Mahindra Vehicles Automotive

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Automotive

Mahindra Vehicles

Mahindra rises with digitally planned new vehicle manufacturing facility

Products Mahindra Vehicle Manufacturers succeed and to create a better future for

Teamcenter, Tecnomatix Limited (Mahindra Vehicles) themselves, their families and their com-

munities. In the spirit of “Rise,” a new

uses Tecnomatix to establish a

Mahindra manufacturing facility recently

Business challenges state-of-the-art automotive rose in the Chakan corridor near Pune,

manufacturing plant India.

Manage global markets and

competition

A world leader in vehicle manufacturing Mahindra Group’s Automotive Sector man-

Shorten the vehicle develop- rises in South Asia ufactures and markets light commercial

ment lead time to reduce Mahindra Group (Mahindra) is among the and utility vehicles, including auto rick-

time-to-market biggest and most powerful publicly listed shaws (three-wheelers). The sector has

Minimize manufacturing companies in the world. It operates in the been the leader in India’s utility vehicles

launch issues to accelerate key industries that drive economic growth, market since its inception, and currently

production ramp-up enjoying a leadership position in tractors, accounts for about half of India’s utility

utility vehicles, information technology vehicle market. The company exports its

Meet increasing demand for

(IT) and vacation ownership. Mahindra products to Europe, Africa, South America,

highly customized vehicles

focuses on enabling people to “Rise,” a call South Asia and the Middle East.

to action to unite the many companies

Keys to success within the Mahindra Group to a common Mahindra decided to expand its lineup to

Get the new Chakan plant up purpose. More specifically, Mahindra include a new range of medium and heavy

and running quickly employees are encouraged to rise, to commercial vehicles, including SUVs,

Improve quality and consis-

tency in manufacturing, sup-

porting “first time right”

approach

Analyze the impact of product

mixes on production through-

put and optimize facilities

layouts

Virtually analyze complex

assembly scenarios of the new

product lines

Share best practice process

data between multiple sites

and with suppliers

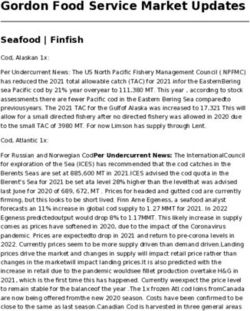

The new Maxximo light commercial vehicle, manufactured at the Final Assembly of the Mahindra Navistar

Mahindra Chakan plant. truck in the Mahindra Chakan plant.

www.siemens.com/plmA Mahindra manufacturing

engineer uses Manufacturing

Process Planner.

Results trucks and buses. This expansion required assembly suppliers use Teamcenter® soft-

Reduced lead time and the a new plant, so Mahindra decided to estab- ware for product lifecycle management

overall duration of a vehicle lish a new manufacturing facility in (PLM). The company also uses NX™ soft-

project Chakan. Mahindra’s challenge was how to ware for some of the powertrain product

assess, design and build the facility, plus design, and a few years ago Mahindra

Decreased capital investment get it running and producing vehicles started using Tecnomatix® software for

in machines and conveyors according to the aggressive schedule that digital manufacturing.

Substantially shortened lead management had defined.

time for concept design of “In 2007, we selected and introduced the

production facilities As of 2012, 1,500,000 cars are produced Tecnomatix solution, because it offers a

Reduced bottlenecks in annually in the Chakan corridor by full range of digital manufacturing tools

production Mahindra, Volkswagen, General Motors, that serve our needs, integrates smoothly

Mercedes Benz and other automotive man- with our existing product data manage-

Increased re-use of manufac-

ufacturers. Mahindra is one of the largest ment systems and clearly stands out in

turing tools

manufacturers in this area, producing light meeting the criteria we had defined,“ says

Maximized production commercial vehicles (LCV), pick-up trucks, Nagesh Nidamaluri, senior general man-

resource utilization SUVs and the Mahindra Navistar heavy ager, Assembly Systems, MES and Digital

duty trucks. Manufacturing, Chakan plant, Mahindra

Vehicles.

Revisiting engineering processes to

establish “state-of-the-art” plant Mahindra uses the Manufacturing Process

Mahindra is a long-time customer of Planner solution in the Teamcenter

Siemens PLM Software. Designers, data portfolio for the planning of various pro-

administrators and some of its product duction processes; as well as Plant

“ The Tecnomatix solution...offers a full range

of digital manufacturing tools that serve

our needs.”

