O-COMMAGAZINE - MEGA FOR BRITA AUTOMATED - Optima

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

O-COM THE MAGAZINE

100%

AUTOMATED

FROM ASSEMBLY THROUGH TO

PALLETIZATION OF WATER FILTERS

MEGA FOR BRITA

EN consumer-nonwovens 03/2018EDITORIAL PREVIEW

14

IN USE

Full automation in China: For the Asian

4 Innovative paperboard cans The InlineCan proves itself at JTI

market, Brita - the world market leader for

water filters - has commissioned a produc- 14 Turnkey in China Automatic water filter assembly to palletization

tion and packaging plant, including palle-

20 Free spaces New system for bags and cartons

tization. Turnkey provider Optima to offer

additional servicing options from its site in 24 Oils and additives Old plus new means high flexibility

China.

EVENT

In-house trade show How non-wovens customers help shape

10

DYNAMIC MARKETS,

the future

OPTIMA TOTAL CARE

FLEXIBLE SOLUTIONS 30 Train the Trainer Training concept for high system efficiency

Dear readers, and shorter time-to-market. In production line for water filters up

20

An exciting trade show fall has Nuremberg and Chicago, we will and running in only 16 months – VR CENTER

One plant that can do it all: Identical

begun. Two top-level shows, Pack find the solutions for your require- from the individual components 33 Site planning with VR How best to fit the line into the hall?

products are offered in a wide variety of

Expo and FachPack, are creating ments. With passion. In this o-com, through to the ready-to-ship pal- packaging types. This example applica-

a stir. Changing Markets. Your you can read how these solutions let. News from Optima Total Care tion illustrates how incontinence products

Needs. Our Passion. – Our motto can look. rounds off this edition. COMPANY

can be packaged both in cartons and in

for these two trade shows reflects Optima Nonwovens set new On that note: Be faster than the film bags on one plant. 28 Smart Production Students plan automated planting system

the challenges of our day. trends in summer with the in- market. Stay flexible. We have the

Word of new product trends house fair “Partnering with the smart solutions to help you do Optima is growing New subsidiary plans new building

32

spreads faster than ever before. Packaging Pioneers.“ Here, the fo- this. I hope you enjoy reading this Makeathon Training camp, networking and prototypes on Gran Canaria

34

IMPRESSUM

And these trends have worldwide cus was also on flexible, modular edition and that the trade shows o-com ist der aktuelle Kommunikations-Service der

Hans Bühler effects. Globally networked influ- machine concepts for dynamic this fall leave you with lasting im- OPTIMA packaging group GmbH

Managing Director / CEO, encers, bloggers and YouTubers markets. Carton or bag? This is one pressions. OPTIMA packaging group GmbH

can send the demand for speci- question the manufacturers of in- Steinbeisweg 20 | 74523 Schwäbisch Hall | Germany HISTORY

OPTIMA packaging

fic product groups skyrocketing. continence products for men will Yours 35 Continuous operation Since 1981 at Hakle: Roll packaging using an

group GmbH OPTIMA consumer GmbH

Orders flood in from all over the no longer have to ask themselves. Geschwister-Scholl-Str. 89 | 74523 Schwäbisch Hall | OPTIMA LBV4R

Germany

world, putting increasing pres- A new stacker type from Optima

sure on producers. But what if that can handle both promises ad- OPTIMA nonwovens GmbH

Steinbeisweg 20 | 74523 Schwäbisch Hall | Germany

the manufacturer’s filling and pa- ded scope in production. This ma-

ckaging machines are not up to kes it easy to accommodate mar- Redaktion

Jan Deininger

the task? ket trends. You can also read how, Felix Henning

That is why our focus is on provi- with support from Optima, the Bri- Dr. Ulla Reutner

ding flexible solutions for shorter ta company managed to get a new Hans Bühler V.i.S.d.P.

Sabine Gauger

2 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 3IN USE

HANDS-ON INSIGHT AT JTI – THE INLINECAN PROVES TO BE

THE IDEAL TOBACCO PACKAGING

A REAL

DREAM TEAM

A look into the production hall at Japan Tobacco

International (JTI) proves that the OPTIMA CFS and the

InlineCan manufacturing machine from Hörauf are a

great team. JTI is one of the largest manufacturers of

tobacco products and uses the InlineCan machine to

package some of their products since May 2017. Why the

concept of Optima and Hörauf is the right concept for JTI

and what role the inductive sealing plays, was explained

by Martin Feilen, Project Manager at JTI in Trier.

Tobacco is one of the oldest, popular to the switch from the round packaging “Tobacco is a very sensitive product, that

and versatile cultivated crops. Already solution to the square carton the “Inline- has to stay fresh”, explained Martin Feilen.

known to the indigenous people of the Can” (more about the InlineCan: see info Tobacco loses its moisture during storage

Americas as a medicinal plant, tobacco box). The EU-wide regulation is in effect and therefore, a moisture barrier is a key

started its success story as a stimulant in since 2016 and regulates that 95 percent factor. The InlineCan has an additional

the 15th century. Dried it serves as a basis of the product package have to contain advantage for JTI – it is less expensive.

for different products: fine cut, chewing, warning messages. According to Martin Regular cans are up to six or seven times

pipe and snuff tobacco, and the most po- Feilen, this was one of the reasons for the more expensive than the InlineCan. In ad-

pular product – the cigarette. Cigarettes change from the round carton package dition, no transport costs occur since the

are still the most popular tobacco product to the square InlineCan – it allowed for carton can is directly manufactured in the

in Germany. more advertising space and less warning production facility. Traffic at the factory

The tobacco market is fast moving. references on the can. Hörauf, the carton- premises is significantly less: instead of 40

Packaging trends are constantly chan- manufacturing expert, introduced JTI to trucks, only one truck is needed to deliver

ging and manufacturers have to react in a Optima Consumer. In order to provide the paper rolls for manufacturing the Inli-

timely manner to consumer requirements. the InlineCan packaging solution, Hörauf neCans. The storage space that was nee-

This also applies to JTI, which is one of the and Optima Consumer worked together ded for the former cans can now be used

world’s leading tobacco product manu- closely. for other purposes.

