Evaluation of the applicability of different viscoelasticity constitutive models in bamboo scrimber short-term tensile creep property research

←

→

Page content transcription

If your browser does not render page correctly, please read the page content below

Science and Engineering of Composite Materials 2021; 28: 363–371

Research Article

Sun Songsong and Wan Maosong*

Evaluation of the applicability of different

viscoelasticity constitutive models in bamboo

scrimber short-term tensile creep property

research

https://doi.org/10.1515/SECM-2021-0034 the modern industry [2–4]. Thus, the correct determina-

received January 19, 2021; accepted June 02, 2021 tion of the mechanical properties of this material becomes

Abstract: Bamboo scrimber is a new natural fiber-rein- important during the design stage.

forced composite material in modern industry. In this To solve this problem, creative work has been con-

paper, the tensile creep characteristics of this material ducted in recent years. For example, He Wen investigated

were chosen as the object of the study. First, axial tensile the mechanical performance of bamboo scrimber made

fracture experiments were conducted on different test spe- from a given type of moso bamboo and treated it with hot

cimens to determine the corresponding strength data. oil [5]. Naresworo Nugroho chose zephyr strands from

Then six sets of standard tensile creep experiments were another type of moso bamboo to make a structural com-

conducted under different given stress levels. Finally, the posite board [6,7]. Huang et al. examined how the acceler-

Maxwell constitutive model was applied in fitting the rela- ated aging method and aging resistance influence the

tionship between strain and time. The results showed that performance of bamboo scrimber and conducted mechanic

the traditional Maxwell viscoelasticity constitutive model experiments on a double cantilever beam and an end-

will result in some errors in the fitting results, while the notched beam [8–10]. Li and Wei conducted an experi-

combined fractional and Maxwell model can provide much mental study on the deformation and failure mechanism

higher accuracy in this study, thus it is more suitable for of bamboo scrimber and proposed an axial stress–strain

engineering applications. This paper provides a solid foun- model [11–13]. According to previous research, a primary

dation for a better understanding of the mechanism of the conclusion can be proposed that bamboo scrimber is a

bamboo scrimber creep behavior. typical kind of plywood. According to the theory of visco-

elastic mechanics, this kind of material always shows obvious

Keywords: bamboo scrimber, fractional derivative, ten- creep characteristic, which has an obvious impact on the

sile creep, viscoelasticity constitutive model service life [14–16]. While in a previous study, this material

is usually considered to be an anisotropic elastic material,

special creep property research of the bamboo material

experimental results has rarely been discovered in the pub-

1 Introduction lished documents.

In this paper, axial tensile fracture experiments were

Bamboo scrimber is a new natural fiber-reinforced com- conducted on different test specimens to determine the

posite material that has been developed in recent dec- corresponding strength data. Then six sets of standard

ades [1]. This material has several advantages (e.g., low tensile creep experiments were conducted under different

cost, green, clean, and low weight) that make it usable in given stress levels. Finally, the Maxwell viscoelasticity

constitutive model was applied in fitting the relationship

between the strain and serving time. The results showed

* Corresponding author: Wan Maosong, Vehicle Engineering, that the traditional Maxwell viscoelasticity constitutive

College of Automobile and Traffic Engineering, Nanjing Forestry

model will result in some errors in the fitting results,

University, Nanjing, 210037, China, e-mail: 513194484@qq.com

Sun Songsong: Vehicle Engineering, College of Automobile and

while the combined fractional and Maxwell model can

Traffic Engineering, Nanjing Forestry University, Nanjing, 210037, provide much higher accuracy in this study, and thus is

China more suitable for engineering applications.

Open Access. © 2021 Sun Songsong and Wan Maosong, published by De Gruyter. This work is licensed under the Creative Commons

Attribution 4.0 International License.364 Sun Songsong and Wan Maosong

2 Method

In the present short-term creep experiments of the fiber-

reinforced composites, the load applied on the specimen

is always determined by the limit strength of the material

(usually the range is no more than 70%). According

to a previous study, some of the mechanical property

parameters of the bamboo scrimber such as the tensile

strength or young’s modulus always show obvious dis-

persion. As a result of this, it is necessary to conduct a

statistical analysis to obtain the distribution property of

the tensile strength before the creep experiment. So the

whole process of the research can be divided into five

steps:

Step 1: Conduct the standard tensile fracture experi-

Figure 1: The experimental equipment.

ment on a set of a specimen to determine the tensile

strength in each case.