Nagesh Nidamaluri

Senior General Manager Assembly Systems, MES and Digital Manufacturing

Mahindra Vehicle Manufacturers LimitedSimulation, FactoryCAD™ software and Laying out the new Chakan plant in 3D “In 2007, we selected and

FactoryFlow™ software, all in the While constructing the new plant in introduced the Tecnomatix

Tecnomatix portfolio, for plant design and Chakan, Mahindra decided to significantly solution, because it offers a

optimization; Process Designer and Process upgrade the way it creates and manages full range of digital manufac-

Simulate and Jack™ software, also all in plant layout data. There were a number of turing tools that serve our

the Tecnomatix portfolio, for assembly issues to deal with, including the fact that needs, integrates smoothly

planning and validation. there was no uniform plant layout method with our existing product

across the enterprise. Each site was man- data management systems

The establishment of a new plant was a aging plant layout separately. Plant layout and clearly stands out in

good opportunity to revisit Mahindra’s cur- drawings were not maintained in a central meeting the criteria we had

rent engineering processes. “We have real- repository, which made it very time-con- defined.“

ized that in order to shorten a vehicle suming to locate them when they were

Nagesh Nidamaluri

manufacturing project, we need to deploy needed. There was no revision manage-

Senior General Manager

concurrent engineering methods,” ment system and only one engineer at a

Assembly Systems, MES and

Nidamaluri says. “This means that manu- time could work on any given layout.

Digital Manufacturing

facturing engineering needs to work con- Drawings provided by suppliers were

Mahindra Vehicle

currently with product design. Digital maintained in different layers in the same

Manufacturers Limited

manufacturing tools provided by Siemens file, resulting in duplication of data and

PLM Software facilitate this approach. This unnecessarily large files, which degrade

is a dramatic change to our current engi- visualization performance.

“Providing the essentials

neering processes.

needed to create detailed

To resolve these issues, FactoryCAD was

and intelligent factory mod-

“We have a gate system, and one of the used to create 3D plant layouts for all of

els, FactoryCAD allowed our

gates is the virtual validation gate. In the the Chakan plant production lines, includ-

planners to use ‘smart

past, mostly the product design group was ing body and trim, chassis and final (TCF).

objects’ to represent their

actually doing validations for this gate; but “Providing the essentials needed to create

factory resources.”

now, with the help of Tecnomatix digital detailed and intelligent factory models,

manufacturing tools, the manufacturing FactoryCAD allowed our planners to use Anupam Patil

engineering group is very active in prepa- ‘smart objects’ to represent their factory Senior Manager

rations for this gate.” resources,” says Anupam Patil, senior man- IT and PLM

ager, IT and PLM, Chakan plant, Mahindra Mahindra Vehicle

Mahindra decided to execute the digital Vehicles. Manufacturers Limited

manufacturing journey at the Chakan plant

in a series of steps, deploying point solu- “This was especially advantageous because

tions to address specific needs, followed the objects provided the ability to snap a

by the manufacturing bill of materials layout model together, instead of wasting

(MBOM) and fi`nally the bill of process time drawing the individual equipment.

(BOP). Mahindra plans to clone proven Using FactoryCAD, we were able to

methodologies developed in the Chakan resolve many issues before erecting and

plant at other plants. commissioning of the factory, such as

interferences of process and utility

Left: Truck cargo mounting analysis created

with Jack human simulation.

Middle: Engine docking station simulation

created with Jack human simulation.

Right: Interference of a robot and a column

found using FactoryCAD.Left: Plant Simulation

model – routing with no

cross-over.

Right: Plant Simulation

model – routing with a

cross-over for empty skids.

equipment with the civil structure, for into three separate TCF assembly lines.

example, as well as a monorail system that Tecnomatix Plant Simulation was used to

caused interference with the supporting conduct a what-if simulation to determine

beams at a specific area and a robot that the best scenarios for the plant’s inter-

caused interference with the building col- shop conveyor system. Several scenarios

umn in another area.” of mixed-model production volumes were

simulated and the optimal size of central

A planned production line, virtually painted body buffer storage and individual

simulated BIW shop storage was determined. This

Before building the production line, simulation project substantially reduces

Mahindra completed a number of simula- the lead time in designing the storage.

