TECHNICAL ARTICLE - The Permanent Way Institution

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

TECHNICAL ARTICLE

AS PUBLISHED IN

The Journal January 2018 Volume 136 Part 1

If you would like to reproduce this article,

please contact:

Alison Stansfield

MARKETING DIRECTOR

Permanent Way Institution

alison.stansfield@thepwi.org

PLEASE NOTE THE OPINIONS EXPRESSED IN THIS JOURNAL

ARE NOT NECESSARILY THOSE OF THE EDITOR OR OF THE

INSTITUTION AS A BODY.TECHNICAL

Studs and squats: AUTHOR:

Stuart L Grassie

BE, MEngSc, PhD, CEng, MIMechE, FPWI

A best practice approach Stuart Grassie Engineering Ltd

This paper was previously published in This paper is based on field work undertaken work, and accordingly also no significant

“Studs and squats: the evolving story”, primarily in NSW to reveal some of the depth of compressive residual stress. These

Wear, vol 366-367, pp194-199, 2016 (also characteristics of stud defects, in particular characteristics are very different from classical

Procs of 10th Intnl Conference on Contact in contrast to rolling contact fatigue (RCF) of squats.

Mechanics and Wear of Rail/Wheel which squats are a classical example. Studs

Systems, Colorado Springs, USA, August are associated with sites where there is high Although some transverse defects (TDs) have

2015). traction, such as the exit from stations. In been associated with studs, both gauge corner

NSW, they commonly initiate at about 10 0 -20 0 cracking (GCC) and studs have coincided in

The paper provides some guidance on to the vertical towards gauge on the high rail all of the cases examined. In these cases, the

treatment and maintenance of studs as well in curves, then grow into the rail at an angle TD has clearly developed in the conventional

as updating a hypothesis that still rests of about 20 0 to the surface. Studs can at first and well understood manner from the GCC.

substantially on circumstantial evidence. develop very quickly e.g. to a depth of 2.2mm The stud has given rise to a dynamic load

in 6MGT. The stud fans out across the rail from that accelerates growth of the TD. But if the

ABSTRACT the initial surface crack, developing across the GCC had not existed, the TD would not have

rail at a substantially constant depth of 3-6mm. developed.

Several railways suffer from a defect that If the stud is left, it may rise to the surface at

has been christened a “stud” which appears the opposite side of the railhead, giving rise to INTRODUCTION

superficially similar to a squat but is very an ugly spall with a fracture surface typical of a

different in character. Although both conventional fatigue crack. This paper follows a pair of papers[1, 2] that

initiation and propagation of studs are poorly examined the current state of understanding

understood, at least a couple of railways have There is no evidence whatsoever that studs of “squat-type defects” in rails and proposed

already benefitted from exploiting the less become transverse defects, nor should this that there existed a defect that was

malevolent nature of studs, particularly the fact occur with a crack that develops across rather commonly confused with a squat but was in

that these do not themselves initiate transverse than along the rail as there is an absence of fact significantly different. In order to avoid

defects. flexure to drive the crack. Studs have grown confusion, this defect was given the less

in rails in which there is no significant plastic appealing name of a “stud”. The original work[2]

was based primarily on analysis of defects

from London Underground (LU), where studs

on some lines were the most prevalent type of

rail defect. These defects have subsequently

been given a lower priority for treatment on

at least some of LU with significant savings in

maintenance and apparently, no increase in

risk.

Studs are apparently also widespread in

Australia, where these have been examined,

for example, as part of the CRC for Rail

Innovation[3]. A considerable body of work on

these defects exists from research groups in

the Netherlands and France[4, 5]. Although the

defects [2 - 5] appear substantially identical, the

author and his colleagues have differed from

others working in this area in concluding that

these are not RCF defects.

A substantial body of work has been

undertaken by staff of RailCorp and successor

organisations, primarily Sydney Trains and the

Asset Standards Authority (ASA), on defects

that they have called “lamination defects”

(LDs)[6]. This has included, amongst other

things, very thorough monitoring of individual

defects over a period of years, documentation

Figure 1: Stud that has spalled out

16TECHNICAL

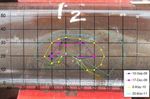

Monitoring is described in more detail in

reference 6. The development of the crack

front for a typical stud at Chatswood is shown

in figure 3. The green dotted line in this Figure

shows the visible crack mouth. Evidently the

crack has initiated at the rail surface towards

the gauge corner then “fanned out” towards the

field side of the rail.