Step 2: Choose three commonly used distribution According to the analysis in the previous chapter, the

models to fit the distribution function between the tensile first step of the statistical analysis is to conduct the frac-

stress and the survival rate. Then the tensile stress under ture experiment of the bamboo scrimber. Figure 1 shows

50% survival rate based on the most accurate function is the structural features of the tensile test equipment, from

selected to be the tensile strength. which it can be found that the whole piece was fixed at

Step 3: Conduct the standard short-term tensile creep both ends, and a pair of strain gages were affixed on both

experiment under six different stress levels (from 10 to sides of the specimen. During the experiment process, a

60% of the tensile strength) and record the strain during steady increased tensile force was applied on it until the

the experiment. final fracture.

Step 4: Choose different viscoelastic constitutive models During the whole experimental process, the mes-

to fit the variations of the strain with time to make a com- sages such as the load and displacement were recorded

parative study. In this way, the most accurate model can be using a computer. The experiment was conducted using

determined for further study. the UTM5504-GD microcomputer-controlled test equip-

ment and the serial number of the experiment standard

applied in this case is ASTM D143-09. During the experi-

ment, the temperature is 25°C and the relative humidity is

set to 60%. Using this equipment to conduct the tensile

3 Results test on a set of given specimens, the results are presented

in Table 1:

3.1 The tensile fracture experiment results

In this paper, the bamboo scrimber material was manu- Table 1: The experimental results of the tensile fracture test

factured by a cold-pressing technology. In the first stage

Case Width Thickness Limit Tensile

of this approach, the fibers were immersed in the phenol

number (mm) (mm) tensile strength

resin under high pressure. Then in the second stage, the

load (N) (MPa)

fibers were dried and put into the steel box and com-

pressed to a standard density. The pressure in this stage 1 9.05 5.00 5,239 110.3

2 9.21 5.04 8,314 175.1

is 22 MPa. Finally, in the third stage, the whole mold was

3 9.49 5.15 9,380 197.5

fixed by a set of bolts and placed in an oast house for 12 h. 4 9.33 5.06 6,336 133.4

In this way, the fibers were recombined into a piece to 5 8.97 5.12 6,430 135.4

provide the manufacturing material of the specimen. The 6 9.21 5.05 7,882 165.9

source of the fiber is a kind of phyllostachys pubescens. 7 9.46 5.08 8,751 184.2

8 9.40 5.10 7,749 163.1

The density of this material is 1.08 × 103 kg/m3 and the

9 9.39 5.09 6,949 146.3

moisture content is 5.6%.Applicability of different viscoelasticity constitutive models in bamboo scrimber 365

According to ref. [17], the primary factor of deciding

whether the data can be taken into further analysis is the

coefficient of variation. According to the experiment stan-

dard demands, the value of CV in a set of given data

should not be more than 20% before analysis. In this

paper, the value of this parameter is 17.7%, which can

fulfill the demands of accuracy.

3.2 Statistical analysis of the tensile

strength

In this paper, three kinds of usual distribution functions

in actual engineering applications are applied to make

a comparative study. From the perspective of the best Figure 2: Fitting results of failure rate distribution of the tensile

fitting effect, the constraint function is equivalent to strength.

varying the fitting parameters to obtain the maximum

value of the fitting correlation coefficient. Table 2 and

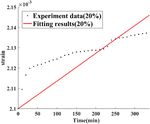

Figure 2 show the fitting results based on these three 200 N/s and then reduced to 0. Then the static creep load

functions, from which it can be discovered that the fitting was applied to the specimen. For each specimen, the load

errors of the three models are all less than 5%, which is lasts for 6 h.

sufficient for actual engineering application. In addition, As shown in Figure 3, the strain was recorded by an

the estimated values of statistical parameters based on extensometer fixed at the middle part of the specimen

different models are nearly the same, especially for the with the smallest cross-section. The standard of the creep

expected values (the relative difference is less than 2%). experiment applied, in this case, is ASTM D2990-17.

