HARTING Han-Ex Connectors for explosion-hazardous environments

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Content & General information

Content

Content & General information..............................02 Maximum surface temperatures for equipment.....11

Basics of explosion protection...............................03 Ignition protection types........................................12

Overview on international standards......................04 Connecting Ex and Non-Ex areas...........................13

Zone classification in Europe.................................05 Han® Ex Sets – Hoods/Housings Size 3A..............14

Gas explosion groups – European standards.........07

Hazardous area classification – North America.....08

Hazardous area classification – Europe.................10

Field of application Note:

HARTING Industrial Connectors are applicable in a wide variety Connectors should not be coupled and decoupled under

of electronic and electrical a pplications. The degree of protec- electrical load. C onnectors of the same or different series

tion of all hoods and housings is in accordance with internatio- being mounted side by side may be protected against incorrect

nal standard IEC 60 529 / EN 60 529. mating by the use of coding options.

■■ Power Utilities General information:

■■ Industrial It is the user’s responsibility to check whether the components

Instrumentation illustrated in this catalogue comply with different regulations

■■ Robotics from those stated in special fields of application which we are

■■ Conveyor Equipment unable to foresee. We reserve the right to modify designs in

■■ Chemical Plants order to improve quality, keep pace with technological advance-

■■ Transportation ment or meet particular requirements in production.

■■ Machine Tool Controls

■■ Injection Moulding Imprint

...and many more. ©2019, Editorial date 11/19, HARTING

Electric GmbH & Co. KG, Espelkamp, Germany

Author: HARTING

Certified according to EN ISO 9001 in All rights reserved, including those of the translation.

design/development, production, No part of this manual may be reproduced in any form (print,

installation and servicing photocopy, microfilm or any other process), processed, dupli-

cated or distributed by means of electronic systems without

Specifications: the written permission of HARTING Electric GmbH & Co. KG,

VDE 0110 Espelkamp.

Table concerning clearance and c reepage distances Subject to alterations without notice.

VDE 0627

Connectors and plug devices

Standards:

DIN EN 175301-801, DIN EN 61 984

02 HARTING Han® ExBasics of explosion protection

Causes of explosions

To set up an exothermic reaction like Each corner of the so-called ignition Today, all protection methods are

an explosion the following three com- triangle (refer to drawing) represents based on the elimination of one or

ponents have to interact: an indipensable component of such more factors within the triangle – in

• F uel: flammable vapors, liquids or an explosion. Once an exothermic order to minimise the potential im-

gases or flammable dusts and fibres reaction is ignited, the results de- pacts of the explosion.

• Oxidizer: generally air or oxygen pending on the energy released can

• Ignition energy: electrical or ther- be controllend combustion, flame

mal waves, or explosion.

Table 1: Effective ignition sources

Source Possible Causes

Sparks Mechanically generated sparks (e.g. by friction, impact or removal processes), electrical sparks

Electric arc Short-circuit, switching operations

Hot surfaces Radiators, machining, heating in operation

Open flame, welding arc Combustion reactions, flying sparks during welding work

Opening/closing of contacts, loose contacts, safety extra-low voltages (UOverview on international standards

Table 2: International standards for electrical equipment in explosive gas atmospheres

Ignition US standard Principle European IEC Norm FM (USA) UL UL CSA

protection standard (USA, (USA, Zone) (Canada)

category (EN) Div.)

General Ignition protection EN 60079-0 IEC 60079-0 FM 3600 CSA

provisions type (ISA 12.00.01) E60079-0

Intrinsic Ex i Energy limitation EN 60079-11 IEC 60079-11

safety

AEx i NEC505 FM 3610 UL 913 UL 60079- CSA

11 E60079-11

(IS)

Increased Ex e Constructional EN 60079-7 IEC 60079-7

safety measures (no

AEx e NEC505 arcs, sparks or hot FM 3600 UL2279 UL 60079-7 CSA

surfaces) (ISA 12.16.01) Pt.7 E60079-7

Protection by tD NEC505 Exclusion of explosive FM 3615 e.g.hood/

enclosure atmosphere C22.2 No. 30 housing:

