Woodardcurran.com - Hudson MA

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

BASIS OF DESIGN

REPORT

Chestnut Street PFAS

Treatment System

PRELIMINARY

DESIGN

SUBMITTAL

DWSRF #6791

40 Shattuck Road | Suite 110

Andover, Massachusetts 01810

800.426.4262

232305.00

Town of Hudson,

Massachusetts

woodardcurran.com

&

COMMITMENT INTEGRITY DRIVE RESULTS

May 2021TABLE OF CONTENTS

SECTION PAGE NO.

1. PROJECT BACKGROUND ............................................................................................................................. 1-1

1.1 Summary of Existing Conditions ............................................................................................................ 1-1

1.2 Project Objective ...................................................................................................................................1-1

1.3 Project Schedule ................................................................................................................................... 1-2

2. SITE/CIVIL DESIGN ........................................................................................................................................ 2-1

2.1 Summary of Existing Conditions ............................................................................................................ 2-1

2.2 Design Criteria ....................................................................................................................................... 2-1

2.3 Proposed Modifications ......................................................................................................................... 2-1

3. PROCESS DESIGN ......................................................................................................................................... 3-1

3.1 Summary of Existing Conditions ............................................................................................................ 3-1

3.2 Proposed Modifications ......................................................................................................................... 3-1

PFAS Pilot Study and Temporary System Operation ................................................................. 3-2

Treatment Modifications.............................................................................................................. 3-2

3.2.2.1 Backwash Handling.......................................................................................................... 3-3

3.2.2.2 Hydraulic Analysis ............................................................................................................ 3-3

Distribution System Pumps and Piping ....................................................................................... 3-4

Chemical Feed Systems ............................................................................................................. 3-4

Procurement of GAC Vessels ..................................................................................................... 3-4

4. ELECTRICAL DESIGN .................................................................................................................................... 4-1

4.1 Summary of Existing Conditions ............................................................................................................ 4-1

Electrical Distribution System ..................................................................................................... 4-1

Standby Emergency Power System ........................................................................................... 4-1

4.2 Proposed Modifications ......................................................................................................................... 4-1

Electrical Distribution System ..................................................................................................... 4-1

Standby Emergency Power System ........................................................................................... 4-2

Fire Alarm System ...................................................................................................................... 4-2

Intrusion Detection ......................................................................................................................4-2

Lighting Systems......................................................................................................................... 4-2

Lightning Protection System ....................................................................................................... 4-2

Materials of Construction ............................................................................................................ 4-3

5. CONTROLS DESIGN ...................................................................................................................................... 5-4

5.1 Proposed Modifications ......................................................................................................................... 5-4

5.1.1.1 New PFAS Control Panel ................................................................................................. 5-4

5.1.1.2 Communications .............................................................................................................. 5-4

6. PLUMBING AND HVAC DESIGN.................................................................................................................... 6-1

6.1 Design Standards .................................................................................................................................. 6-1

6.2 Proposed Work ...................................................................................................................................... 6-1

6.2.1.1 HVAC ............................................................................................................................... 6-1

6.2.1.2 Heating ............................................................................................................................. 6-1

6.2.1.3 Ventilation ........................................................................................................................6-1

Town of Hudson i Woodard & Curran

2021.05.10 Preliminary Design Report May 20216.2.1.4 Dehumidification............................................................................................................... 6-1

6.2.1.5 Cooling ............................................................................................................................. 6-1

6.2.1.6 HVAC Controls ................................................................................................................. 6-1

6.2.1.7 Plumbing .......................................................................................................................... 6-1

7. ARCHITECTURAL DESIGN ............................................................................................................................ 7-1

7.1 Summary of Existing Conditions ............................................................................................................ 7-1

7.2 Existing Building .................................................................................................................................... 7-1

7.3 New PFAS Treatment Building .............................................................................................................. 7-1

7.4 Life Safety and FIre Protection .............................................................................................................. 7-1

8. STRUCTURAL DESIGN .................................................................................................................................. 8-2

8.1 Structural Design Criteria and Standards ..............................................................................................8-2

8.2 Proposed Work ...................................................................................................................................... 8-2

8.3 Pre-Engineered Metal Building .............................................................................................................. 8-2

8.4 Geotechnical and Foundation Criteria ...................................................................................................8-2

9. PERMITTING ................................................................................................................................................... 9-3

FIGURES

Figure 3-1: Chestnut Street WFP Proposed Schematic ............................................................................................. 3-3

TABLES

Table 3-1: Chemical Feed Systems ........................................................................................................................... 3-1

Table 3-2: PFAS Treatment Design Criteria............................................................................................................... 3-4