Martin Feilen, Project Manager

facturers. The facility in Trier manufactures at the JTI plant in Trier and Ulrich

THE INLINECAN REDUCES 40 INDUCTION VERSUS THERMAL: THE

tobacco products for the German market

but also for export. JTI was looking for a TRUCKLOADS TO ONE SEALING AS A DECISIVE ADVANTAGE

Burkart, Sales Director for Food

machine manufacturer who was able to The coordinated approach of Optima Since May 2017, JTI is gaining experi- Solutions at Optima, discuss the

provide a packaging solution for a square

tobacco can. Besides market trends, the

and Hörauf made sense to JTI according

to Martin Feilen. The most relevant requi-

ence with the two OPTIMA CFS machines

that fill the Inline Cans with Make-Your-

final technical details.

TPD 2 – tobacco guidelines contributed rement for the package was air tightness. Own (MYO) tobacco and closes them. This

4 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 5IN USE IN USE

was the perfect time for the Optima edito- minute leave the machine, independent ma is worth it”, commented Martin Feilen.

rial staff to check: how satisfied is JTI and on the format size. The machine efficiency In addition, a well-coordinated pro-

why is the OPTIMA CFS the perfect soluti- reaches 97 percent. The JTI specifications ject management from both sides was

on for the company? were far exceeded. The reject rate is also very important since JTI was the general

Martin Feilen emphasized the induc- less than required by JTI with 0.3 percent. contractor and had to rely on its suppliers.

tion sealing: “The membrane is the key Format changes are completed without This was very well structured through se-

factor for the freshness of the tobacco.” If tools within ten minutes since the Inline- veral design reviews at Optima. Martin

the membrane is damaged, the tobacco Cans are only different in height, but the Feilen commends the cooperation as a

loses moisture. The inductive seal ensures footprint is the same. An additional ad- “showcase management project”. Due to a

that the cans are correctly sealed. An ad- vantage resulting from the quick format constant communication, new ideas were

ditional benefit of this process is that only change overs is it permits tests and small implemented immediately.

the film is heated and not the product. Ul- batch production.

rich Burkart, Sales Director Food Solutions What about cleaning and hygiene? To PREVENTIVE MAINTENANCE WILL BE

at Optima Consumer added: “the challen- fulfill the hygienic requirement the Opti- AN IMPORTANT SUBJECT

ge of inductive sealing is the need for ab- ma engineers made sure that the machine In the future JTI will place great im-

solute tightness and the requirement to does not have any cavities. “The cleaning portance on line management and the

remove the film in one piece without any and cleanliness of the machine is very im- digital interaction, reported Martin Feilen.

Martin Feilen and Ulrich Burkart in conversation in front of the Martin Feilen is very happy with the project progression. He

OPTIMA CFS that has been filling the InlineCans with Make-Your- emphasizes the inductive seal: “The membrane is the key to the remnants.” Only Optima was able to offer portant. This was an emphasis during the Maintenance, service and support are

Own (MYO) tobacco since May 2017. The re-sealable plastic lid tobacco’s freshness.” this extremely high tightness said Mar- design phase”, said Martin Feilen. An anti- becoming increasingly important to the

makes the paperboard can exceptionally practical for c onsumers.

tin Feilen. Induction sealing requires less static puck cleaning ensures cleanliness company since the storage of expensive

cleaning time and rarely leads to downti- during the return transport and avoids spare parts such as components for con-

mes compared to thermal sealing. product contamination. trol units is problematic. More than once

The machines run in a three-shift ope- the parts didn’t work when they were nee-

ration, six days a week. The installation QUALITY AND PRODUCTION SECURITY ded.

was completed within four weeks without WERE KEY FACTORS This confirms that Optima is on the

any problems. “The Optima service tech- “JTI is very particular and expects the right track with its Life Cycle Manage-

nicians knew what they were doing,” said highest quality”, said Martin Feilen. Tobac- ment Optima Total Care (as reported in

Martin Feilen. co customers are demanding and therefo- the o -com special edition Total Care). It

Due to the modular design, the pa- re quality is a special focus. Optima Consu- fulfills the high requirements for a life-

ckaging machine is flexible and JTI is mer relieved initial concerns regarding the long service of packaging machines, as

able to react quickly to new market re- high demands of a tobacco packaging so- described by Martin Feilen. With WEmain-

quirements. For example, leaflets can be lution quickly. “The biggest challenge was tain and TCAP Optima Total Care offers

inserted or moisture-containing sponges the dust that causes wear on everything a system for a cycle based, as well as a

can be glued to the inside of the closure. inside the packaging machine” noted condition based maintenance.

Martin Feilen praises the machine in ad- Martin Feilen. Optima Consumer maste- Based on this overall positive expe-

dition for its easy accessibility that makes red this challenge. The Optima machine rience JTI decided to buy two additional

the cleaning simple and benefits the work seamlessly integrates into the production OPTIMA CFS machines. “In close coopera-

ergonomics during repair work. process. Besides the package quality the tion with Optima and Hörauf we develo-

production security was a deciding fac- ped a solution and we want to continue

THE MACHINES ACHIEVE A 97 PERCENT tor for JTI. The Optima and Hörauf design on this path,” so Martin Feilen. The story of

The carton can is produced inline in the machine. Tablets visualize individual machine parts so they can be EFFICIENCY were the most convincing in this regard. the successful duo is far from over.

discussed right at the machine. Very positive is the output of the ma- That Optima was not the least expensive

chine for Martin Feilen: 150 products per vendor was only a secondary issue: “Opti-

6 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 7IN USE

WHAT IS THE INLINECAN?

WHAT CAN BE FILLED

INTO THE INLINECAN?

THE INLINECAN ALSO

CONQUERS THE COFFEE

InlineCans are carton containers that

Sweets, snacks, cereals, coffee, tea,

are manufactured in a consistent process

milk powder, dry pet food and other

and immediately filled and closed. This

dry product can be packaged with the

INDUSTRY

means that the manufacturing of the

InlineCan. Depending on the product,

package is completed at the packaging

the appropriate dosing systems are ins-

location. If required a complete process

talled. In connection with the calibrated

chain, including secondary packaging,

weighing technology highly accurate

can be created: without extra transporta-

weighing results are created that reduce

tion, intermediate storage and cleaning

product loss to a minimum. The closed The InlineCan proved its versatility

processes. The InlineCan can be square,

cans can be transported directly to the at Aldi Süd. The ground organic coffee

rectangular or polygon. It can combine

secondary packing. “COFFEE3” is available in the cubic-shaped

round and angular forms and it can be

containers at these Aldi stores since the

oval or round.

middle of March. “Several years of intense

team work with Optima took place from

the first idea to the final product. Now we

are really looking forward to present the

result in our stores,” said Michael Körnig,

Managing Director of NewCoffee GmbH &

Co. OHG. NewCoffee is a subsidiary of Aldi

Süd and produces coffee at its location in

Mühlheim at the Ruhr and in Ketsch for

the food corporation. An OPTIMA CFS fil-

ling and closing machine takes over the

semi-completed package from a Hörauf

production machine at these locations.