This is remarkably similar to the pattern shown

for supposed “normal squat development” in

reference 7.

Figure 2: Multiple studs with unusual development The author was a co-author of reference 7,

albeit not of this section of the document, and

would suggest that the document exemplifies

of the occurrence of defects and factors Beach marks that are typical of conventional

the confusion of studs and squats, and the

that appear to affect their development, and fatigue are apparent on the fracture surface,

need for a clear differentiation of two very

examination of the extent to which defects can and the defect extends from the gauge corner

different rail defects, see figure 3.

be detected using the ultrasonic test train that right across to the field side of the rail. There is

is used on the NSW system. no sign of the defect having turned down, see

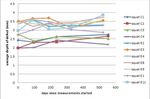

The average depth of the crack front has been

figure 2.

calculated for 4 studs at Chatswood and 7 at

The paper provides some guidance to

Erskineville, and is shown as a function of time

differentiate studs from squats and proposes Although the features shown in figure 1 are

in figure 4. There is a consistent difference in

measures regarding treatment of studs. The by far the most common, studs do develop in

depth between the sites (a range of 2.06-

evidence in NSW, as in London, has been other ways. For example, the defects shown in

2.62mm and 3.00-3.37mm in mean depth for

that studs do not initiate broken rails. This figure 2 were in the high rail of a curve on the

Chatswood and Erskineville respectively) but

remains the case. Some progress is made uphill approach to signals where many trains

no significant change in depth with time. See

on a hypothesis for studs that is as yet poorly would stop. These appear to have initiated

figure 4.

developed. towards the field side of the rail and developed

towards gauge. The line along which defects

Overall the measurements suggest that the

This paper is based on work done by the initiate is probably the preferred line along

defects develop at a roughly constant depth,

author as part of a project, initially for Railcorp, which the wheels run that initiate the defects in

substantially across (not along) the rail. This

to review previous work on LDs and to advise these conditions of e.g. high traction, high cant

is very different from a squat. The rate of

in certain areas. It includes work undertaken excess.

growth of depth is also very much greater than

by his colleagues in NSW that was part of that

that of an RCF defect: a not atypical defect at

review. Nevertheless, the views contained here Similar behaviour of a preferred line of initiation

Chatswood developed from 0mm to 2mm depth

are those of the author alone. of studs has been noted on rails from at least

in 6MGT while one at Erskineville developed

one, very different, system. Evidently the

from 0.9mm to 3.5mm depth in 7MGT.

MONITORING OF DEFECTS detailed tangential contact stresses, arising

probably from both curving and traction,

Metallurgical examinations have shown that

Some characteristics of studs and differences influence crack growth.

cracks grow initially at about 20 to the rail

between these studs and GCC are highlighted

surface towards the field side of the rail from

here, see figure 1. A well-developed stud that Comprehensive monitoring of individual stud

gauge. A possible explanation of this behaviour

has spalled out is shown in figure 1, in which defects had been undertaken over a period of

is that the crack grows under the relatively

traffic is towards the left and gauge corner to about 18 months by RailCorp staff at sites at

shallow sub- surface layer of compressive

the bottom. Some general characteristics of Chatswood (14MGT p.a., 1010m radius) and

residual stress. Although plastic working of

studs are apparent here, including the inverted Erskineville (13MGT p.a., 402m radius) on the

the material is required to develop residual

V towards the gauge corner, where the stud suburban network[6]. Studs at both sites were

stress, and some studs develop in almost virgin

initiates. In NSW this is typically at 10 0 -20 0 to in 60kg/m head-hardened rail in the high leg of

rail, in older rails (such as those shown here),

vertical towards gauge. the curves. Monitoring included photography

there would be a layer of compressive residual

and detailed measurements of depth using a

stress.

hand-held ultrasonic gauge.

Figure 4: Variation of average defect depth with time

Figure 3: Growth of individual stud (13-14MGT p.a. of traffic)

17TECHNICAL

an indentation that increases dynamic loading.

The localised dynamic loading has increased

flexural stresses, thereby accelerating

propagation of the fatigue crack from RCF.

The character of studs and typical GCC is such

that confusion between the two is unsurprising.

For example, a rail with a couple of studs and

coincident, light GCC is shown in figure 6.

