MONASH MOTORSPORT ACCELERATES DEVELOPMENT WITH ANSYS

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

ACADEMIC STUDENT TEAM

MONASH MOTORSPORT

ACCELERATES

DEVELOPMENT

WITH ANSYS

The team from Monash University uses ANSYS software to design an

innovative drag reduction system.

By Scott Wordley, Stuart Buckingham, Damien McArthur, Marc Russouw, Luke Phersson and

Matt Corallo, Monash Motorsport, Monash University, Melbourne, Australia

F

ormula SAE competition chal-

lenges university students

each year to design, build,

market and race a small,

open-wheeled, Formula-style

car against other such insti-

tutions from around the globe. Monash

Motorsport, from Monash University in

Melbourne, Australia, is one of these

teams.

The Monash Motorsport team com-

prises approximately 70 under-

graduate students, primarily from

the Department of Mechanical and

Aerospace Engineering but also from

disciplines such as science, business,

marketing and even law. The demand-

ing nature of the competition gives stu-

dents the chance to develop important 2011 Monash Motorsport car finishing the endurance event at Formula Student Germany

skills in teamwork, communication and in 2012. The Monash team finished in fourth place overall.

project management, along with helping

them to prepare for the challenges they

will face when they embark on profes-

sional careers in industry. Through a close relationship with ANSYS software and present examples of

Engineering students who partici- the local ANSYS channel partner, LEAP their work.

pate in this program benefit greatly from Australia, the group developed a range Monash Motorsport recently final-

the opportunity to develop their exper- of tutorials to help team members ized design and development of its

tise in computer-aided design and engi- and other students conduct finite ele- latest racer, the M13. The team’s cars are

neering (CAD and CAE) by modeling and ment analysis (FEA) and computational well known for their distinctive aerody-

simulating many different components fluid dynamics (CFD) studies for com- namic packages; Monash claimed four

and systems within the Formula SAE mon Formula SAE applications. Each competition wins and several top-five

car. Monash Motorsport team members year over spring break, the Monash places in recent Australian, U.K. and

have utilized ANSYS engineering simula- team organizes a three-day symposium German events. Aerodynamic packages

tion software for more than a decade to called Design to Win, during which local in Formula SAE are becoming popular, as

accomplish this work. Formula SAE teams receive training on teams learn that wings do indeed offer

© 2014 ANSYS, INC. ANSYS ADVANTAGE Volume VIII | Issue 1 | 2014ACADEMIC STUDENT TEAM

benefits! Successful implementation of a

well-designed aero package can result in

significant improvements in a car’s per-

formance on tight, twisting Formula SAE

tracks, even though the average track

speed is low — at around 60 kilometers

per hour.

AERODYNAMIC IMPROVEMENTS

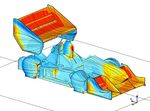

The new M13 racer is a clean-sheet

redesign in all respects, incorporat-

ing a number of significant aerody- The Monash M12 car with DRS engaged and flaps open during on-track testing

namic improvements and novel design

features made possible by extensively

using ANSYS Mechanical, ANSYS CFX

and ANSYS Fluent. The car is one of

only a few Formula SAE vehicles world-

wide to utilize a drag-reduction system

(DRS), used in current Formula One rac-

ing. This innovation enables the angle of

the flaps in the multi-element front and

rear wings to be dynamically adjusted

via pneumatic cylinders and linkages.

As a result, the car has two distinct aero-

dynamic modes: high downforce and

low drag.

The DRS is activated when the driver

presses a button on the steering wheel,

so the low-drag setting can be used when

the car is driving in a straight line and ANSYS CFX velocity contours and vectors show how the different flap rotation angles for

DRS were tested and optimized, using a 3-D CFD model of the entire car.

significant downforce is not required. By

using a button to engage DRS, the driver

can revert to the high-downforce mode

and maximize the car’s downforce (and

drag) before applying the brakes at the

end of a straight — which an automated

system cannot do reliably without GPS-

enabled track mapping.

Having access to a drag-reduction

system has allowed this year’s Monash

team to significantly increase its down-

force target for the M13 car to a CL.A

(“A” denotes frontal area — when com-

bined with lift coefficient, this provides ANSYS CFX results demonstrate the dramatic differences in surface pressure magnitude

a more representative measure of the and vortex structures (iso-surfaces) generated by high-downforce mode (left) and

car’s performance on track while taking DRS-engaged low-drag mode (right). DRS activation results in a 50 percent reduction

geometry into account) of greater than in drag generated by the full car.

