Corrosion of Borosilicate Glasses - Berliner Glas Gruppe

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Corrosion of Borosilicate Glasses

Constans M. Weber1,*, Jörg Stockmann1,2 and Elisabeth Rosier1

1

Berliner Glas KGaA Herbert Kubatz GmbH & Co., Waldkraiburger Strasse 5, 12347 Berlin

2

BAM Bundesanstalt für Materialforschung und –prüfung, Unter den Eichen 87, 12203 Berlin

* Corresponding author: cweber@berlinerglas.de

Abstract

In contact with aqueous media glass tends to corrode leading to different surface properties. For the precision

application this alteration might cause product failure. Hence precise knowledge of the surface interactions is

essential. We performed an extensive investigation on the behavior of borosilicate glass under corrosive attack in

order to identify critical processes. We identified appropriate investigation methods including sequential chemical

analysis, ATR-IR, ellipsometry and SNMS. These techniques allow to identify the influence of specific production

processes.

Key words: glass corrosion, borosilicate glass, SNMS, ellipsometry, ATR-IR

performed an extensive investigation of the corrosion

1. INTRODUCTION behavior of borosilicate glass, including sequential

chemical analysis, ellipsometry, Attenuated Total

The surface of certain components in the Reflection Infrared spectroscopy (ATR-IR) and

lithography industry needs to be of glassy material Secondary Neutral Mass Spectroscopy (SNMS).

due to the very high requirements with respect to the

surface roughness and flatness. In the case for the 2. EXPERIMENTAL

components produced by Berliner Glas this surface is

an alkaline free borosilicate glass. Due to the very Pieces of bare polished borosilicate glass were

high surface standards it is necessary to know the used for experiments. The samples underwent a chain

behavior of the glass surface during the production of typical processes in order to capture even effects

process. In particular the interaction with aqueous that originate from the combination of processes. The

systems applied while polishing, cleaning, and final processes of the samples are:

etching may alter the surface in an unwanted manner. G101: Reference (no processing)

It is known that ions can diffuse out of the surface G102: Caro’s acid (piranha)

layers of the glass [1, 2]. This leads to different

G103: diluted hydrofluoric acid (HF) dip and rinse in

properties of the relevant top surface from the bulk

sodium carbonate

properties. Common alterations of the surface include

homogeneous gel layers (subsurface zone), gel G104: HF etch

droplets, crystallite and hole formation (see Figure G105: Cr coating and removal with Cr Etch

1). The modifications are present within some tens to G106: Ion Beam Figuring (IBF) and diluted HF dip

hundreds of nanometers of the surface. Therefore we

The glass investigated with SNMS underwent similar

processes but is part of a symmetrical stack of glass

with a ceramic body.

The experimental techniques were chosen in

order to investigate the relevant region of the

Figure 1: Dimensions of typical degradations from left to samples. Figure 2 shows the considerations that lead

right: Homogeneous gel layer, gel droplet formation, to the choice of the mentioned techniques. Surface

formation of crystallites, and holes and craters [2]. sensitive methods like AFM or contact anglemeasurements only account for the topmost surface can capture gel droplets on the surface. Compared to

region (green in Figure 2) whereas bulk methods like other glasses these findings are considered modest.

Figure 2: Schematic representation of the information

depth of surface sensitive (green), bulk sensitive (yellow)

and intermediate techniques (red).

Figure 3: DIC microscopy of the corrosion layer with gel

XRF and UV-Vis spectroscopy are not sensitive to droplets.

the surface.

Microscopy was performed using a Zeiss Axio 3.2. SEQUENTIAL CHEMICAL ANALYSIS

Imager A2 Vario in brightfield, darkfield and DIC Sequential chemical analysis shows non-bulk

(Differential Interference Contrast) illumination. properties only in the first step of the investigation.

Sequential chemical analysis includes short dips This again indicates a stable system compared to

in diluted hydrofluoric acid, precision weighing of other glasses, still an accumulation of barium ions

the sample and chemical analysis of the applied acid along the process chain can be observed.

[3]. The investigated depth is determined by the

number of steps and the etch time. 3.3. ATR-IR

Ellipsometry was performed using Woolam M- The obtained spectra (see Figure 4) show

2000 (mapping ellipsometry), Accurion EP3 SE significant peaks in the region of 600 to 4000 cm-1.