So the tensile strength under the 50% survival rate is During the experiment, the sampling frequency is set to

determined to be 155 MPa. be 1 min.

Table 3 shows the detailed load information of the

creep experiment. Based on the above stress level, six

groups of experiments were conducted. Corresponding

3.3 Tensile creep experiment results experimental results are shown in Figure 4 and Table 4.

The initial strain refers to the strain recorded at the begin-

Based on the strength parameter obtained in the previous ning of the creep experiment, while the final strain refers

section, the creep experiment can be conducted. During to the strain recorded at the end of the experiment. From

the experiment, the temperature and humidity are fixed these six curves, a clear conclusion can be proposed that

to be the same as those in the tensile fracture experiment. the curves of the low-stress level (10 and 20% of the

Before the creep experiment, two load cycles have been tensile strength) are nearly horizontal. The relative incre-

applied on the specimen for a pretreatment, during which ments in both cases are less than 2%, which means that

the load was increased from 0 to 7 kN with the speed of the whole amount of strain was mainly made up of the

Table 2: Fitting functions of failure rate distribution of the tensile strength

Model type Distribution function Estimated value of a statistical parameter Correlation coefficient

Normal μ = 155.7 0.983

y=Φ − ( x − 155.7

29.2 ) σ = 29.2

Lognormal y = Φ (− μ = 152.9 0.966

)

ln x − 5.03

0.2

σ = 29.4

Three-parameter Weibull μ = 156 0.979

y = 1 − exp (1 − ( )

x − 93.9 3.11

72.9 ) σ = 28.6366 Sun Songsong and Wan Maosong

Figure 4: The strain history during the creep experiment.

Figure 3: The creep experiment equipment. 3.4 Creep model analysis

As mentioned above, the creep behavior of the bamboo

elastic strain and the creep behavior under this stress

scrimber changes with the stress level applied to it.

level is not obvious. In addition, the initial strain and

In a previous study, several viscoelasticity constitutive

the final strain are almost correlated linearly with the

models were proposed to research this property of com-

stress. While for the 30, 40, and 50% levels, the creep

posite materials. Among which the Maxwell model is con-

strain increases more obviously with higher slopes.

sidered to be an effective model in analyzing the creep

The relative creep increments within these cases are

behavior [18,19]. This model can exhibit previous rheolo-

much higher than those of the first two cases. This means

gical behavior, which is similar to the creep process. As

that the creep resistance of the material under these

shown in Figure 5, this model is made up of a series

stress levels becomes weaker. For the highest stress level

combination of a spring model and a Newtonian dashpot

(60%), the increasing rate of the strain with the given

model. The stress–strain relationship of this model can

stage becomes unsteady. The unstable accelerated creep

be expressed as follows:

appears although the fracture has not happened so far.

Generally speaking, the creep property of the bamboo σ1 = σ2 = σ0, (1)

scrimber is influenced by the stress level. The values of σ1 = E0 ε1(t ) , (2)

the creep resistance under the low-stress conditions are

dε2 (t )

more obvious than that under the high-stress conditions. σ2 = η0 , (3)

dt

Table 3: Load parameters of the creep experiment Table 4: The initial and final strain state of the creep experiment

Case Width Thickness Stress Stress Case Initial Final Relative

number (mm) (mm) level (%) (MPa) number strain (10−3) strain (10−3) increment (%)

1 9.24 5.03 10 15.5 1 1.01 1.02 1.2

2 9.67 5.01 20 31 2 2.10 2.14 1.8

3 9.34 4.99 30 46.5 3 3.09 3.19 3.2

4 9.09 4.99 40 62 4 4.62 4.82 4.3

5 9.38 5.02 50 77.5 5 5.18 5.41 4.4

6 9.60 5.01 60 93 6 6.5 7.09 9.1Applicability of different viscoelasticity constitutive models in bamboo scrimber 367

Table 5: Model parameters based on the conventional maxwell

model

Case E0 (MPa) η0 (GPa/min) Correlation

number coefficients

Figure 5: The structure features of the Maxwell model.