The Optima machine then fills, pre-gasses

and closes the InlineCans.

“We responded to the market requi-

rements,” explained Ulrich Burkart, Sales

WHAT ARE THE Director food Solutions at Optima. After Outstanding barrier properties make the InlineCan the ideal packaging s olution

for products that are sensitive to air and humidity, such as coffee.

ADVANTAGES? several years of development, the Inline-

Can celebrates its first success in the cof-

WHO INVENTED THE Everyone profits from the InlineCan.

Manufactures have a wide variety of for-

fee sector. The InlineCan can be used for

INLINECAN? mats to choose from since the format

ground coffee but also for instant coffee

and whole beans”, added Ulrich Burkart.

keeps the flavors fresh in the packagage.

“The gas-tight InlineCan is ideal for air and

tion, permanent brand messaging can be

achieved since the original package will

The manufacturing process is based on change is easy due to the unchanged

Like tobacco, coffee has high require- humidity sensitive products like ground remain and no refilling is necessary.

the packaging machine suppliers Hörauf’s footprint of the InlineCan. A high quality

ments to the packaging since the valuab- coffee,” said Ulrich Burkart. Mainly due to If the InlineCan will replace the estab-

and Optima’s expertise. Both companies and trendy look excites consumers. B arrier

le aroma has to be protected. “Up to 800 the excellent barrier features. The packa- lished vacuum package is yet to be seen.

introduced their leading technologies and features protect sensitive products and

different flavors are hidden in the beans”, ge is appealing with its trendy design and Several companies have been showing

experiences with this project: Hörauf is a keep the aroma. The environment is

informed Aldi Süd. Optima Consumer large area that leaves space for product interest in the package solution. The

specialist for the manufacturing of carton another winner of the InlineCan system:

guarantees the flavor by filling under ni- information. Coffee manufacturers are not objective of Optima is the recyclability of

containers and Optima’s expertise is the only film material has to be transported

trogen directly after the coffee is ground bound to the usual standard weights of the InlineCan. An aluminum-free version

filling and weighing of powder, granulate and the trucking of ready-to-use, empty

and roasted. The protective membrane 250 gram and 500 gram anymore. In addi- is the goal.

and solid products, as well as the closing packages is not needed anymore. At the

of containers. same time the transport and storage cost

are reduced.

Additional information can be found at:

www.inlinecan.comEVENT EVENT

IN-HOUSE SHOW AT OPTIMA NONWOVENS

TESTING WITH THE

PACKAGING PIONEERS

Higher expenses, a shorter time-to-market, digitalization

and more complex packaging processes – the hygienic

paper industry faces huge challenges. “Partnering with the

Packaging Pioneers” – is the Optima Nonwovens answer. This

was the motto of an in-house show from June to August at

Optima in Schwäbisch Hall. New concepts for modularity,

automation, communication and service were presented by

the Optima experts and the course for future technologies

was set, in collaboration with the users. Markus Urich (Key Account Manager at

Optima Nonwovens and Organizer of the

Wilfried Laser, Key Account Manager at Optima Nonwovens explains to Martin Gärtner and his team how Ontex can adjust their machines

easily with modular machines to meet the new market requirements.

in-house show.)

Mr. Urich, what is new with this show fore, increasing the success rate of our lenges. There are new, agile project ap- Why did you pick the topic modularity? lity and a presentation. With the prepared at one aspect more closely – the resta-

concept? products. It is also conceivable to start the proaches and methods. During the course Our understanding of modularity is procedures and target oriented questions, cking of bags. This is the only work requi-

Until now, we showed existing tech- dialog for a development partnership du- of these changes, we recognized that it is that the user receives a machine that ad- we want to check how customer oriented red at our machines and needs the most

nologies and looked far into the future ring the in-house show. important to get in touch with the users apts without difficulties to changing mar- our designs are. labor performance.

during shows. This year’s in-house show of our machines and software solutions, in ket requirements. The market, and there-

“Partnering with the Packaging Pio- order to offer customized products. These fore, the consumer needs are changing Keyword automation – how is this topic How can this effort be reduced?

neers” also looks into the future but with

“We want to get in were the reasons for our in-house show. constantly hence, the machines have to implemented? We have two concepts. For the first

a healthy dose of realism. We want to in- touch with the machine adjust easily and in a timely manner. We Most of our machines still have a HMI concept the operator is supported by a

clude our customers early on to develop What are you trying to find out? are successful in this area, but believe we (Human Machine Interface) during the cobot – a robot that is designed to phy-

future concepts.

users in a timely manner We are convinced that the concepts can and have to move the subject to an production. Due to faster running machi- sically interact with humans in a shared

to offer customized that are presented will give our custo- even higher level to sustain our success. nes and high labor costs, the importance workspace. The operator will only fill a

What are the objectives of Optima Non- mers added value. Whether or not our of reducing personnel is increasing. Au- buffer while the cobot will take care of the

wovens with the in-house show?

solutions” customers feel the same way - will have to How are you going to present the tomation can help to reduce the need for restacking.

We want to start discussions with our be seen during the in-house show. If the topic at the show? operator personnel, make it more efficient The second concept is an “end-to-end-

customers at an early stage of the design Why is this so important? technologies are not what the customers We are visualizing our solution approa- and lastly, eliminate the need for operator solution”. This design has the objective

phase and get their immediate feedback. The industry is changing. People are want, we have the option, with this event, ches with live demonstrations, a video clip, personnel altogether. We presented the to have no operator personnel at all. This

We want to know if we are on the right changing. Our time is fast moving and we to find out early and change the course of VR-applications in which the customers Optima Zero concept during our previous might be solved with the fully automatic

track with our ideas for the future, there- are constantly confronted with new chal- our developments. can observe the concepts in a virtual rea- shows. We will revive this subject and look delivery of bags to the machine.

10 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 11EVENT EVENT

How are the customers experiencing is happening right now and discuss how for industrial applications?

these concepts? we can further develop this concept. Con- Absolutely correct, that is the intent.