(imaging ellipsometry) and Sentech SE-900 The individual peak can be allocated to specific

(infrared) ellipsometers. This technique measures the vibrations in the glass [4]. The peaks at 2300 cm-1

dielectric properties of a surface by comparing the correspond to carbon dioxide. Negative values are

polarization of an incident beam with the reflected therefore changes of the air composition relative to

beam. The investigated depth is determined the time of calibration. Minor peaks at 2900 cm-1 are

evanescent field, which depends on the incident associated with CH2 or CH3 scissor vibration and

angle. might originate from organic solvents. Faint peaks at

3000 to 3700 cm-1 show OH stretching vibrations of

ATR-IR was done using a Bruker Hyperion 3000.

adsorbed or even embedded water.

This technique measures the absorption of the

evanescent field. Depending on the used materials In order to identify the chemical changes along

and illumination angle the investigated depth is in the the process chain the entire spectrum is fitted with

range of some hundreds of nanometers. individual peaks by means of a Gaussian profile

using Origin 2015 as shown in Figure 4 bottom. The

SNMS measurements were performed with a

area of the individual peak is then used as a measure

SPECS INA-X system. This technique removes the

for the presence of individual chemical compounds.

surface of the sample by argon ion sputtering. The

The results compared to the reference glass G101 is

ejected atoms from the surface are post-ionized and

shown in Figure 5. The most dominant modifications

detected in a mass analyzer. The investigated depth is

show the samples G103 (cleaning in diluted HF and

depending on the sputter time.

sodium carbonate rinse) and G105 (coating and

3. RESULTS decoating of chromium) with an enrichment of Al2O3

and AlSiO as well as a depletion of MgO,

3.1. MICROSCOPY respectively.

Investigation with optical microscopy shows

minor modifications along the process chain.

Differential interference contrast (DIC) microscopyFigure 4 Top: ATR-IR spectra with corresponding chemical Figure 6 Top: Comparison of FT-IR and ATR-IR spectra.

bonds. Bottom: Fit of the measured ATR-IR spectrum with Bottom: Fit of the measured FT-IR spectrum with multiple

multiple individual peaks. individual peaks.

The peaks correspond to ATR-IR peaks but in

particular Al2O3 and AlSiO are less intense.

Furthermore the differences of the individual glass

samples are less pronounced than in ATR-IR.

Therefore the variations of the areas of the

investigated samples are smaller. Nevertheless the

samples G103 and G105 show again an enrichment

of Al2O3 and AlSiO as well as a depletion of MgO,

respectively (c.f. Figure 7).

Figure 5: Intensity of the individual ATR-IR peaks along

the process chain.

3.4. IR-ELLIPSOMETRY

The signal of the IR-ellipsometry was used to

analyze the spectrum in a similar way to ATR-IR.

Figure 6 top shows both, ATR-IR and FT-IR spectra

of all samples. The spectrum was again decomposed

in single peaks corresponding to chemical

compounds (Figure 6 bottom).

Figure 7: Intensity of the individual IR ellipsometry peaks

along the process chain.3.5. ELLIPSOMETRY refractometer that was not able to detect any changes.

The thickest layer is present on sample G104 after HF

For the analysis with ellipsometry a model of the etching and ultra pure water (UPW) rinse.

system has to be fed in the data analysis system. We Simultaneously the absorption is very close to the

assumed a system of bulk glass (layer 0 in Figure 8) absorption of the reference. This indicates that the

with a gel layer (layer 1) and a top roughness of 1 nm etching process restored bulk properties but at the

(layer 2). same time, this fresh surface is vulnerable to attack

by water. The enhanced absorption of sample G106

(IBF and diluted HF dip) shows that IBF produces

residues on the surface that are not completely

Figure 8: Model of the glass surface used for the

removed by the diluted HF dip. The two samples

ellipsometry.

with the deviating IR-spectra G103 and G105 have

The optical properties of the bulk glass were elevated though not extreme values for n, k and d.

measured at a sample of freshly HF etched glass. The

obtained values for refractive index n and extinction 3.6. SNMS

coefficient k are kept constant for the consecutive The chemical depth profile of the reference

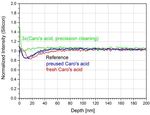

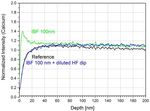

analysis. Using this model the optical properties n sample acquired by SNMS is shown in Figure 10.

and k and the thickness d of the gel layer are fitting Whereas most ions are depleted at the surface,

parameters for the analysis. The results of two sodium is strongly enriched.

different ellipsometric methods (mapping and

imaging ellipsometry) performed on two different

instruments are shown in Figure 9 combined with an

estimated mean squared error (MSE).