1 15,346 392,305 0.915

2 14,832 331,197 0.823

3 15,048 129,960 0.697

where σ0 is the static stress generated by the load, t is the

4 13,420 88,787 0.782

time, E0 is the elastic modulus of the material and η0 is 5 14,961 92,781 0.719

the viscosity coefficient. σ1 and σ2 are the stress generated 6 14,308 48,261 0.939

by the spring and the Newtonian dashpot model, respec-

tively. ε1(t ) and ε2 (t ) are the strain response from the

spring and the Newtonian dashpot model, respectively.

According to the previous study, the strain responses of

this model can be expressed as follows:

σ0

ε1(t ) = , (4)

E0

σ0

ε2 (t ) = t, (5)

η0

σ0 σ

ε (t ) = ε1(t ) + ε2 (t ) = + 0 t. (6)

E0 η0

According to the definition of the traditional Maxwell

model, both the parameters E0 and η0 can be treated

as material constants. Based on the experiment results

above, the parameters of the model can be determined

by a fitting approach. The theoretical basis of the process

can be expressed as follows:

(1) The initial values of the strain obtained based on

the experiment data and the response equation are Figure 6: Fitting results based on the conventional Maxwell model

and 10% stress level.

the same.

σ

ε (t = 0) = 0 . (7)

E0

(2) The sum of the relative difference percentage between

the experiment data and the response equation is the

minimum. The definition of the relative difference

percentage is:

n

ε (ti ) − εei

f= ∑ , (8)

i=1

εei

where f is the relative difference percentage and ε (ti )

and εei are the values of the strain obtained by the

response equation and the experiment at the ith time

node. Based on this assumption, the model para-

meters in each set can be determined. The results

are shown in Table 5 and Figures 6–11.

As shown in Figures 6–11, a clear conclusion can be

proposed that the values of the strain obtained by the

experiment and the response function are quite different Figure 7: Fitting results based on the conventional Maxwell model

from each other. In addition, the parameters in each set and 20% stress level.368 Sun Songsong and Wan Maosong

Figure 10: Fitting results based on the conventional Maxwell model

Figure 8: Fitting results based on the conventional Maxwell model and 50% stress level.

and 30% stress level.

Figure 9: Fitting results based on the conventional Maxwell model Figure 11: Fitting results based on the conventional Maxwell model

and 40% stress level. and 60% stress level.

are obviously different from those in other set, which can According to previous research, the fractional-order

be attributed to the diversity of the material. Besides, model usually has the time-variant characteristic. In

some of the correlation coefficients of the fitting results a previous study, some experts applied this theory to

are mainly less than 90%, which means that the relative research the creep behavior of some geologic materials

error in these sets are more than 10%. This accuracy can such as rock and clay [20,21]. The application of this

not fulfill the actual engineering demands. The main approach in bamboo material has rarely been reported.

reason for this phenomenon may be the definition of In addition, the creep behavior research based on the

the viscosity coefficient η0 . In the traditional application fractional-order theory is usually long-term type, the

of the Maxwell model, this parameter is usually consid- applicability of this theory in short-term creep behavior

ered to be a material constant. While in recent years, is still unclear. In this paper, we applied this theory to fit

some experts discovered that this parameter has a time- the short-term creep strain curve to make a comprehen-

variant characteristic. sive comparative study.Applicability of different viscoelasticity constitutive models in bamboo scrimber 369

Up to now, there are several fractional models such

as the Riemann–Liouville (RL) model, the Caputo model,

and so on. According to the previous study, the RL model

seems to be appropriate for viscoelastic materials [22]. So

in this paper, we applied this model in bamboo scrimber

short-term creep behavior research. The definition of this

model can be expressed as refs. [23–26]:

t

dα 1 d

dt α

[ f (t )] =

Γ(1 − α ) d t

∫ (t f−(ττ))α dτ (9)

0

where Γ represents the gamma function and α(0 < α < 1))

is the order. According to this model, the strain response

during the creep stage can be determined. The stress–

strain relationship of the Maxwell model can be expressed

as follows:

Figure 13: Fitting results based on the fractional defined Maxwell

σ0

ε1(t) = , (10) model and 20% stress level.