APPENDICES

Appendix A: Project Locus Map

Appendix B: List of Specifications

Appendix C: Equipment Summary

Appendix D: Geotechnical Report

Town of Hudson ii Woodard & Curran

2021.05.10 Preliminary Design Report May 20211. PROJECT BACKGROUND 1.1 SUMMARY OF EXISTING CONDITIONS The Town of Hudson (Town) in Massachusetts is situated approximately 30 miles west of Boston and borders Marlborough to the north. The Town is located between exits 25A and 26 of Interstate 495. Multiple rivers and streams run through the Town including the Assabet River and its tributaries along with the Fort Meadow Brook, which is fed by the Fort Meadow Lake Reservoir. Hudson has a total area of 11.8 square miles, of which approximately 11.5 square miles are land and approximately 0.3 square miles, or 2.54%, is water. The Town supplies drinking water to approximately 19,864 residents using a blend of 91% groundwater from five wells and 9% surface water. Sources include two groundwater wells located on Chestnut Street (Wells 2 and 3), the Kane Well located on Main Street, the Cranberry Well located off Parmenter Road, and surface water from the Gates Pond Reservoir located in Berlin, MA. A pair of groundwater wells including an original well and a newer replacement well (Wells 1/1R) are located on Chestnut Street as well. The groundwater from Kane Well, Cranberry Well, and all three Chestnut Street Wells is combined and treated at the Chestnut Street Water Filtration Plant (WFP), located at 72 Chestnut Street. Surface water from the Gates Pond Reservoir is treated at the Gates Pond Filtration Plant. The Town’s water system has five (5) distribution storage tanks and 10 pump stations, eight (8) of which are public and two (2) are private. Between August 2016 and June 2018, seven (7) samples were analyzed for per- and polyfluoroalkyl substances (PFAS) from the Chestnut Street WFP effluent. The sum of the concentrations of five Massachusetts Department of Environmental Protection (MassDEP) regulated PFAS compounds (PFAS5) ranged from a minimum of 34.8 parts per trillion (ppt) to a maximum of 67.6 ppt. In response, the Town designed and constructed a temporary treatment system at the Chestnut Street site to maintain operation of the facility. The system became operational in July 2019 as a MassDEP permitted temporary system and has been providing PFAS treatment until a permanent system can be installed. The temporary treatment process consists of two (2) ion-exchange (IX) resin trains, with each train including two (2) pressure vessels. Since the installation of the temporary PFAS treatment system, in October 2020, MassDEP added an additional regulated PFAS compound and established the current health guideline and new maximum contaminant level (MCL) for the sum of the concentrations of six MassDEP regulated PFAS compounds (PFAS6). The MCL is 20 ppt. 1.2 PROJECT OBJECTIVE This project includes the design, bidding, and construction of a new PFAS treatment system, which includes six (6) Granular Activated Carbon (GAC) vessels, in a stand-alone pre-engineered steel building located at the Chestnut Street WFP. A new building on a concrete slab will be constructed to the east of the existing Chestnut Street WFP. The proposed project will also include piping, chemical addition for post-treatment following the new PFAS treatment system, building systems, associated instrumentation and controls, a new emergency generator, and all necessary local and state agency approvals. Standard design practice, which the Town will follow, includes the installation of multiple treatment trains with two PFAS removal vessels in each train. With this design, breakthrough (i.e. detectable concentrations) will occur in the lead vessel effluent while effluent from the lag vessel is maintained at non-detect levels. This will provide the Town sufficient time to replace the media in the lead vessels, switch the order of the vessels, and resume the cycle. In this way the Town will be able to maintain non-detect levels of PFAS6 in the water entering the distribution system. Town of Hudson 1-1 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

1.3 PROJECT SCHEDULE Design of a new PFAS treatment system is proceeding through May 2021, with the construction of the new system anticipated to begin in late summer, and with the treatment process coming online in the fall and building construction and final site work following. The construction phase shall be coordinated with the Town to minimize any impacts to the distribution system during peak times. This project has been listed in the final list of projects being awarded for DWSRF funding. Town of Hudson 1-2 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

2. SITE/CIVIL DESIGN

2.1 SUMMARY OF EXISTING CONDITIONS

The Chestnut Street WFP is located at 72 Chestnut Street in Hudson, Massachusetts. The WFP property abuts Fort

Meadow Brook to the east, private property to the north, Chestnut Street to the west, and Main Street to the south.

The existing site is partially located within the 100-year floodplain with base flood elevations but is outside of the 200-

foot riverfront setback from Fort Meadow Brook, which is a tributary to the Assabet River.

2.2 DESIGN CRITERIA

The site modifications will be provided for accessibility for servicing of each site component. The site modifications

will not extend into any wetlands and will minimize impact to the floodplain. Site access shall accommodate drilling

rigs, chemical/carbon delivery trucks, and maintenance/service vehicles.

Limited paving and grading adjustments to the existing site access driveway along with construction of the new PFAS

Treatment Building are proposed within the 100-foot buffer zone to the bordering vegetated wetlands and within the

100-year floodplain. Site improvements will be designed in accordance with the Town of Hudson Engineering

Checklist for Site Plan Review and will have no adverse hydrologic impact. Low-impact development techniques

consisting of site planning to minimize creation of new impervious surfaces, reductions in amount of existing paved

surfaces, maintaining the existing hydrologic pattern, and restoring areas of the site presently in hydrologically poor

condition will be employed to control post-development peak runoff rates to below pre-development levels. Runoff

patterns from the site will remain unaltered and no new untreated stormwater discharges to the wetland resource

areas and associated buffer zones are proposed. Additional information about the site/civil design for this project is

described in a stormwater report that will be sent to the Town under a separate package.

2.3 PROPOSED MODIFICATIONS

The site improvements will include the following major components:

A new PFAS Treatment Building of approximately 2,800 square-feet;

Site piping between existing WFP Building and new PFAS Treatment Building;

Site piping between new PFAS treatment system and existing booster pumps;

A new Pump House Building for existing booster pumps of approximately 240 square-feet;

Minor adjustments to the existing access driveway;

Site runoff treatment using stormwater best management practices (BMPs) and sized to accommodate the

required water quality volume in accordance with the Massachusetts Stormwater Handbook standards for

critical areas;

Drywell for new PFAS Treatment Building roof and floor drains; and

New overhang over existing exterior mounted VFDs.

Town of Hudson 2-1 Woodard & Curran

2021.05.10 Preliminary Design Report May 20213. PROCESS DESIGN

3.1 SUMMARY OF EXISTING CONDITIONS

As noted in Section 1, the groundwater from Chestnut Street Wells 2 and 3, Kane Well, and Cranberry Well is

combined and treated at the Chestnut Street WFP. The Chestnut Street WFP, which was constructed in 1995, was

primarily designed to remove iron and manganese from the raw water through unit processes including chemical

addition and greensand filtration, using five (5) 12-foot diameter filtration vessels, as well as to provide residual

disinfection in the distribution system.

Prior to treatment at the Chestnut Street WFP, the following chemicals are used to pretreat the groundwater: 1)

sodium hypochlorite for disinfection and oxidation and 2) potassium hydroxide for pH adjustment and corrosion

control. Once inside the Chestnut Street WFP, water is treated using greensand filtration for iron and manganese

removal, then the following chemicals are added to the water 1) hydrofluorosilicic acid for dental health, 2) sodium

bisulfite is for de-chlorination, and 3) potassium hydroxide for corrosion control. Water is then filtered using two bag

filters and is treated using an ion-exchange (IX) treatment system for PFAS removal. The IX treatment system was

installed in 2019 as a temporary PFAS treatment system to be utilized until a final, permanent system could be

designed and constructed. Final chemical treatment at the Chestnut Street WFP, before water is pumped to the

distribution system, consists of sodium hypochlorite for disinfection and optional potassium hydroxide for corrosion

control.