6, given that drag is no longer a signif-

icant limitation on straight-line perfor-

mance. Before starting design, the team

invested time in developing a standard The team chose to use a symmetry The Monash Motorsport team won its fifth

fluid domain and boundary setup to model (using only half the car) to maxi- consecutive Australasian FSAE Champion-

ensure consistency and comparability mize mesh resolution, given RAM-based ship in 2013, with a strong performance on

track and in all static events. The team will

among all future simulations. Domain meshing and solution time limitations

also compete with their 2013 car at Formula

size and mesh sensitivity studies were when working on single local nodes. Student UK and Germany in 2014, hoping to

undertaken, and benchmarking tests Testing showed that approximately improve upon third- and fourth-place finishes

were conducted with different turbu- 15 million to 20 million elements for in these events in 2012.

lence models.

© 2014 ANSYS, INC. ANSYS ADVANTAGE Volume VIII | Issue 1 | 2014ACADEMIC STUDENT TEAM

the symmetry model provided the best

compromise between mesh resolution

and solver time, based on Monash’s

current computational resources. A

400-iteration run using the k-omega SST

turbulence model generally solved in

less than six hours, which was consid-

ered an acceptable turnaround time.

The eight-person aero team conducted

and documented almost 200 unique Colored velocity profiles — and vectors

Sample ANSYS CFD-Post pressure contours at inlet to the undertray — are useful to

aerodynamic design iterations over a

and surface streamlines for M13 car. qualitatively compare how much mass

three-month period at the start of 2013. flow is being captured by the inlet (low

Yellow and red areas denote pressures

A team-developed ANSYS CFD-Post state above static pressure, and blue denotes transverse velocity components shown

file was used to allow fast and consis- areas below static pressure. Surface by the vectors in the plane but also high

tent automated post-processing as well streamlines help denote flow separation resultant velocity magnitude shown by

and re-attachment lines as well as vortex the color contours) as well as separate

as output of figures (pressure contours, planes in regions of interest for automated,

activity impinging on vehicle surfaces.

streamlines and vortex cores), tables quantitative calculation of mass flow rates

of force and coefficient results via the (for example, radiator and diffuser tunnels).

report function. The team utilized cus-

tom pressure color scales to clearly dif-

ferentiate positive pressures (yellow to

red) from suction pressures (blue). A

custom red/blue scale was applied to

stream-wise vorticity and used to color

vortex core iso-surfaces, neatly high-

lighting the direction of vortex rotation.

Chord-wise plots of coefficient of pres-

sure for the front and rear wings at a

range of span-wise locations were rou-

tinely generated to fine-tune wing pro- Semi-transparent vortex core iso-surfaces, colored for stream-wise vorticity, to indicate

files as well as to better understand direction of vortex rotation. Due to use of a symmetry model and reflection of the results,

span-wise pressure variations. colors are the same on either side of the car.

Keyframe animations were used

extensively to generate longitudinal

total pressure sweep videos and vortex

core videos, providing insight into the

complex vortex and wake interactions

that dominate the vehicle’s near field.

Juggling these vortex and wake interac-

tions proved crucial in maximizing the

downforce produced by the front wing

and underbody diffuser, as well as in

balancing the front and rear downforce

distribution for the whole car. These

full-car interactions drove the team’s

final choice of rear-wing height and pro-

vided confidence with respect to the

cooling flows entering the radiator and

turbo intercooler.

The full results from each run, along

with associated CAD models and ANSYS

Workbench archives, were updated to a

private team Wiki in real time through-

Example of chord-wise coefficient-of-pressure plots for 2012 three-element front wing.

out the design phase, which facilitated

Dark blue denotes the slice at the centerline of car; lighter blues are slices taken moving

rapid communication and results shar- progressively outboard from center. These results demonstrate the significant contribution

ing among the team. This ensured that made by the center of the wing, justifying the team’s choice to increase car nose height to

all members remained updated on the maintain the wing in this region. Note that there is no centerline data for the last wing

design progress, which minimized repe- element due to a two-element configuration in the center section under the nosecone.

tition and duplication as well as helped

© 2014 ANSYS, INC. ANSYS ADVANTAGE Volume VIII | Issue 1 | 2014ACADEMIC STUDENT TEAM

student engineers to discuss and incor-

porate the best design features into the

next round of CFD runs.

INFRASTRUCTURE FOR

COMPLEX SIMULATIONS

Beyond conducting CFD analysis, the

Monash team developed a methodology

and hardware infrastructure required to

conduct large and complex simulations

(incorporating up to 200 million ele-

ments) combined with a rotating refer-

ence frame. A rotating reference frame

is needed for modeling aerodynamic

effects when the car is turning a corner,

since the interactions cannot be accu-

rately estimated nor understood using

traditional fixed-flow yaw angles applied

to the entire car (as in a wind tunnel).

The team developed a 100-node

local Beowulf-style cluster by utilizing

Steps necessary to solve CFD simulation, including software package used for each

idle desktop machines in the Monash stage. All processes in the yellow box have been scripted to run on the Beowulf cluster.