Figure 10: SNMS depth profile of the reference sample.

Both, silicon and oxygen show a depleted zone

within the first 10 to 20 nm under the surface but are

at bulk concentration at the very surface. In general

the depth of the gel layer is about 50 nm, which is

relatively few compared to other glasses (up to few

hundred nanometers). The silicon depletion zone is

considered a measure for strength of the glass

corrosion. Figure 11 shows the influence of

hydrofluoric acid, Caro’s acid and IBF on the silicon

depletion zone.

No major differences are visible for different HF

processes, which means that bulk properties with

some kind of “natural gel layer” are always present

Figure 9: Fitting results of mapping ellipsometry (top) and

after any kind of HF treatment. This is even true if the

imaging ellipsometry (bottom).

prior process was IBF. Whereas IBF alone alters

Both techniques reveal a qualitatively similar both, the silicon depletion layer (thinner) and the

result even though absolute numbers differ. The calcium concentration (c.f. Figure 12) at the surface

refractive index barely changes in both (higher), a consecutive dip in diluted hydrofluoric

measurements being consistent with the results of a acid restores typical properties. For Caro’s acid thebehavior is less obvious. A treatment with pre-used

Caro’s acid, which is less concentrated and of lower

temperature has no influence on silicon and calcium

concentration. When using fresh and hot (T > 100°C)

Caro’s acid the glass is affected approximately 10 nm

deeper. A triple treatment with fresh Caro’s acid with

intermediate ultrasonic and megasonic rinse in UPW

does not intensify this effect, instead inverses it. This

leads to nearly bulk properties nearly up to the very

top surface in terms of silicon concentration. At the

same time an enrichment of calcium is present at the

surface that might originate from calcium sulfate

formed by the reaction with the sulfuric acid of the

Caro’s mixture.

Figure 12: Comparative SNMS depth profiles for calcium

depending on different HF etching, IBF and Caro’s acid

processes.

4. SUMMARY

Different techniques are employed to investigate

the corrosive influence of different production

processes on the gel layer of borosilicate glass. In

general the degradation is small compared to other

glasses. Infrared methods show that hydrofluoric acid

with a consecutive soda rinse alters the glass surface

most significantly. Ellipsometry shows that etching

with hydrofluoric acid and UPW rinse leads to the

thickest gel layer. SNMS reveals that IBF and

repeated etching with Caro’s acid leave residues on

the surface but minimize the depth of the gel layer.

5. ACKNOWLEDGEMENTS

SNMS measurements were performed at

Clausthal University of Technology by Thomas

Peter. Ellipsometry and ATR-IR were performed at

at the Federal Institute for Materials Research and

Testing (BAM) with support of Uwe Beck, Andreas

Hertwig and Jennifa Baier. Sequential chemical

analysis was done at Aachen University by Klara

Sülz.

Figure 11: Comparative SNMS depth profiles for silicon

depending on different HF etching, IBF and Caro’s acid

processes.6. REFERENCES

[1] R. Conradt, "Chemical Durability of Oxide

Glasses in Aequeous Solutions: A Review,“

American Ceramic Society, pp. 728-735, 2007.

[2] E. Rädlein, "Glas und Witterung,“ in

Glastechnische Tagung der DGG, Amberg,

2009.

[3] P. S. Djambazov, "Theoretische und

experimentelle Untersuchungen der

Frühstadien bei der wässrigen Korrosion von

Silicatgläsern", Rheinisch-Westfälische

Technische Hochschule Aachen, 2014.

[4] V. P. Tolstoy, "Handbook of Infrared

Spectroscopy of Ultrathin Films", John Wiley &

Sons, 2003.You can also read