With the help of “use cases”. We will tinuous improvement is the keyword. And of course how these solutions should

introduce them and our customs have be further developed in order to be intu-

the opportunity to take part. An automa- This includes, for example, a new hu- itively operable. Industrial developments

tic bag stacker and a cobot will offer the man machine interface and a completely are, in part, still in its infancy. Augmented

possibility to reproduce any application new operation philosophy. This is the con- realty applications, for example, have to be

directly. Virtual reality supports the expe- cept we want to check on its practical ap- checked for practicality. We want to set an

rience of the second concept. plication and future viability. example and be pioneers and therefore,

we need the feedback of our customers.

What is the story behind the topics,

communication and service? “We want to be a This sounds like a paradigm shift?

Here, we will focus on Optima Total Yes, that is correct. We want to be more

Care, continue with it and discuss it with

machine supplier and than just a machine supplier, we also want

our customers. However, we don’t want to service provider” to be a service provider that is the correct The cobot places packaging material onto the bag infeed under the watchful eyes

of the visitors. A cobot is an industrial robot that is designed to physically interact

The visitors listen intently to the explanations of Wilfried Laser

regarding the topic of modularity.

just look into the future, but also concen- contact for any concern. This is our aspira- with humans in a shared workspace.

trate on developments at the beginning. tion and motivation.

We have many pilot projects with custo- In other words: you want to know which

mers. We will gather feedback, show what Industry 4.0 solutions are really suited Mr. Urich, thank you for the information

“The focus during in-house shows is more on the cus-

tomers and their requirements”

Martin Gärtner, Group Manufactu- are increasing. The presentation with the

ring Director at Ontex visited the in- three topics was also very interesting.

house show with a five-member dele- I can only recommend in-house shows Martin Gärtner describes his impressions during the in-house What will the communication of the future be? Dominik Roll, Project Manager at

gation. He describes his experience for since the focus is more on the customers show in the interview with the editor Jan Deininger. Optima Nonwovens has some answers. One possibility: augmented reality.

the o-com readers. and their requirements - different than

“I didn’t have any specific expectations large shows where one can say “hello” and

for the in-house show, I came to see what “good bye” and cannot discuss p rojects

is new with Optima Nonwovens. I saw or problems in detail. Shows are their

some approaches that are very interes- own industry. They are expensive for the

ting and we will continue to follow them exhibitor and the visitor. Therefore, in-

over the next few months and years. It is house shows are a great alternative to

always interesting to be inspired by new conventional shows. I would prefer them

approaches. We were especially intrigued anytime over larger shows, maybe even in

by the cobot. When we saw how it placed combination with virtual impressions on

the stack of pre-made bags onto the bag the website in advance. I am sure this will

infeed conveyor, it made us think. This is become even easier and more common in

an approach worth thinking about, espe- the future.

Martin Gärtner is the Group Manufacturing Director at

Ontex Headquarters in Belgium. He was convinced of cially for countries where the labor costs

the Optima concept during the in-house show.

The automation topic presents the advantages of robots during the bag Mixed-reality glasses are used during the presentation for the automation topic.

infeed. “An interesting approach in times of expensive labor costs”, remarked The glasses help to better understand the utilization of the cobots.

Martin Gärtner.

12 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 13IN USE

FILTRATION SOLUTION FOR BRITA INSTALLED IN CHINA: TURNKEY SOLUTION WITH A WIDE VARIETY OF TECHNOLOGIES.

EVERYTHING FLOWS SMOOTH

WITH WATER FILTERS

From individual components, to ready-to-use water filters,

to the ready-to ship palette. This complex undertaking was

performed by a complete line with 60 meters of completely

automated functions. OPTIMA was selected as a turnkey

vendor for Brita at its China facility. Almost all modules and

technologies for this project are supplied from Optima. The

technical design was completed within just a few months.

“A project of this magnitude is only ridges. This machine produces 120 filters that sufficient components and filter ma- retrofitting the cartoning machine, the machine. The product transfer from the fication. Each of the complex machines

feasible if the customer and vendor work per minute. Currently, the machine pro- terial is consistently fed into the line and case packer can still process individual, clean room to the conventional environ- has an HMI that forwards the order speci-

closely together”, said Stefan Bauer who cesses one cartridge format. However, ad- are taking care of the final transport pa- flow-wrapped cartridges. This is accom- ment takes place in this zone. fic information to the modules. Typically,

managed the commercial aspects of the ditional formats are easy to set-up. Seven lette. plished by using a bypass through the OP- this information is entered manually. The

project. To illustrate the scale of the pro- different sales packages from the indivi- TIMA CBF cartoning machine. EVERYTHING IS UNDER CONTROL information is elaborate and can result in

ject again: first the filter cartridge is as- dual carton to the multipack with 15 cart- DEVELOPING COMMON POTENTIALS With an appropriate production sche- WITH OPAL errors when inputting manually. In con-

sembled, consisting of plastic parts and ridges per carton are presently packaged. The entire process was designed to be dule, downtimes are minimized. The auto- The software OPAL is used to conti- trast, OPAL takes the complex data from

activated carbon, followed by sterilization as efficient as possible. Due to the close clave also shows the close collaboration nuously determine the efficiency of the the customer’s ERP system and prepares it

in an autoclave. The filter is then packaged Eight additional machines are integ- collaborative effort between Brita and of the companies. The design to load and machine OEE (Overall Equipment Efficien- for the machine.

into a flow-wrap pouch, inserted into car- rated in the automated line besides the Optima engineers, the line uses state-of- unload the filters for sterilization, batch cy). In addition, OPAL analyzes systemati-

tons (sales package) in different counts OPTIMA CFL machine (see overview). The the-art technology and maximizes per- by batch, was developed by Brita and cally occurring process or operator errors, Similarly, recipe changes are made

and sizes. Finally, the full cartons are pa- modular design proves itself all along the formance potential. Stefan Bauer repor- Optima. like error frequency and error duration. centrally and automatically with the OPAL

ckaged into various size cases and palle- line (literally) providing easy accessibility ted about ideas that went even further: Processes with different cycle times software, which adjusts each individual

tized for transport. via guard doors that extend all the way “Today the line produces sales packs that can be handled separately and allows for An additional function of OPAL is the machine and module of the line based

to the floor. All component hoppers and are in cartons which are subsequently re- the machine output to remain at the de- batch specific controlling and scheduling on the format settings. The machine then