UL 1203

Flameproof Ex d Constructional EN 60079-1 IEC 60079-1

enclosure measures (enclosing

AEx d NEC505 flammable parts of FM 3600 (ISA UL2279 UL 60079-1 CSA

equipment) 12.22.01) Pt.1 E60079-1

Cast Ex m Exclusion of EN 60 079- IEC 60079-18

enclosure potentially explosive 18

atmosphere

AEx NEC505 FM 3600 UL2279 UL 60079- CSA

m (ISA 12.23.01) Pt.18 18 E60079-18

Oil Ex o Exclusion of EN 60079-6 IEC 60079-6

immersion potentially explosive

AEx o NEC505 atmosphere FM 3600 UL2279 UL 60079-6 CSA

(ISA 12.16.01) Pt.6 E60079-6

Powder filling Ex q Exclusion of EN 60079-5 IEC 60079-5 FM 3622

potentially explosive

AEx q NEC505 atmosphere FM 3600 UL2279 UL 60079-5 CSA

(ISA 12.25.01) Pt.5 E60079-5

Pressurised Ex p Exclusion of

potentially explosive

AExp NEC505 atmosphere EN 60079-2 IEC 60079-2

Typ X, NEC500

Y, Z

Ignition Ex n Improved industrial EN 60079-15 IEC 60079-15

protection quality

type “n” AEx n NEC505 FM 3600 UL2279 UL 60079- CSA

(ISA 12.12.02) Pt.15 15 E60079-15

Intrinsically Ex i Restriction of EN 60079-25 IEC 60079-25

safe electrical energy

electrical within equipment and

systems of wiring exposed to

„i-Sys“ explosive atmosphere

Intrinsically Ex i Energy limitation EN 60079-27 IEC 60079-27

safe Fieldbus

systems

Optical Ex op Limitation or EN 60079-28 IEC 60079-28

radiation containment of

radiation intensity

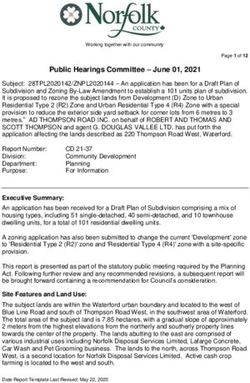

04 HARTING Han® ExZone classification in Europe

Table 3: Assignment of equipment group and category

Equipment group Category Degree of protection Protection guarantee Operating conditions

I M1 Very high safety degree If one installation protection For reasons of safety, it must be

measure fails, a second protection possible to continue operating a

measure must guarantee the product even if the atmosphere is

necessary safety. Even if two potentially explosive.

independent errors occur, a

very high safety level remains

guaranteed.

I M2 High safety degree Equipment will switch off, if a In normal operation, the protective

potentially explosive atmosphere measures must still guarantee the

occurs. required safety even in difficult

conditions, or if equipment

is treated roughly or ambient

influences have changed.

II 1 Very high Two independent protective Equipment can still be used in

measures guarantee safety, if two zones 0, 1, 2(G) and 20, 21, 22 (D)

faults occur independently of one and continue to be operated.

another.

II 2 High Safety is guaranteed under normal Equipment can be used in zones 1,

operating conditions, even if 2(G) and 21, 22 (D) and continues

common faults occur. to be operational.

II 3 Normal Safety is guaranteed under normal Equipment can still be used

operating conditions. in zones 2(G) and 22 (D) and

continues to be operational.

Equipment group and categories were previously divided into Zones tion Certificate must be present. In

Equipment group I: Equipment inten- 10 and 11. Following an EC directive, addition, equipment for Zone 0 must

ded for use in underground parts the dual classification system was be explicitely approved for this kind of

and surface installations of mines transferred to a three-zone-scheme, application. In Zone 2, electrical ap-

which is exposed to explosion risks differentiating on the basis of more

paratuses that may concern the basic

from mine gases and/or combustible detailed criteria. As an example, the

health and safety requirements of the

dusts. The assigned categories M1 allocation to a particular zone is now

94/9/EC Directive are only permitted

and M2 are defined in the directive depending on the conductivity of

94/9/EC. the relevant dust. Conductive dust if the manufacturer declares their

Equipment group II: Equipment for (with specific electrical resistance compliance with the requirements

use in all the other areas that might R > 103 Ω m) in Zone 22 is alloca- of the ATEX Directive. Obviously, the

be endangered by an explosive ted to equipment category 2D. In equipment certified for use in Zones 0

atmosphere. Three subcategories – such environments, only apparatus and 1 can also be used in Zone 2.

1, 2 and 3 – are defined within this certified for the relevant category

group. (2D) must be used. Devices for non- Table 4 (refer to provides an over-

conductive dusts (R > 103 Ω m) are

view on the zones of explosive gas

Zone classification allocated to category 3D. For these

atmospheres and the allocation of

Hazardous areas are classified into devices, a Manufacturer’s Declarati-

equipment for the relevant zones.

zones to facilitate the selection of on of Conformity is sufficient.

appropriate electrical equipment as In both zones, 0 and 1, only elec- The correlation between category

well as the design of suitable electri- trical equipment with a Certificate and zones (according to the operator

cal installations – in order to minimi- of Conformity complies with the directive 1999/92/EC) is also shown.

se explosion risks. In Germany, dusts standard –or an EC-Type Examina-

Connectors for explosion hazardous environments 05Table 4: Definitions of Zones (acc. to EN 60079-10-1)

Substance Zone Equipment Illustration

Gases Zone 0 1G

Vapors Areas where dangerous concentrations of flammable gases/vapors Zone 2

are continuously or long-term present

Zone 1 2G, 1G Zone 0

Zone 1

Areas where dangerous concentrations of flammable gases/vapors

are occasionally present Zone 0

Zone 2 3G, 2G, 1G

Areas where dangerous concentrations of flammable gases/vapors

are rarely and – in case only - briefly present

Dust Zone 20 1D

Areas where dangerous concentrations of flammable dusts occur

Zone 20

continuously or for a long term

Zone 21 2D, 1D

Zone 21

Areas where dangerous concentrations of flammable dusts

ocasionally occur

Zone 22 3D, 2D, 1D

Areas where dangerous concentrations of flammable dusts rarely

occur and, in case, only briefly Zone 22

Type of protection types of protection such as IEC EN minimal ignition temperature of a

