MefCO 2 - Methanol Fuel From CO 2 - Reference (call): H2020-SPIRE-2014-2015 Start/end date: Dec. 2014 / Dec. 2018 Partners

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Horizon 2020

European Union Funding

for Research & Innovation

MefCO2 – Methanol Fuel From CO2

• Reference (call): H2020-SPIRE-2014-2015

• Start/end date: Dec. 2014 / Dec. 2018

• Partners:

• EC funding: 8,622,292.60€

• Private investment: 2,419,244.86 €

• Leverage factor: 0,2805

This project has received funding from the European Union’s

Horizon 2020 research and innovation programme under grant

agreement No 637016.Horizon 2020

European Union Funding

Project Case Study for Research & Innovation

1. The EU/ SPIRE needs 4. How will this happen?

2020 2030 2050

Building up a pilot plant in Germany:

GHG reduction* 20% 40% 80-95%

• Production capacity: 1t /day

Renewable energy share 20%** 27% -

Efficiency increase 20% Min 27% -

• CO2 capture capacity per ton of MeOH: 1,5 t/d

*From 1990 levels • PEM electrolyser (600 kWel) with improved dynamic

** 10% Renewable resources for transportation response.

KC1 FEED: Valorisation of flue gases as alternative sources for • MeOH unit: scalable production process with a novel

chemicals and fuels patent protected catalyst with improved conversion

KC2 PROCESS: New energy and resource management concepts and selectivity

KC3 APPLICATIONS: New materials contributing to develop

energy and resource efficient processes Scaling up the pilot plant for commercialization: Business

KC4 WASTE2RESOURCE: Pilot economically and cases for methanol plants of 10,000 and 50,000 t/yr

environmentally sustainable and technically feasible process

models

KC5 HORIZONTAL: dissemination of cross-sectorial transfer of

good energy and resource efficiency solutions and practices

3. Value to Customers

KC6 OUTREACH: comprehensive dissemination strategy • Mitigation of CO2 emissions by making a

feasible business case for CCS+CCU.

2. The Project Solution • Stabilisation of electric grid by the consumption

of the electric energy at its peaks.

Green chemicals (P2C) and advanced fuel production

• Methanol blending with conventional gasoline

(P2F) using captured CO2 as feedstock, an energy

or methanol use in biodiesel production

storage technology using methanol as energy vector

contribute to the achieving the renewable

in liquid fuels and a test bench for the provision of

energy content and advanced fuels content in

grid services using flexible electrolysers

transportation.What are the key expected sustainability impacts of MefCO2?

Indicator (Max 3-4 key indicators) Baseline Expected Impact

Reduction of CO2 emissions of methanol as renewable 34 g/MJ Emission associated with methanol fuels are expected to be below to

fuel the reference value of 1st generation biofuels (34 g/MJ) with an

expected emissions well below 20 g/MJ. A more accurate value shall

be provided when the LCA analysis is completed.

Global Warming Potential (CO2 emission reduction) of -- 11 Mtons/year (without CCS) if methanol production were to cover

CCU w/o CCS methanol imports in the EU and 3% v/v blending with gasoline is

achieved.

Fossil energy intensity --- Highly dependent of the energy mix in the area in which the plant is

located and the mode of operation.

Fossil fuel displacement when substituting fossil gasoline --- Up to 1.3% on energy basis of gasoline consumption could be

displaced if 3% v/v direct blending was achieved.

Horizon 2020

European Union Funding

for Research & InnovationHorizon 2020

European Union Funding

for Research & Innovation

What outputs or learning from MefCO2 could have value for other SPIRE

projects here?

• Renewable hydrogen production: demonstration of flexible operation of water electrolysers can be used to decrease

energy costs of renewable hydrogen production and reducing the reliance on natural gas steam reforming.

• Surplus Oxygen can be sold or used directly in several industrial process such as combustion processes.

• Optimised power plant operation when coupled with flexible hydrogen production for methanol production. Plants can be

operated steadily at their maximum efficiency since flexible electrolysers can be adjusted to match supply and demand.

• Job preservation: CCU+CCS can help carbon leakage sensitive industries, such as the steel or cement industry, to maintain

its competiveness while reducing their emissions.

• Growth of cost competitive non- manageable renewable energy generation will spur a new set of business opportunities

for those who can build business models based integrating renewable energy surplus and stabilising the electrical grid.

• MefCO2 results could contribute to the reduction of the dependency on methanol imports for the chemical industry in the

EU-28. An average of 5.8 Mtons where imported Jan-Nov 2016.

• Methanol produced in MefCO2 is considered an advanced fuel and its renewable energy content can be double counted

towards the Renewable energy content in transport. Moreover, direct blending of methanol with gasoline can reduce the

imports of gasoline. A 3% v/v blending with gasoline would add 2.2 Mton/year of additional methanol demand and

displace up to 1 Mtoe of gasoline on an energy content basis.Horizon 2020

European Union Funding

MefCO2 approach H2 production 600 kW PEM electrolyser for Research & Innovation

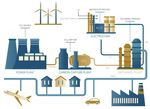

Niederaussen Coal fired power Post-combustion CO2

plant amine scrubber

(Germany)

MeOH plant

Max MeOH output

1000 kg/day

Max CO2 input 1500

kg/day

Watch our video!Horizon 2020

European Union Funding

for Research & Innovation

Contact

Project coordinator and exploitation manager:

• Mr. David Cuesta: david.cuesta.pardo@everis.com

• Ms. Rocío Pacios: rocio.pacios.blein@everis.com

Project website: www.mefco2.eu

info@mefco2.comYou can also read