The base machine solution that was bunkers are designed to allow the machi- packaged by a case packer into transport sign speed of 120/min. The sterilized pro- of the production orders. The order quan- provides confirmation of proper adjust-

used for filling of the activated carbon ne to run for 30 minutes autonomously. cases. However, the line can also packa- ducts are cooled automatically at the rear tity and format have to be defined, as well ment before the OPAL system will release

is an OPTIMA CFL machine, adjusted to The entire line is overseen by two to three ge the individual flow-wrapped cart- of the autoclave, they are then unloaded as country specific labels or prints that the entire line for production. If a size

accommodate the large size of the cart- operators. These employees are ensuring ridges directly into transport cases while and transported to the flow-wrapping have to be inspected according to speci- part needs to be changed manually, the

14 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 15IN USE IN USE

operator confirms the correct execution at in other projects and upon recommendati- were visiting Optima in Schwäbisch Hall or more from the first initial conversation of our customer, flexibility, output, and

the HMI. This system brings the machine to on of Brita Optima integrated them in the often, to get to know the machine. German to the FAT. Together Brita and Optima suc- process safety are imperative and require

production mode in a very short time. line solution – Optima still acting as the and Chinese employees performed the in- ceeded in reducing the time to 16 months. specialized expertise from the machine

Guaranteed Traceability: Batches are main contact for all parties. stallation and the training in China. In the A significant contribution to the success builder. Profound expertise was required

diligently separated from each other. This meantime, the line is completely serviced of this project was the close and trusting for the installation and the service duties

is done by coding, starting with the prima- FAR AWAY BUT STILL FAMILIAR by the Chinese Optima subsidiary. cooperation. Brita started its regular pro- in China. Last but not least, without the

ry packaging to the palette. Besides the technical expertise and the duction in August 2017, approximately 20 close collaboration of Brita and Optima,

Only the line structure in combinati- turnkey aspect there is another important TIME TO MARKET – TIME IS MONEY months after order placement. the line could not have been completed in

on with the OPAL line control permits the characteristic to this project: “the China Projects of this magnitude and comple- Conclusion: This line stands for techno- such a short time.

parallel production of a batch in the front A reject discharge ensures high product quality. competence”. Starting with customs: how xity usually have a duration of three years logical variety like no other. In the opinion

of the machine while the back of the line can a machine be shipped to China fast

is still retrofitted. Thus OPAL provides the

system that allows bulk production into contact. On the Optima side, this contact

shipping cases while a format change is partner coordinates all concerned depart-

being performed at the cartoning machi- ments. During the entire project duration,

ne. weekly meetings with Brita took place.

In the Chinese and Asian markets, the- The customer didn’t have to worry about

se water filters are a premium product. The which company is responsible for what.

product quality is the most important is- Technical interfaces – mechanical, electri-

sue for the customer. This is evident with cal and software – are not easy to manage

the stringent fill accuracy, package quality when multiple vendors are used for one

control, and packaging material require- project. This is also not an issue anymore, The OPTIMA TFL punches the cartridge lid mesh for the

ments. Therefore, the line has various qua- if the equipment is designed according to the water filters. INTERVIEW WITH LUKAS PLATZ (DIRECTOR GROUP MANUFACTURING

lity control sensors that inspect the pro- consistent standards. GROUP TECHNOLOGY & OPERATIONS AT BRITA GMBH)

cesses and parameters for each individual As a result, it is much easier to integrate and cost effective? Whoever understands

cartridge and monitor the primary and se- and adjust the various technologies in an the country specific procedures has a clear How was your experience of the coope- more important to BRITA than the con- ferent vendors. Both companies can be

condary packaging as well as the palettes. automated process. The only third party advantage, emphasized Stefan Bauer. The- ration with Optima in the realization tract. Although a contract is necessary. proud of the result.

The quality requirements also have an equipment, the flow wrapping machine re are several departments at Optima that phase of the project? Both companies have known each other

impact on the machine’s construction ma- and the autoclave, were integrated under are experts on this subject. Our cooperation was characterized by for a long time. We know how to treat Functional scopes in this magnitude and

terials. Product contact parts and materi- Optima’s direction into the process. Last Technical qualified support is impor- mutual trust, respect for the task and a each other, what we have to pay attention variety in one line are still the exception

als that are in contact with the filter media but not least, the uniform logic of the HMIs tant for the successful operation of such a common goal. The level of the line quality to and how to manage the ups and downs today. As far as you are able to answer:

require materials that are already certified is easier to understand for the Brita opera- complex line. A local subsidiary and quali- and maintaining schedule were the cons- that are normal in each project. Would you go for a fully automatic sys-

to be used in the machine building pro- tors than if it would be different HMIs that fied employees on both sides in China are tant focus. It is too early for long-term proficiencies tem again?

cess. Asia has similar legal regulations as are all structured differently. imperative to success. Optima has had its but what are first experiences with the Now more than ever :-). The internal over-

Europe or the U.S.A. The selection of the non-Optima com- own subsidiary in China since 2012, but What were the decision criteria to give line since the SAT and thereafter? head is less. We were able to test the entire

ponents, also showed the close coope- the market was served by Optima before the order to Optima? I am sure that we would not have been line before shipping and saved both com-

CENTRAL RESPONSIBILITY: OPTIMA ration with Brita. The company had good that. The employees from both companies Trust in the Optima management, es- able to realize the timeline nor the pro- panies an expensive and lengthy start-up

The first advantage for the customer experiences with the manufacturer of the were involved early on in the project. Chi- pecially into Rainer Feuchter who I have duction readiness if we would have indi- in China.

in a turnkey project is to have a central autoclave and the flow wrapping machine nese employees from Brita and Optima known for almost 20 years. His word was vidually ordered the machines from dif-

16 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 17IN USE IN USE

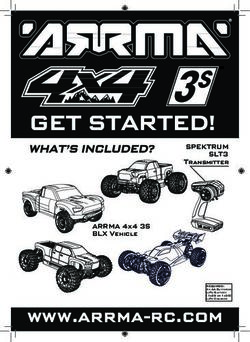

AN OVERVIEW OF THE MACHINES

OF THE LINE

OPTIMA CFL20 | Dosing module OPTIMA CBF | Carton transfer

OPTIMA CFL20 |

OPTIMA TFL | Mesh rolls OPTIMA CFL20 | Container hopper OPTIMA CBF | Carton loading OPTIMA CPF2 | Carton feed hopper