The type of protection describes 60079-6 ff. 5 mm dust layer.

various safety concepts for different

applications to prevent the ignition Temperature classes °C

of a potential explosive atmosphere With regard to ignition protection,

T=600°

according to European IEC EN 60079 the surface temperature-classes of

Hydrogen 560° (T1)

standards. The standards of this the equipment groups I and II are dif- Methane 537° (T1)

series can be applied to equipment ferent (refer to Figure 1: Temperature

individually or in combination. classes [°C] of equipment group II). T1=450°

Ethylene 425° (T2)

The above spreadsheet shows the Temperature limits with dust

allocation of protection types to In the case of potential dust-explosi-

zones. Protection methods are ve areas, the maximum surface tem- T2=300°

Acethylene 305° (T2)

adapted to the normative standards perature is given as a temperature

concerning surface temperature, value [°C]. There is no classification Kerosene 210° (T3)

T3=200°

clearance and creepage distances, into groups. Generally, the permis- Ethyl ether 160° (T4)

to the identification of electrical ope- sible temperatures for each type T4=135°

T5=100°

rating equipment, the assignment of of dust have to be determined by T6=85°

Carbon disulphide (T6)

the electrical operating equipment, experiments. The maximum surface

to the area of application and the de- temperature is different for a dust T = 0°

gree of protection. For all areas with cloud and a dust layer.

requirements going beyond basics, With regard to a dust cloud a safety

the respective protection methods factor has to be considered. The

are defined. surface temperature of the apparatus

The IEC EN 60079-0 describes must not exceed 2/3 of the minimum

Figure 1: Temperature classes [°C]

general requirements for the design ignition temperature of the dust

of equipment group II, accor-

of electrical equipment used in cloud. Deposited dust ignites earlier

ding to European standards and

explosive atmospheres. These than a dust cloud. To provide this, a

ignition temperatures of relevant

requirements are supplemented by safety factor of 75 K has to be taken

substances.

individual standards concerning the in account. This factor refers to the

06 HARTING Han® ExGas explosion groups – European standards

Previously, all chemical gases or be derived for electrical equipment The classification of the subgroups

vapours used by the industry were that is used in the relevant area or depends on the substance’s minimal

classified by assignating them to two atmossphere. ignition energy.

different explosion groups (I, II). Group I comprises gases creating

Meanwhile, the former second ex- potentially explosive atmospheres in

plosion group was split in two, thus mines (firedamp).

generating a third group that con- In Group II, different gases, vapors

tains conductive and non-conductive and mists are considered that may

dusts as well as flammable fibres/ create an explosive atmosphere.

lint. From the explosion group, the Group II is again devided into three

maximum surface temperature can subgroups (EN 60079-0:2009).

Table 5: Gas explosion group I

Explosion subgroup Gases Ignition energy

I Firedamp (methane from coal Maximum permissible

mines) temperature depends on

deposits of carbon dust in

the area

Table 6: Gas explosion group II

Explosion subgroup Gases Ignition energy

IIA Propane, acetylene ≈ 300µWs

IIB Ethylene, ethanol ≈ 150µWs

IIC Hydrogen, carbon disulphide ≤ 50µWs

Table 7: Gas explosion group III

Explosion Gases

subgroup

IIIA Combustible substances (fibres)

IIIB Not conductible flammable dust, specific electric resistance > 10³Ω

IIIC Conductible flammable dust, specific electric resistance ≤ 10³Ω

Connectors for explosion hazardous environments 07Hazardous area classification – North America

Definition of hazardous area design-in of equipment, and different material is reacting with other mate-

Explosion-hazardous areas are most installation standards. rials in the atmosphere.

frequently found in places where The categorisation of hazardous The North Amercian standards

emissions of flammable gas or dust areas in North America is derived further categorize hazardous areas

occur. In such areas, gases, vapours, from the National Electrical Code’s into groups depending on the pro-

mists and dusts can form explosive (NEC/NFPA) definition of material perties of the combustible gases or

atmospheres in combination with air groups in article 500. There, explosi- vapors involved (refer to table 9).

while an equipment is under normal on relevant materials are divided into

operation or responding to an event the following groups:

of fault, e.g., due to wear and tear of Class I – Locations containing flam-

seals or other components. Hazar- mable gases, flammable liquid-pro-

dous atmospheres containing inflam- duced vapors, or combustible liquid

mable gases or dusts are designated produced vapors

as risks to machinery and operators. Class II – Locations containing com-

bustible dusts

Differences to European standards Class III – Locations containing fibres

Concerning standards, we have and flyings

differences between the European

IEC system and the North American According to the NEC, the differen-

electrical codes (CEC, NEC). Inter tiation into two divisions – refer to

alia, differences derive from the ca- table 8 below – gives the oportunity

tegorisation of hazardous areas, the to determine the probability that a

Table 8: Division of materials according to US National Electric Code (NEC)

