RITTER MilliGascounter Type MGC-1

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Models

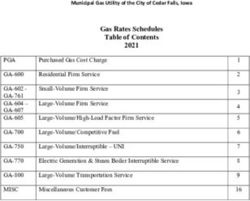

The MGC is available in the following casing/measurement cell materials:

(from left to right: casing material/measurement cell material) PMMA/PVDF, PVDF/PVDF, PVC-red/ PVC-red.

The RITTER MilliGascounter®

Type MGC-1

Applications Measurement Principle with Advantages compared to

The MilliGascounter (1) (MGC) Schematic other Systems

is designed for the volumetric The gas to be measured flows ભ Individual volumetric calibration

measurement of the smallest through the gas inlet nozzle 3 and of each MGC traceable to National

amounts of gas with ultra-low flow micro capillary tube 9 within the Primary Standard

rates. It is suitable for measurement base plate into the casing of the ભ Total gas production measured

of all inert, slightly corrosive gases MGC which is filled with a packing (instead of Methane only)

such as biogas (PMMA model) and

liquid !2. The gas rises as small

ભ Head space volume of fermenta-

aggressive gases (PVDF model). tion bottle at measurement start

bubbles through the packing liquid

Furthermore, it can be used for (= air) not erroneously measured

and is collected in the measurement

volumetric leak detection. as pure methane volume

cell !3.

The measurement cell consists of

ભ No false readings due to CO2

absorption by combination of

two measuring chambers, which

2 acidulated packing liquid and

are filled successively by the rising

1 software correction (more: www.

www.ritter.de

gas bubbles. When a measuring

3 ritter.de/en/products/milligas-

12345678 chamber is filled, the buoyancy of counters)

4

10 the filled chamber causes the mea-

surement cell to tip over abruptly. Measuring-Range

11 The second measuring chamber The minimum flow rate is theo-

then begins to fill and the first one retically zero ltr/h as there are no

13 is emptied at the same time. The mechanical limitations with the MGC

tipping of the measurement cell which would define a minimum flow.

12

9 triggers a pulse by means of the However, at such micro flow rates

permanent magnet !1 and the reed there are external influences

contact !0 which is registered by becoming evident: temperature and

the counter unit 1. For external pressure variation, tightness of the

data logging (PC) the switching hose connection, permeability of

pulses of the second reed contact the gas inlet hose. Therefore, the

(1)

Developed at the University of can be obtained via the signal minimum flow rate was defined to

Applied Sciences Hamburg, 1 ml/h. The maximum flow rate is

output socket 2. The measured gas

Prof. Dr. Paul A. Scherer 1.0 ltr/h.

exhausts through the gas output

nozzle 4.Performance Specifications

Minimum flow rate Qmin 1 ml/h Measuring accuracy (2) ±3 / ±1 %

Maximum flow rate Qmax 1 ltr/h Display accuracy (3)

0.01 ml

Measurement cell volume,

Minimum gas inlet pressure 8 mbar 3 ml

approx.

Maximum gas inlet pressure 100 mbar Packing liquid quantity, approx. 120 ml

Gas inlet pressure Operating temperature (4)

+10 ~ +60/+80/+40 °C

8 mbar

at measurement start Connection gas in-/outlet PVDF screw-type tube connection

(2)

Without / with software »RIGAMO« across the whole measurement range.

(3)

For display of volume corrected by calibration factor with 2 decimals.

(4)

Max. Operating temperature for PMMA/PVDF/PVC

Apparatebau

123456.12

109

Ø98

1 Counter unit with LCD display / 2 Signal output socket (reed contact) / 3 Gas inlet / 4 Gas outlet

5 Air-vent screw for filling / 6 Gas inlet channel / 7 Casing / 8 Base plate / 9 Micro capillary tube

!0 Two reed contacts / !1 Permanent magnet / !2 Packing liquid / !3 Measurement cell (tilting body) with twin-chambers

!4 Tracing screw for liquid level / !5 Inspection screw gas inlet channel

Display, Signal Output Standard Equipment Accessories

The volume of the measured gas is ભ Electronic counter / display ભ Software »RIGAMO«

displayed on the electronic digital ભ Cleaning rod for micro capillary for data acquisition by PC

display located on top of the MGC ભ Signal output (reed contact), ભ Packing liquid:

casing. Additionally a floating reed floating output, 0.1 sec., 100 / 500 / 1,000 ml

contact can be used as a signal max. load 100 V/DC / 0.33 A ભ Additional gas connection tubing

output. ભ Twin measuring chamber Tube material:

ભ 200 ml packing liquid · PVC with PMMA & PVC casing

Accuracy ભ 1.5 m connection tubing · PTFE with PVDF casing

Because of the physical measure- Tube material:

ment principle, the measurement · PVC with PMMA & PVC casing

error is dependent on the flow rate · PTFE with PVDF casing

and it rates ±3% across the full flow ભ Connection gas in-/outlet:

rate range. Each MGC is individually PVDF screw-type tube coupling

calibrated at the standard flow rate Ø 4i / 6o mm

of 0.5 ltr/h so that the measurement

error is approx. 0% at this flow rate.

At minimum flow rate the measure-

ment error is approximately +3%,

at maximum flow rate approximate-

ly -3%. The »RIGAMO« software

(available as accessory) provides

an algorithm which automatically

recalculates the actual measure-

ment data into the real volume at

the respective actual flow rate on

the basis of the calibration curve.

The remaining error is smaller

than ±1% across the full flow rate

Multiple MilliGascounters

range. The volume is measured

connected to a Biogas

with a resolution of approximately Batch Fermentation

3 ml equivalent to the volume of the System. More info:

measurement cell. https://www.ritterde/en/

products/biogas-batch-

fermentation-system

Subject to alterations.Dr.-Ing. RITTER Apparatebau

GmbH & Co. KG

Coloniastr. 19-23

D-44892 Bochum

Germany

„Worldwide –

Tel +49-234-92293-0 with the precision

Fax +49-234-92293-50

mailbox@ritter.de

of the original! “

www.ritter.de

»You can reach more than

75 RITTER distribution partners

directly through our website!«

www.ritter.de

Rev 2021-03You can also read