Lid presence monitoring

PRE-FABRICATION OF THE FILLING, MANUFACTURING AND SALES (CARTONED) PACKAGE,

CARTRIDGE COMPONENTS PACKAGING LINE FOR FILTER CARTRIDGES CASE PACKING AND PALLETIZING

OPTIMA OPTIMA OPTIMA Autoclave Flow-wrapping OPTIMA OPTIMA OPTIMA OPTIMA

TFL CFL20 Tray Stacker machine CBF CPF1 CPF2 P300

cutting and sealing of cartridge components a gantry system loads performs the sterilization packages the sterile and the cartoning machine the sales packages are With a bypass of the palletizer with three

metal screen/mesh into are fed into the machine the filter cartridges onto of the filter cartridges. individual filter cart- erects the carton bottom multi packed in a large OPTIMA CBF cartoning pallet positions. The

cartridge lids. in multiple lanes, the a tray and the loaded Automatic infeed and ridges in bags. and lid from pre-cut carton and labeled. machine, the cartridges transport packages/

dosing system fills gra- trays are stacked. The transport to the flow- carton material. Flow- packaged in film are cartons from both case

nulated activated carbon filter cartridges are wrapping machine. wrapped filter cartridges transported to the packers are palletized in

into the cartridges. The unloaded from the tray are placed by a pick case packer 2. The case a parallel pattern.

lid is fed into the machi- after sterilization. The and place system into a packer 2 places the All modules are equip-

ne and sealed onto the empty trays are stacked carton. The lid is placed individual cartridges into ped with a quality

filled cartridges. and returned to be loa- on the carton and closed a carton. The cartons are process control system.

ded again. with hot adhesive. The labeled. The automated line is

ready-to-go carton pa- adjusted and controlled

ckages (seven formats: with OPAL using batch

1 to 15 cartridges) pass specific production data.

a check-weigher and The OEE analysis is also

coding station. completed by OPAL.

18 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 19IN USE IN USE

CARTON AND BAG PACKAGING WITH A STACKER

FAST, NOT FURIOUS

A new stacker type from Optima promises added

scope in production without compromising

on processing speed. The special feature: a

manufacturer of incontinence products can switch

the process to carton packaging or bag packaging

at the touch of a button. In addition, with this new

product, Optima has significantly increased the

processing stability of the stacker and the cartoning

process.

Now for the first time, paper hygiene products can Carton and foil packaging; the new line can handle both.

be packaged both in plastic bags and in cartons. The

central innovation on the new line is a new type of

stacker.

One product – countless packaging packs for care facilities are a further vari- of increased output. Today’s system pro- system within the stacker. The larger this an expanded product format range. To shed into the carton. This also increases

types and sizes: a common practice with ant for which there is growing demand. cesses 80 cycles per minute, an increase buffer is, the higher the output. achieve this, for the first time, O ptima tolerances for the product dimensions

today’s paper hygiene products. Incon- Last but not least, marketing campaigns of around 250 percent compared to the The stacker itself is equipped with two Nonwovens has integrated a height that can be processed. Incontinence pro-

tinence products for men are a relatively further increase the range of variants. previous performance. discharges positioned diagonally. They adjustment in the bridging conveyor ducts, in particular, vary greatly in thick-

new market segment. But here, too, there On the other side, there is the manu- That kind of increase is not possible mark the transition points to an OPTIMA between the stacker and cartoner. The ness, with a maximum product thickness

is already great variety. Ideally, a system facturing and packaging process that has simply by adjusting a few set screws. One OS2 packaging machine for plastic bags correct lateral guide can now be quickly of 14 mm, tolerances of plus/minus 4 mm

should be capable of packaging large and to map this diversity. Together with the challenge of the new design is that on one or to an OPTIMA CM 180/10 cartoner. The set up for each product size. In this way, are now possible with the new system.

small packs and almost every size in bet- multi-stage packaging process, the con- side of the stacker, the incontinence pro- advantage of this diagonal constellati- incontinence products with the current This further increases processing stability.

ween. And of course, a system needs to verter forms an integrated line with high ducts flow in a continuous stream from on is that it ensures the ‘right’ direction product dimensions (additional formats Process reliability has also been clear-

master a wide range of product variants, output. How is it possible to implement the converter into the paddle chain. On of processing in each case. The bagger will be added in the future) are transpor- ly increased during cartoning. To do this,

which are equivalent to product formats. this wide range of requirements into the opposite side of the stacker, the padd- receives the products in a linear fashion. ted onward with high reliability into the the Optima developers have decoupled

When it comes to packaging sizes, the highly flexible processes without a loss of le chain with the product stack (count) In contrast, the products are pushed late- next process station. the process. The carton blanks are ext-

paper hygiene product manufacturers’ performance? needs to be stopped briefly for transfer rally onto the cartoner, which docks on at The stacker is equipped with another racted, then spread, erected and inserted

marketing experts know exactly whether and transport into the packaging process. a 90-degree angle. This makes an additi- new feature at the transition point in the into the transport system. Previously, this

consumers prefer to buy products in car- (R)EVOLUTION The challenge is that there is continuous onal change in direction at this point su- cartoning process; a second compression was virtually one continuous procedure.

tons or plastic bags and precisely how the An initial user already employed a movement on one side of the stacker perfluous. station has been added after the initial This, however, meant that minor devia-

products should be aligned inside the pa- previous version of the new stacker, it also and brief stopping of the paddle chain pre-compression process. The second tions from the defined parameters trig-

ckaging. The color of the sales packaging allowed packaging both in cartons and on the other side to allow discharging of PROCESSING STABILITY TIMES THREE compression process takes place at the gered errors. The clear separation of this

is also immensely important in the case bags. But the new project represents a the count. This is achieved with the help The customer also profits from greatly end of the bridging conveyor which is sequence has slightly increased the di-

of incontinence products for men. Bulk major step forward, especially in the form of a new, improved intermediate storage increased processing stability and from shortly before the product stack is pu- mensions of the cartoner, but the process

20 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 21IN USE

Focus

ON PROCESS

RELIABILITY

This has been increased significantly.