Class I Class II Class III

Gases and vapors Flammable dust and powder Flammable fibres or suspended

NEC 500.5 NEC 500.6 particles

NEC 500.7

Division 1 Areas containing dangerous concen- Areas containing dangerous con- Areas containing dangerous con-

trations of flammable gases, vapors centrations of flammable dusts – centrations of flammable fibres or

or mist – continuously or occasional- continuously or occasionally under suspended particles – continuously

ly under normal operating conditions normal operating conditions or occasionally under normal opera-

ting conditions

Division 2 Areas probably not containing dan- Areas probably not containing dan- Areas probably not containing dan-

gerous concentrations of flammable gerous concentrations of flammable gerous concentrations of flammable

gases, vapors or mist – under normal dusts – under normal operating fibres or suspended particles – un-

operating conditions conditions der normal operating conditions

08 HARTING Han® ExHazardous area classification – North America

Table 9: Subgroups of hazardous area classification

Class l Group A Atmospheres containing acetylene

Group B Atmospheres containing hydrogen and flammable process gases with more than 30% of

hydrogen in volume, or gases and vapors posing a level of risk comparable to butadiene

and ethylene oxide

Group C Atmospheres containing ether, ethylene or gases and vapors posing the same level of risk

Group D Atmospheres containing acetone, ammonia, benzene, butane, cyclopropane, ethanol,

gasoline, hexane methanol, methane, natural gas, naphtha, propane or gases and vapors

posing the same level of risk

Class II Group E Atmospheres containing combustible metal dusts, including aluminum, magnesium and

their commercial alloys, or other combustible dusts which – due to particle size, abrasive-

ness and conductivity – present a similar threat to the use of electrical equipment

Group F Atmospheres containing combustible carbonaceous dusts including carbon black, char-

coal, coal, or coke dusts and consisting by more than 8 percent of total entrapped vo-

latiles, or dusts that have been sensitized by other materials, thus causing an explosion

hazard

Group G Atmospheres containing combustible dusts not included in group E or group F, including

fluorine, grain, wood, plastic and other chemicals

Class III Atmospheres containg easily ignitable fibres and flyings, which will normally not be in su-

pensions in the air leding to quantities sufficient to produce explosive or ignitable mixtures

The illustration below (Figures 2) Since 1996, an additional section has inflammable category with regard to

shows the different categorizations of been added to the NEC 500 stan- gases and dusts into three zones

classes and divisions of NEC 500 using dard. The new section NEC 505 is (0, 1 and 2, refer to Figure 3, next

the example of a gas station. based on the IEC model, deviding the page).

Class I, Division 2

Class I,

Division 1 Class I,

Division 1

Class I,

Division 1

Figure 2: Classes and divisions

using the example of a gas station

acc. to NEC 505

Connectors for explosion hazardous environments 09Hazardous area classification – Europe

The European standard IEC/EN de- rent zones. Figure 3 describes the Figure 4, refer to illustration below,

scribes the probability of inflammab- different gas zones by the example of explains the dust zone classification

le gases and dusts in three diffe- a gas station. on the example of a bulk container.

Zone 2

Zone 20

Zone 0

Zone 1

Zone 21

Zone 0

Zone 22

Zoneneinteilung des explosionsgefährdeten Zoneneinteilung des explosionsgefährdeten

Bereichs bei Gasen, laut IEC/EN 60 079 Bereichs bei brennbaren Stäuben, laut

IEC/EN 60 079

Table 10: Hazardous area zones for mixtures of air with flammable substances (acc. to IEC/EN 60 079)

Zone 0 Areas, where explosive atmospheres consisting of mixtures of air with flammable substances in the

form of gas, vapor or mist are present continuously, for long periods of time or frequently

Zone 1 Areas, where explosive atmospheres consisting of mixtures of air with flammable substances in the

form of gas, vapor or mist under normal operation conditions are likely to occur occasionally

Zone 2 Areas, where explosive atmospheres consisting of mixtures of air with flammable substances in the

form of gas, vapor or mist under normal operation conditions are not likely to occur occasionally

Table 11: Hazardous area zones for combustible dusts (acc. to IEC/EN 60 079)

Zone 20 Areas, where ignitable atmospheres in the form of clouds of combustible dusts in the air are present

continuously, for long periods of time or frequently

Zone 21 Areas, where ignitable atmospheres in the form of clouds of combustible dust in the air under normal

operational conditions are likely to occur occasionally

Zone 22 Areas, where ignitable atmospheres in the form of clouds of combustible dust in air are ot likely to occur

under normal operation conditions. If they occur anyway, they will persist for a short period of time only

10 HARTING Han® ExMaximum surface temperatures for equipment

The European standard IEC/EN Table 12: Equipment classification to zones acc. to IEC/EN 60 079-0

60079-0 offers a classification for

equipment used in explosion hazard

Group I Equipment used in mining where methan and coal dusts occur

areas to three different groups (refer

in the atmosphere

to table 12).

Group II Equipment used in industrial environment where explosive

Categorization of surface gases occur in the atmosphere

temperatures for equipment

Group III Equipment used in industrial environment where explosive

Regarding the surface temperature

dusts occur in the atmosphere

of equipment, the European standard

offers six different classes. The cate-

in relation to a standard environment

gories are defined by the maximum

of 40°C. If an equipment needs a

surface temperature for the equip-

different ambient temperature to be

ment to remain functional. Figure 5

functional, this must be visibly docu-

forms the categories by temperature.

mented on the equipment.