tion projects that helped to make impor-

tant decisions in configuring the Another project was to determine the

production line. One of the projects optimal routing method of painted vehicle

addressed the inter-connections of the bodies from the single paint line to the

body-in-white (BIW) welding shop, paint three TCF assembly lines. “The simulation

line and the TCF assembly line, where all helped to identify bottlenecks, and

the parts are assembled to form a com- verify the robustness of the selected

pleted vehicle. option,” says Amit Jahagirdar, digital man-

ufacturing manager, Chakan plant,

The goal of the simulation project was to Mahindra Vehicles. “One simulated option

find out the optimal buffer storage capac- was a clockwise flow of bodies with no

ity in between these production lines. The cross-over. The simulation showed that in

challenge arose because there were three the event that one of the three TCF lines is

BIW planned production lines (for the shut-down, the respective bodies in the

Maxximo, Genio and XUV vehicles) going main line would create blockage in moving

into a single paint line, which then goes bodies to the other TCF lines. The second

option was a counter-clockwise flow, with

a cross-over for the empty skids to flow

back to the paint shop. This is a more

“The simulation helped to robust option because each TCF feeder line

is practically independent of others. So,

identify bottlenecks, and there is little or no impact on the overall

performance of the line shutdowns.”

verify the robustness of the Using Plant Simulation, Mahindra gained

critical insight regarding its factory layout

selected option.” and installation processes across vehicle

lines. Accurate and fast validation of pro-

cesses enabled the company to achieve its

Amit Jahagirdar

goal of getting the implementation right

Digital Manufacturing Manager,

the first time. Detailed throughput exami-

Chakan plant

nation notably reduced bottlenecks, and

Mahindra Vehicle Manufacturers Limited“So, we decided to use dedicated tools for

this task, and developed a robust MBOM

creation and update methodology using

Manufacturing Process Planner.”

Anupam Patil

Senior Manager

IT and PLM

Mahindra Vehicle Manufacturers Limited

what-if analysis capabilities substantially process. For example, in the paint line, the

decreased unnecessary capital investment chassis will be represented by a bare chas-

in machines and conveyors. sis, cathodic electrocoat deposition body

and painted body. These forms, which we

MBOM creation means no part is call ‘semi-finished parts,’ appear as a single

forgotten in the production assembly in the EBOM, but as different

The engineering bill of materials (EBOM) is assemblies in the MBOM. Another exam-

created and managed using Teamcenter. ple of MBOM-specific information is the

Then manufacturing engineers create the addition of scrap weight to the stamped

MBOM using Manufacturing Process parts, as this information is used down-

Planner by consuming parts from the stream in the recycling process.

EBOM. The MBOM is then sent from

Manufacturing Process Planner to SAP® “Handling the MBOM changes throughout

software, the enterprise resource planning the development lifecycle is crucial for us.

(ERP) system Mahindra uses. Therefore, the engineering notifications

are transferred along with the EBOM from

“In the previous method, planners used Teamcenter. The notifications are put into

Microsoft Excel to define and maintain the a common pull, and from there they are

MBOM,” Patil says. “While the tool is intui- assigned to the relevant MBOM planner. In

tive, it was clear to us that this is not sus- addition, once an initial MBOM is created,

tainable for handling large BOMs and all subsequent changes in the MBOM are

sharing engineering data. So, we decided done in a controlled configuration, using

to use dedicated tools for this task, and the incremental change mechanism,

developed a robust MBOM creation and which enables us to analyze very clearly

update methodology using Manufacturing the impact of any EBOM change on the

Process Planner. Using this methodology, MBOM. Within the incremental change,

we use the workflow mechanism of MBOM in Manufacturing Process

planners adjust the EBOM and add relevant

Planner with “make or buy” definitions.

production information such as a ‘make or Teamcenter which helps ensure that every

buy’ definition for each item and the point change goes through a predefined

of consumption along the production line, sequence of events and an authorized

which is later used by the shop floor logis- approval. These capabilities are unique,

tics management system.” and provide us the ability to put a lot of

structure into the MBOM creation

“The MBOM will include the car parts in process.”

