Non-Contact Color management solutions for the cosmetics industry - How do you choose a measurement instrument?

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Non-Contact Color management solutions for the cosmetics industry How do you choose a measurement instrument?

About X‐Rite • X‐Rite is the global leader in color science and technology • The company develops, manufactures, markets and supports innova>ve color management solu>ons through measurement systems, so?ware, color standards and services. • X‐Rite’s exper>se in measuring, formula>ng, communica>ng and matching color helps users get color right the first >me and every >me, which translates to beEer quality and reduced costs for our customers. • X‐Rite serves a range of industries, including prin>ng, packaging, photography, graphic design, video, automo>ve, paints, plas>cs, tex>les, dental and medical.

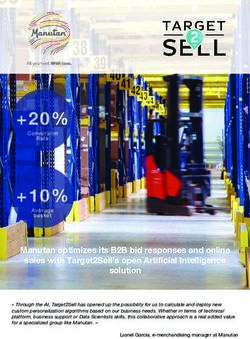

A Revolu)on in Color Measurement X-Rite is please to introduce two new Color QC solutions for the cosmetics industry: • VS450 non-contact 45/0° spectrophotometer • MA98 multi-angle spectrophotometer

Color Measurement Challenges in Cosme>cs Measuring, controlling and formula>ng the appearance of cosme>cs products are real industrial challenges and a genuine problem due to the nature of these products in that they are commonly liquid, paste or powdered form Current methodologies and processes for measuring these products is to place the sample in a cuveEe or petri dish and measuring through the glass or plas>c using a contact based spectrophotometer While this process can provide repeatable results, it does not provide data that correlates with what the human eye sees, what the consumer sees in the finished product

Color Measurement Challenges in Cosme>cs The human eye “sees” color based on a response to light reflec>ng off of the surface of the sample at a 45 degree angle This color percep>on is a response to not only the reflec>ve color of the sample, but also includes other surface appearance aEributes of the sample Total surface appearance depends upon the texture and the gloss of the sample in addi>on to its color

Color Measurement Challenges in Cosme>cs Typical lab based instruments use a spherical “diffuse” geometry, meaning that they illuminate with diffuse light and read the sample at 8 degrees and may or may not include the surface gloss Diffuse geometry is preferred when formula>ng certain products, like paint, however 45 degree geometry is preferred for QC Even though 45 degree spectrophotometers are readily available, they are largely contact based, meaning that the instrument must contact the sample This obviously makes measurement of powders, pastes and liquids difficult:

Color Measurement Challenges in Cosme>cs Contac>ng these samples contaminates the instrument, which can result in costly instrument maintenance and repair A tradi>onal method to address this problem is to place the sample in a cuveEe or petri dish, and measure the sample through the glass or plas>c This method certainly addresses the contamina>on issue, but it does induce other errors into the measurement:

Color Measurement Challenges in Cosme>cs

• Compressing these products will change the appearance of

the product (ex. compressing powder into a cuveEe reduces

the amount of light scaEer that is natural in its raw form)Color Measurement Challenges in Cosme>cs

• Measuring through a translucent barrier introduces a “depth

of field” variable between the instrument and the sample.

This becomes an error source that must be addressed

• This glass or plas>c barrier also introduces a first surface and

second surface reflec>on error (typically 4% per surface)

that must be accounted for.

• The glass or plas>c barrier allows unwanted ambient light to

“pipe” into the measurement area. This too, is a poten>al

source of error

• Condi>on of the glass or plas>c (scratches, yellowing) can

also impart varia>on and errorColor Measurement Challenges in Cosme>cs So, while measuring through a transparent barrier may provide repeatable results, the results will not correlate to the eyes natural response to the color when in its natural form The only way to truly measure a color and get a colorimetric result that correlates to the human eye is to measure the sample in its natural form, without contac>ng the sample, using 45 degree geometry

Color Measurement Challenges in Cosme>cs

• Growing popularity of affect pigments which change in color

when viewed at different angles

• These pigments can not be adequately measured with

diffuse or single angle geometryA Revolu)on in Color Measurement • VS450 non-contact 45/0° geometry spectrophotometer • MA98 multi-angle spectrophotometer

VS450 • VS450 is a non‐ contact, 45/0° spectrophotometer designed to measure all kinds of powder, paste and liquid samples in their natural form

VS450 • VS450 is the ideal product for use in produc>on for Quality Control inspec>ons • Can detect change in color or surface appearance of the sample, reducing scrap and waste costs, and allowing further evalua>on and analysis

VS450

PRODUCT FEATURES:

• Non‐Contact 45/0° geometry

• Line of Sight™ targe>ng

• Ac>ve Visual Targe>ng ™

• Large and small measurement

spot sizes:

• LED illumina>on for long life and

durability, >20 million

measurements

• 60 ° correlated gloss

• Best in Class color measurement

accuracyMA98 • Next genera>on mul>‐angle measurement tool designed for consistent, precise color measurement of pearlescent and other complex special effect pigments • Provides 10 measurement angles and 2 illumina>on angles

MA98 Examples of 2nd and 3rd genera>on effect

MA98

PRODUCT FEATURES:

• Accurate, repeatable sample posi>oning is

obtainable with pressure feedback control

and LED indicators

• Portable, lightweight, and rugged design

featuring so? touch overmold case with two‐

hand configura>on

• Ten angles of measurement and two

illumina>on angles allow for complete

analysis

• Strategic design ensures aperture loca>on

and measurements that are unaffected by

ambient light

• Communica>on available through USB or

wireless (Bluetooth)Quality Control So?ware

PRODUCT FEATURES:

• Tailored to work with standard

measurement instruments and database

formats

• Built‐in flexibility — supports a variety

of database formats to expedite color

analysis and streamline repor>ng and

data management

• Allows for any number of loca>ons to

easily communicate and share data

without the need of a network

X‐Color QC

• System and user friendly features make

So?ware Applica>ons Solu>ons it easy to perform color collec>onFixtures and Sample Holders Standard and Custom sample holders available

Fixtures and Sample Holders

Standard Sample Holders:

• Instrument stand

• Spoon holders for measurement of

opaque liquids, pastes and powders

• Petri dish holder for measurement of

translucent liquidsFixtures and Sample Holders Custom sample holders • Include but not limited to: Founda>ons Lips>ck Eye Shadow

A Revolu)on in Color Measurement • MA98 and VS450, combined with X‐Color QC and custom fixtures and sample holders, provide a comprehensive Lab to Produc>on solu>on for Quality Control and evalua>on and analysis, allowing color measurements of samples in their natural state, the way the eye sees them!

A Revolu)on in Color Measurement

Thank You

Q&AYou can also read