Engineering Computer Labs, which were By running these processes remotely, the workstation computer is freed up to do other

made available for the team’s use over- tasks. The large files created for the mesh and solution are generated remotely. Users must

night and on weekends. A fully auto- download the results to post-process, but transferral of large mesh files from the remote

mated grid-generation outsourcing tool system is not needed.

was scripted to allow geometry clean-

up, surface and volume meshing, and

solving to be completed remotely on

the cluster, thereby avoiding RAM lim-

itations and slow transfer times for the

large meshes, which otherwise would be

generated locally.

The incident angle, θ, is the angle that the freestream air makes with the car centerline

at the point of impact. The freestream vector is tangential to the center of rotation and,

therefore, perpendicular to any line that radiates from the center of rotation. The angle

is identical to that formed between the line radiating from the center of rotation to the

Dimensions of far-field domains. All dimen- point of interest and the line that radiates from the center of rotation and is perpendicular

sions are non-dimensionalized by dividing to the centerline of the car. By decreasing the parameter r, both θfront and θrear increase.

by total car length. Increasing the parameter ψ moves the center of rotation point rearward. This has the effect

of reducing the rear incidence angle, θrear, but increasing the front incidence angle, θfront.

Due to the large cost in time of setting up, solving and post-processing a rotating reference

frame simulation on the cluster, only one case was considered. The 200 runs conducted

by the team were completed for a straight line case, and automation allowed runs to be

turned around in 12 hours. Using this method, the team could cycle through many different

iterations within a very narrow design window of approximately three months.

© 2014 ANSYS, INC. ANSYS ADVANTAGE Volume VIII | Issue 1 | 2014Turbulent wake profile of rotating reference frame case visualized

using volume render to turbulent kinetic energy (TKE) measured

in J/kg. The edges of the ground plane indicate the bounds of the

fluid domain. This type of representation serves to illustrate the

asymmetry of the wake behind the car in the rotating reference

frame. (Rendering palette used in this visualization is different

Test case of empty domain (reduced to only a few elements in from other cases and should not be used for direct comparison.)

height) to confirm that boundary conditions set for the domain

produced expected flow

WIND TUNNEL EXPERIMENTS

Monash Motorsport is fortunate to have

access to a full-scale automotive wind

tunnel on campus; this has allowed the

team’s engineers to extensively correlate

aerodynamic predictions obtained from

ANSYS software with data from on-track

testing. Typically, the team starts by cor-

relating wind tunnel and CFD results

for performance of wings in isolation,

via wing angle-of-attack and yaw angle

Turbulent wake profile of rotating reference frame case visualized using volume render of

sweeps made in freestream in the tun- turbulent kinetic energy, as viewed from right side of race car

nel. Then the car is added, which allows

a detailed study of the rear wing height

along with endplate size, shape and

detail features. Cooling performance is

measured using a specific-dissipation

test rig within the tunnel, which circu-

lates heated coolant through the radiator

at a measured flow rate. Thermocouples

in the coolant lines allow the team to

calculate heat dissipation as a function

of the temperature differential between

ambient air flow and coolant.

Turbulent wake profile of rotating reference frame case visualized using volume render of

turbulent kinetic energy, as viewed from above race car

© 2014 ANSYS, INC. ANSYS ADVANTAGE Volume VIII | Issue 1 | 2014Example of full car yaw sweep undertaken in wind tunnel

Results of specific dissipation testing undertaken

in wind tunnel

2011 Monash Motorsport car finishing the endurance event at

Formula Student Germany in 2012. The Monash team finished in

fourth place overall.

Team engineers extensively

correlate aerodynamic predictions

obtained from ANSYS software

On-track testing results were used to correct wind tunnel results

with data from on-track testing.

for the front wing.

SUMMARY significant improvement in team knowl- Authors’ Note

CFD has proven to be a powerful tool edge transfer (with reports of each run Monash Motorsport has published sev-

for the Monash Motorsport team, par- saved on the team knowledge data- eral SAE papers on the aerodynamic

ticularly since wind tunnel testing time base for future members to access and development of its past cars, and team

is limited to a few days each year. The learn from) as well as ease of compar- members are happy to talk with other

team can narrow down the most prom- ison between runs. The use of CFD has teams implementing aerodynamic

ising design concepts without having to allowed the team to spend financial and studies. The team sincerely thanks all

incur the cost of fabricating each design time resources for building and testing current and past team members for

change and physically testing it in the various prototype designs on only the their hard work and dedication to this

wind tunnel or on track. Furthermore, most promising few. project — as well as LEAP Australia,

automation of the simulation setup in ANSYS, the Department of Mechanical

ANSYS software has allowed for quicker and Aerospace Engineering at Monash,

turnaround times on simulations (down and the Monash wind tunnel facility.

to 12 hours from 24 hours), and stan-

dardized report generation has yielded

© 2014 ANSYS, INC. ANSYS ADVANTAGE Volume VIII | Issue 1 | 2014You can also read