The temperature classes are defined

EU US

T1=450

T2=300

T2A=280

T2B=260

T2C=230

T2D=215

T3=200

T3A=180

T3B=165

T3C=160

T4=135

T5=100

T6=85

0 0

Figure 5: E

uropean classification of maximum Figure 6: Equipment groups and maximum sur-

surface temperatures for equipment in face temperatures acc. to European

explosion hazard zones and North American standards

Connectors for explosion hazardous environments 11Ignition protection types

Depending on equipment and envi- protection methods, defined by the ignition of a potential explosive

ronment the standards offer different relevant IEC/EN standards. atmosphere. The different catego-

protection principles. Table 13 shows Each type of protection implies ries can be applied individually or in

a selection of protection types and various safety concepts for different combination. The basical standard is

principles from an overall of 13 applications to prevent from the IEC/EN 60079-0 ff.

Table 13: Ignition protection types in potentially explosive gas atmospheres

Protection Basic of CENELEC IEC UL Zone, Protection principle

types protection Class

Ex d Flameproof EN 60079 -1 IEC 60079 -1 UL 60079-1 Class 1, Explosion prevention

Zone 2

Ex e Increased EN 60079 -7 IEC 60079-7 UL 60079-7 Class 1, Prevention of sparks

safe Zone 2

Ex m Encapsulation EN 60079-18 IEC 60079-18 UL 60079-18 Class 1, Exclusion of explosion atmosphere

Zones 0

and 1

Ex q Powder filling EN 60079-5 IEC 60079-5 UL 60079-5 Class 1, Prevention of sparks

Zones

Ex tD Protection by EN 60079-31 IEC 60079-31 ISA 61241-1 Class 2, Exclusion of explosion atmosphere

enclosure Zones 21

and 22

IPXX

Ex p Pressurized EN 60079-2 IEC 60079-2 UL 60079-2 Class 1, Exclusion of explosion atmosphere

Zone 1

Ex o Oil immersion EN 60079-6 IEC 60079-6 UL 60079-6 Class 1, Exclusion of explosion atmosphere

Zone 1

Ex i lntrinsic safe EN 60079-11 IEC 60079-11 UL 60079-11 Class 1, Energy limitation

Zones 0

and 1

12 HARTING Han® ExConnecting Ex and Non-Ex areas

Han® Ex connectors are designed to can safely be used in a methane-coal protection method. The intrinsic

meet the intrinsic safety require- atmosphere. In addition, hoods and safety protection technique is based

ments for ignition protection in housings offer protection IP65 (in on the limitation of energy supply,

explosion-hazard areas zoned 1 and mated position). Furthermore, the thus ensuring a safe operation of

2. In intrinsically safe circuits, a limit hood’s/housing’s blue colour indica- electrical equipment in hazardous

is set to energy so that even a spark tes that an intrinsically safe circuit areas. The limitations may relate to

would not ignite an explosive envi- is present. The inserts compatible current, voltage, capacitivity and/

ronment. With the Han® Ex series, with Han® Ex allow for high-density or inductivity. Finally, a Han® Ex con-

HARTING offers a comprehensive contact arrangements, meeting the nector is always part of a compre-

and well-matched connection sys- standards of the category intrinsically hensive supply system for devices in

tems consisting of hoods/housings, safe even in the tightest of spaces. the field, including current transfers

inserts and cable glands. Hoods and Han® Ex connectors are designed between Ex and Non-ex areas, which

housings are made from an alloy that especially for the named explosion is explained by Figure 7.

Additional electrical equipment Field devices

Sensor

PLC

Actor

Non-Ex area Ex area

Figure 7: H

an® Ex is a comprehensive connector system allowing for the safe

transmission of power, signal and data between Non-Ex and Ex areas.

Connectors for explosion hazardous environments 13Han® Ex Sets – Hoods/Housings Size 3A

Connector sets for explosion-hazardous environments

Features Technical characteristics

• Connector sets especially for explosion-hazar- Specifications DIN EN 60 079-0

dous applications DIN EN 60 079-11

• Suitable for zone 1 and zone 2

Hoods/housings

• Hoods, housings and inserts in one set Material Zinc die cast

• Inserts with compact design and a high number Colour RAL 5015 (blue)

of connections Surface Powder coated

• Available with innovative Han-Quick Lock® Locking element Stainless steel

termination technology Lever type Netal lever

Seal NBR

Industrial connectors of the Han® Ex series Limiting temperatures -20 °C ... +40 °C