One “leg” of the surface-breaking crack on

each stud is at almost the same angle as

the GCC, and the dark spot is clear from the

depressed layer over each stud. It would be

easy to conclude from casual observation that

there was a single problem here, whereas

Figure 5: Transverse defect associated with stud: note coincident RCF in there are in fact two problems that appear

running band to have completely different origins, which

develop at very different rates, in substantially

different directions and with different

TRANSVERSE DEFECTS, RCF cracks. Coincidentally the running band has consequences.

broadened where a crack has grown sub-

AND STUDS

surface towards the field side of the rail. The author has examined several TDs that

It had been noted in both Australia[8] and the have been associated with studs from two

What appears to have happened at this different railway systems. In every case these

UK [2] that transverse defects (TDs) were not

location is that an RCF crack has initiated share the features shown in figure 5.

associated with studs, although TDs are a

at the rail surface, developed longitudinally

common occurrence with RCF that is not

(doubtless under the influence of water), turned The stud is significant because it has

maintained or eliminated. In the last few years

down on reaching the edge of the layer of accelerated development of the TD. However,

there has been some association of TDs with

compressive residual stress and developed if there had not been RCF in the rail or if RCF

studs that may call the apparently benign

into a TD under the influence of flexural had been controlled e.g. by routine reprofiling

nature of studs into question. To examine this,

stresses in the rail. This mechanism is well and a modified profile that relieved the area

a TD that has been associated with a stud is

understood. At the same location, a stud has in which RCF is initiated, the TD would not

shown in figure 5.

developed (for reasons that are as yet poorly have occurred. Growth of a stud across the

understood). rail would not and does not result in a TD.

The fracture surface of this defect has the

characteristic appearance of a break that It nevertheless presents a risk because a

This has developed substantially across (rather stud could conceal a conventional TD from

has occurred from an RCF crack that has

than along) the rail. The large sub-surface ultrasonic inspection. RailCorp and their

developed longitudinally and then turned

crack has resulted in a thin, poorly supported contractor for ultrasonic inspection have made

down into the rail. Moreover, the rail surface

surface layer that has deformed and caused significant progress in identifying studs[6].

is covered in relatively closely-spaced RCF

Further progress appears likely in this area

even if relatively little is known about the

detailed development of these defects. It is

particularly important to develop a routine

method of distinguishing studs from genuine

TDs, whose signature is very similar, see

figure 6.

RAIL TYPE, REPROFILING AND

STUD DEVELOPMENT

It has been noted that studs are less prevalent

in standard carbon than in head-hardened rail

on the NSW system [6]. Evidence for this was

also noted during this project. Photographs

in figures 7 are from a curve that was being

rerailed because of defects. The SC rail

in this curve, from 1995, is free of defects

whereas HH rail only 11m away in the same

high rail of the curve, rolled in 2002, is

riddled with defects. This behaviour is quite

contrary to what would be expected for RCF

defects, provided routine reprofiling had been

undertaken to a profile that did not increase

contact stresses, see figures 7a and 7b.

A possible explanation for the different

propensity for defects in different types of rail

steel is that rail wear is higher in the softer rail.

This could also act as a guide to the extent

Figure 6: Rail with light GCC and coincident studs of reprofiling required to keep defects at bay.

18TECHNICAL

propagate across the rail and often rise to

the rail surface beyond the running band to

cause an ugly spall suggests that compressive

residual stress influences crack growth and

that the crack may grow under the layer of

compressive residual stress. Unfortunately,

this hypothesis remains both tentative and

poorly developed.

Illustrations of different propensity of defects to occur in HH rail ACKNOWLEDGEMENTS

Figure 7a: Quasi-continuous defects in 2002 HH rail at 1.741km, high rail

The author is grateful to RailCorp for funding

the study and for their tentative permission to

publish the paper. He is indebted to Malcolm

Kerr, Andrew Wilson and David Cooper,

whose enthusiasm, openness and generosity

contributed greatly to this project. Others

contributed to this work, but the opinions and

omissions are his alone.

REFERENCES

[1] SL Grassie, “Squats and squat-type defects

Figure 7b: Defect-free 1996 SC rail at 1.730km, high rail in rails: the understanding to date”, Journal

of Rail and Rapid Transit, Procs of I mech E,

To this end a very preliminary examination understood and has been studied exhaustively. 2012, 226F, 235-242.

was made to correlate metal removal with the On the other hand, the stud develops across

presence of defects in head-hardened rail. the rail, slightly below the surface, thereby [2] SL Grassie, DI Fletcher, AE Gallardo-

Notwithstanding the limitations of the data causing a depression that exacerbates Hernandez and P Summers, “’Studs’: a

there was a tendency for defects to have dynamic loading. The high dynamic loading squat-type defect in rails”, Journal of Rail and

developed where MR was low and for there to accelerates development of fracture from the Rapid Transit, Procs of I mech E, 2012, 226F,

be no defects where MR was relatively high. RCF. However, in the absence of RCF the 243-256.