their form through the entire production“We use the workflow mecha- Due to the importance of maintaining an could support sufficient door opening. The

nism of Teamcenter which accurate MBOM, starting from the engi- limit to which the doors can be opened

ensures that every change neering team and down to the shop floor, was calculated based on the virtual 3D

goes through a predefined Mahindra uses Teamcenter to execute a simulation, instead of waiting for actual

sequence of events and an daily update to synchronize any incremen- parts to arrive at plant. This resulted in

authorized approval. These tal changes to the EBOM. In a similar man- cost and time savings and reduced the

capabilities are unique, and ner, Teamcenter integration for SAP number of iterations of the hanger

provide us the ability to put synchronizes the MBOM daily with SAP design,” says Jahagirdar.

a lot of structure into the based on make or buy attributes. For

MBOM creation process.” example, any assembly node with children,

which was identified in the MBOM as a

Anupam Patil

purchased assembly, will be automatically

Senior Manager

exported and will appear in SAP as a

IT and PLM

single node.

Mahindra Vehicle

Manufacturers Limited

Dynamic 3D simulation supports

analysis of complex assembly scenarios

“Manufacturing engineers for the new Maxximo

used Process Simulate to val- The painted body of the Maxximo mini-

idate hanger design that truck is transported inside the new assem-

could support sufficient door bly shop for operations. The car body is Process Simulate is used to simulate the doors

opening while the truck is on a hanger.

opening. The limit to which moved along using a hanger system in the

the doors can be opened was underbody areas and on transfer lines. The

calculated based on the vir- system was initially designed to carry the The assembly process for the Maxximo was

tual 3D simulation, instead car body with the doors closed. After ana- planned so that the engine assembly from

of waiting for actual parts to lyzing the conceptual flow of assembly, the engine production unit is transferred

arrive at plant. This resulted other possible assembly operations were to the final assembly shop from a logistic

in cost and saving of time analyzed. It was found that in order to area. It moves on a predefined track and

and iterations of the hanger reduce production time, some assembly gets synchronized with the conveyor carry-

design.” operations could be executed when the car ing the Maxximo car bodies on hangers.

body is on the hanger, as long as the doors Because this is a complex scenario, which

Amit Jahagirdar

could be opened to a certain extent, which involves many parameters, manufacturing

Digital Manufacturing

will enable operators to work inside the engineers also performed a dynamic 3D

Manager

cabin area. simulation of this scenario. “The main

Mahindra Vehicle

objective of this simulation was to validate

Manufacturers Limited

“Manufacturing engineers used Process the planned process and its duration esti-

Simulate to validate hanger design that mation. The ergonomics of operators was

“ Manufacturing engineers used Process

Simulate to validate hanger design....This

resulted in cost and saving of time and

iterations of the hanger design.”

Amit Jahagirdar

Digital Manufacturing Manager

Mahindra Vehicle Manufacturers LimitedImplementing Tecnomatix portfolio

enabled a 25 percent reduction in the green

field plant setup time, a 28 percent

improvement in effective working time.

also evaluated based on Mahindra stan- “The digital manufacturing tools play a key “We have defined a workflow

dards,” Jahagirdar says. role in the first steps of a car project,” says using Teamcenter to classify

Nidamaluri. “These tools are already used our existing and new tools

Tools management lowers cost by in the requirements definition phase of a by part number, so that

enabling re-use new or modified production line. This eventually we will have a

Mahindra plans to use the resource classifi- enables us to provide more mature engi- structured library of tools

cation capability of Teamcenter to manage neering information upfront to our system across the Mahindra auto-

its many production tools. According to suppliers, and will therefore reduce lead motive sector.”

Jahagirdar, “The objective of this initiative time and the overall duration of a car proj-

Amit Jahagirdar

is to lower costs, reduce lead time and ect. I also expect that our production facili-

Digital Manufacturing

improve quality by helping the manufac- ties and tools suppliers will interact with

Manager

turing engineer/planner select the proper the system, and introduce their inputs.”

Mahindra Vehicle

resource, increasing the re-use of manu-

Manufacturers Limited

facturing tools, reducing tool inventory, Mahindra Vehicles receives top award

maximizing resource utilization and deliv- Mahindra Vehicles received the top honor

ering digital models for verification and in Siemens PLM Software’s Asia Pacific “The benefits of the

simulation.” Innovation Awards 2012, which places a Tecnomatix digital manufac-

spotlight on how PLM technology enables turing tools for Mahindra are

“We have defined simple categories for any companies to make smarter decisions that already invaluable. This tool-

tool we have in our production plants, lead to the creation of better products. set deployment strengthens

including a tool suitable to a specific part, The top award is presented to the com- the ‘first time right’ mindset

such as fixtures or specific gauges. There pany that uses PLM technology in a way we have in Mahindra, as it

are also more generic tools, such as robots that enables it to be a hallmark of success enables us to conduct differ-

and torque wrenches. Based on this, we in the manufacturing industry, maximizing ent ‘what-if’ analyses of pro-

are defining a workflow using Teamcenter the value derived from its products duction scenarios.”

to classify our existing and new tools by throughout the entire lifecycle to stream-

Nagesh Nidamaluri

part number, so that eventually we will line its productivity and performance.