NOTICE are designed exclusively for the use in Protection degree

intrinsically safe electrical circuits of categories "ia", "ib" acc. to DIN EN 60 529

and "ic"! in locked position IP65 / IP67

▶▶ The explosion group is defined by the corresponding intrin- is achieved with seal screw

sically safe equipment. and cable gland

▶▶ Temperature class according to DIN EN 60 079-11

Inserts

Number of contacts 4, 7, 8, 12

Pollution degree 3

Insulation resistance ≥ 1010 Ω

Material Polycarbonat

Limiting temperatures -20 °C ... +40 °C

Mechan. working life

- mating cycles ≥ 500

Contacts

Material Copper alloy

Surface

- hard-silver plated 3 µm Ag

Contact resistance ≤ 1 mΩ

Crimp termination 0.14 ... 2.5 mm²

AWG 26 ... 14

Han-Quick Lock ® termination 0.5 ... 2.5 mm²

AWG 20 ... 14

Max. insulation diameter 3.6 mm

14Han® Ex Sets

Identification Part number Size Drawing Dimensions in mm

Han® Ex 4A

Quick Lock Set 10 36 004 0003 3A

M

F

Contact arrangement

view: termination side

Panel cut out: 22 x 22 mm

Han® Ex 8D

Quick Lock Set 10 36 008 0007 3A

M

F

Panel cut out: 22 x 22 mm

Assembly manual Removal manual

Remove cable jacket and strip Do not twist the Insert the screw driver1) at an angle of 45° into the ope-

the fine stranded wires. fine stranded wires! ning and lever the blue slide out.

Push the fine stranded wires into the Han-Quick Lock® contact

and push the blue slide with a screw driver1) until it comes

to a stop.

1)

Screw driver: 0.4 x 2.5 mm

HARTING Han® Ex 15Hoods/Housings Size 3A

Identification Part number Size Drawing Dimensions in mm

Han® Ex Q7 Set

Order crimp contacts M

separately! 10 36 007 0001 3A

F

Contact arrangement

Panel cut out: 22 x 22 mm

view: termination side

Han® Ex 8D Set

Order crimp contacts

separately!

M

10 36 008 0006 3A

F

Panel cut out: 22 x 22 mm

Han® Ex Q12 Set

Order crimp contacts

separately! 10 36 012 0001 3A M

F

Panel cut out: 22 x 22 mm

Wire gauge Part number

Identification mm² Male contact Female contact Drawing Dimensions in mm

Crimp contact

silver plated 0.14-0.37 09 15 000 6104 09 15 000 6204

0.5 09 15 000 6103 09 15 000 6203

0.75 09 15 000 6105 09 15 000 6205

1.0 09 15 000 6102 09 15 000 6202

1.5 09 15 000 6101 09 15 000 6201

2.5 09 15 000 6106 09 15 000 6206

Wire gauge Ø Stripping length

mm

0.14-0.37 mm² AWG 26-22 0.9 8 mm

0.5 mm² AWG 20 1.1 8 mm

0.75 mm² AWG 18 1.3 8 mm

1.0 mm² AWG 18 1.45 8 mm

1.5 mm² AWG 16 1.75 8 mm

2.5 mm² AWG 14 2.25 6 mm

16 Connectors for explosion hazardous environmentsHan® Ex Sets

Connectors for explosion hazardous environments – standard sizes

Features Technical characteristics

• Hoods and housings in the sizes 6 B, 10 B, 16 B, Specifications DIN EN 60 079-0, -11, -14

24 B and 48 B DIN EN 60 664-1

DIN EN 61 984

• Connectors especially for explosion hazardous

applications Hoods/ housings

• Suitable for intrinsically safe circuits Material zinc die cast

• Inserts on basis of Han® E with 6 to 24 contacts Colour RAL 5015 (blue)

Surface powder coated

• Suitable for areas classed 1 und 2

Locking element stainless steel

Lever type metal lever

Seal NBR

Ambient temperature

acc. to DIN EN 60 079-11 -20 °C ... +40 °C

Industrial connectors of the Han® Ex

WARNING! series are designed exclusively for Limit temperature for

the use in intrinsically safe electrical circuits of categories connectors -40 °C ... +125 °C

„ia“, „ib“ and „ic“! Maximum

▶▶ The explosion group is defined by the corresponding surface temperature

intrinsically safe equipment. acc. to DIN EN 60 079-11 T6 = 85 °C

▶▶ Temperature class according to DIN EN 60 079-11 Protection degree

acc. to DIN EN 60 529

in locked position IP65

is achieved with cable gland

General description Inserts

Number of contacts 6, 10, 16, 24

The connectors are designed to meet the intrinsic

Rated current 16 A

safety requirements for ignition protection class in

Rated voltage 90 V

explosion hazardous areas classed as 1 and 2. In

Insulation resistance ≥ 1010 Ω

intrinsically safe circuits, energy is limited in such a

Material polycarbonate

manner that even a potential spark cannot ignite an

Limiting temperatures

explosive environment. acc. to DIN EN 60 079-11 -20 °C ... +40 °C

The Han® Ex product portfolio offers complete Mechan. working life

connector systems consisting of housings and - mating cycles ≥ 500

inserts, including housings made from an alloy that

can be used in pulverised methane-coal dust Contacts

atmospheres. They also offer ignition protection Material copper alloy

class 65 in the mated condition. The housing’s blue Surface

- hard-silver plated 3 µm Ag

colour indicates that an intrinsically safe circuit is

Contact resistance ≤ 1 mΩ

present. The contact inserts provide a high number

Crimp termination 0.14 ... 2.5 mm²

of pins and meet the standards of the ignition AWG 26 ... 14

protection class even in the tightest of spaces. Screw connection 0.75 ... 2.5 mm²