The chemical feed systems are located in the existing Chestnut Street WFP and their components are summarized in

Table 3-1.

Table 3-1: Chemical Feed Systems

Chemical System Storage Tanks Day Tanks Pumps

Hydrofluorosilicic Acid 1,500-gallon 30-gallon 1 transfer pump

2 chemical feed pumps

Sodium Hypochlorite (1) 500-gallon (1) 30-gallon 2 transfer pumps

(1) 250-gallon (1) 50-gallon 4 chemical feed pumps

Potassium Hydroxide 3,000-gallon 100-gallon 1 transfer pump

2 chemical feed pumps

Potassium Permanganate 1,000-gallon mixing tank 250-gallon 1 transfer pump

4 chemical feed pumps

Sodium Bisulfite 225-gallon 25-gallon 1 transfer pump

2 chemical feed pumps

3.2 CHESTNUT STREET WFP IMPROVEMENTS

Improvements to the Chestnut Street WFP will include the following:

Rehabilitation of existing interior pipe and valves;

Replacement of interior pipe coating system; and

Replacement of media in greensand filter vessels.

Town of Hudson 3-1 Woodard & Curran

2021.05.10 Preliminary Design Report May 20213.3 PROPOSED MODIFICATIONS

PFAS Pilot Study and Temporary System Operation

A small-scale pilot test was conducted using GAC media (FILTRASORB® 400) and IX resin (SORBIX LC3 resin)

over an 8-month period at the Chestnut Street WFP to aid in the design of a full-scale PFAS treatment system. The

primary goal of the pilot study was to determine the effectiveness of each technology for PFAS removal to establish

full-scale design criteria. Based on the pilot study results, the removal of PFAS varied between the two different

media/resin types. Results indicated similar removal efficiencies in the first column of both medias; however, IX had a

higher removal efficiency than GAC in subsequent columns. GAC was still able, however, to remove PFAS from the

Chestnut Street water to levels below the MassDEP MCL of 20 ppt for the entirety of the study at empty bed contact

times of 9.7 minutes and 14.5 minutes.

In addition to the pilot study, a full-scale, temporary treatment system has been operating at the Chestnut Street WFP

since July 2019. The temporary treatment system was supplied by Evoqua and includes two IX resin trains. Each

train includes two, 10-foot diameter vessels in a lead/lag configuration. Each vessel contains DOWEX™ PSR2 resin.

The temporary treatment system has been removing PFAS to non-detect levels since its implementation in July

2019. However, as a result of maintenance challenges and frequent media changeouts than anticipated at the time of

installation, the Town has expressed interest in switching to GAC filtration vessels for the new PFAS treatment

system. As the Pilot study results support, GAC was also a comparable treatment technology to remove PFAS from

the raw water at this Facility to levels below MassDEP MCL of 20 ppt.

Treatment Modifications

Currently combined well water flows through the Chestnut Street WFP, which includes chemical addition, greensand

filtration, and filtration through bag filters. Following the Chestnut Street WFP, water flows through the temporary

PFAS treatment system, which includes IX and chemical addition. Finally, effluent from the temporary PFAS

treatment system flows back into the Chestnut Street WFP for backwash applications and to the booster pumps prior

to the distribution system.

The building for the new PFAS treatment system will be located east of the existing Chestnut Street WFP. The

proposed permanent system will replace the existing temporary PFAS treatment system within the process

sequence. As shown in Figure 3-1, water exiting the Chestnut St WFP will enter the new PFAS treatment system and

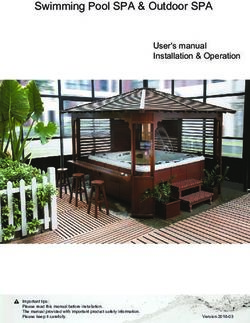

effluent from the permanent system will be directed to the Chestnut Street WFP for backwash applications or to the

booster pumps prior to the distribution system. The proposed permanent system will be composed of three (3) trains

of vessels, with each train having two (2) GAC vessels operating in lead-lag configuration. During normal operations,

two (2) trains will be in service with the third train for redundancy. Each vessel will be capable of holding 40,000 lbs.

of GAC media to adsorb the PFAS compounds and the process piping will be composed of 12-inch and 8-inch

diameter water mains. Chemical additions including sodium hypochlorite for disinfection and an optional injection port

for potassium hydroxide for corrosion control will be installed on the effluent side of the GAC vessels.

Town of Hudson 3-2 Woodard & Curran

2021.05.10 Preliminary Design Report May 2021Figure 3-1: Chestnut Street WFP Proposed Schematic 3.3.2.1 Backwash Handling Although GAC filtration in certain treatment processes can require backwashing, when used as adsorbers for PFAS removal, it is generally not recommended to backwash the GAC media beds as backwashing will redistribute the media and possibly allow premature breakthrough. Therefore, we anticipate that no waste stream will be generated by the new GAC treatment process during regular operation. However, the vessels will be backwashed during carbon changeout periods to adequately prepare the GAC system for operation. Chlorinated finished water will be utilized for backwash supply. Carbon manufacturers stated that backwashing of GAC media, after initial fills, with chlorinated water (< 1 parts per million (ppm)) will not have a significant impact on the useful life of carbon to remove PFAS. Backwash influent water to the new PFAS treatment system will be supplied from the finished water line following the booster pumps. The backwash effluent water will be discharged from the vessels to the existing lagoons, as shown on the preliminary site plans. 3.3.2.2 Hydraulic Analysis A hydraulic analysis was conducted for the Chestnut Street WFP to determine if the existing well pumps will be capable of providing water to the new PFAS treatment system and if the existing booster pumps will be capable of providing water to the distribution system following installation of the proposed permanent system. Based on a review of headloss for the GAC vessels, it was estimated that there is a total head loss of up to 15 psi through GAC vessels. The hydraulic grade at the influent of the Chestnut Street WFP is approximately 417 ft, the hydraulic grade at the effluent of the Chestnut Street WFP is approximately 383 ft, the hydraulic grade at the effluent of the new PFAS treatment system is estimated to be approximately 345 ft, and hydraulic grade at the effluent of the Town of Hudson 3-3 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

booster pumps is approximately 416 ft. Therefore, when the head loss from the GAC vessels is factored into the

hydraulic analysis, it was determined that both the well pumps and the booster pumps are adequately sized to

provide enough head to advance water through the proposed GAC vessels and fill the Pope’s Hill Tank.

