACHINE

CONFIGURATION

Possibility of two machine

fixed configurations:

• Stick distance 15 cm

• Stick distance 23 cm with

loop formation 45 cm

PATENTED

DOUBLE-SPRAY BAR

bar

FOR LOOP FORMATION

Steam pressure

1

Handling of the chain by means of a mechanical guiding system, with loop formation

0,5

realized by the combined action of the overfeed roller and the modular steam flow

0,1 that, in addition to pushing the loop, eliminates the possible formation of static

0 30 60 200 cm electricity. Possibility of working with steam as well as compressed air by modulating

Loop formation the relative flow in function of the fold length.

THE DNA OF THE ARIOLI STEAMER

RECIRCULATION

OF FAN MOTORS

Highly efficient, modulating

speed up to 0 in order to limit

fold oscillations during digital

processes.

DESIGN COVER

Ergonomically-oriented

cover restyling with panels

containing all the utilities.

AUTOMATIC STEAM

CONTROL AND PLC

Temperature and steam flow are

automatically controlled by means of an

external touch screen set-up comfortably

showing effective values.

Machine remote control available.CYLINDERS AND STICKS

Cylinders and sticks ensure optimum contact of the fabric, thanks to which the operator

can work with the loop at the maximum length (obtaining maximum productivity of

the machine). In addition, the new Arioli sticks have the fundamental advantage of

being fixed to the transport chain and are equipped with a special fibreglass sleeve.

DOUBLE WATER INJECTION

NOZZLES AND STEAM SPRAY

Useful for temperature control

when working in saturated steam

(102°C), and in order to return the

correct percentage of humidity to

the re-circulated steam.

Humidification nozzles with the

possibility of working with saturated

steam, compressed air or utilizing

both modulating according to the

temperature variation.

DOUBLE STEAM

DISTRIBUTION SYSTEM

PATENTED

The special steam distribution

system in the treatment chamber

enables important advantages

including: steam consumption

reduction by 30 %, less need of

urea in printing pastes and in digital

preparation process, reduction of

the steaming time and consequent

increase of productivity.

Possibility of injecting steam into

the chamber in different points and

in different quantities by means of

two different lines depending on the

process: whether traditional or

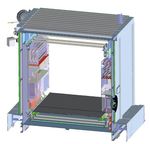

digital.VENTILATION SECTION

Depending on the model chosen, a specific number of fans will be installed in order

to obtain high-performance circulation of steam and air. Secondly an appropriate

number of water trays will be added to generate saturated steam directly in the

steaming chamber, thus ensuring the correct compensation of overheated steam in

the machine and a perfect humidification

• Ventilation dedicated to each single module plate

• Sturdy covering of each ventilation

• Thermo oil or gas exchanger

• Steam distribution ducts throughout the chamber

PATENTED

OPTIONAL CONFIGURATION

Fabric introduction system / Pre-humidification chamber

Introduction of the fabric in the chamber without tension and contact on the

printed side, thanks to a special drum with laser system. By means of the pre humidification

system, the Arioli steamer prevents the fabric from undergoing uncontrolled thermal

shock and preventing air entering inside the chamber.

Fabric extraction system

Formed by a laser system, that prevents contact and friction between the loops.

Continuous chains for stick support

This technology allows working without loop fluctuations, avoiding colour repetition.

Variable rod rotation system

This device allows reducing or stopping the standard rotation of rods avoiding

reprints or fabric curling.

Drying fabric before touching the printed side

A 48 cm diameter steam heated drum dries the unprinted side of the fabric avoiding

replicas on cylinders at the outlet.Vapo Hybrid Eco

Why?

VAPO Tradition aimed to the future

HYBRID Versatility in the simplicity of use makes our Vapo “universal”

ECO Respect for nature in saving energy intended as: reduced chamber dimensions,

differentiated steam distribution, operating speed, maintenance saving over time

Main advantages

PROCESS TEMPERATURE (°C)

Saturated steam • Shorter loop length (2 mt)

102 - 106 °C

temperature

• New system for digital fabric printing

• Traditional tested fabric transportation

• Tested loop fabric formation

H.T. superheated steam

165 - 190 °C • Sticks fixed to the transport chains

temperature

• Sticks equipped with new special fibreglass sleeve

• Steam consumption reduced by 30%

Hot air pigment polymeri- • Less need of urea in the printing paste and in the digital

90 - 190 °C

zation temperature process preparation

3500

2050 A 2750

B

Inlet Left ventilation Neutral Left ventilation Outlet

Right ventilation Right ventilation

MODEL

Fabric content P 15 (mt) 85 120 160 200 230 270 310 350 380 420 460 500

Fabric content P 23 (mt) 60 85 110 135 160 185 210 235 260 285 310 335

Roller width (mm) 2200 - 2600 - 3600

Steam consumption (kg/h) 200 300 300 - 400 400 - 500 500 - 600 600 - 700 700 - 800

Length A (m) 3.9 5.2 6.5 7.8 9.1 10.4 11.7 13.0 14.3 15.6 16.9 18.2

Length B (m) 8.7 9.5 10.8 12.1 13.4 14.7 16.0 17.3 18.6 19.9 21.2 22.5ARIOPRINT STEAMERS WASHING

Arioli S.p.A.

via G. P. Clerici, 2 - 21040 Gerenzano (Va) - Italy

+39 02 9639931 +39 02 96399399 info@arioligroup.com arioligroup.com

CAP. SOC. €1.017.053 i.v. - P.IVA/CF 05757800965 - REA di Varese 313430 - MECC. VA 059132

VAPO - Arioli - Eng - 05 - 2019You can also read