Senior General Manager

have a structured library of tools across the

Assembly Systems, MES and

Mahindra automotive sector.” Implementing Tecnomatix portfolio

Digital Manufacturing

enabled Mahindra Vehicles to come closer

Mahindra Vehicle

The next step is the development of the than ever before to real-time digital manu-

Manufacturers Limited

BOP using Manufacturing Process Planner. facturing. Other benefits included a 25

Assembly operations and their duration are percent reduction in the green field plant

defined, and then linked to the parts that setup time, a 28 percent improvement in

should be handled and to the specific tools effective working time by validating and

required to carry out the work. This meth- reducing nonvalue-added activities and an

odology enables Mahindra manufacturing overall increase in flexibility, which pro-

engineers to re-use best practices and cap- duced more product model mixes and

tured knowledge in planning or modifying reduced time-to-market.

a production line.Solutions/Services

Teamcenter

Manufacturing Process Planner

www.siemens.com/teamcenter

Tecnomatix

Process Designer

Process Simulate

Plant Simulation

FactoryCAD

FactoryFlow

Jack

www.siemens.com/tecnomatix

Robotic simulation created with Tecnomatix to reduce cycle time of welding operations.

Customer’s primary business

Mahindra Vehicle

Manufacturers Limited manu-

“First time right” will lead to a brighter robots in our Chakan plant. Currently, even

factures and markets utility future the slightest change in a robot program

and light commercial vehicles,

“The benefits of the Tecnomatix digital requires us to contact the line builder and

including auto rickshaws

manufacturing tools for Mahindra are ask for modifications. I believe we can

(three-wheelers). It is the

already invaluable,” Nidamaluri says. “This develop skills by using the Tecnomatix

leader in utility vehicles in

toolset deployment strengthens the ‘first robotics offline programming tools to con-

India and currently accounts

time right’ mindset we have in Mahindra, duct some of this work ourselves. This will

for about half of the country’s

as it enables us to conduct different ‘what- bring multiple benefits, including higher

utility vehicle market. The

if’ analyses of production scenarios. Still, flexibility due to greater engineering capa-

Mahindra Group’s Automotive

we are looking forward to make more bility, shortening the modifications lead

Sector is part of the globally

progress in the digital manufacturing jour- time and reducing cost.”

recognized Mahindra Group,

ney. For example, we have more than 100

which is among the top 10

industrial companies in India.

www.mahindra.com

Customer location

“ The benefits of the Tecnomatix

Chakan, Pune,

Maharashtra District

digital manufacturing tools for

India

Mahindra are already invaluable.”

Partner Nagesh Nidamaluri

Tesis PLMware GmbH Senior General Manager Assembly Systems

www.tesis.de/plmware MES and Digital Manufacturing

Mahindra Vehicle Manufacturers Limited

Siemens Industry Software

Americas +1 314 264 8499 © 2014 Siemens Product Lifecycle Management Software Inc. Siemens and the Siemens logo are registered trademarks of

Europe +44 (0) 1276 413200 Siemens AG. D-Cubed, Femap, Fibersim, Geolus, GO PLM, I-deas, JT, NX, Parasolid, Quality Planning Environment, Solid

Edge, Syncrofit, Teamcenter and Tecnomatix are trademarks or registered trademarks of Siemens Product Lifecycle

Asia-Pacific +852 2230 3308

Management Software Inc. or its subsidiaries in the United States and in other countries. Jack is a trademark or registered

trademark of The Trustees of The University of Pennsylvania. AutoCAD a registered trademark of Autodesk, Inc. SAP is a

trademark or registered trademark of SAP Aktiengesellschaft. Excel is a registered trademark of Microsoft Corporation. All

other logos, trademarks, registered trademarks or service marks used herein are the property of their respective holders.

www.siemens.com/plm Z29 30584 2/14 BYou can also read