Distribution System Pumps and Piping

No changes are proposed to the existing well pumps, booster pumps and motors, or associated discharge piping,

valves, and fittings due to the new PFAS treatment system installation at the Chestnut Street WFP.

Chemical Feed Systems

No changes are proposed to the existing chemical feed systems at the Chestnut Street WFP. Chemical injection

points for sodium hypochlorite and potassium hydroxide will be installed within the building of the proposed

permanent system; however, the existing chemical feed systems within the Chestnut Street WFP will be used to

supply these injection points.

Procurement of GAC Vessels

The Town has decided to expedite the design and installation of new PFAS treatment system. The Town, with the

assistance of Woodard & Curran, is investigating if MassDEP would allow pre-procurement of primary treatment

equipment, the GAC vessels, as it is a critical path item due to the long lead times. Once procured and fabricated,

offloading and installation of the filtration equipment, as well as all other elements of construction, will be part of a

Construction Contract to be bid under standard procurement procedures. Process equipment other than the GAC

vessels, such as valves, instrumentation, and controls, have shorter lead times and therefore will be procured as part

of the Construction Contract.

The design criteria that will be used for the procurement of GAC vessels is summarized in Table 3-2.

Table 3-2: PFAS Treatment Design Criteria

Design Criteria Value

Maximum Design Flow 2,000 gpm

Average Flow 1,200 gpm

Number of Treatment Trains 3

Number of Vessels per Train 2

Total Vessels 6

Operation Lead - Lag

Design Basis TIGG CP-40K-12 or Equal

GAC per Vessel 40,000 lbs

Maximum Flow – 2 Trains Operational

Flow per Train 1,000 gpm

Loading Rate 8.84 gpm/sf

Empty Bed Contact Time ~10 min per vessel

Pressure Drop ~13 psi

Average Flow – 2 Trains Operational

Flow per Train 600 gpm

Loading Rate 5.31 gpm/sf

Empty Bed Contact Time ~16.7 min per vessel

Pressure Drop ~15 psi

Town of Hudson 3-4 Woodard & Curran

2021.05.10 Preliminary Design Report May 20214. ELECTRICAL DESIGN

4.1 SUMMARY OF EXISTING CONDITIONS

Electrical Distribution System

The existing Chestnut Street WFP is served by Hudson Light and Power via two (2) utility feeds. One service feeds

the existing WFP Building at 120/208V 3-phase via an aerial feed and is sized for 200 amps. The second service

feeds the booster pumps at 480/277V 3-phase via an aerial feed and is sized for 400 amps.

The existing 400-amp service for the Finished Water Pumping System was evaluated to verify if the system has

capacity to serve the PFAS upgrades, and it was determined to have adequate capacity. Therefore, this system will

be utilized to serve the new PFAS Treatment Building.

The existing 480/277V 3-phase aerial service may conflict with the proposed location of the new PFAS Treatment

Building and inhibit construction activities. Therefore, this aerial service may need to be relocated to accommodate

construction of the new PFAS Treatment Building. This will be further evaluated during the detailed design effort once

the exact location of the new building is confirmed.

Standby Emergency Power System

The existing WFP has A 35kW natural gas-engine-driven generator that provides standby emergency power to the

120/208V 3-phase service only via a 200A automatic transfer switch (ATS). The electrical distribution system for the

Finished Water Pumping System does not have standby emergency power available.

The existing generator does not have sufficient capacity to serve the PFAS upgrades and has exceeded its useful

life. Therefore, a new emergency generator will be provided to serve the entire site.

4.2 PROPOSED MODIFICATIONS

Electrical items proposed for the modifications to the Chestnut Street WFP are detailed in the following sections.

Electrical Distribution System

The 120/208V 3-phase electrical distribution system associated with the existing WFP will essentially remain

as-is except for the replacement of the existing ATS as outlined in Section 4.2.2.

The existing overhead utility feed that that serves the 480/277V 400A Finished Water Pumping System may

require replacement and/or relocation to accommodate construction of the new PFAS Treatment Building.

This will require further evaluation during the detailed design effort.

The new PFAS Treatment Building will be powered from the existing 480/277V Finished Water Pump

Distribution system. An existing/spare 125A enclosed circuit breaker located on the back side of the WFP

will be utilized to feed a new 480/277V Main Panelboard in the PFAS Treatment Building. The main panel

will be used to feed all 480V equipment within the new PFAS Treatment Building and will also feed a

120/208V panel via a dry-type step down transformer. The 120/208V panel will be utilized to feed

miscellaneous building loads, lighting, receptacles, HVAC equipment, instrumentation, etc.

A new structure/shed is being provided to enclose the existing Finished Water Pumping System which is

currently located outside and exposed to the elements. Several general use receptacles and LED lighting

will be provided in the shed and will be powered from the existing WFP electrical system.

Town of Hudson 4-1 Woodard & Curran

2021.05.10 Preliminary Design Report May 2021Standby Emergency Power System

The Contractor will be responsible for removal and disposal of the existing 35kW emergency generator.

The Town of Hudson will be responsible for procurement of a new Diesel-Engine-Driven Generator and

Automatic Transfer Switches to serve the entire site. Woodard & Curran will work closely with the owner

during the procurement process to ensure the new system meets the requirements of the project.

The Contractor will be responsible for offloading and installation of the owner furnished generator, providing

a full tank of diesel fuel for testing purposes, and coordination efforts required during the startup process.

The new generator will be utilized to provide emergency power to the existing 120/208V 3-phase distribution

system serving the WFP and the 480/277V 3-phase distribution system serving the Finished Water Pumping

System via two (2) new Automatic Transfer Switches (one for each distribution system).

The existing 120/208V 3-phase Automatic Transfer Switch (ATS) within the WFP electrical room will be

demolished and replaced with one of the new ATS’s. Due to space constraints at the site, the 400A breaker

that serves the Finished Water Pumping System will be removed to accommodate installation of the second

ATS. This ATS will be furnished as a Service Rated ATS will integral main breaker and will be installed in

the location of the existing/removed 400A main breaker.