Tightening torque 0.5 Nm

Max. insulation diameter 3.6 mm

HARTING Han® Ex 17Hoods and Housings – Sizes 6 B, 10 B, 16 B, 24 B, 48 B

Cable

Identification Part number entry Drawing Dimensions in mm

Hood 6 B

top entry 19 36 006 1440 M20

19 36 006 1441 M25

Hood 6 B

side entry 19 36 006 1540 M20

19 36 006 1541 M25

Hood 10 B

top entry 19 36 010 1420 M20

19 36 010 1421 M25

Hood 10 B

side entry 19 36 010 1520 M20

19 36 010 1521 M25

18 Connectors for explosion hazardous environmentsHan® Ex Sets

Cable

Identification Part number entry Drawing Dimensions in mm

Hood 16 B

top entry 19 36 016 1421 M25

19 36 016 1422 M32

Hood 16 B

side entry 19 36 016 1521 M25

19 36 016 1522 M32

Hood 24 B

top entry 19 36 024 1421 M25

19 36 024 1422 M32

Hood 24 B

side entry 19 36 024 1521 M25

19 36 024 1522 M32

HARTING Han® Ex 19Hoods and Housings – Sizes 6 B, 10 B, 16 B, 24 B, 48 B

Identification Part number Drawing Dimensions in mm

Housing, bulkhead mounted 6 B

09 36 006 1301

Panel cut out

Housing, bulkhead mounted 10 B

09 36 010 1301

Panel cut out

Housing, bulkhead mounted 16 B

09 36 016 1301

Panel cut out

Housing, bulkhead mounted 24 B

09 36 024 1301

Panel cut out

20 Connectors for explosion hazardous environmentsHan® Ex Sets

Cable

Identification Part number entry Drawing Dimensions in mm

Hood 48 B

top entry 19 36 048 0447 M32

19 36 048 0448 M40

Hood 48 B

side entry 19 36 048 0547 M32

19 36 048 0548 M40

Hood 48 B

with cover 09 36 048 0301

Panel cut out

HARTING Han® Ex 21Sales network – worldwide

Armenia: China Greece: Kosovo:

Refer to Russia HARTING (Zhuhai) Sales Ltd. Refer to Italy Refer to Austria

Room 3501, Grand Gateway I

Australia and Oceania No. 1 Hong Qiao Road Hong Kong Macedonia:

HARTING Pty. Ltd. Xu Hui District HARTING (HK) Limited Refer to Austria

Suite 11 / 2 Enterprise Drive Shanghai 200030 Regional Office Asia Pacific

Bundoora 3083, University Hill Phone +86 21 3418 9758 3512, Metroplaza Tower 1 Malta:

Melbourne, Victoria cn@HARTING.com 223 Hing Fong Road Refer to Italy

Phone 1800 201 081 Kwai Fong, N. T.

+61 3 9466 7088 Croatia: Phone +852 2423 7338 Mexico

au@HARTING.com Refer to Austria ap@HARTING.com HARTING Mexico S.A. de C.V.

IOS Torre Virreyes

Australia and Oceania: Czech Republic Hungary Pedregal No. 24,

Refer to Australia HARTING s.r.o. HARTING Magyarország Kft. Co. Molino Del Rey

Mlýnská 2 Fehérvári út 89-95 Suites 357 A, B, C

Austria 160 00 Praha 6 1119 Budapest Del Miguel Hidalgo

HARTING Ges.m.b.H. Phone +420 220 380 495 Phone +36 1 205 34 64 Mexico D.F. 11600

Deutschstraße 19 cz@HARTING.com hu@HARTING.com Phone +1 800 123 0415

1230 Wien HARTING.mexico@HARTING.com

Phone +43 161 621 21 Denmark India

at@HARTING.com HARTING ApS HARTING (India) Private Limited Middle East:

Resilience House 7th Floor (West Wing) Refer to United Arab Emirates

Azerbaijan: Lysholt Allé 8 Central Square II

Refer to Turkey 7100 Vejle Unit No.B 19 part, B 20 & 21 Montenegro:

Phone +45 70 25 00 32 TVK Industrial Estate Refer to Austria

Baltic States: dk@HARTING.com Guindy, Chennai 600032

Refer to Finland Phone +91-44-43560415 Netherlands

Finland in@HARTING.com HARTING B.V.

Belarus: HARTING Oy Larenweg 44

Refer to Russia Teknobulevardi 3-5 Ireland: 5234 ’s-Hertogenbosch

01530 Vantaa Refer to Great Britian Phone +31 736 410 404

Belgium Phone +358 207 291 510 nl@HARTING.com

HARTING N.V. fi@HARTING.com Israel:

Z.3 Doornveld 23 Refer to Turkey Norway

1731 Zellik France HARTING A/S

Phone +32 2 466 0190 HARTING France EURL Italy Østensjøveien 36

be@HARTING.com ZAC Paris Nord 2 HARTING S.R.L. 0667 Oslo

181 avenue des Nations Via dell‘ Industria 7 Phone +47 22 700 555

Bosnia Herzegovina: 95934 ROISSY CDG 20090 Vimodrone (MI) no@HARTING.com

Refer to Austria Phone +33 1 4938 3400 Phone +39 02 250801

fr@HARTING.com it@HARTING.com Pakistan:

Brazil Refer to United Arab Emirates

HARTING Ltda. Germany Japan

Alameda Caiapós, 643 HARTING Deutschland HARTING K.-K. Poland

06460-110- Barueri - São Paulo GmbH & Co. KG Yusen Shin-Yokohama HARTING Polska Sp. z o.o.