If an attempt were made to implement these stud itself would not develop into a rail break.

findings in a reprofiling programme to control This problem is treated most successfully by [3] WJT Daniel, S Pal and M Farjoo, “Rail

studs, the indication was that MR rates of at reprofiling to control the development of RCF. squats: progress in understanding the

least 0.025mm/MGT would be required and Australian experience”, Journal of Rail and

less than 0.020mm/MGT would be inadequate. The common morphology of a stud is for it to Rapid Transit, Procs of I mech E, 2013, 227F,

Routine preventative reprofiling may in practice initiate towards the gauge side of a rail, at an 481-492.

be extremely difficult given the experience of angle of about 10 0 -20 0 to gauge. The crack

rapid stud growth e.g. at Chatswood from 0mm grows initially into the rail at about 20 0 to the [4] Z Li, R Dollevoet, M Molodova, X Zhao,

to 2mm depth in 6MGT. A second possible rail surface to a depth of 3-6mm, then fans “Squat growth – some observations and the

explanation of the behaviour is given by the out from the point at which it initiates, mainly validation of numerical predictions”, Wear,

work of Joerg and his co-authors[9]. This work across but to some extent also along the rail in 2011, 271, 148-157.

tentatively suggests that a narrow band of both directions. The depth of the crack remains

high tensile residual stress may exist in some substantially constant. A well- developed [5] S Simon, A Saulot, C Dayot, X Quost, Y

circumstances at the edge of the running band. stud may rise to the surface of the field side of Berthier, “Tribological characterisation of rail

This band would tend to be more concentrated the rail, perhaps when it extends beyond the squat defects”, Wear, 2013, 297, 926- 942.

on a harder rail as the contact would broaden layer of compressive residual stress. Different

less as a result of plastic deformation. The characteristics, in particular a different initiation [6] M Kerr, A Wilson, S Marich and S

high tensile residual stresses could initiate the point across the rail and different growth Kaewunruen, “Wheel/rail conditions and squat

cracks from which studs propagate. pattern, are associated with different wheel/rail development on moderately curved tracks”,

contact conditions and tangential tractions. CORE 2012, Brisbane, 10-12 September 2012.

CONCLUSIONS

Studs are less common in standard carbon [7] “Rolling contact fatigue in rails: a guide to

Observations are recorded from field than in head hardened rail. A possible reason current understanding and practice”, Railtrack

investigations undertaken on the NSW railway for this is a higher wear rate of the softer rail. plc, RT/PWG/001 Issue 1, February 2001.

system of rail defects that have been called There is evidence that studs do not develop

“studs”. It is clear from these observations that in head hardened rails if the wear rate is [8] M Kerr, A Wilson and S Marich, “The

studs are not rolling contact fatigue and that sufficiently high. A very simplistic analysis epidemiology of squats and related rail

they differ significantly from RCF. suggests that few defects exist if the metal defects”, CORE 2008, Perth, 7-10 September

removal rate is more than 0.025mm/MGT 2008.

Of critical importance for the safety and whereas studs are prevalent at sites with a

integrity of the railway, there is as yet no metal removal rate of less than 0.020mm/MGT. [9] A Joerg, R Stock, S Scheriau, HP Brantner,

evidence that transverse defects propagate B Knoll, M Mach, W Daves, “The squat

from studs. Although TDs have been The evidence remains that these defects condition of rail materials – a novel approach to

associated with studs, the evidence in all initiate from wheelslip, and possibly from squat prevention”, Procs of 10th International

cases is that TDs have occurred where thermally transformed material that is the Conference on Contact Mechanics and Wear

RCF and studs coincide. The TD develops result of wheelslip. The different morphology of Rail/Wheel Systems, Colorado Springs,

from propagation of RCF, which is initially of defects in areas in which tangential USA, 2015.

substantially longitudinal. Once the RCF turns tractions differ significantly suggests that the

down into the rail, it develops as a result of defects grow under the influence of tangential

flexural stresses. This mechanism is well tractions. The fact that defects usually

19thepwi.org

Journey with us

FaceBook: PermanentWayInstitution

Twitter: @PermWayInstit

LinkedIn: Permanent Way Institution

You Tube: The PWI

Instagram: @the_pwiYou can also read