The generator will be provided with an integral double-walled-diesel-belly-tank and will be mounted on a

new concrete pad. The tank will be sized for 48 hours of operation under full load.

The generator will be furnished with a sound attenuated enclosure.

The generator will be furnished with two circuit breakers to accommodate connection to the two services

and associated transfer switches.

Fire Alarm System

A fire alarm system is not required for this facility per code requirements. However, several heat and/or

smoke detectors will be provided within the new PFAS Treatment Building and connected to SCADA to

notify the owner in the event of a potential hazard.

Intrusion Detection

Intrusion switches will be provided for all man-doors and overhead doors in the new PFAS Treatment

Building and will be connected to SCADA for alarming purposes.

Lighting Systems

Interior and exterior lighting systems will be provided with energy efficient Light Emitting Diode (LED)

fixtures. Interior lighting systems will be controlled via local on/off switches, and exterior lighting will be

controlled via photocell, timeclock and H/O/A switch to provide a means to manually override the lights ON

or OFF. Emergency lighting will be provided for egress lighting in accordance with applicable life safety

codes.

Lightning Protection System

Due to the proposed height of the new PFAS Treatment Building, a lightning protection system is

recommended to protect the facility, personnel, and equipment from damage from potential lightning strikes.

The lightning protection system will be designed per NFPA 780 requirements, constructed, tested, and

certified to receive a UL master label.

Town of Hudson 4-2 Woodard & Curran

2021.05.10 Preliminary Design Report May 2021Materials of Construction

Conduit:

PVC Schedule 40 will be specified for all underground applications.

Rigid Galvanized Steel Conduit will be specified for all exterior above-grade locations.

Rigid Galvanized Steel Conduit will be specified for all installations within the PFAS Treatment Building.

Rigid Galvanized Steel Conduit will be specified for all installations within the Chestnut Street WFP.

EMT Conduit will be specified for all installations within the Finished Water Pump Building.

Rigid Galvanized Steel Conduit will be specified for all conduit stub-ups through the concrete slab within the

PFAS Treatment Building.

Supporting Devices:

All supporting devices, fasteners and hardware will be specified as Stainless Steel for use in all locations.

Enclosures:

Exterior - NEMA 4X

New PFAS Treatment Building – NEMA 4X

Chestnut Street WFP – NEMA 12

Finished Water Pump Building – NEMA 12

Town of Hudson 4-3 Woodard & Curran

2021.05.10 Preliminary Design Report May 20215. CONTROLS DESIGN

5.1 PROPOSED MODIFICATIONS

5.1.1.1 New PFAS Control Panel

A new PFAS Control Panel, will be provided for control and monitoring of process instrumentation and

control valves associated with the new PFAS treatment system. This Control Panel will be NEMA 4X rated.

The control panel will contain an Allen Bradley CompactLogix series remote I/O communications adapter

and associated I/O cards for all process control and monitoring of the new PFAS treatment system. All

control will be handled by the existing SCADA Control Panel in the Control Room in the existing treatment

building.

The PFAS control panel will interface with the following instrumentation and equipment in the new PFAS

treatment system:

a. Differential Pressure Switches on each GAC vessel assembly (provided by Vendor)

b. Pressure transmitters on each GAC vessel (provided by Vendor)

c. Pressure transmitters on the upstream and downstream of each GAC train

d. (4) Motor operated butterfly control valves (one each on GAC vessel influent piping and one on the

common effluent pipe from the GAC Vessel)

e. (4) Magnetic Flow Meters (one each on the GAC vessel influent piping and one on the common

Backwater influent to the GAC vessels)

f. New PFAS Treatment Building Temperature and Humidity Transmitters for monitoring of Building

environment.

5.1.1.2 Communications

A Fiber optic cable will be provided between the Chestnut Street WFP and the new PFAS treatment system

for SCADA Communications.

Town of Hudson 5-4 Woodard & Curran

2021.05.10 Preliminary Design Report May 20216. PLUMBING AND HVAC DESIGN

6.1 DESIGN STANDARDS

Proposed work will be designed using the following design standards:

780 CMR, Ninth Edition (Massachusetts State Building Code)

o Mechanical based on modified version of 2015 International Mechanical Code (IMC)

248 CMR 10.00, Massachusetts State Uniform Plumbing Code

6.2 PROPOSED WORK

6.2.1.1 HVAC

The following summarizes the HVAC design conditions for the new PFAS Treatment Building.

The 99% dry bulb (DB) temperature used for heating system design is 10ºF.

The spaces will typically be unoccupied.

6.2.1.2 Heating

Gas unit heaters will provide heat in the PFAS Treatment Building.

6.2.1.3 Ventilation

The new PFAS Treatment Building will be serviced by an exhaust fan. The exhaust fan will be mounted on the

building wall. The exhaust fan will be energized to provide general exhaust airflow at a speed selected at a wall

switch. The exhaust fan will also provide heat relief. When the building interior temperature exceeds 80°F, the fan

will energize (or increase in speed) to the design heat relief airflow. The exhaust fan will be sized to maintain the

building temperature at 10°F greater than ambient.

An intake louver and associated motor operated damper will be provided to allow outdoor air to enter the building.

The motor operated damper will be interlocked with the exhaust fan and will open when the exhaust fan is energized.

The louver will be in the building wall.

6.2.1.4 Dehumidification

Portable dehumidifiers will be provided for the new PFAS Treatment Building. The dehumidifiers will be used to

prevent condensation from forming on the pipes and GAC vessels during parts of the year.

6.2.1.5 Cooling

Cooling will be provided through the building’s exhaust fan.

6.2.1.6 HVAC Controls

Stand-alone electric/electronic controls will be provided for all heating and ventilation equipment. A standalone

thermostat will be provided and will be connected to the WFP SCADA system to notify the WFP if the building

temperature drops below 45°F.

6.2.1.7 Plumbing

Two floor drains will be provided for the building to capture any washdown or condensation from the GAC vessels.