E0

σ0 tα

ε2 (t) = , (11)

η0 Γ(α + 1)

σ0 σ tα

ε (t ) = ε1(t ) + ε2 (t ) = + 0 . (12)

E0 η0 Γ (α + 1)

Compared with the conventional Maxwell model, this

modified model has one more parameter in all. Based on

this response function and the experimental results, the

parameters of the model can be determined. Figures

12–17 and Table 6 show the fitting results based on this

modified Maxwell model, a clear comparison can be

found that compared with the traditional model, this

fractional order-defined model can exhibit much higher

Figure 14: Fitting results based on the fractional defined Maxwell

model and 30% stress level.

accuracy in expressing the creep strain curve. The values

of the strain obtained based on the response function

are quite near to those from the experiment data at

the same time nodes. Among the six groups, the correla-

tion coefficients are all over 98.5%, which makes it com-

pletely enough for engineering applications. Besides, the

values of the parameter α in every set based on the fitting

results are located within its definition range (from 0 to 1).

Thus, this model is more suitable for actual engineering

applications.

Figure 12: Fitting results based on the fractional defined Maxwell In a previous study, some experts found that the

model and 10% stress level. Burgers viscoelasticity constitutive model which has370 Sun Songsong and Wan Maosong

Figure 15: Fitting results based on the fractional defined Maxwell Figure 17: Fitting results based on the fractional defined Maxwell

model and 40% stress level. model and 60% stress level.

Table 6: Model parameters based on the fractional defined Maxwell

model

Case number α Correlation coefficients

1 0.324 0.985

2 0.607 0.987

3 0.431 0.998

4 0.474 0.997

5 0.378 0.998

6 0.646 0.999

conducted to obtain the tensile strength of the material.

Then, six sets of short-term tensile creep experiments

were done to obtain the strain history throughout the

Figure 16: Fitting results based on the fractional defined Maxwell whole process. Finally, different models were applied in

model and 50% stress level. analyzing the creep property of the material. Corresponding

conclusions are shown as follows:

four parameters according to its definition could get a (1) The tensile strength experiment results show obvious

high accuracy in fitting the tensile creep strain curve. randomness property. Based on the commonly used

Compared with this model, the modified Maxwell model distribution models, the tensile strength under the

proposed in this paper can fit the strain curve well with 50% survival rate can be determined. The results

fewer parameters. This makes it superior to the other from different models are nearly the same.

models in engineering applications. (2) Compared with the traditional model, the combined

fractional and Maxwell model can provide much

higher accuracy in fitting the creep strain curve,

thus it is more suitable for engineering applications.

4 Discussion and conclusion

This study mainly focuses on researching the effects

The short-term tensile creep behavior of the bamboo of stress levels on the tensile creep properties of bamboo

scrimber is selected as the object of this study. First, sev- scirmber and the short-term strain predictive model under

eral sets of standard tensile fracture experiments were certain conditions of temperature and humidity. However,Applicability of different viscoelasticity constitutive models in bamboo scrimber 371

many factors, such as temperature and humidity, affect the [11] Li H, Zhang H, Qiu Z. Mechanical properties and stress strain

creep of bamboo scrimber. Additionally, the parameters relationship models for bamboo scrimber. J Renew Mater.

based on different fitting results show an obvious random 2020;8(1):13–27.

[12] Yang W, Xuewei JI, Maojun D. Model for axial stress–strain

property. So more properties of the creep behavior of the

relationship of bamboo scrimber. Acta Materiae Compositae

bamboo scirmber will be the focus of the next phase of Sin. 2018;35(3):572–9.

research. [13] Li H-T, Zhang Q-S, Wu G. Stress–strain model under com-

pression for side pressure laminated bamboo. J Southeast

Conflict of interest: Authors state no conflict of interest. Univ (Nat Sci). 2015;45(6):1130–4.

[14] Zhang Y, Wang A. remaining useful life prediction of rolling

bearings using electrostatic monitoring based on two-stage

information fusion stochastic filtering. Math Probl Eng.

March 17, 2020;2020:2153235.