Insertion into the paddle chain is identical to other stacker In the cartoning section, too, Optima has now integrated

versions. a second compression stage.

is now e xtremely robust. Although there stacker picks up the products in its paddle back again with little time required. The

is no long-term experience to fall back on, chain and positions them as ‘counts’ rea- manufacturer of paper hygiene products

the paper hygiene product manufacturer dy for discharge. These pre-compressed makes use of changeover times on the

is currently in the process of conducting product stacks exit the machine toward bagger or cartoner, for example in order to

Product Acceptance Tests (PAT) and the the cartoner or bagger, where additional configure different product or packaging

possibility of retrofitting existing lines compression is performed. Then the actu- formats, for manual packaging.

with these new, improved features is al- al packaging of the products takes place, In summary, the user benefits from the

ready being discussed. The new systems according to the respective principle. Fi- very high process stability and, with the

Carton and film packaging types:

are convincing from start to finish, which nally, the two lines converge in a case pa- new stacker type, greatly increased flexi- the new system can pack both.

is confirmed by the error-free PATs. cker. (A second case packer would not be bility. The flexibility to react quickly to the

cost-efficient). current market, customer or marketing re-

INTERLINKING: AN OVERVIEW OF THE Here, the paper hygiene product quirements, but also the flexibility within

PROCESS manufacturer profited from the close

the company that comes from the opti-

Today, the converter and the pa- collaboration between the three suppliers mum deployment of personnel and ma-

ckaging process are closely linked. After involved. The interfaces between conver- chines without periods of inactivity. And

leaving the converter, the incontinence ter, packaging machines and case packer last but not least, the new stacker does

products travel first into an Optima quali- were coordinated without problems. And away with the need for a (conventional)

ty gate with a flipper. The converter has no if any problems should occur, the quali- complete line (plus operating personnel)

separate reject after the folding functions, ty gate offers the user a further advan- that could package products only in car-

but it does contain monitoring functions tage. All product parameters, that could tons or only in plastic bags.

where signals are sent to the quality gate. have negative effects on the process, are Finally, the new stacker is always an

This allows a rejected product to be di- precisely documented. This means that

interesting option when you want to in-

scharged independent of the process and sources of error can be pinpointed or crease capacities but it is not possible to

manufacturer. ruled out. clearly assess future market potential.

The quality gate itself checks the di- The stacker’s second discharge, whether

mensions of the products, which also WHAT’S THE BOTTOM LINE? for packaging in cartons or plastic bags,

allows conclusions to be drawn with re- On the new stacker, the changeover does not have to be used right away, if

gards to correct folding and quality. In ad- between packaging in cartons or plastic the potential for a second packaging me-

dition, the required spacing is monitored, bags is virtually seamless. Processing swit- thod materializes, the financial threshold

without slowing the process down. The ches from one direction to the other and is considerably lower.

22 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 23IN USE

READY FOR THE FUTURE

THE “CRAB” OFFERS

Labeling unit for three-sided labels

THE MOST FLEXIBILITY

Motor and gear oil flows smoothly into containers

ranging from one to twenty-five liters at Addinol.

Beginning in August 2016, Addinol’s new Optima

line handles this application while working

seamlessly with the existing integrated packaging

line. This combination solution provides maximum

flexibility for handling a complete range of new

containers and closures, providing more flexibility.

Even at an automotive and industrial visit to the Optima booth during a trade This, paired with OPTIMA’s intelligent ma- name: “project crab”. The existing con- placed on the container and screwed-on.

lubrication manufacturer, not everything show uncovered the opportunity to com- chine design, was able to give Mr. Minke veyors were modified to fit the dual-lane During the closing process the containers

runs smoothly. A little over two years ago bine two filling machines (one existing the comfort and confidence to place the upgrade. Bottles are loaded by layers onto are continuously transported. The advan-

Addinol wanted to increase their product and one new) in a dual-lane solution that order with Optima. a buffer table where they are manually tages: first, this prevents spillage from in-

and format range. The existing machine supplies a single capping machine in dual- pushed onto the main transport conveyor termittent transporting of the bottles and,

delivered in 2006, with a capacity from lane execution. Effectively doubling the WELL TESTED by the operators who are supported by a secondly, the machine reaches an output

0.6 to 5 liters, was becoming fully utilized line’s capacity and expanding the contai- The final layout of the two lines that lifting device. of up to 2,000 containers per hour with

and limited in the ability to handle new ner range that can be processed. meet at the double-laned closing machi- The first addition to the new part of the one liter containers (both lines reach an

formats. These two issues pointed Addi- Optima was also selected as the ven- ne was created in close cooperation with line is the OPTIMA SHF-4 filling machine output up to 4,000 containers per hour).

nol executives toward a new investment. dor of the first filling machine that would Optima. Only the existing starwheel clo- that accurately fills various oils with a ro- The output for 20 liter containers is 200

Siegmar Minke (Addinol) reported about challenges

The only problem: Where to place a new be used as part of this project. However, sing machine had to be eliminated for the tary piston pump system and delivers reli- but also of solutions, for example the restricted space.

containers per hour (new part of the line).

machine? Siegmar Minke (Head of Purchasing, Pro- new concept. The project engineers were able results. During the transport through A labeler with three label dispensing

Floor space is extremely limited in duction and Logistics at Addinol) still able to find the perfect solution to fit in the filling machine a drip tray indexes un- stations follows. An additional label will

Addinol’s manufacturing hall and a buil- wanted to get a market overview and in- the existing space while maintaining easy der the filling nozzles to catch any drop of a dual-lane design built as a single frame be placed on the rear of the large 20-liter

ding expansion was not an option. In or- vestigate solutions from other possible access to the machine. product that may hang from the closable capping machine capable of processing containers to give the container an ap-

der to move ahead with the project the vendors. Eventually he gravitated toward From above the line has the outline nozzle ends and prevents contamination containers ranging from one to 25-liter pealing design. A checkweigher controls

new system had to fit into the existing the proven solution. “We know what is of a “crab” where each “claw” indicates the of the machine. containers. The closures are sorted and the contents and ensures that any under-

space. The team’s initial thought was to possible, especially in the service area. placement location for the containers. The second step in the process is a li- transferred from two separate cap un- weight containers will be rejected. The last

simply replace the existing machine. A This was the deciding factor”, he reports. This outline gave the project its internal near closing machine. The OPTIMA KVG is scrambling hoppers with elevators then station is a group of inkjet p rinters that

The new and old system sections are merged

in the twin-track lid fitting unit.

24 o-com consumer-nonwovens 03/2018 25IN USE

One Line – many formats:

the Optima line gives

Addinol free reign for

the fill volume

print specific information such as batch while the existing line remained in pro- technology was integrated by Optima

numbers, day/lot codes, etc. Finally, the duction. First the existing line was disas- and a third-party provider. The process

containers are transported to the final pa- sembled and relocated to its new location prevents transfer errors, for example,

ckaging station equipped with a robot. and re-started to produce product in a transposed numbers and also accelerates

transitional mode. Next, the new line was the input process compared to the past

MACHINE DESIGN WITHOUT installed and the “old” machine was then manual versions. One scan, one push of a

PACKAGING MATERIAL integrated into the new concept. The pro- button, followed by a beep and the data is

A special project challenge was that duction interruption was scheduled for a transferred to all applicable components.