The floor drains will be serviced by vent piping that will terminate at the building roof. The floor drain piping will exit

Town of Hudson 6-1 Woodard & Curran

2021.05.10 Preliminary Design Report May 2021the building and will drain to the nearby drywell. Plumbing materials will be per the Massachusetts State Plumbing Code, 248 CMR. Town of Hudson 6-2 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

7. ARCHITECTURAL DESIGN 7.1 SUMMARY OF EXISTING CONDITIONS The existing condition of the location of the new PFAS Treatment Building is a grassy lot surrounded by forested and wetland areas. Adjacent to the proposed building site are an existing greensand filtration building, an existing exterior pad-mounted temporary PFAS treatment system, an existing buried holding tank and an existing exterior pad- mounted generator. 7.2 EXISTING BUILDING The existing greensand filtration building will continue to be used with no modifications as part of this project. The existing building is approximately 100 ft x 48 ft with concrete masonry unit (CMU) exterior bearing walls and a wood roof. The occupancy group is Hazardous Group H-3 due to storage of hazardous chemicals which are chemically volatile and corrosive. The building is not sprinklered and has openings in the exterior walls which are presumed to be unprotected with respect to fire protection. Exterior cavity walls are 12-inch CMU with 4-inch split-face block veneer. 7.3 NEW PFAS TREATMENT BUILDING The proposed building is a 70 ft x 40 ft Pre-Engineered Metal Building (PEMB) with a fully-adhered EPDM rubber roofing system over rigid roof insulation. Prefinished insulated metal panels will be used in the exterior walls with rigid insulation at the concrete foundation to achieve energy code compliance. The foundation insulation will be covered with a fiberglass reinforced plastic (FRP) barrier to conceal and protect the rigid insulation. The roof will have a gable profile and 1:12 slope with gutters and downspouts. An 8’-0” x 8’-0” insulated steel coiling door will be provided. Future removal/replacement of GAC vessels will be via removable wall panels. The insulated metal panel wall construction will simplify removal and replacement of these panels should the need arise. The new building houses support equipment for drinking water filtration. While access for service and maintenance is required, the facility will not be a daily workplace for staff members. The building may be categorized as utility occupancy Group U. No interior partition walls are needed. Interior finishes will be prefinished metal panels full height of wall and the ceiling finish will be the underside of the galvanized metal roof deck. Galvanized steel rod bracing, purlins and girts will be exposed to view. The floor will be exposed, hardened concrete. Wall panel color(s) shall be selected by Owner. 7.4 LIFE SAFETY AND FIRE PROTECTION Per Massachusetts State Building Code the new building requires a minimum fire separation distance of 10 ft assuming Type VB construction. Due to unprotected openings in the east existing building wall and the H-3 Occupancy Group designation, a minimum fire separation distance of 15 ft is required at the existing building. The minimum total separation between the new and existing buildings is 25 ft and the new building may be constructed of combustible and non-combustible structural elements. Therefore, no fire-rated wall assemblies are required. The building will not be sprinklered. Two standard 3’-0” x 7’-0” man door exits are provided and are spaced to meet egress requirements. Town of Hudson 7-1 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

8. STRUCTURAL DESIGN

8.1 STRUCTURAL DESIGN CRITERIA AND STANDARDS

Proposed work will be designed using the following criteria, material properties and design standards:

780 CMR, Ninth Edition (Massachusetts State Building Code)

o 2015 International Building Code, Risk Category III

o American Society of Civil Engineers Minimum Design Loads for Buildings and Other Structures,

ASCE 7-10

Design strength of concrete: 4,500 pounds per square inch (psi) at 28 days

Reinforcing: ASTM A615, 60,000 psi minimum yield strength

Allowable Soil Bearing Pressure: 2,000 psf

Frost depth: 4-ft

8.2 PROPOSED WORK

The site improvements will include the following major components. GAC vessels for PFAS treatment will be

mounted to a concrete mat slab. The PEMB will house the GAC filtration system and will also be supported from the

mat slab.

New concrete foundation for PEMB and PFAS treatment system: Concrete Mat Slab with thickened

perimeter edge

Pre-engineered metal building

Demolition of existing exterior generator pad

New exterior generator pad in the same location

New Pump House Building for existing booster pumps

8.3 PRE-ENGINEERED METAL BUILDING

The PEMB will be designed, manufactured and installed by vendor. The primary structural system will be clear-span

rigid steel frames. Framing at the gable ends will be designated as post-and-beam type. Steel rod bracing will be

used to resist lateral loads in the longitudinal direction and at the gable end walls. Secondary framing includes roof

purlins and bypass wall girts to transfer roof and wall pressures to the primary structural system. The metal building

structural system will be galvanized steel.

A single concrete mat slab with thickened perimeter edge will be provided to support both the PEMB as well as

process piping and equipment. Frost protection is achieved by means of foundation insulation in accordance with

ASCE 32-01, Design and Construction of Frost-Protected Shallow Foundations. A perimeter underdrain will be

provided.

Town of Hudson 8-2 Woodard & Curran

2021.05.10 Preliminary Design Report May 20218.4 GEOTECHNICAL AND FOUNDATION CRITERIA A Geotechnical Engineering Report has been provided by Northeast Geotechnical, Inc. dated April 21, 2021, which provides more information of existing soil and groundwater conditions and can be found in Appendix D. The geotechnical report provides information regarding subsurface conditions, groundwater, excavations, and foundation design recommendations. Town of Hudson 8-2 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

9. PERMITTING

Woodard & Curran will prepare the following permit applications prior to the construction and activation of the new

PFAS treatment system:

Prepare and submit an application to the Massachusetts Historical Commission (MHC).

Prepare and submit a BRP WS 25 Application for Treatment Facility Modification to MassDEP for approval.

Prepare a DWSRF Pre-Bid Construction Contract Application Checklist and submit along with one copy of

the pre-bid construction contract (plans and specifications) to MassDEP for approval.

Prepare and submit a WPA Form 3: Notice of Intent for the Wetlands Protection Act to MassDEP for

approval.

Prepare and submit a Site Plan Application and Zoning Permit Application with the Hudson Planning and

Zoning Department.

Prepare and submit an Underground Injection Control (UIC) Permit to MassDEP for approval.