Phone +55 11 5035 0073 Simeonscarré 1 1 Chome Bldg., 2F 1-7-9, ul. Duńska 11

br@HARTING.com D-32427 Minden Shin-Yokohama, Kohoku-ku 54-427 Wrocław

Phone +49 571 8896 0 Yokohama 222-0033 Phone +48 71 352 81 71

Canada de@HARTING.com Phone +81 45 476 3456 pl@HARTING.com

HARTING Canada Inc. jp@HARTING.com

475 Dumont Avenue, Suite 300 Georgia: Romania

Dorval, Quebec, H9S 5W2 Refer to Russia Korean Republic HARTING Romania SCS

Phone +1 855 659-6653 HARTING Korea Co. Ltd. Str. Europa Unita nr 21

info.ca@HARTING.com Great Britain B-B108, Worim Lions Valley 5th, 550018 Sibiu

HARTING Limited 302 Galmachi-ro, Jungwon-gu, Phone +40 369 102 610

Central America and the Caswell Road Seongnam-si, Gyeonggi-do, ro@HARTING.com

Caribbean: Brackmills Industrial Estate 13201 Republic of Korea

Refer to USA NN4 7PW GB – Northampton Phone +82 31 750 0380

Phone +44 1604 82 75 00 kr@HARTING.com

Central Asia: salesuk@HARTING.com

Refer to Russia

22Sales network – worldwide

Russia South America: Turkey

LLC HARTING Refer to Brazil HARTING Türkei Elektronik

Sverdlovskaya nab., 44, Ticaret

lit. Yu, office 612 South Asia: Limited Sirketi

195027, St. Petersburg Refer to Singapore Bayar Cad. Şehit İlknur Keleş

Phone +7 812 327 6477 Sok.

ru@HARTING.com South Pacific: Dural Plaza No:3 K.11

Refer to Australia 34742 Kozyatagı – Istanbul

Serbia: Phone +90 216 688 81 00

Refer to Austria Spain tr@HARTING.com

HARTING Iberia S.A.U.

Singapore C/Viriato, 47 8º Planta Ukraine:

HARTING Singapore Pte. Ltd. Edificio Numancia, 1 Refer to Poland

25 International Business Park 08014 Barcelona

#04-108 German Centre Phone +34 933 638 484 United Arab Emirates

SGP-Singapore 609916 es@HARTING.com HARTING Middle East FZ-LLC

Phone +65 6225 5285 Knowledge Village

sg@HARTING.com Sub-Sahara countries: Block 2A – Office F72

Refer to South Africa P.O. Box: 454372

Slovakia Dubai

HARTING s.r.o. Sweden Phone +971 4 453 9737

Slovakia branch HARTING AB uae@HARTING.com

Štefániková Trieda 71, (areál Gustavslundsvägen 141B

pivovaru) 167 51 Bromma HARTING Inc. of North America

949 01 Nitra Phone +46 8 445 7171 1370 Bowes Road

Phone +421 37 655 9089 se@HARTING.com USA-Elgin, Illinois 60123

sk@HARTING.com Phone +1 847 741 1500

Switzerland us@HARTING.com

Slowenia: HARTING AG

Refer to Austria Volketswil branch

Hofwiesenstrasse 4 A

South Africa 8604 Volketswil

HARTING South Africa Phone +41 44 908 20 60

Proprietary Ltd. ch@HARTING.com

Ground Floor, Twickenham

Building Taiwan

The Campus HARTING Taiwan Ltd.

Cnr Main & Sloane Street Room 1, 5/F, 495 GuangFu South

Bryanston, Johannesburg 2021 Road

South Africa RC-110 Taipei

Phone +27 (0) 11 575 0017 Phone +886 227 586 177

za@HARTING.com tw@HARTING.com

Distributors – worldwide / General contact

ARROW: www.arrow.com HEILIND Electronics: HARTING Electric HARTING Electronics GmbH

www.heilind.com GmbH & Co. KG P.O. Box 1433

Digi-Key Corporation: P.O. Box 1473 32328 Espelkamp

www.digikey.com Mouser Electronics: D-32328 Espelkamp Germany

www.mouser.com Germany Phone +49 5772/47-97200

Farnell: www.farnell.com Phone +49 5772/47-97100 electronics@HARTING.com

RS Components: electric@HARTING.com www.HARTING.com

FUTURE Electronics: www.rs-components.com www.HARTING.com

www.futureelectronics.com

23HARTING.com –

the gateway to your

country website.

2019-11-06/1.0 / Online PDF version only

HARTING Technology Group

info@HARTING.com

www.HARTING.com

www.product-news.HARTING.comYou can also read