Parallel lid fitting

Addinol was in the process of a compo- maximum of six days. What is the feedback from the custo-

nent redesign effort during the purchase fine adjustments took place much later mer in regards to flexibility? “We achieved

of the machine, including the 1 liter clo- than usual and several adjustments and GLADLY TURNKEY the objective we had in mind. If needed,

sure that was especially designed for Ad- optimizations were made during instal- Addinol wanted a continuous, reliab- we can add formats between 0.5 liter and

dinol. This meant that Optima had to de- lation. However, after the startup process le solution from one supplier who would 25 liter fill volume at a later date. Today

sign and build the machine with very few was completed the operators are now plan and implement the new line from we are able to run different formats on

containers, closures or labels. Production very happy with the machine, says the A to Z with all its functions. At the same the line. This means different fill volumes

samples were first made available for the purchasing manager. time, proven components such as printers and the new and the “old” containers

machine’s internal check-out (just before The installation at the customer’s site from a specified supplier had to be incor- can be run on the machine. If we have a

FAT). “This was very challenging for both was another challenge for the turnkey porated. new container design we definitely will

sides and created enormous pressure for vendor: “We executed the entire project Another highlight of the line was the be more flexible and faster to implement

us”, said Siegmar Minke when reflecting live”, remembers Siegmar Minke. This me- wireless data transfer to the four printers it.” Conclusion: The “crab” is ready for the

on the project challenges. Therefore, the ant the installation had to be completed for the containers and carton labels. This future. The filling machine for the new system section

26 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 27OPTIMA TOTAL CARE

TRAIN THE TRAINER

THE BEST LEARN FROM THE BEST

Packaging systems are expensive and extremely complex. The

goal of new systems is to deliver new products to the market

as quickly as possible. This goal is frequently not achieved

due to a lack of qualification and expertise on the part of the

customer. The training of operating personnel in the “start

phase” is an important part of Optima’s Total Care program.

The Optima Consumer service department has developed

various strategies to provide the best possible support during

this process with things such as an “embedded engineer”

who supports the customer over an extended period of time.

Another alternative is the new Train the Trainer concept: The

user’s project lead receives optimal training from Optima’s

project lead. Michael Weber, Service Director of Optima Consumer, Isabell Majanguissa, developer of the Train the Trainer

aims to maintain system efficiency at a high level in the concept, explains to the customer’s future system

future using the Train the Trainer concept: “To ensure operator how the Optima installer will support him

this, the customer must select his best man for training.” over the days to come.

The system has been installed and MAINTAINING EFFICIENCY AT THE ORIGI- know every detail of every system. Weber has at least one talented employee on FACE-TO-FACE TRAINING PRODUCES operator’s expert can use them to pass on

a ccepted, it was put into operation and NAL HIGH LEVEL - NOT AN EASY TASK has a pragmatic solution: “We send the his team with a particular expertise,“ said TARGETED TRAINING MATERIALS his expertise in the future. Weber pointed

well tested, with the help of the Optima System efficiency deteriorates over installer, who knows the system best, out Weber. In the event of future productivity Of course, operating manuals and out the opportunities this presented: “For

Consumer installers, and all machine time. Everything can be running perfectly to the customer.” Armed with this in-depth losses, this employee could “turn the right training documents for individual sys- some customers, we make these training

operators are familiar with the system. In but in just a few weeks, or even days, later, knowledge of the specific system, the in- screws” and teach other system operators. tem components already exist before this documents and explanatory videos availa-

short: The new system from Optima Con- problems can arise. When this happens, staller provides support during commis- This would ensure that there are no further face-to-face training takes place. “Never- ble online through the server. In addition,

sumer is running with high output and the the skilled Optima installer is deployed sioning – and in many cases, whenever deficits caused by incorrect operation. This theless,“ explained Isabell Majanguissa, “it this database, also referred to as a “UIL“

customer is completely satisfied. to set things right. “There has to be a bet- service is required in the future. Train the Trainer concept works – on one is far more productive if all explanatory (User Information Library) can be used in

A few weeks later a phone call is ter solution,“ said the Optima Consumer condition: the customer, too, must assign sketches and teaching videos are created the future for the transfer of knowledge

received from the customer, who is already service team, and they asked themselves STANDARD TRAINING COURSES ARE NOT his best man to this task. during the training process itself.“ This en- between Optima and the customer. We

somewhat annoyed. System production is the question: “What can our installer do ENOUGH If this condition is met, the Train the sures that with the training documents, add supplementary documents to the

now falling far short of expectations and that the customer can’t? Why is it that the “Classroom’ seminars, no matter how Trainer program begins. The best-qualified the system expert receives the precise database as additional documents and

the operators seem out of their depth. No customer’s operating personnel, who have didactically perfect, and despite the Optima installer passes on his expertise support he or she personally requires. In films are created.”

problem, the people at Optima Consumer been trained on the system, are unable to support of technology such as virtual

to the customer’s future system expert. Majanguissa’s opinion, it is important that And of course, the operator’s expert

say, and they send one of their installers to maintain its efficiency at a high level?” reality, may be of great value, but they This takes place directly on the system, for the Optima installer and the customer’s can consult the former trainer if a problem

the customer. A few hours later, the system And Optima Consumer found answers. are not enough. “The training concept of example during the run-in process. Expe- employee would be able to talk face to occurs that he or she cannot solve on their

is running perfectly again. The operators “In the Consumer sector, no two machines Optima Consumer focuses on practical rience shows that one week of extremely face. This ensures a quick and smooth own. Often, it will not even be necessary

now know where the problem was and or systems are alike,” stated Michael Weber, training,” emphasized Isabell Majanguissa, intensive instruction is required to exp- transfer of knowledge. for the trainer to travel to the customer’s

feel competent to handle any difficulties. Service Director at Optima Consumer. He who, as a training expert, is responsible for lain all of the machines and functions, put As a follow-up, the documents crea- premises. The former teacher and student

Everything is under control. said that even his own team would have the training methodology. them through their paces and answer all ted during the Train the Trainer course are have become a well-oiled team and master

difficulties if everyone was expected to “Every customer, in our experience, questions. processed in such a way that the system any new challenge with ease.

28 o-com consumer-nonwovens 03/2018 o-com consumer-nonwovens 03/2018 29You can also read