Town of Hudson 9-3 Woodard & Curran

2021.05.10 Preliminary Design Report May 2021APPENDIX A: PROJECT LOCUS MAP Town of Hudson 9-4 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

Gree

n sandF

iltra

tio

n

B

a ck

w ashLag oons

C

hestn

utW

ell 1

C

hestn

utS

tre

etW

FP

P

ropose

dP FAS

T

rea

tm entB

uild

ing

e

tre ig

tF re

u .a

s rx

p

T

empora

ryPFAS

utS

T

rea

tmentS

yste

m

ro

\P c

je \C

ts e

hstn

t

tree

m

te IS

\G

tS

y

CSs

u

A

1G

n

2

t

0

es

ip\2

h

\w

C

o

:\\woa

d c

rdu n

rra e

.n h

t\s re

a \P

d je

ro ts

c 2

\033

20.0

5 u

0Hdo

s F

A-P

nM A re

ST tm

a n

e y

tS e

sDs nB

ig d

id g

in

L

e g

end

dM axare

,a

M ie

croso

ilf

ting

ing

P

rop

ose P

FASTr tm n tB

u d

eUs

C

hestn

utS

tre

etW

FPP

arce

l

roe

brg

±

:s

ChestnutS treet

y

1B

PFAST reatmentS ystem

2

A ppen

d ixA

/2

0 0

Dep

artmen tofPu b licW o

rks

/2

:4

P

rojectLocusMap T

ownofHud so n

,M assach usetts

xpo d

rte

0 5

0 1

00 2

00

reE

Fe

et P

roje

ct# :0232

30 5 .00

u

MapC re

a te

d:April 2

021

ig

F

T

hirdP

artyG

ISD

is

cla

ime

r:Thism apisfo

rrefe

ren

cea

ndgra

phicalpurp

os e

so nlya ndshouldn

otb erelie

du po

nb yth

irdpartie

sfo

ran

yle

gald

ecis

ion

s.

An

yre lia

nceuponthemapo

rda

tacontain

edh ereins

h all b

eatth

eu sers

’solerisk

.D ataSourc

es :APPENDIX B: LIST OF SPECIFICATIONS Town of Hudson 1 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

0232305.00 Chestnut Street PFAS Treatment System

Issue Date: May 2021 Town of Hudson, MA

SECTION 00 01 10

TABLE OF CONTENTS

SPECIFICATIONS

Division 00 – Bidding and Contracting Requirements

To be determined after review of Town procurement documents.

Division 01 – General Requirements

To be determined after review of Town procurement documents.

Division 03 – Concrete

03 11 00 Concrete Forming

03 16 00 Concrete Specialties

03 20 00 Concrete Reinforcing

03 30 00 Cast-In-Place Concrete

03 30 20 Concrete Placing, Curing, and Finishing

Division 05 – Metals

05 50 00 Metal Fabrications

Division 07 – Thermal and Moisture Protection

07 21 00 Thermal Insulation

07 60 00 Flashing and Sheet Metal

07 92 00 Joint Sealants

Division 08 – Openings

08 11 00 Metal Doors and Frames

08 33 23 Overhead Coiling Doors

08 71 00 Door Hardware

Division 09 – Finishes

09 90 00 Painting and Coating

Division 10 – Specialties

10 44 16 Fire Extinguishers

Division 13 – Special Construction

13 34 19 Metal Building Systems

Division 22 – Plumbing0232305.00 Chestnut Street PFAS Treatment System Issue Date: May 2021 Town of Hudson, MA 22 00 00 Plumbing Division 23 – HVAC 23 05 00 Common Work Results for HVAC 23 05 15 Mechanical Identification 23 05 93 Testing, Adjusting, and Balancing for HVAC 23 34 00 HVAC Fans 23 82 39 Unit Heaters 23 84 16 Portable Dehumidifiers 23 90 00 Louvers and Vents Division 26 – Electrical 26 05 00 Common Work Results for Electrical 26 05 19 Low-Voltage Electrical Power Conductors and Cables 26 05 23 Control-Voltage Electrical Power Cables 26 05 26 Grounding and Bonding for Electrical Systems 26 05 33 Raceways and Boxes for Electrical Systems 26 05 43 Underground Ducts and Raceways for Electrical Systems 26 22 00 Low-Voltage Dry-Type Transformers 26 24 16 Panelboards 26 27 26 Wiring Devices 26 28 16 Enclosed Switches and Circuit Breakers 26 29 13 Enclosed Controllers 26 32 13.13 Diesel-Engine-Driven Generator Sets 26 41 00 Facility Lightning Protection 26 43 00 Surge Protective Devices 26 51 00 Interior Lighting Division 27 – Communications 27 00 00 Communications Division 31 – Earthwork 31 00 00 Earthwork 31 10 00 Site Clearing Division 32 – Exterior Improvements 32 12 16 Asphalt Paving 32 16 13 Curbs and Gutters 32 92 19 Seeding Division 33 – Utilities 33 01 10.58 Disinfection Water Utility Piping Systems 33 14 11.01 Water Utility Piping – Ductile Iron 33 14 19 Valves and Hydrants for Water Utility Service

0232305.00 Chestnut Street PFAS Treatment System

Issue Date: May 2021 Town of Hudson, MA

33 49 00 Storm Drainage Structures

Division 40 – Process Integration

40 00 00 Basic Process Materials and Methods

40 05 13 Process Pipe and Fittings

40 05 15 Process Pipe Supports

40 05 23 Process Valves

40 61 01 Instrumentation & Controls General Requirements

40 63 43 Programmable Logic Controllers

40 67 00 Control System Equipment Panels and Racks

40 70 00 Instrumentation for Process Systems

Division 46 - Water and Wastewater Equipment

46 61 13.01 Granular Activated Carbon

46 61 35 Granular Activated Carbon Vessels

END OF SECTIONAPPENDIX C: EQUIPMENT SUMMARY Town of Hudson 2 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

0232305.00 Chestnut Street PFAS Treatment System

Issue Date: May 2021 Town of Hudson, MA

APPENDIX C

EQUIPMENT SUMMARY

The following is a list of major equipment to be installed as part of this project, and manufacturer’s cut sheets are

attached to this appendix.