References [15] Wang A, Zhang Y, Zuo H. Assessing the performance degra-

dation of lithium-ion batteries using an approach based on

[1] Hong C, Li H, Xiong Z, Lorenzo R, Corbi I, Corbi O, et al. Review fusion of multiple feature parameters. Math Probl Eng.

on connections for Engineered bamboo structures. J Build Eng. 2019;2019:3091071.

2020;30:101324. [16] Chang CC, Zheng YP, Sun WM, Ma Z. LPV estimation of SOC

[2] Li X, Ashraf M, Li H, Zheng X, Al-Deen S, Wang H, et al. based on electricity conversion and hysteresis characteristic.

Experimental study on the deformation and failure mechanism J Energy Eng. 2019;145(6):04019026.

of Parallel Bamboo Strand Lumber under drop-weight pene- [17] Wei Y, Zhou M, Yuan L. Mechanical performance of glulam

tration impact. Constr Build Mater. 2020;242:118135. bamboo columns under eccentric loading. Acta Mater Comp

[3] Tan C, Li H, Wei D, Lorenzo R, Yuan C. Mechanical performance Sin. 2016;33(2):379–85.

of parallel bamboo strand lumber columns under axial com- [18] Stan F, Turcanu A-M, Fetecau C. Analysis of viscoelastic

pression: experimental and numerical investigation. Constr behavior of polypropylene/carbon nanotube nanocomposites

Build Mater. 2020;231:117168. by instrumented indentation. Polymers. 2020;12:2535.

[4] Li H, Zhang H, Qiu Z, Su J, Wei D, Lorenzo R, et al. Mechanical [19] Peng G. Nanoindentation creep of nonlinear viscoelastic

properties and stress strain relationship models for bamboo polypropylene. Polym Test. 2015;43:38–43.

scrimber. J Renew Mater. 2020;8(1):13–27. [20] Peng R, Peng W, Hua Z. Nonlinear behavior of clay creep and

[5] He W, Song J, Wang T, Li J, Xie L, Yang Y, et al. Effect of heat oil its fractional derivative creep model. Eng Mech.

treatment on bamboo scrimber properties. J Forestry Eng. 2020;32(9):153–60.

2017;2(5):15–9. [21] Zhilei H, Dezhen Z, Mingli Z, Zhi-jing L. An unsteady creep

[6] Naresworo N, Naoto A. Development of structural composite constitutive model based on fractional order derivatives. Rock

products made from bamboo I: fundamental properties of Soil Mech. 2016;37(3):737–44.

bamboo zephyr board. J Wood Sci. 2000;46(1):68–74. [22] Xu J, Chen Y, Tai Y. Vibration analysis of complex fractional

[7] Naresworo N, Naoto A. Development of structural composite viscoelastic beam structures by the wave method. Int J Mech

products made from bamboo II: fundamental properties of Sci. 2020;167:105204.

laminated bamboo lumber. J Wood Sci. 2001;47(3):237–42. [23] Tian J, Ding J, Zhang C, Luo S. Four-wheel differential

[8] Huang D, Sheng B, Shen Y. An analytical solution for double steering control of IWM driven evs. IEEE Access.

cantilever beam based on elastic-plastic bilinear cohesive law: 2020;8:152963–73.

Analysis for mode I fracture of fibrous composites. Eng Fract [24] Xu X, Jiang Y, Chen N, Lee HP. Dynamic behavior of a vehicle

Mech. 2018;02(193):66–76. with rear axle compliance steering. J Vibroeng.

[9] Huang D, Bian Y, Huang D. An ultimate-state-based-model for 2017;19(6):4483–97.

inelastic analysis of intermediate slenderness PSB columns [25] Tai Y, Chen N, Wang L, Feng Z, Xu J. A numerical method for

under eccentrically compressive load. Constr Build Mater. a system of fractional differential – algebraic equations

2015;06(94):306–14. based on sliding mode control. Mathematics.

[10] Huang D, Bian Y, Zhou A. Experimental study on stress–strain 2020;8:1134.

relationships and failure mechanisms of parallelstrand [26] Chang C, Zheng Y, Yu Y. Estimation for battery state of charge

bamboo made from Phyllostachys. Constr Build Mater. based on temperature effect and fractional extended Kalman

2015;01(77):130–8. filter. Energies. 2020;13:5947.You can also read