Table B-1: Equipment for Chestnut Street PFAS Treatment System

Item Equipment

Location Quantity Manufacturer Model Number Design Criteria

No. Name

GAC PFAS

3 Trains TIGG Corp CP-40K-12 40,000-lb dual

1 Adsorption Treatment

(6 Vessels) or Equal or Equal vessel

System Facility

PFAS

2 Generator Treatment 1 Milton CAT TBD TBD

Facility4 3 2 1

N6

N3

VENT EL. 294"

OPTIONAL

M1

CARBON FILL EL. 2791 2"

90°

B N3 B

N1

N6

N4

N11

N10

N9

144"Ø

N8

80" 78" 180° M2 N1 N2 0° 107"

268" M1 N6

N7

N8

N4

N9 216"

N11 SAMPLE - 4 2" 150# FLANGE SIDE SHELL

N10

N10 SAMPLE - 3 2" 150# FLANGE SIDE SHELL

M2 N9 SAMPLE - 2 2" 150# FLANGE SIDE SHELL

N11 N8 SAMPLE - 1 2" 150# FLANGE SIDE SHELL

N2 11 4" N7 DRAIN 2" 150# FLANGE BOTTOM HEAD

128"

120" ANCHOR HOLE N6 VENT 3" 150# FLANGE TOP HEAD

110" 270° N5 CARBON OUT 4" 150# FLANGE BOTTOM HEAD

92" N4 CARBON OUT 4" 150# FLANGE SIDE SHELL

80" 107"

74" N3 CARBON IN 4" 150# FLANGE TOP HEAD

64"

N2 OUTLET 8" 150# FLANGE SIDE SHELL

PLAN N1 INLET 8" 150# FLANGE SIDE SHELL

M2 MANWAY 20" 150# FLANGE W/ BLIND SIDE SHELL

141 16" M1 MANWAY 14"x18" ELL. MANWAY TOP HEAD

N5 MARK SERVICE DESCRIPTION LOCATION

N7 NOZZLE SCHEDULE

REVISION HISTORY

ELEVATION REV

0

DESCRIPTION BY DATE

PROJECT

A VESSEL STANDARDS: A

VESSEL MATERIAL: SA-516-70

CK-40K-12

TIGG LLC.

• HEAD THICKNESS: 5/8" HEAD TYPE: 2:1 ELLIPTICAL

• SHELL THICKNESS: 5/8"

COATINGS:

• INTERIOR LINING: PLASITE 4110 – DFT 35-45(MAX) PROJ. NO. STANDARD

• EXTERIOR COAT: EPOXY BASE W/ URETHANE TOP PO. NO.

INTERNALS: THIS DRAWING AND DESIGN ARE THE PROPERTY OF TIGG LLC.

AND SHALL NOT BE REPRODUCED IN WHOLE OR IN PART.

• 304 STAINLESS STEEL NOR EMPLOYED FOR ANY PURPOSE OTHER THAN

VESSEL PROPERTIES: SPECIFICALLY PERMITTED IN WRITING BY TIGG LLC. THIS

DRAWING LOANED SUBJECT TO RETURN BY DEMAND.

• MAWP: 125 PSIG / -15 PSIG AT 150 f

• EMPTY SHIP WEIGHT: 25,500 LBS

DRAWN BY JB GENERAL ARRANGEMENT

DESIGN BY JB

• TOTAL VESSEL VOLUME: 1,866 FT³ CHECKED BY BB

DATE

SCALE

4/12/2017

NTS CP-40K-12-GA-001 0

4 3 2 1APPENDIX D: GEOTECHNICAL REPORT Town of Hudson 3 Woodard & Curran 2021.05.10 Preliminary Design Report May 2021

GEOTECHNICAL ENGINEERING REPORT

PROPOSED GAC FILTER BUILDING

72 CHESTNUT STREET

HUDSON, MA

Prepared For:

Woodard & Curran

40 Shattuck Road, Suite 110

Andover, MA 01810

Prepared By:

Northeast Geotechnical, Inc.

166 Raymond Hall Drive

North Attleborough, MA 02760

Project No. O425.00

April 21, 2021April 21, 2021 Project No. O425.00

Srivalli B. Sukuru, P.E.

Project Engineer | Associate Principal

Woodard & Curran

40 Shattuck Road, Suite 110

Andover, MA 01810

SUBJECT: Geotechnical Engineering Report

Proposed GAC Filter Building

72 Chestnut Street

Hudson, MA

Dear Valli:

Northeast Geotechnical, Inc. is pleased to present the results of our geotechnical engineering studies

performed in support of the proposed building project at the subject site. The purpose of our studies

has been to assess the subsurface soil and groundwater conditions in the area of the proposed building

and based on our findings, provide geotechnical engineering recommendations for use by the project

team in design and construction. Our studies have been performed in accordance with our proposal

dated February 2, 2021. This report is subject to the Limitations and Service Constraints included in

Appendix A.

We have prepared recommendations for use in planning and performing earthwork construction

activities to support the proposed building using standard spread footing foundations and a floor slab

on grade.

The attached report contains a summary of our studies and presents our findings, conclusions and

recommendations for use in design and construction of the proposed project. Please feel free to contact

Glenn A. Olson, P.E. at 508-274-0887 or at golson@northeastgeotechnical.com if you have any

questions or need anything further.

Sincerely,

Northeast Geotechnical, Inc.

Christian B. Rice, P.E. Glenn A. Olson, P.E.

Senior Project Engineer Principal EngineerTABLE OF CONTENTS

1.0 INTRODUCTION .................................................................................................................. 1

2.0 SUBSURFACE EXPLORATIONS......................................................................................... 1

3.0 LABORATORY TESTING..................................................................................................... 2

4.0 SUBSURFACE CONDITIONS .............................................................................................. 3

5.0 CONCLUSIONS AND RECOMMENDATIONS .................................................................. 3

5.1 Building Area Earthwork ............................................................................................... 3

5.2 Off-Site Fill Materials .................................................................................................... 5

5.3 Foundations .................................................................................................................... 6

5.4 Floor Slab ....................................................................................................................... 7

5.5 Seismic Design Criteria .................................................................................................. 7

6.0 CONSTRUCTION OBSERVATION, TESTING AND REVIEW ......................................... 7

FIGURE

1 Subsurface Exploration Location Plan

APPENDICES

A Limitations and Service Constraints

B Test Boring Logs

C Laboratory Soil Test Results

iYou can also read